Professional Documents

Culture Documents

Natural Bend Radius Cal Rev. C PDF

Uploaded by

hamid sobirinOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Natural Bend Radius Cal Rev. C PDF

Uploaded by

hamid sobirinCopyright:

Available Formats

Surveyor Indonesia

JASA PERENCANAAN PENGADAAN DAN

KONSTRUKSI PEMNBANGUNAN PIPA GAS

CIKARANG LISTRINDO JABABEKA

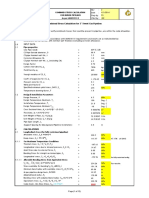

Doc. No.: CKL-EPC-00-PLI-CAL-002 Originator : Sym

Calc. Title : Natural Bend Radius Calculation Checked By : SWD

Revision : C Approved By : AAD

Date : 15-Jan-2020

____________________________________________________________________________________________

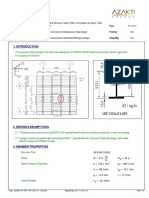

1 INTRODUCTION

The aim of this calculation is to determine the radius of curvature in accordance with Pipeline Rules of Thumb

Handbook, 7th Edition 2009 Section Pipe Laying, Eg. 13 and ensure it is with acceptable limits set by para

A842 223 of ASME B31.8.

2 REFERENCES

The reference data for this calculation has come from:

Referece 1: ASME B 31.8 - Gas Transmission and Distribution Piping systems

3 INPUT DATA

Nominal Outside Diameter Do := 16 in = 406.4 mm

Corrosioan Aloowance Ca := 3mm

Nominal Wall Thk. for Pipeline t s := 12.7mm - Ca

Internal Diameter ( )

ID := Do - 2 t s = 15.24 in

Design Pressure P d := 625 psi = 4.31 MPa

Design Temperature Td := 150 °F = 65.6 °C

Installation Temperature Ti := 80 °F = 27 °C

Material API 5L Gr. B

Specified Minimum Yield Strength SMYS := 35000 psi = 241.32 MPa

6

Modulus Young (@150oF) E := 29.5 10 psi = 203395 MPa

-5 1 Interpolate from Table

Thermal Expansion Coefficient αt := 1.10 10

Δ°C 832.5 ASME B31.8

Poisson factor ( v := 0.3)

Longitudinal Joint Factor f e := 1 for HFW pipe

Temperature Derating Factor f t := 1 for design temp < 250 degF

Load Duration Coefficient k := 0.9 long duration load

Safety Factor of Pipeline (class 3) s 1 := 0.5 ASME B31.8 Table 841.114A

External Force Fe := 0 N

Pipe length Lp := 12.2m

Tangent Length at Cold Bend Ltg := 2m

Natural Bend Radius Cal Rev. C.xmcd 1 of 3 09:40 15/01/2020

Surveyor Indonesia

4 CALCULATION

4.1 Hoop Stress

Pd Do

Hoop Stress Calculation σH := σH = 90.27 MPa

2 ts

4.2 Radius of Curvature

Radius of Curvature in Accordance Pipeline Do - ts

Rules of Thumb Handbook, 7th Edition r := = 198.35 mm

2

Minimum Curvature Radius 3E r

rc := = 501.54 m

with Design Factor 2 SMYS s 1

Minimum Natural Curvature Radius to Source from Mc. Allister, E.W,

rb := Do 1553 = 631.14 m

accommodate Tresca Combined Stress Pipeline Rules of Thumb Handbook,

7th Edition on Page 53

Maximum Degree for Natural 360° Lp

Mde := = 1.11 deg

Curvature Radius / 12.2 2π rb

Maximum Degree for Cold (

360° Lp - 2Ltg )

M40D := = 28.9 deg

Bend with Radius 40D 2 π 40 Do

4.3 Longitudinal Stress (ASME B31.8 para 833.2/3)

Due to Internal Pressure σLin := v σH σLin = 27.08 MPa

E Do

Due to Bending Load σb := Outer Radius σb1 := σb = 65.48 MPa

2 rb

Inner Radius σb2 := -σb = -65.48 MPa

Due to Thermal Exp. (

σT := αt E Ti - Td ) σT = -87.01 MPa

Fe

Due to External Forces σF := σF = 0 MPa

A

σL1 := σLin + σb1 + σT + σF σL1 = 5.56 MPa

Total Longitudinal Stress

σL2 := σLin + σb2 + σT + σF σL2 = -125.41 MPa

4.4 Combined Stress (ASME B31.8 para 833.4)

Tresca Combined Stress σct1 := σH - σL1 = 12286.65 psi σct1 = 84.71 MPa

σct2 := σH - σL2 = 31282.14 psi σct2 = 215.68 MPa

0.5

σcv1 := σH - σH σL1 + σL1

2 2

Von Mises Combined Stress = 12708.9 psi σcv1 = 87.62 MPa

0.5

σcv2 := σH - σH σL2 + σL2

2 2

= 27210.71 psi σcv2 = 187.61 MPa

4.5 Allowable Stress

Allowable Hoop Stress S H := SMYS s 1 f e f t = 17500 psi S H = 120.66 MPa

Allowable Longitudinal Stress S L := 0.9 SMYS = 31500 psi S L = 217.18 MPa

Allowable Combined Stress S C := SMYS k f t = 31500 psi S C = 217.18 MPa

Natural Bend Radius Cal Rev. C.xmcd 2 of 3 09:40 15/01/2020

Surveyor Indonesia

4.6 Check for Stress Requirement

Hoop Stress Ratio σH

rhoop := rhoop = 74.82 %

SH

(

if rhoop < 1 , "OK" , "NOT OK" = "OK" )

Max Longitudinal Stress Ratio

rlong :=

(

max σL1 , σL2 ) = 57.74% rlong = 57.74 %

SL

( )

if rlong < 1 , "OK" , "NOT OK" = "OK"

Max Combined Stress Ratio (

max σcv1 , σcv2 , σct1 , σct2 )

rcom := rcom = 99.31 %

SC

( )

if rcom < 1 , "OK" , "NOT OK" = "OK"

Natural Bend Radius Cal Rev. C.xmcd 3 of 3 09:40 15/01/2020

You might also like

- Wall Thickness Calculation Verification under StressDocument1 pageWall Thickness Calculation Verification under StresshhgjdfNo ratings yet

- 24in Pipeline Buoyancy CalculationDocument1 page24in Pipeline Buoyancy CalculationAdaghara67% (3)

- Pipl Stress AnalysisDocument62 pagesPipl Stress AnalysisShanthaNo ratings yet

- Piping Stress Analysis Design Basis PDFDocument38 pagesPiping Stress Analysis Design Basis PDFSaima SaimaNo ratings yet

- Material and anchor load data for steel pipeDocument4 pagesMaterial and anchor load data for steel pipeMichael RobinsonNo ratings yet

- ASME B31.3.4.8 Wall Thickness CalculatorDocument26 pagesASME B31.3.4.8 Wall Thickness Calculatoreko123100% (1)

- Wall thickness calculation for 36-inch gas pipelineDocument1 pageWall thickness calculation for 36-inch gas pipelinetitir bagchiNo ratings yet

- Pipeline Anchor Length Calculation PDFDocument3 pagesPipeline Anchor Length Calculation PDFAlvin SmithNo ratings yet

- Pipe Lowering CalculationDocument8 pagesPipe Lowering CalculationMochamad Safarudin50% (4)

- Vortex Shedding Load On PipingDocument1 pageVortex Shedding Load On Pipingananyo_sengupta100% (1)

- Virtual Anchor Length - KBRDocument22 pagesVirtual Anchor Length - KBRSammar Adhikari100% (2)

- Pipe wall thickness calculation sheet for high pressure natural gas lineDocument1 pagePipe wall thickness calculation sheet for high pressure natural gas lineAris KancilNo ratings yet

- ASME B16.49 Factory Made Wrought Steel Butt Welding Induction Bends For Transportation and Distribution Systems PDFDocument19 pagesASME B16.49 Factory Made Wrought Steel Butt Welding Induction Bends For Transportation and Distribution Systems PDFMuhammadNo ratings yet

- Project- Pipeline stress analysis reportDocument881 pagesProject- Pipeline stress analysis reportAnkithNo ratings yet

- Upheaval Buckling Calculation 24Document10 pagesUpheaval Buckling Calculation 24Moustafa Fares100% (1)

- MJPN-PGAS-3514-PL-CA-001 (Calculation For Pipeline Free Span) Rev. B (REVIEW)Document11 pagesMJPN-PGAS-3514-PL-CA-001 (Calculation For Pipeline Free Span) Rev. B (REVIEW)frusdt100% (3)

- Quality Requirements For Line Pipe: JanuaryDocument14 pagesQuality Requirements For Line Pipe: JanuaryJose Anisio Silva100% (1)

- Pipeline BucklingDocument14 pagesPipeline Bucklingmicael_89100% (1)

- River Crossing Pipeline - PaperDocument6 pagesRiver Crossing Pipeline - PaperJoko NugrohoNo ratings yet

- Stability-Calculation For PipelineDocument2 pagesStability-Calculation For PipelineGeorge100% (1)

- K Peters-Tech Paper-Upheaval BucklingDocument7 pagesK Peters-Tech Paper-Upheaval BucklingISRAEL PORTILLO100% (2)

- Pipeline Design Criteria 40RSN 00 BD PL DSC 2001 A0Document15 pagesPipeline Design Criteria 40RSN 00 BD PL DSC 2001 A0hgolestaniNo ratings yet

- Wall Theo PDFDocument23 pagesWall Theo PDFFranklin UkaohaNo ratings yet

- Attachment - 1 Document No. 081113B-CL-303-R0 Permissible Elastic Bend Limit Calculation (48in Hassyan Gas Pipeline Location Class 4)Document4 pagesAttachment - 1 Document No. 081113B-CL-303-R0 Permissible Elastic Bend Limit Calculation (48in Hassyan Gas Pipeline Location Class 4)ISRAEL PORTILLONo ratings yet

- PTGGP-00-PL-CAL-004 - 0 Pipeline Buoyancy and Stability Calculation Grissik-PusriDocument16 pagesPTGGP-00-PL-CAL-004 - 0 Pipeline Buoyancy and Stability Calculation Grissik-Pusrihamid sobirin100% (3)

- Elastic Bending Radius Calculation of PIPELINESDocument1 pageElastic Bending Radius Calculation of PIPELINESmailmaverick816777% (13)

- Axial Stress Calculation For Restrained Pipeline - Intergraph CADWorx - AnalysisDocument5 pagesAxial Stress Calculation For Restrained Pipeline - Intergraph CADWorx - AnalysisSharun SureshNo ratings yet

- L T Piping Engineering 3 Day ProgremmeDocument352 pagesL T Piping Engineering 3 Day ProgremmenndhoreNo ratings yet

- CAESAR II PIPELINE STRESS ANALYSISDocument16 pagesCAESAR II PIPELINE STRESS ANALYSISSikandar_30No ratings yet

- Stress Analysis of GRPDocument4 pagesStress Analysis of GRPSuthan SelvarajNo ratings yet

- Caesar II Load CaseDocument2 pagesCaesar II Load CasevikramacbNo ratings yet

- SGP Stress Analysis ReportDocument14 pagesSGP Stress Analysis ReportDenstar Ricardo Silalahi100% (2)

- Permissible Elastic Bend Limit Calculations for PipelinesDocument4 pagesPermissible Elastic Bend Limit Calculations for Pipelinesheldermanuel100No ratings yet

- Pipeline Buoyancy AnalysisDocument12 pagesPipeline Buoyancy AnalysisbonnicoNo ratings yet

- Flange Leakage Check SheetDocument1 pageFlange Leakage Check SheetEhtisham AndrAbiNo ratings yet

- Buried Pipeline AnalysisDocument9 pagesBuried Pipeline Analysisim4uim4uim4uim4u100% (1)

- Calculation Cover SheetDocument8 pagesCalculation Cover SheetYogesh PangareNo ratings yet

- IDBU-CW-LSPDS-000029 Rev G - Upstream Piping Comp. SelectDocument115 pagesIDBU-CW-LSPDS-000029 Rev G - Upstream Piping Comp. Selectjoey garciaNo ratings yet

- Horizontal Directional Drilling SpecificationsDocument17 pagesHorizontal Directional Drilling SpecificationsThomas Bennett100% (1)

- Stress Analysis of Buried Pipeline Using Finite Element MethodDocument16 pagesStress Analysis of Buried Pipeline Using Finite Element MethodMaria TnsNo ratings yet

- ASME B31 8 Riser CalcDocument12 pagesASME B31 8 Riser CalcEmmanuel LawrenceNo ratings yet

- Upheavel Buckling CalculationDocument8 pagesUpheavel Buckling Calculationsaravanakkumar boominahtanNo ratings yet

- Stress Analysis 1Document20 pagesStress Analysis 1Rjeb mohamed0% (1)

- Pipeline Stress AnalysisDocument8 pagesPipeline Stress Analysise_budzyNo ratings yet

- Pipe Stress Analysis of Steam Line 4MS-20201-ED1-HDocument11 pagesPipe Stress Analysis of Steam Line 4MS-20201-ED1-HAbu SuraisyNo ratings yet

- Basics of Pipe Stress AnalysisDocument79 pagesBasics of Pipe Stress Analysisashish shrivastav100% (2)

- Stress Analysis Guidelines for Liquid Pipelines per ASME B31.4Document4 pagesStress Analysis Guidelines for Liquid Pipelines per ASME B31.4Nilesh GohelNo ratings yet

- Mathcad - Natural Bend Radius Cal Rev. 0Document3 pagesMathcad - Natural Bend Radius Cal Rev. 0hamid sobirin100% (2)

- Design of Coping Beam (Portal) : A. Basic DataDocument7 pagesDesign of Coping Beam (Portal) : A. Basic DataUzziel Abib GabiolaNo ratings yet

- Combined Stress Calc Rev. 2Document12 pagesCombined Stress Calc Rev. 2babu75% (4)

- Villanueva Residence - Two-Way Slab Design S3 PDFDocument11 pagesVillanueva Residence - Two-Way Slab Design S3 PDFMcKen FloresNo ratings yet

- TEMA Type E Heat Exchanger DesignDocument8 pagesTEMA Type E Heat Exchanger DesignLEONARDO MOLERO CLEMENTENo ratings yet

- Bellow As Per EJMA - 1Document2 pagesBellow As Per EJMA - 1966571016208No ratings yet

- Ejma 8TDocument3 pagesEjma 8TpiziyuNo ratings yet

- Appendix A1Document5 pagesAppendix A1Thomas Stephen100% (1)

- Buckling Analysis Per Aisc 360-10Document2 pagesBuckling Analysis Per Aisc 360-10Christian LeobreraNo ratings yet

- Flange Analysis For Internal Pressure - ASME Section VIII, Division 1, Appendices 2 and S - 2004 EditionDocument1 pageFlange Analysis For Internal Pressure - ASME Section VIII, Division 1, Appendices 2 and S - 2004 Editionגרבר פליקסNo ratings yet

- Detail Calculation A. Calculation of Ballast Tank VolumeDocument5 pagesDetail Calculation A. Calculation of Ballast Tank VolumeIndra HazamiNo ratings yet

- DEBA-DD-EL-CC-3141-0.1-flexible Conductor Size CalculationDocument4 pagesDEBA-DD-EL-CC-3141-0.1-flexible Conductor Size Calculationjie zhangNo ratings yet

- LSB-1-0808-02-A2-001 - NewDocument5 pagesLSB-1-0808-02-A2-001 - NewariyaNo ratings yet

- Ball Valve Seat Design FeaturesDocument3 pagesBall Valve Seat Design Featureshamid sobirinNo ratings yet

- Weld Cracking PDFDocument5 pagesWeld Cracking PDFjuanNo ratings yet

- Valves PresentationDocument36 pagesValves PresentationZikireya79100% (1)

- Study On The Electrochemical BDocument8 pagesStudy On The Electrochemical Bhamid sobirinNo ratings yet

- Seat Design Types and Differences Between DBB and DIB ValvesDocument2 pagesSeat Design Types and Differences Between DBB and DIB Valveshamid sobirin100% (2)

- Piping ValveDocument36 pagesPiping Valvehamid sobirinNo ratings yet

- Decree of The Minister of Mines and Energy No-300 K-38-M PE-1997 PDFDocument6 pagesDecree of The Minister of Mines and Energy No-300 K-38-M PE-1997 PDFhamid sobirinNo ratings yet

- ASME B36 10M-2015 Welded and Seamless Wrought Steel PipeDocument30 pagesASME B36 10M-2015 Welded and Seamless Wrought Steel PipeDaniel Diaz PrietoNo ratings yet

- Introduction 140107234332 Phpapp01Document32 pagesIntroduction 140107234332 Phpapp01prashant mishraNo ratings yet

- Mathcad - Natural Bend Radius Cal Rev. 0Document3 pagesMathcad - Natural Bend Radius Cal Rev. 0hamid sobirin100% (2)

- 11-Opt-O-Dwg-1001 - Pipeline Alignment Sheet Drawing Rev 2Document4 pages11-Opt-O-Dwg-1001 - Pipeline Alignment Sheet Drawing Rev 2hamid sobirin100% (3)

- Gs-Hydro Hydraulic Piping Standard Handbook Revision 1Document200 pagesGs-Hydro Hydraulic Piping Standard Handbook Revision 1Haris StavrouNo ratings yet

- AFT Evaluating Pipe Dynamic Loads Caused by Waterhammer 01-02-2013 SIDocument24 pagesAFT Evaluating Pipe Dynamic Loads Caused by Waterhammer 01-02-2013 SIpca97No ratings yet

- PTGGP-00-PL-CAL-004 - 0 Pipeline Buoyancy and Stability Calculation Grissik-PusriDocument16 pagesPTGGP-00-PL-CAL-004 - 0 Pipeline Buoyancy and Stability Calculation Grissik-Pusrihamid sobirin100% (3)

- AFT Evaluating Pipe Dynamic Loads Caused by Waterhammer 01-02-2013 SIDocument24 pagesAFT Evaluating Pipe Dynamic Loads Caused by Waterhammer 01-02-2013 SIpca97No ratings yet

- Piping MaterialDocument4 pagesPiping Materialhamid sobirin100% (1)

- Material High Temperature & Corrosion Resistant Rev.2Document33 pagesMaterial High Temperature & Corrosion Resistant Rev.2hamid sobirinNo ratings yet

- 11-Opt-O-Dwg-1000 - Pipeline Ga Drawing Rev 2Document1 page11-Opt-O-Dwg-1000 - Pipeline Ga Drawing Rev 2hamid sobirin100% (1)

- Lowering Analysis 10 in Gas PipelineDocument3 pagesLowering Analysis 10 in Gas Pipelinehamid sobirin100% (3)

- Onshore Pipeline Design Course in JakartaDocument52 pagesOnshore Pipeline Design Course in Jakartahamid sobirinNo ratings yet

- Especificaciones Tanques de AceroDocument6 pagesEspecificaciones Tanques de AcerojhobanybernalNo ratings yet

- DNV Free Spaning Pipeline RP F105 PDFDocument46 pagesDNV Free Spaning Pipeline RP F105 PDFrachedNo ratings yet

- Scour at Offshore StructuresDocument11 pagesScour at Offshore Structureshamid sobirin100% (1)

- Bab 10 Dynamic CapabilityDocument50 pagesBab 10 Dynamic CapabilityWendi JunaediNo ratings yet

- DNV Free Spaning Pipeline RP F105 PDFDocument46 pagesDNV Free Spaning Pipeline RP F105 PDFrachedNo ratings yet

- Pipe StressDocument16 pagesPipe Stresshamid sobirinNo ratings yet

- Corrosion Under Insulation (CUI) : A Review of Essential Knowledge and PracticeDocument9 pagesCorrosion Under Insulation (CUI) : A Review of Essential Knowledge and PracticeDiego MoralesNo ratings yet

- DNV Free Spaning Pipeline RP F105 PDFDocument46 pagesDNV Free Spaning Pipeline RP F105 PDFrachedNo ratings yet

- Casing SpacersDocument8 pagesCasing Spacershamid sobirinNo ratings yet

- Turbine Clearance ControlDocument135 pagesTurbine Clearance ControlAnu Partha100% (1)

- LW C100plus Auto Chemistry Analyzer Operation ManualDocument125 pagesLW C100plus Auto Chemistry Analyzer Operation Manualgerson100% (1)

- GEMINI II Operating Instructions 06-235975-001 Print 5127 2014-05-08Document120 pagesGEMINI II Operating Instructions 06-235975-001 Print 5127 2014-05-08Nattapong Natt100% (1)

- FRP Technology by WeatherheadDocument20 pagesFRP Technology by WeatherheadSagarNo ratings yet

- An Overview On Performance of Steel Slag in Highway IndustryDocument12 pagesAn Overview On Performance of Steel Slag in Highway Industrybkollarou9632No ratings yet

- ZF6HP19-26-32 G1 With 053-SepPlateDocument1 pageZF6HP19-26-32 G1 With 053-SepPlatenorrqvarn-nedreNo ratings yet

- CS134 Web Site Design & Development Midterm ExamDocument3 pagesCS134 Web Site Design & Development Midterm Examalex saavedraNo ratings yet

- Rotrex Technical Datasheet C30 RangeDocument7 pagesRotrex Technical Datasheet C30 RangeSidney RiveraNo ratings yet

- QuantityWare Quantity Data Flow BCPDocument16 pagesQuantityWare Quantity Data Flow BCPspsuman05No ratings yet

- Solidworks SimulationDocument30 pagesSolidworks SimulationDavid Raj100% (1)

- Manual de Operación y Mantenimiento Sistema de Bombeo Contra Incendios SCDocument157 pagesManual de Operación y Mantenimiento Sistema de Bombeo Contra Incendios SCAndres Bojorquez100% (3)

- SM Maintenance Instructions: Author: Lars Rydén, Konecranes AB, SwedenDocument132 pagesSM Maintenance Instructions: Author: Lars Rydén, Konecranes AB, SwedenDan VekasiNo ratings yet

- Huawei DBS3900 Spare Parts CatalogueDocument102 pagesHuawei DBS3900 Spare Parts CatalogueKhalidox SolitaireNo ratings yet

- ELLXDocument23 pagesELLXRey Rizkio firdausNo ratings yet

- Despiece Hyosung Aquila GV 125Document119 pagesDespiece Hyosung Aquila GV 125Oriel Merino CortesNo ratings yet

- Ignition HMI To SLC Through ANC-100e or ANC-120eDocument6 pagesIgnition HMI To SLC Through ANC-100e or ANC-120eJonathanNo ratings yet

- Fundamentals Satellite Communication Part 1Document51 pagesFundamentals Satellite Communication Part 1Safwan MohamedNo ratings yet

- 3 Chapter 2 (13-21)Document9 pages3 Chapter 2 (13-21)Edjay HiguitNo ratings yet

- CSC 551: Web Programming Spring 2004: Basic HTMLDocument18 pagesCSC 551: Web Programming Spring 2004: Basic HTMLprasad150686100% (1)

- J. Barbero Cap 4Document42 pagesJ. Barbero Cap 4jessieNo ratings yet

- Multileaf Data VCDDocument4 pagesMultileaf Data VCDalexa_liviaNo ratings yet

- HFSS Intro 19.0 L02 Lecture Bounds SimSpaceDocument22 pagesHFSS Intro 19.0 L02 Lecture Bounds SimSpaceTinghao LiangNo ratings yet

- Data Warehousing - FundamentalsDocument3 pagesData Warehousing - FundamentalsJinendraabhiNo ratings yet

- MONLEON, REI JULIAN KYLE T. - Module 3 - Assignment 3 - MT NPBST 11 A1Document5 pagesMONLEON, REI JULIAN KYLE T. - Module 3 - Assignment 3 - MT NPBST 11 A1Christian Felix GuevarraNo ratings yet

- Machine Learning Guide For Oil and Gas Using PythonDocument1 pageMachine Learning Guide For Oil and Gas Using Pythonogiri agbehiNo ratings yet

- C LanguageDocument135 pagesC LanguageSandeep SandyNo ratings yet

- Cranes Us ArmyDocument21 pagesCranes Us ArmyNancyNo ratings yet

- Arindam Sarkar ABAPDocument5 pagesArindam Sarkar ABAPMowmita MandalNo ratings yet

- ACE Pilot User GuideDocument109 pagesACE Pilot User GuideEnrique Tejada FarfanNo ratings yet

- Business Class m2 Workshop ManualDocument2,354 pagesBusiness Class m2 Workshop ManualWilfredo A Molina63% (8)