Professional Documents

Culture Documents

Mobilett Plus

Uploaded by

زيد محمدCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mobilett Plus

Uploaded by

زيد محمدCopyright:

Available Formats

h

c

d

rie

F

MOBILETT Plus/ -E/ -M

SP

Maintenance Instructions

System

MOBILETT Plus/ -E/ -M

Including DHHS requirements

The protocol SPR8-215.832.04.03.02 is required for

these instructions

06337617

06337609

06215300

© Siemens AG 2002

The reproduction, transmission or use

of this document or its contents is not

permitted without express written

authority. Offenders will be liable for

damages. All rights, including rights

created by patent grant or registration

of a utility model or design, are

reserved.

Print No.: SPR8-215.831.04.03.02 English

Replaces: SPR8-215.831.04.02.02 Doc. Gen. Date: 07.05

2 Revision / Disclaimer

1Revision / Disclaimer

Document revision level

The document corresponds to the version/revision level effective at the time of system

delivery. Revisions to hardcopy documentation are not automatically distributed.

Please contact your local Siemens office to order current revision levels.

Disclaimer

The installation and service of equipment described herein is to be performed by qualified

personnel who are employed by Siemens or one of its affiliates or who are otherwise

authorized by Siemens or one of its affiliates to provide such services.

Assemblers and other persons who are not employed by or otherwise directly affiliated

with or authorized by Siemens or one of its affiliates are directed to contact one of the

local offices of Siemens or one of its affiliates before attempting installation or service pro-

cedures.

MOBILETT Plus/ -E/ -M SPR8-215.831.04.03.02 Page 2 of 64 Siemens AG

07.05 CS PS 24 Medical Solutions

Table of Contents 3

0 Table of Contents

1 _______ General ________________________________________________________ 5

Check at the beginning of the maintenance session . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Training. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Required documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Required tools, measurement and auxiliary devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Required lubricants. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Replacement parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Text emphasis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Safety information and protective measures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Protective measures when working on the capacitor bank . . . . . . . . . . . . . . . . . . . . . . 14

Service information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Information pertaining to the USA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Explanation of abbreviations in the maintenance certificate. . . . . . . . . . . . . . . . . . . . . . 18

Technical Safety Checks (TSC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

2 _______ Inspection and maintenance _____________________________________ 24

Visual inspection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Damage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Mechanical inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Rear wheels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Front wheels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Supporting wheels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Turn plate (MOBILETT Plus/Plus M only). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Brakes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Transport safeguard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Handles. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Collimator adjustment knobs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Arm system and single tank . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Mains cable. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Arm system mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Arm cable harness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Motor batteries (MOBILETT Plus M only). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Service mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Maintenance tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Backup battery G1/D1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Test of kV accuracy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Test of mAs accuracy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Check for reproducibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Remote exposure switch system (optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

DAP measuring system (optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Siemens AG SPR8-215.831.04.03.02 Page 3 of 64 MOBILETT Plus/ -E/ -M

Medical Solutions 07.05 CS PS 24

4 Table of Contents

Replacing the collimator lamp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Checking the luminance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Coincidence of radiation and light fields . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Checking the radiation indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Checking the manual exposure interrupt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Protective conductor measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Equivalent leakage current measurement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Cleaning the system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Checking the kV and mAs displays. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Motor drive function (MOBILETT Plus M only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

3 _______ Changes to the previous version __________________________________ 63

MOBILETT Plus/ -E/ -M SPR8-215.831.04.03.02 Page 4 of 64 Siemens AG

07.05 CS PS 24 Medical Solutions

General 5

1-

1 General

1.1 Check at the beginning of the maintenance session

The system condition should be checked via remote service (if available). If error mes-

sages appear, the necessary spare parts have to be ordered. If necessary, a new appoint-

ment for Preventive Maintenance has to be arranged.

A quick check must be carried out directly at the system. For this, the "Quality Assurance"

procedure or similar procedures can be used.

Additionally, check the system logbook for system problems (if available).

The necessary escalation measures have to be initiated after deviations. If necessary, a

new appointment for Preventive Maintenance has to be arranged.

Siemens AG SPR8-215.831.04.03.02 Page 5 of 64 MOBILETT Plus/ -E/ -M

Medical Solutions 07.05 CS PS 24

6 General

1.2 Training

• Due to the type of technology used in this system, service and maintenance work may

be performed only by service engineers who have the required training and work autho-

rization for MOBILETT Plus.

MOBILETT Plus/ -E/ -M SPR8-215.831.04.03.02 Page 6 of 64 Siemens AG

07.05 CS PS 24 Medical Solutions

General 7

1.3 Required documents

• Installation and Start-up SPR8-215.814...

• Service Instructions SPR8-215.898...

• Wiring Diagram SPR8-215.051...

• FDA Form FD2579 (for USA only)

• Instructions for Use SPR8-220.201...

• Technical Safety Checks – Protocol * SP00-000.834.01...

NOTE The Instructions for Use contain the label locations, tube cooling

charts and other information useful for maintenance.

* Within the purview of DIN VDE 0751-1, we recommend documenting the maintenance

results both in the maintenance protocol and in the TSC protocol. The protocols should be

filled out completely and handed over to the client after maintenance is completed.

Siemens AG SPR8-215.831.04.03.02 Page 7 of 64 MOBILETT Plus/ -E/ -M

Medical Solutions 07.05 CS PS 24

8 General

1.4 Required tools, measurement and auxiliary devices

NOTE All tools, measurement and auxiliary devices, with the exception of

those marked "* ", are listed in the STC (Service Tools Catalog)

along with their specifications.

• Standard service equipment*

• Digital multimeter

• kV measurement device (works with the filter comparison method)

or storage oscilloscope with ± 2.5 % accuracy

• Storage oscilloscope with ± 2.5 % accuracy

• Protective conductor meter

• Equivalent leakage current meter

• Torque wrench 6-12 Nm

• Torque wrench 20-25 Nm

• Lux meter (only for USA)

• Spring scale for 350 N

• Dose meter (only for USA or if optional ’DAP measuring system’ is installed)

• Cable (min. 4 m long; min. 1000 N tensile strength)*

• 2 pieces of wood, approximately 50 x 75 x 500 mm (2.5 x 3 x 20 inches)*

• Calibration tool for ’DAP measuring system’, part no. 65 84 978

MOBILETT Plus/ -E/ -M SPR8-215.831.04.03.02 Page 8 of 64 Siemens AG

07.05 CS PS 24 Medical Solutions

General 9

1.5 Required lubricants

• Viscogen oil

Siemens AG SPR8-215.831.04.03.02 Page 9 of 64 MOBILETT Plus/ -E/ -M

Medical Solutions 07.05 CS PS 24

10 General

1.6 Replacement parts

• Collimator lamp (every year) 04 48 738

• Backup battery (every 5 years) 31 65 289

• Remote control battery (optional) (every year) 9 volt alkaline battery

For units with cable winder only:

• Cable winder cpl. (incl. mains cable) (every 4 years) 65 08 746

• Mains cable (every 2 years) 65 00 792

For units without cable winder only:

• Mains cable (every 2 years) 64 11 438 (in USA)

64 11 388 (in rest of world)

MOBILETT Plus/ -E/ -M SPR8-215.831.04.03.02 Page 10 of 64 Siemens AG

07.05 CS PS 24 Medical Solutions

General 11

1.7 Text emphasis

! DANGER DANGER indicates when there is an immediate danger that

l e a d s to death or serious physical injury.

! WARNING WARNING indicates a risk of danger that m a y l e a d to death

or serious physical injury.

! CAUTION CAUTION used with the safety alert symbol indicates a risk of

danger that leads to slight or moderate physical injury and/ or

damage to property.

NOTICE NOTICE used without the safety alert symbol indicates a risk of

danger that if disregarded leads or may lead to a potential

situation which may result in an undesirable result or state other

than death, physical injury or property damage.

Fig. 1: Safety Notes

NOTE NOTE contains information provided with special emphasis to fa-

cilitate proper use of the equipment or proper execution of a pro-

cedure, i.e. hints, tips.

Siemens AG SPR8-215.831.04.03.02 Page 11 of 64 MOBILETT Plus/ -E/ -M

Medical Solutions 07.05 CS PS 24

12 General

1.8 Symbols

X Checks and adjustments that must be performed with radiation ON are identified by the

radiation warning symbol.

V This symbol means "Dangerous voltage".

C This symbol means "Attention, consult the documentation".

Several of the sections in these instructions are for the USA only. These sections are

identified with this symbol.

Sections marked with this symbol have been included in the Siemens Training Video

(part of the self-study package), which can be ordered through Siemens Customer Ser-

vice.

E This symbol indicates components sensitive to electrostatic discharge (ESD).

MOBILETT Plus/ -E/ -M SPR8-215.831.04.03.02 Page 12 of 64 Siemens AG

07.05 CS PS 24 Medical Solutions

General 13

1.9 Safety information and protective measures

WARNING Risk of death, injury or material damage.

Non-compliance can lead to death, injury or material damage.

¹ When performing service work and tests adhere to the

product-specific safety information in the documents.

¹ When performing service work and tests adhere to the

general safety information contained in ARTD Part 2.

¹ Only connect the MOBILETT Plus/Plus E/ Plus M to a

mains power supply outlet (receptacle) that corresponds

to the installation requirements of VDE 0107 or to coun-

try-specific regulations.

¹ Remove or install boards only when the generator is

switched OFF. Adhere to the ESD guidelines e .

¹ Checks and adjustments performed with radiation ON

are identified by the radiation warning symbol x . Dur-

ing these types of adjustments, radiation protective

clothing must be worn.

¹ Perform the protective conductor test according to

ARTD-002.731.17... upon completion of the work and

after all covers have been reattached.

WARNING When working on the open unit there is a risk of electric shock!

Non-compliance can lead to injury or death.

Observe the following:

¹ Never work with the system open if the capacitor is

charging or has just been charged.

¹ The capacitor bank may still be charged even if the sys-

tem is switched OFF and the mains cable is discon-

nected. There is a risk of life-threatening electric shock.

¹ To avoid danger, refer to the section entitled “Protective

measures when working on the capacitor bank”.

Siemens AG SPR8-215.831.04.03.02 Page 13 of 64 MOBILETT Plus/ -E/ -M

Medical Solutions 07.05 CS PS 24

14 General

1.10 Protective measures when working on the capacitor

bank

NOTE Comply with the information given in this section before opening

the system.

Fig. 2: Fig. 3:

DANGER When working on the open unit there is a risk of electric shock!

Non-compliance can lead to injury or death.

Observe the following:

¹ Never work with the system open if the capacitor is

charging or has just been charged.

¹ The capacitor bank may still be charged even if the sys-

tem is switched OFF and the mains cable is discon-

nected. There is a risk of life-threatening electric shock.

¹ Consult the information in this chapter.

• System OFF.

• Disconnect the mains cable.

• Remove the upper system cover.

• Discharge the capacitor bank with S10 (D7) (Fig. 2 / p. 14).

• Wait 5 minutes, then remove the left and right covers and the cover with the cassette

compartment.

• Measure the residual voltage at test points CAPPOS and CAPNEG on board D7

(Fig. 3 / p. 14). The measured voltage must be less than 10 V.

MOBILETT Plus/ -E/ -M SPR8-215.831.04.03.02 Page 14 of 64 Siemens AG

07.05 CS PS 24 Medical Solutions

General 15

WARNING Risk of electric shock!

Non-compliance can lead to injury or death.

¹ If the voltage measured between CAPPOS and CAPNEG

is 0 V, the measurement device could be defective or the

wires between the CAPPOS and CAPNEG test points on

the capacitor bank could be damaged.

¹ The capacitors could still be charged.

¹ In this case, proceed as follows:

- Make sure that the correct measurement range is set on the measurement device.

- Connect the measurement device to CAPPOS and CAPNEG.

- Switch S10 off. Connect the mains cable and switch the system ON.

- Check whether the voltage increases.

- Switch the system OFF, disconnect the mains cable and switch S10 on.

- Check whether the voltage decreases.

WARNING If charging/discharging does not function, the capacitor bank

must be assumed to be ”charged”.

This means there is a risk of high voltage.

¹ Use caution when performing measurements at the bus

bar of the capacitor bank. Use only the specified mea-

surement devices (350 V DC). If one of the fuses in the

capacitor series has blown out, this series must be con-

sidered to be fully charged.

Siemens AG SPR8-215.831.04.03.02 Page 15 of 64 MOBILETT Plus/ -E/ -M

Medical Solutions 07.05 CS PS 24

16 General

1.11 Service information

Service engineers must complete and sign the maintenance protocol. Repair measures

and other service work not contained in the report must be listed separately.

MOBILETT Plus/ -E/ -M SPR8-215.831.04.03.02 Page 16 of 64 Siemens AG

07.05 CS PS 24 Medical Solutions

General 17

1.12 Information pertaining to the USA

To ensure compliance with the applicable regulations in the ”US Federal Performance

Standard”, the system user must ensure that the following maintenance is performed at

least once a year. Neither the system manufacturer nor its representatives assume any

responsibility in the event of non-compliance with the above requirement.

Siemens AG SPR8-215.831.04.03.02 Page 17 of 64 MOBILETT Plus/ -E/ -M

Medical Solutions 07.05 CS PS 24

18 General

1.13 Explanation of abbreviations in the maintenance

certificate

Abbrev. Description

SI Safety Inspection

SIE Electrical Safety

SIM Mechanical Safety

PM Preventive Maintenance

PMP Periodic Preventive Maintenance

PMA Preventive Maintenance Adjustments

PMF Preventive Check of Operating Values/Functions

Q System Quality, Image Quality

QIQ Image Quality

QSQ System Quality Check

SW Software Maintenance

CSE Customer Service Engineer

KSK No. Customer-specific code

IVK Installed Volume Component

GR Maintenance Unit

The steps identified by these abbreviations are part of the maintenance certificate and

should be checked off upon completion.

MOBILETT Plus/ -E/ -M SPR8-215.831.04.03.02 Page 18 of 64 Siemens AG

07.05 CS PS 24 Medical Solutions

General 19

1.14 Technical Safety Checks (TSC)

Abbreviation: TSC = Technical Safety Checks

NOTE • Within the purview of DIN VDE 0751-1, the operator of medical

engineering products has to perform technical safety checks at

regular intervals.

• The checks listed in these maintenance instructions contain all

technical safety checks according to DIN VDE 0751-1 – except

for the checks regarding the completeness, presence and legi-

bility of the necessary operator documents.

• A separate protocol with print number SP00.000.834.01... is

available for each technical safety check.

• Within the purview of DIN VDE 0751-1, we recommend docu-

menting the maintenance results both in the maintenance pro-

tocol and in the TSC protocol. The protocols should be filled

out completely and handed over to the client after maintenance

is completed.

• In the table below, each technical safety check listed in docu-

ment SP00.000.834.01... is assigned to the corresponding

maintenance work.

Technical Safety Checks, Maintenance instructions - check/

Test certificate - check Comments

1 Identification data Please fill in the fields.

2 General checks n.a.

2.1 Visual inspection: Is there any damage 2.1.1 Damage, checks:

affecting safety? SIM Covers

SIM Cassette compartment

SIM Control and display panel

SIM Exposure release cable

SIM Single tank generator

SIM Collimator

2.2 Are all cables and cable guides firmly 2.2.10 Mains cable, checks:

attached and in place, without any visible SIM Cable winder

damage?

SIM Damage

SIM Protective conductor

2.2.12 Arm cable harness, check:

SIM Damage

Siemens AG SPR8-215.831.04.03.02 Page 19 of 64 MOBILETT Plus/ -E/ -M

Medical Solutions 07.05 CS PS 24

20 General

Technical Safety Checks, Maintenance instructions - check/

Test certificate - check Comments

2.3 Are the accessories being used free of 2.1.1 Damage, check:

damage? SIM DAP (optional)

2.4 Are the system’s radiation protection 2.15 Checking the radiation indicator,

devices installed and damage-free? (no checks:

radiation protection for the building) SIE Radiation indicator

SIE Audible signal

2.16 Checking the manual exposure inter-

rupt, checks:

SIE Message "USE20"

SIE 10 short beep signals

2.5 Are the required operator documents The operating instructions must be

complete, present and legible? present. Ask the client for further required

operator documents and check if the docu-

ments are complete, present and legible.

2.6 Are all warning labels in place and rec- 2.1 Visual inspection, check:

ognizable? SIM Labels

2.7 Are the operating symbols, light indica- 2.5 Maintenance tests, check:

tors and button labels OK? SIE Display test

2.20 Checking the kV and mAs displays,

checks:

SIE Visibility of displays

SIE Correct displays

3. Electrical checks n.a.

3.1 Measurement of the protective conduc- 2.17 Protective conductor measurement,

tor resistance check:

SIE Measured value

3.2 Measurement of leakage current or n.a.

equivalent leakage current

3.2.1 Leakage current n.a.

3.2.2 Equivalent leakage current 2.18 Equivalent leakage current measure-

ment, check:

SIE Measured value

3.3 Measurement of patient leakage cur- n.a.

rent or equivalent patient leakage current

3.3.1 Patient leakage current measurement n.a.

MOBILETT Plus/ -E/ -M SPR8-215.831.04.03.02 Page 20 of 64 Siemens AG

07.05 CS PS 24 Medical Solutions

General 21

Technical Safety Checks, Maintenance instructions - check/

Test certificate - check Comments

3.3.2 Equivalent patient leakage current n.a.

measurement

4. Mechanical checks n.a.

4.1 Are all wall, ceiling and floor mountings n.a.

firmly attached, in place, and damage-free?

4.2 Are all mechanically movable system 2.2.6 Transport safeguard, checks:

parts clean and running smoothly (lubri- SIM Damage

cated, if required)?

SIM Locking

2.2.9 Arm system and single tank, checks:

SIM Movement of the arm system and the

single tank

SIM Movement of the single tank fork

SIM Single tank movement

4.3 Are the wire cables, chains, belts and 2.2.1 Rear wheels, check:

spindles free of wear and tear? SIM Drive belt

4.4 Mobile equipment: Are the wheels, cas- 2.2.1 Rear wheels, checks:

tors and brakes OK? SIM Brake lining

SIM Secure mounting

SIM Ease of movement

2.2.2 Front wheels, checks:

SIM Secure mounting

SIM Ease of movement

2.2.3 Supporting wheels, checks:

SIM Ease of movement

SIM Damage

2.2.5 Brakes, checks:

SIM Uniformity SIM Braking force

SIM Locking

4.5 Is there any unusual noise during oper- 2.2.9 Arm system and single tank, check:

ation (e.g. gearing)? SIM Movement of the arm system and the

single tank

5. Functional checks n.a.

5.1 Function of the emergency-stop switch n.a.

Siemens AG SPR8-215.831.04.03.02 Page 21 of 64 MOBILETT Plus/ -E/ -M

Medical Solutions 07.05 CS PS 24

22 General

Technical Safety Checks, Maintenance instructions - check/

Test certificate - check Comments

5.2 Are the warning devices functioning 2.15 Checking the radiation indicator,

properly? checks:

SIE Radiation indicator

SIE Audible signal

5.3. Do all system movements stop prop- n.a.

erly in their end positions?

5.4 Does the collision protection device n.a.

stop all system movements properly

(e.g. collision protection)?

5.5. Are all safety distances (wall, floor, n.a.

ceiling) met or ensured by other appropri-

ate measures (such as light barriers)?

5.6. Are the other safety shutdown devices 2.21 Motor drive function, check:

functioning properly (e.g. safety floor SIE Shutdown

plate)?

5.7 Are the positions of the table and unit n.a.

reproducible (e.g. zero positions, layer

height, etc.)?

MOBILETT Plus/ -E/ -M SPR8-215.831.04.03.02 Page 22 of 64 Siemens AG

07.05 CS PS 24 Medical Solutions

General 23

Technical Safety Checks, Maintenance instructions - check/

Test certificate - check Comments

6. Product-specific checks 2.2.7 Handles, check: SIM Mounting

2.2.8 Collimator adjustment knobs, check:

SIM Mounting

2.2.11 Arm system mounting, check:

SIM Screws and lock nuts

2.2.11.1 Adjustment screw, checks:

SIM Lock nuts

SIM Base mounting

2.2.11.2 Arm connecting piece, check:

SIM Screws and nuts

2.2.11.3 Single tank fork, checks:

SIM Screw connections on the fork

SIM Single tank screw connections

2.10 Remote exposure switch system

(optional), check:

SIE Function of remote exposure switch

system

2.11 DAP measuring system (optional),

check:

SIE Function of DAP measuring system

7. Test result/evaluation: Evaluate the long-term trends of the pro-

tective conductor resistance and the equiv-

alent leakage current by comparing the

current measuring values with those of the

preceding technical safety check. A sud-

den or unexpected increase in the mea-

sured values may indicate a

safety-relevant defect – even if no limit

value is exceeded.

Fill in the result of the check.

Have the operator, or a person authorized

by the operator, sign the TSC protocol.

Hand the TSC protocol over to the opera-

tor, or a person authorized by the operator.

Siemens AG SPR8-215.831.04.03.02 Page 23 of 64 MOBILETT Plus/ -E/ -M

Medical Solutions 07.05 CS PS 24

24 Inspection and maintenance

2-

2 Inspection and maintenance

2.1 Visual inspection

SIM Labels

• Certification labels, labels with the model and serial numbers and a ”WARNING” label

are attached to the unit. The label locations are indicated in the Instructions for Use.

• Ensure that all labels are legible and visible.

PMP Customer documentation

• Check that the following documents are filed on site:

- Instructions for Use

- User statements and a copy of FDA form FD 2579, completed and signed by the as-

sembler at the time of installation

- Periodic maintenance records/checks/protocol

- Assembler reports after major repairs

2.1.1 Damage

Check the following parts for cracks and other damage.

Repair or replace any damaged parts.

SIM Covers

SIM Cassette compartment

SIM Control and display panel

SIM Exposure release cable

SIM Single tank generator

SIM Collimator

• Make sure that neither the single tank generator nor the collimator have any mechani-

cal damage that could affect radiation protection.

SIM DAP (optional)

• Make sure there are no scratches on the DAP ionization chamber. Make sure the cable

and the connector are intact. Make sure the DAP display is intact as well.

MOBILETT Plus/ -E/ -M SPR8-215.831.04.03.02 Page 24 of 64 Siemens AG

07.05 CS PS 24 Medical Solutions

Inspection and maintenance 25

2.2 Mechanical inspection

2.2.1 Rear wheels

Fig. 1: Fig. 2:

• Jack up one side of the unit with a piece of wood (Fig. 1 / p. 25).

• Secure the rear wheel on the other side with two blocks. Do not apply the parking

brake.

• Remove the wheel:

- for MOBILETT Plus/Plus E (Fig. 1 / p. 25)

- for MOBILETT Plus M (Fig. 2 / p. 25)

SIM Drive belt (for MOBILETT Plus M only)

• Check the condition and tension of the drive belt.

NOTE Under normal operating conditions, the drive belt does not require

adjustment throughout the lifetime of the system.

Siemens AG SPR8-215.831.04.03.02 Page 25 of 64 MOBILETT Plus/ -E/ -M

Medical Solutions 07.05 CS PS 24

26 Inspection and maintenance

Fig. 3:

SIM Brake lining

• Check the brake lining (Fig. 3 / p. 26). If the lining is worn down to less than 1 mm, it

must be replaced. Refer to the section on ”Adjustment of the hand brake/parking brake”

in the service instructions.

• Remount the wheel.

SIM Secure mounting

SIM Ease of movement

• Check that the wheel is securely mounted and that it turns freely.

• Check the other wheel following the same procedure.

2.2.2 Front wheels

Fig. 4: Fig. 5:

MOBILETT Plus/ -E/ -M SPR8-215.831.04.03.02 Page 26 of 64 Siemens AG

07.05 CS PS 24 Medical Solutions

Inspection and maintenance 27

• Lock the rear wheels with the parking brake.

• Lift up the front wheels using the tilt bar and jack them up with a piece of wood

(Fig. 4 / p. 26).

SIM Secure mounting

SIM Ease of movement

• Check that the wheels are securely mounted and that they turn freely. If necessary,

tighten the Allen screws (Fig. 4 / p. 26).

PMP Cleaning

If the wheels need thorough cleaning, they must be removed:

• Remove the Allen screws.

• Remove the wheels (Fig. 5 / p. 26).

• Clean the wheels.

• Remount the wheels.

• Check the other set of wheels in the same way.

2.2.3 Supporting wheels

Fig. 6:

Pos. 1 Supporting wheels

• Lock the rear wheels with the parking brake.

• Jack up one side of the unit with a piece of wood.

SIM Ease of movement

SIM Damage

• Check that the supporting wheels turn freely and do not show any signs of damage. If

they must be replaced, refer to ”Replacing the supporting wheels” in the service instruc-

tions.

Siemens AG SPR8-215.831.04.03.02 Page 27 of 64 MOBILETT Plus/ -E/ -M

Medical Solutions 07.05 CS PS 24

28 Inspection and maintenance

2.2.4 Turn plate (MOBILETT Plus/Plus M only)

Fig. 7:

• Connect the mains cable and switch the system ON.

• Move the unit to a level surface.

PMF Button illumination

• Press one of the turn plate buttons. The buttons must light up when the turn plate is acti-

vated.

PMF Function

• Check whether the system can be rotated around the turn plate (Fig. 7 / p. 28).

• Press the turn plate button again and check whether the turn plate retracts to the park-

ing position.

• Repeat the same test with the other turn plate button. If a problem arises, proceed ac-

cording to the section ”Adjustment and replacement of the turn plate” in the service in-

structions.

MOBILETT Plus/ -E/ -M SPR8-215.831.04.03.02 Page 28 of 64 Siemens AG

07.05 CS PS 24 Medical Solutions

Inspection and maintenance 29

2.2.5 Brakes

Fig. 8:

WARNING There is a risk of life-threatening electric shock.

¹ Make sure protective measures have been taken prior to

opening the unit.

¹ Disconnect the system from the mains.

¹ (Protective measures when working on the capacitor

bank / p. 14).

SIM Uniformity

SIM Braking force

SIM Locking

• Check whether the hand brake is sufficient to stop the unit and that it does not pull to the

left or the right when the brake is applied.

• Lock the brake.

¹ It should not be possible to push the MOBILETT using average force. Slight

skidding is permissible when applying a force greater than 350 N.

• Remove the front, rear, left and right covers.

• The brake force can be increased by increasing the tension on the brake cable

(Fig. 8 / p. 29). Additional information can be found in the section on ”Adjustment of the

hand brake/parking brake” in the service instructions.

Siemens AG SPR8-215.831.04.03.02 Page 29 of 64 MOBILETT Plus/ -E/ -M

Medical Solutions 07.05 CS PS 24

30 Inspection and maintenance

2.2.6 Transport safeguard

Fig. 9: Fig. 10:

Pos. 1 Transport safeguard

SIM Damage

SIM Locking

• Check the transport safeguard (Fig. 9 / p. 30) for mechanical damage. In case of dam-

age, the transport safeguard must be replaced.

• Check that the handle of the arm system locks securely into the transport safeguard.

2.2.7 Handles

SIM Mounting

• Check that the handle of the support arm is securely mounted. If necessary, tighten the

screws with a torque of 15-20 Nm.

2.2.8 Collimator adjustment knobs

SIM Mounting

• Check whether the adjustment knobs on the collimator are tightened securely

(Fig. 10 / p. 30).

If necessary, tighten both Allen screws on each of the knobs.

MOBILETT Plus/ -E/ -M SPR8-215.831.04.03.02 Page 30 of 64 Siemens AG

07.05 CS PS 24 Medical Solutions

Inspection and maintenance 31

2.2.9 Arm system and single tank

Fig. 11:

SIM Movement of the arm system and the single tank

• The entire arm system including the single tank must not move by itself in any position.

However, it must be easy to move to a new position. If this is not the case, proceed ac-

cording to the section ”Adjusting the friction linings” in the service instructions.

SIM Movement of the single tank fork

• Check that the single tank fork can be easily turned and stays in any desired position.

SIM Single tank movement

• Check that the single tank moves easily in the fork and stays in any desired position.

Siemens AG SPR8-215.831.04.03.02 Page 31 of 64 MOBILETT Plus/ -E/ -M

Medical Solutions 07.05 CS PS 24

32 Inspection and maintenance

2.2.10 Mains cable

Fig. 12:

Pos. 1 Protective conductor

PMP Replace the cable winder every 4 years (units with cable winder only).

• The cable winder should be replaced every four years.

SIM Cable winder (for units with cable winder only)

• Move the cable up and down while winding it, in order to avoid any slack, until the cable

is completely rolled up. Ensure proper functioning of cable winder and brake.

PMP Replace the mains cable every 2 years.

• The mains cable must be replaced every two years.

NOTE New cable winder 65 08 746 comes with the new mains cable.

Therefore, it is not necessary to replace the mains cable, if the ca-

ble winder has been replaced already.

SIM Damage

• Check the mains cable and plug for damage. If necessary, replace them.

PMP Cleaning

• Clean the mains cable using a paper towel dampened with a lukewarm solution of wa-

ter and a household cleaning agent.

SIM Protective conductor

• Disconnect the power supply plug.

MOBILETT Plus/ -E/ -M SPR8-215.831.04.03.02 Page 32 of 64 Siemens AG

07.05 CS PS 24 Medical Solutions

Inspection and maintenance 33

• Check the protective conductor connection to the plug. The protective conductor must

be securely attached and must be slightly longer than the other two wires. This applies

for all plug types.

• Close the plug after inspecting it.

2.2.11 Arm system mounting

Fig. 13:

Pos. 1 Upper link (check without torque)

Pos. 2 Check without torque

Pos. 3 Nut

Pos. 4 Upper link

Pos. 5 Lower link

Siemens AG SPR8-215.831.04.03.02 Page 33 of 64 MOBILETT Plus/ -E/ -M

Medical Solutions 07.05 CS PS 24

34 Inspection and maintenance

• Remove the arm covers as well as the upper and lower cover plates of the column.

The lower column cover can be lifted up.

SIM Screws and lock nuts

• Check that all the screws and lock nuts on the arm system are tightened securely

(Fig. 13 / p. 33).

2.2.11.1 Adjustment screw

Fig. 14: Fig. 15:

Pos. 1 Adjustment screw (check without torque) Pos. 1 Check without torque

Pos. 2 Foot

WARNING If the screw is loosened, the arm might fall!

¹ When checking the adjustment screw, do not loosen the

nuts or turn the adjustment screw.

¹ Avoid loosening the screw and the nuts.

SIM Lock nuts

• Check the lock nuts on the adjustment screw (Fig. 14 / p. 34).

SIM Base mounting

• Check the base mounting in the chassis (Fig. 14 / p. 34).

2.2.11.2 Arm connecting piece

SIM Screws and nuts

• Remove the cover of the lower connecting piece.

MOBILETT Plus/ -E/ -M SPR8-215.831.04.03.02 Page 34 of 64 Siemens AG

07.05 CS PS 24 Medical Solutions

Inspection and maintenance 35

NOTE Note the assembly sequence.

• Check the screws and nuts on the connecting piece (Fig. 15 / p. 34).

2.2.11.3 Single tank fork

Fig. 16: Fig. 17:

Pos. 1 Check without torque

SIM Screw connections on the fork

• Check and tighten all screw connections of the fork on the support arm (Fig. 16 / p. 35).

SIM Single tank screw connections

• Check the four screw connections of the single tank. They are accessible from the top

side of the single tank without removing the cover (Fig. 17 / p. 35).

2.2.11.4 Lubrication

Remove the cover of the column stand.

Siemens AG SPR8-215.831.04.03.02 Page 35 of 64 MOBILETT Plus/ -E/ -M

Medical Solutions 07.05 CS PS 24

36 Inspection and maintenance

Fig. 18: Fig. 19:

Pos. 11 Rotation wear

PMP Glide bushing on the connecting rod

Lubricate the glide bushing on the connecting rod (Fig. 18 / p. 36).

2.2.12 Arm cable harness

SIM Damage

• Check all the cables for damage. Closely inspect the areas that are frequently subject-

ed to torsion strain (Fig. 19 / p. 36).

• Replace any damaged or broken cables. If you cannot determine any direct cause for

the damage, replace all cable harnesses.

Refer to the section entitled ”Replacement of the support arm cable harness” in the

service instructions.

MOBILETT Plus/ -E/ -M SPR8-215.831.04.03.02 Page 36 of 64 Siemens AG

07.05 CS PS 24 Medical Solutions

Inspection and maintenance 37

2.3 Motor batteries (MOBILETT Plus M only)

PMF Battery voltage

• Check the battery voltage (+ 24 V) at K103 (2 each 12 V batteries in series).

PMF Condition

• In order to assess the condition of the batteries, ask the operating personnel whether

the batteries need to be recharged more frequently than previously. If this is the case,

the batteries should be replaced.

PMF Charging indicator

• Check that the charging indicator is functioning correctly.

Siemens AG SPR8-215.831.04.03.02 Page 37 of 64 MOBILETT Plus/ -E/ -M

Medical Solutions 07.05 CS PS 24

38 Inspection and maintenance

2.4 Service mode

Fig. 20:

• Reattach all cover parts with the exception of the upper system cover.

NOTE Switch S10 on D7 OFF prior to the following inspection.

Entering service mode

Switch S1:1 on board D1 must be switched over (S1:1 to ON) to call up the service pro-

gram. The program version is then displayed:

kV mAs

vEr x.x = version x.x

(depends on the software version installed)

(To exit the service mode, switch S1:1 on board D1 must be switched back to OFF. This

will cause any program that is still running to be shut down.)

Selection of test programs with buttons "kV+/ -"

Several test programs are available. The respective program number appears in the kV

window of the display while the mAs window remains blank. Example of the display for

program no. 6:

kV mAs

P06

MOBILETT Plus/ -E/ -M SPR8-215.831.04.03.02 Page 38 of 64 Siemens AG

07.05 CS PS 24 Medical Solutions

Inspection and maintenance 39

Pressing the ”kV+” button calls up the next test program. As soon as the last test program

has been reached and ”kV+” is pressed again, the display begins again with the program

version.

The "kV-" button allows you to run the test programs in reverse order. The "collimator

lamp" button is used for the ON/OFF function, i.e., it starts or stops the displayed test pro-

gram.

Example of the display for P06 after activation of the collimator lamp (starts the formation

of the capacitor bank):

kV mAs

CAP For = capacitor formation program

The test program is stopped by pressing the "collimator lamp" button a second time.

Example of the display for P06:

kV mAs

P06 Stop

Program P06 is now stopped. A new service program can be selected with the ”kV+/-”

buttons or program no. 6 can be restarted by pressing the "collimator lamp" button.

NOTE Messages appearing in service mode, with the exception of "Quick

adjustment", are only displayed, i.e. they are not incorporated in

the error memory.

Siemens AG SPR8-215.831.04.03.02 Page 39 of 64 MOBILETT Plus/ -E/ -M

Medical Solutions 07.05 CS PS 24

40 Inspection and maintenance

2.5 Maintenance tests

Use these service programs to check the display, filament heating, rotating anode and

capacitors.

While the test is running, observe the display. If an error is determined during the course

of the test, the program is interrupted and the associated error is displayed, accompanied

by an audible signal.

Additional information about each test can be found in the section "List of test programs

available in service mode" in the service instructions. The test sequences are also

described in this section.

• Start the programs by activating the collimator lamp.

SIE Display test

PMF Filament test

PMF Rotating anode test

PMF Capacitor bank and charge test

P04 Display test. Check whether the display and the LEDs light up and

whether the buzzer sounds. The test will automatically be repeated

once.

P01 Filament test. When the test is successfully completed, the following

message will appear for 4 seconds:

FIL PASS = The filament test was successfully completed.

P02 Rotating anode test. During this test, rotating anode start-up is checked

and the rotation frequency is displayed. The following message

appears when the test has been successfully completed:

rot PASS = The rotating anode test was successfully completed.

P03 Capacitor bank and charge test. During the test, the actual voltage in

the capacitor bank is displayed. The following message appears when

the test has been successfully completed:

CAP PASS = The capacitor bank and charge test was successfully completed.

If an error is determined during any of the tests, the current program stops and the follow-

ing message appears:

Err xx = Test results are "not valid".

MOBILETT Plus/ -E/ -M SPR8-215.831.04.03.02 Page 40 of 64 Siemens AG

07.05 CS PS 24 Medical Solutions

Inspection and maintenance 41

2.6 Backup battery G1/D1

PMP Replace every 5 years

The backup battery (3.0 V, 1.2 A lithium battery) on board D1 must be replaced every

5 years. Refer to the section ”Replacing the backup battery” in the service instructions.

PMF P11 - Backup battery test

The status of the backup battery can be checked using service program P11.

After activating program no. 11 via the "collimator lamp" button, the battery voltage is dis-

played:

kV mAs

bAt 3.2 = 3.2 volts

If the battery voltage is 2.9 V or less, the battery must be replaced. Refer to the section

”Replacing the backup battery" in the service instructions.

After 5 seconds, the program ends. If the battery voltage is too low, the following message

appears and an audible signal sounds:

kV mAs

P 11 CAL31

If the battery voltage is within the correct range, the following message appears:

kV mAs

P 11 PASS = battery charge is okay

Exit the service mode by switching S1:1 on board D1 OFF. This will end all currently run-

ning programs.

Siemens AG SPR8-215.831.04.03.02 Page 41 of 64 MOBILETT Plus/ -E/ -M

Medical Solutions 07.05 CS PS 24

42 Inspection and maintenance

2.7 Test of kV accuracy

Fig. 21:

Requirement:

The measured kV values must lie within the limit values listed in the table.

NOTE If the MOBILETT is equipped with a DAP measuring system, re-

move the DAP ionization chamber first.

Required measurement devices:

kV meter that works with the filter comparison method, e.g. the PTW Nomex. Use the cor-

rection factor indicated in the kV meter operating instructions for non-invasive kV mea-

surements. If there is no kV meter available, the measurement can also be performed with

an oscilloscope at test points "HTPEAK” and "GND” on board D1. The measurement

result is 40 kV/V.

NOTICE Increased filtration leads to higher kV values.

The actual filtration of MOBILETT can be taken from the test proto-

col.

¹ If the actual inherent filtration is not known, make the

correction with a value of 5 mm AI.

Procedure:

• Prepare the kV meter for the measurement (refer to the operating instructions for the kV

meter).

• Place the measuring detector on a tabletop or other suitable surface. Using the collima-

tor lamp, check whether the detector is located in the radiation field (Fig. 21 / p. 42).

• Set the SID according to the information given in the operating instructions for the kV

meter.

MOBILETT Plus/ -E/ -M SPR8-215.831.04.03.02 Page 42 of 64 Siemens AG

07.05 CS PS 24 Medical Solutions

Inspection and maintenance 43

X • Set the following exposure parameters and release an exposure:

kV meter Exposure parameter Limit values* to be maintained

selection

52 kV 50 mAs 49.0-55.0 kV

81 kV 20 mAs 77.0-85.0 kV

MOBILETT Plus/Plus M MOBILETT Plus/Plus M

DC voltage

133 kV 20 mAs 126.4-139.6 kV

MOBILETT Plus E MOBILETT Plus E

125 kV 20 mAs 118.8-131.2 kV

* The measurement inaccuracy of the respective measurement device must be sub-

tracted from these limit values.

Setting

• Proceed according to section "P10 - Fast adaptation" in the service instructions in order

to adjust excessively high deviations.

PMF 52 kV, 50 mAs

PMF 81 kV, 20 mAs

PMF 133 kV, 20 mAs

PMF 125 kV, 20 mAs

Siemens AG SPR8-215.831.04.03.02 Page 43 of 64 MOBILETT Plus/ -E/ -M

Medical Solutions 07.05 CS PS 24

44 Inspection and maintenance

2.8 Test of mAs accuracy

Requirement

The actual product of the exposure time and tube current (mAs) must match the dis-

played value within the limits established by Siemens.

Required measurement devices:

Storage oscilloscope with a measurement accuracy of ± 2.5 %.

Procedure:

• Close the collimator.

• Connect the oscilloscope to test points ”MAPOS” and ”GND” on board D1.

• Switch on the X-ray system and the oscilloscope and wait approximately 5 minutes un-

til the units have stabilized.

Example: Calculating the mAs

Fig. 22:

The mA signal is comprised of a series of pulses. To get the real tube current, it is neces-

sary to use an oscilloscope with the possibility of showing part of the time sweep

expanded so that each current pulse is clearly visible. The current can then be measured

according to the figures above.

The mAs value can be calculated using the information displayed on the oscilloscope.

Surface ”A” corresponds to the mAs value.

mAs = Tube current x exposure time

mAs = 340 mA x 0.006 s = 2.0 mAs

MOBILETT Plus/ -E/ -M SPR8-215.831.04.03.02 Page 44 of 64 Siemens AG

07.05 CS PS 24 Medical Solutions

Inspection and maintenance 45

NOTE The signal contains a high frequency of 20-40 kHz, which can lead

to measurement problems with the oscilloscope (aliasing effect).

Always use an oscilloscope with a high sampling rate.

X • Calculate the product of the tube current x the exposure time for the following exposure

parameters:

Set on the control and display panel Acceptable mAs value*

kV mAs

40 5 4.7 - 5.3

81 2 1.9 - 2.1

MOBILETT Plus/Plus M

133 10

9.5 - 10.5

MOBILETT Plus E

125

* The measurement inaccuracy for the measurement device must be subtracted from

these limit values.

• Determine whether the mAs product (tube current + reactive current) x exposure time

lies within the indicated tolerances.

Setting

• Proceed according to section "P10 - Fast adaptation" in the service instructions to elimi-

nate slight deviations.

PMF 40 kV, 5 mAs

PMF 81 kV, 2 mAs

PMF 133 kV, 10 mAs

PMF 125 kV, 10 mAs

Siemens AG SPR8-215.831.04.03.02 Page 45 of 64 MOBILETT Plus/ -E/ -M

Medical Solutions 07.05 CS PS 24

46 Inspection and maintenance

2.9 Check for reproducibility

Requirement:

• The coefficient of fluctuation of the radiation dose may not be greater than 0.045 for

any combination of exposure parameters if the X-ray system is supplied with line volt-

age as specified by Siemens.

NOTE The following test requires 10 sequential exposures, which must

be taken within one hour.

After each measurement, the exposure parameters should be set

to different values for a short time.

If the MOBILETT is equipped with a DAP measuring system, re-

move the DAP ionization chamber first.

Required measurement devices:

• Dose meter

Procedure:

• Wait until the system has reached thermal stability. A 15 minute warm-up time is re-

quired for the generator to be ready.

X • Release the specified number of exposures with the following exposure data:

- 85 kV, 1.0 mAs, 10 exposures.

• Measure the dose for each exposure with the dose meter.

• Reset the measurement display prior to each new measurement.

Calculations: Fluctuation coefficient C

• The fluctuation coefficient C for a dose measurement sequence of 10 exposures is:

Fig. 23:

Where:

s = standard deviation of the measurements

= average measurement value of the sequence

xi = i-th measurement value of the sequence

n = number of measurements in the measurement sequence

The fluctuation coefficient C must be ≤ 0.045.

Setting

MOBILETT Plus/ -E/ -M SPR8-215.831.04.03.02 Page 46 of 64 Siemens AG

07.05 CS PS 24 Medical Solutions

Inspection and maintenance 47

• If the value for the calculated fluctuation coefficient is higher than 0.045, the reason for

the deviation must be determined and corrective measures must be taken.

Refer to section "P10 - Fast adaptation" in the service instructions.

QSQ Fluctuation coefficient C

Steps for calculating C

Example:

The values used in the example are not real values.

• Release 10 exposures and record the measured values.

Exposure Measured val-

(n=10) ues

(xi)

1 1.01

2 1.02

3 1.03

4 1.04

5 1.03

6 1.02

7 1.02

8 1.01

9 1.03

10 1.04

• Add the measured values:

Σ = 1.01 + 1.02 + 1.03 + 1.04 + 1.03 + 1.02 + 1.02 + 1.01 + 1.03 + 1.04 => S = 10.25

• Calculate the average value:

Fig. 24:

• Calculate the standard deviation:

Fig. 25:

Siemens AG SPR8-215.831.04.03.02 Page 47 of 64 MOBILETT Plus/ -E/ -M

Medical Solutions 07.05 CS PS 24

48 Inspection and maintenance

Fig. 26:

Fig. 27:

• Calculate the coefficient:

Fig. 28:

In this example, C = 0.0105 and is therefore ≤ 0.0450,

⇒

i.e. the generator is within the specifications.

• Reattach the upper cover.

MOBILETT Plus/ -E/ -M SPR8-215.831.04.03.02 Page 48 of 64 Siemens AG

07.05 CS PS 24 Medical Solutions

Inspection and maintenance 49

2.10 Remote exposure switch system (optional)

X • Check the function of the remote exposure switch system by switching on the collima-

tor light and releasing an exposure.

SIE Function of the remote exposure switch system

PMP Replace the remote control battery every year.

Siemens AG SPR8-215.831.04.03.02 Page 49 of 64 MOBILETT Plus/ -E/ -M

Medical Solutions 07.05 CS PS 24

50 Inspection and maintenance

2.11 DAP measuring system (optional)

• Press the test button on the display. The value on the display should be in the range

80-120 µGym2 (DAP resolution 0.1 µGym2) or 8-12 µGym2 (when using a highly sensi-

tive chamber, i.e. DAP resolution 0.01 µGym2). If not, calibrate the system according to

the service instructions.

X • Check the function of the DAP measuring system by releasing an exposure. Check if a

measured value is shown on the display.

SIE Function of the DAP measuring system

MOBILETT Plus/ -E/ -M SPR8-215.831.04.03.02 Page 50 of 64 Siemens AG

07.05 CS PS 24 Medical Solutions

Inspection and maintenance 51

2.12 Replacing the collimator lamp

Fig. 29: Fig. 30:

Fig. 31:

PMP Replace every year

• The collimator lamp must be replaced every year.

• Remove the cover (1/Fig. 29 / p. 51) by removing the four screws marked ”A”

(Fig. 29 / p. 51). Turn the collimator so that the lamp housing is accessible.

• Remove the protective plate (2/Fig. 30 / p. 51) covering the collimator lamp. Loosen

the screws marked ”B” by one turn. Do not remove them. Do not remove nuts ”C”, ”D”

and ”E” in this process (Fig. 30 / p. 51).

• Remove the lamp and replace it with a new lamp, (Fig. 31 / p. 51). Do not touch the

glass bulb with your fingers.

Siemens AG SPR8-215.831.04.03.02 Page 51 of 64 MOBILETT Plus/ -E/ -M

Medical Solutions 07.05 CS PS 24

52 Inspection and maintenance

• Reinstall the protective plate and tighten the screws marked ”B”.

• Reattach the cover (1/Fig. 29 / p. 51).

PMF Function of the collimator lamp

• Check the function of the collimator lamp.

MOBILETT Plus/ -E/ -M SPR8-215.831.04.03.02 Page 52 of 64 Siemens AG

07.05 CS PS 24 Medical Solutions

Inspection and maintenance 53

2.13 Checking the luminance

Fig. 32:

Required measurement devices: lux meter

NOTE If the MOBILETT is equipped with a DAP measuring system, re-

move the DAP ionization chamber first.

PMF Luminance

If the collimator lamp is switched on for the purpose of illuminating the radiation field, the

average luminance must be 180 lux at a distance of 100 cm. The average luminance is

determined by taking measurements in the approximate center of each of the four quad-

rants of the light field, (Fig. 32 / p. 53).

Siemens AG SPR8-215.831.04.03.02 Page 53 of 64 MOBILETT Plus/ -E/ -M

Medical Solutions 07.05 CS PS 24

54 Inspection and maintenance

2.14 Coincidence of radiation and light fields

Fig. 33:

NOTE If the MOBILETT is equipped with a DAP measuring system, re-

move the DAP ionization chamber first.

• Insert a film into the 35x35 cm (14"x14") cassette.

• Place the cassette on a table or similar surface.

• Set the SID to 100 cm (39") (use a tape measure).

• Switch the collimator lamp on and align the cassette. Now collimate the light field to

25x25 cm (10"x10").

• Mark the four corners of the light field with coins and identify one of the corners with an

additional coin, (Fig. 33 / p. 54)

Fig. 34:

• Set 52 kV and 2.0 mAs on the control and display panel.

X • Release an exposure.

• Develop the film and measure the deviation between the light and radiation fields. A de-

viation of ± 1.7% of the SID is acceptable. (Fig. 34 / p. 54)

MOBILETT Plus/ -E/ -M SPR8-215.831.04.03.02 Page 54 of 64 Siemens AG

07.05 CS PS 24 Medical Solutions

Inspection and maintenance 55

• If the deviation is larger than 1.7%, correct the coincidence of the light and radiation

fields by adjusting the nuts marked "D” and "E”. (Fig. 30 / p. 51)

X • Check the setting by releasing another exposure.

• If necessary, repeat the adjustment until the deviation of the light and radiation fields

lies within the acceptable tolerance.

QSQ Deviation ((A + C) / SID)

QSQ Deviation ((B + D) / SID)

Siemens AG SPR8-215.831.04.03.02 Page 55 of 64 MOBILETT Plus/ -E/ -M

Medical Solutions 07.05 CS PS 24

56 Inspection and maintenance

2.15 Checking the radiation indicator

Fig. 35:

Pos. 1 Exposure light indicator

• Set 81 kV and 10 mAs.

X • Release an exposure and check whether an indicator lights up on the control and dis-

play panel and an audible signal sounds at the end of the exposure.

SIE Radiation indicator

SIE Audible signal

MOBILETT Plus/ -E/ -M SPR8-215.831.04.03.02 Page 56 of 64 Siemens AG

07.05 CS PS 24 Medical Solutions

Inspection and maintenance 57

2.16 Checking the manual exposure interrupt

The user must be able to interrupt the exposure at any time.

• Set 55 kV, 160 mAs for MOBILETT Plus/Plus M.

• Set 55 kV, 80 mAs for MOBILETT Plus E.

• Release an exposure and immediately interrupt it by letting go of the exposure switch.

The message ”USE 20” appears on the display indicating that the exposure release

switch was interrupted during the exposure. In addition, 10 short "beep" signals

sound.

X • The message can be erased by pressing the ”kV+” button.

SIE Message "USE20"

SIE 10 short beep signals

NOTE All covers must be remounted.

Siemens AG SPR8-215.831.04.03.02 Page 57 of 64 MOBILETT Plus/ -E/ -M

Medical Solutions 07.05 CS PS 24

58 Inspection and maintenance

2.17 Protective conductor measurement

• Perform the protective conductor test, with all system covers closed, according to

ARTD-002.731.17... (Safety-Related Rules for Installation and Maintenance). The

measured values are to be entered in the maintenance protocol. The protective con-

ductor resistance must not exceed 0.2 ohms.

SIE Measured value

MOBILETT Plus/ -E/ -M SPR8-215.831.04.03.02 Page 58 of 64 Siemens AG

07.05 CS PS 24 Medical Solutions

Inspection and maintenance 59

2.18 Equivalent leakage current measurement

• Measure the equivalent leakage current according to ARTD-002.731.17... (Safety-

Related Rules for Installation and Maintenance).

The measured values are to be entered and evaluated in the maintenance protocol.

The limit values of 2 mA must not be exceeded.

NOTE Evaluate the results by comparing the first measured value to the

corresponding value of preceding maintenance procedures or

safety checks. A sudden or unexpected increase in the measured

values may indicate that an error occurred in the primary circuit of

the power supply (damaged insulation, damage caused by water

ingress or humidity, etc.) – even if the limit value of 2 mA is not ex-

ceeded.

SIE Measured value

Siemens AG SPR8-215.831.04.03.02 Page 59 of 64 MOBILETT Plus/ -E/ -M

Medical Solutions 07.05 CS PS 24

60 Inspection and maintenance

2.19 Cleaning the system

• Clean the system with a cloth dampened with a lukewarm solution of water and a com-

mercially available cleaning agent. Refer to the section on "Cleaning" in the instruc-

tions for use.

PMP Cleaning

MOBILETT Plus/ -E/ -M SPR8-215.831.04.03.02 Page 60 of 64 Siemens AG

07.05 CS PS 24 Medical Solutions

Inspection and maintenance 61

2.20 Checking the kV and mAs displays

• Check whether the green "ready" lamp lights up approximately 2 minutes after the

system is switched on. If it doesn’t light up, an error message will appear on the dis-

play. Refer to the chapter "Display messages" in the service instructions.

• Check whether the kV and mAs values are clearly visible from the operator’s position.

Determine whether all exposure parameters are displayed correctly.

PMF "Ready" indicator

SIE Visibility of displays

SIE Correct displays

Siemens AG SPR8-215.831.04.03.02 Page 61 of 64 MOBILETT Plus/ -E/ -M

Medical Solutions 07.05 CS PS 24

62 Inspection and maintenance

2.21 Motor drive function (MOBILETT Plus M only)

Fig. 36:

Pos. 1 Safety switch

Pos. 2 Forward

Pos. 3 Reverse

• Both switches must be activated to drive the unit.

• The drive speed must increase at a constant rate until a nominal speed of approx. 1

m/sec is reached.

• The drive is switched off if one of the two switches is released.

PMF Forward/reverse

PMF Acceleration

SIE Shutdown function

MOBILETT Plus/ -E/ -M SPR8-215.831.04.03.02 Page 62 of 64 Siemens AG

07.05 CS PS 24 Medical Solutions

Changes to the previous version 63

3-

3 Changes to the previous version

Document was converted to DMS.

The hazard information was adapted to the current guidelines.

Siemens AG SPR8-215.831.04.03.02 Page 63 of 64 MOBILETT Plus/ -E/ -M

Medical Solutions 07.05 CS PS 24

64 Changes to the previous version

MOBILETT Plus/ -E/ -M SPR8-215.831.04.03.02 Page 64 of 64 Siemens AG

07.05 CS PS 24 Medical Solutions

You might also like

- 3-Service Manual S-ScanDocument166 pages3-Service Manual S-ScanSergio Alejandro Castro100% (1)

- Siemens Arcadis Varic Service ManualDocument30 pagesSiemens Arcadis Varic Service ManualRoger RogelioNo ratings yet

- Datex-Ohmeda Aespire 7900 Anaesthesia Machine - User Reference Manual 1 PDFDocument88 pagesDatex-Ohmeda Aespire 7900 Anaesthesia Machine - User Reference Manual 1 PDFDaniel Roberto Chacon MatuNo ratings yet

- Hardcopy Cameras, Camera Information With SOMARIS 5 VB30 CSTD CT02-023.805.02 CT02-023.814.70Document258 pagesHardcopy Cameras, Camera Information With SOMARIS 5 VB30 CSTD CT02-023.805.02 CT02-023.814.70Klaus BöhmdorferNo ratings yet

- Service Manual REV1.4 (Pancorp) - EnglishDocument120 pagesService Manual REV1.4 (Pancorp) - EnglishMary TrujilloNo ratings yet

- CR Systems: Hardware GuideDocument73 pagesCR Systems: Hardware Guidetha_ansNo ratings yet

- FONA XPan DG Plus Net v2 Technical Manual GB Rev 1 27491Document148 pagesFONA XPan DG Plus Net v2 Technical Manual GB Rev 1 27491Rubén DíazNo ratings yet

- SIREMOBIL Compact: System ManualDocument68 pagesSIREMOBIL Compact: System Manualoswaldoguzman guzmanNo ratings yet

- Criticare Ncompass 8100H Service ManualDocument142 pagesCriticare Ncompass 8100H Service Manualadin othmanNo ratings yet

- Arcadis VaricDocument64 pagesArcadis VaricJair Amezquita100% (1)

- TM50590 - 5.0 (Technical Manual)Document40 pagesTM50590 - 5.0 (Technical Manual)SusiNo ratings yet

- Medrad Stellant D PM ChecklistDocument5 pagesMedrad Stellant D PM ChecklistDario BriceñoNo ratings yet

- HF-110A and HF-110AM: Operator I Installation I Service ManualDocument41 pagesHF-110A and HF-110AM: Operator I Installation I Service ManualVremedSoluCionesNo ratings yet

- sm784 Cs-8100-Family User-Guide Ed07 English enDocument48 pagessm784 Cs-8100-Family User-Guide Ed07 English enJackNo ratings yet

- Fujitsu W510 PC, Used With System SW VC10 and VD10 CSTD AXD3-500.805.01 AX41-060.841.07Document103 pagesFujitsu W510 PC, Used With System SW VC10 and VD10 CSTD AXD3-500.805.01 AX41-060.841.07Izzeldin Zaki100% (1)

- Technical Manual LilyumDocument6 pagesTechnical Manual Lilyum111No ratings yet

- VITA CR System Version 3.2 Software: Installation GuideDocument47 pagesVITA CR System Version 3.2 Software: Installation GuideFrank OforiNo ratings yet

- MAN-03310-En - 006 - Horizon Service ManualDocument568 pagesMAN-03310-En - 006 - Horizon Service ManualMario PadillaNo ratings yet

- SecurView DX-RT v11.0 Workstation User Guide (MAN-07257-002) English (OUS) Rev - 002 07-2021Document204 pagesSecurView DX-RT v11.0 Workstation User Guide (MAN-07257-002) English (OUS) Rev - 002 07-2021GirayNo ratings yet

- (PAPAYA 3D) Technical Manual Eng Ver 1.5-Appendix - CE 2460Document88 pages(PAPAYA 3D) Technical Manual Eng Ver 1.5-Appendix - CE 2460Marko SalarNo ratings yet

- Sonix Manual de UsuarioDocument282 pagesSonix Manual de UsuarioPedro RdzNo ratings yet

- Drystar 5500: User Manual Software 2.xDocument60 pagesDrystar 5500: User Manual Software 2.xMouhamadou Moustapha RassoulNo ratings yet

- ENG - 6904911503 - Rev1 (Service Manual)Document173 pagesENG - 6904911503 - Rev1 (Service Manual)Ruben ForgesNo ratings yet

- Rayos X Odont Cranex - S - M PDFDocument206 pagesRayos X Odont Cranex - S - M PDFDaniel Parada VanegasNo ratings yet

- Part Number: MAN908080-00 MAN908080-01 Revision: KDocument261 pagesPart Number: MAN908080-00 MAN908080-01 Revision: KAquiles Tolosa SotomayorNo ratings yet

- Dash 3000Document228 pagesDash 3000Marysia KordaszewskaNo ratings yet

- Q3E-EA1511 Noblus TECHNICAL MANUAL For CustomerDocument29 pagesQ3E-EA1511 Noblus TECHNICAL MANUAL For CustomerAngel LuisNo ratings yet

- Siemens Acuson p300Document18 pagesSiemens Acuson p300Jose LagosNo ratings yet

- USER-Opera T90-T30 ENGDocument125 pagesUSER-Opera T90-T30 ENGSergey KakarovNo ratings yet

- Fresenius-4008s Service - ManualDocument416 pagesFresenius-4008s Service - ManualJana SFNo ratings yet

- EN - I-Max Touch - User Manual - Rev9Document144 pagesEN - I-Max Touch - User Manual - Rev9labakoum badr-eddineNo ratings yet

- Arcadis Orbic: System Maintenance InstructionsDocument42 pagesArcadis Orbic: System Maintenance InstructionsHomeroPerezNo ratings yet

- Operating Manual Ergometrics ER 900 (English) PDFDocument84 pagesOperating Manual Ergometrics ER 900 (English) PDFmiryangelNo ratings yet

- Aseptico ARU-HF70 Field Dental X-Ray - Maintenance ManualDocument17 pagesAseptico ARU-HF70 Field Dental X-Ray - Maintenance ManualStevenNo ratings yet

- Instrumentarium Dental OP-200, OC-200 Dental Panorama X-Ray - User Manual PDFDocument136 pagesInstrumentarium Dental OP-200, OC-200 Dental Panorama X-Ray - User Manual PDFChandra Noor Satriyo100% (1)

- MGA21324 - DefiMonitor XD - GB - JDocument102 pagesMGA21324 - DefiMonitor XD - GB - JJulio Benancio ZuluagaNo ratings yet

- Coroskop Planning GuideDocument86 pagesCoroskop Planning Guidefelipedejpinedoc3564No ratings yet

- Document Information For:: 5339157TST 5339157TSTDocument19 pagesDocument Information For:: 5339157TST 5339157TSTMkrtich AltunyanNo ratings yet

- FONA XPan ManualDocument64 pagesFONA XPan Manualطارق حمادNo ratings yet

- 1417WGC/WCC: User & Installation Manual Service ManualDocument97 pages1417WGC/WCC: User & Installation Manual Service ManualMad MichuNo ratings yet

- Rws Service PDFDocument288 pagesRws Service PDFbruce huNo ratings yet

- Kodak 101-102 SDocument20 pagesKodak 101-102 Sspaske_No ratings yet

- Zoll M Series Defibrillator Manual PDFDocument111 pagesZoll M Series Defibrillator Manual PDFAhmad TanveerNo ratings yet

- GalileosDocument78 pagesGalileospolicromicoNo ratings yet

- Service Manual Td850 (Te698883-10 - E-Sm40)Document72 pagesService Manual Td850 (Te698883-10 - E-Sm40)Bio-Scientific GroupNo ratings yet

- MIM Service Manual v5 0Document374 pagesMIM Service Manual v5 0Iranildo BarbosaNo ratings yet

- Xgenus X-Ray PDFDocument61 pagesXgenus X-Ray PDFAli NuriNo ratings yet

- Display, 19 Color TFT Monitor DSC 1913-D DC CSTD CT02-023.805.02 TD00-000.841.46Document102 pagesDisplay, 19 Color TFT Monitor DSC 1913-D DC CSTD CT02-023.805.02 TD00-000.841.46Klaus BöhmdorferNo ratings yet

- 08-UM - TH 5942x H01 Vx101 - User ManualDocument32 pages08-UM - TH 5942x H01 Vx101 - User ManualВадім Русинчук100% (1)

- Manual Ecoview 9Document175 pagesManual Ecoview 9Jhon Fredy Santos TovarNo ratings yet

- 3DQuorum User Guide Supplement (MAN-06029-002) English Rev - 004 07-2021 - 0Document20 pages3DQuorum User Guide Supplement (MAN-06029-002) English Rev - 004 07-2021 - 0tipozkaya101No ratings yet

- Chapter 5 - Electrical DrawingsDocument68 pagesChapter 5 - Electrical DrawingsmazighiNo ratings yet

- COROMETRICSDocument440 pagesCOROMETRICSANELYNo ratings yet

- Arco C PulsarDocument27 pagesArco C PulsarRene CabreraNo ratings yet

- 4 - Description of Operation Exposcop 7000 PDFDocument50 pages4 - Description of Operation Exposcop 7000 PDFToddNo ratings yet

- Trumpf Accesoriosmesas EspecialidadesDocument92 pagesTrumpf Accesoriosmesas Especialidadesghozi zeiss100% (1)

- Modular Design With New Flexibility in Urology: ModularisDocument28 pagesModular Design With New Flexibility in Urology: ModularisKamal WardiNo ratings yet

- LP9 P7 Arm 5582435 1 00Document234 pagesLP9 P7 Arm 5582435 1 00Dante NuevoNo ratings yet

- Mac 1200 ServiceDocument150 pagesMac 1200 Servicesoso loloNo ratings yet

- Educate - Empower: EnhanceDocument9 pagesEducate - Empower: Enhancenaufal hakimNo ratings yet

- Pioneer HPM1100 OwnersDocument2 pagesPioneer HPM1100 OwnersStanko CaneNo ratings yet

- Seria As: Caracteristici Tehnice Articole StandardDocument12 pagesSeria As: Caracteristici Tehnice Articole StandardDan StroescuNo ratings yet

- Manual 203 06 001 - 205 067 001 Mpico Series Qe 1 0 1Document65 pagesManual 203 06 001 - 205 067 001 Mpico Series Qe 1 0 1Cao CaoNo ratings yet

- cgs75 VcsDocument5 pagescgs75 VcsMustafa Umut SaracNo ratings yet

- EME PresentationDocument31 pagesEME PresentationNicholas FrederickNo ratings yet

- Harmonic Mitigating Transformers InformationDocument3 pagesHarmonic Mitigating Transformers InformationJoseph B Delos ReyesNo ratings yet

- Issues in Timing: Digital Integrated Circuits © Prentice Hall 1995 TimingDocument14 pagesIssues in Timing: Digital Integrated Circuits © Prentice Hall 1995 TimingAbhishek BhardwajNo ratings yet

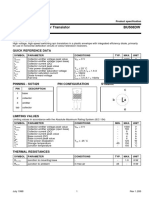

- Silicon Diffused Power Transistor BU508DW: General DescriptionDocument7 pagesSilicon Diffused Power Transistor BU508DW: General Descriptionmazen frgNo ratings yet

- Electrochemical Machining Process: Presented By: Kanishq Gandhi A2399818011 5ME1XDocument10 pagesElectrochemical Machining Process: Presented By: Kanishq Gandhi A2399818011 5ME1XKanishq GandhiNo ratings yet

- 440 - Example OHL Setting - 1-54Document1 page440 - Example OHL Setting - 1-54varofNo ratings yet

- Samsung Dryer Error CodesDocument2 pagesSamsung Dryer Error CodesRolando Alfaro NuñezNo ratings yet

- Publisher in ResearchDocument8 pagesPublisher in Researchrikaseo rikaNo ratings yet

- Lal SeriesDocument19 pagesLal Seriessaviye6587No ratings yet

- Power Electronics in Wind and Solar System-Sample-Question-Paper (Msbte-Study-Resources) PDFDocument4 pagesPower Electronics in Wind and Solar System-Sample-Question-Paper (Msbte-Study-Resources) PDFRevati KalalNo ratings yet

- CHAPTERWISE QUESTIONS FROM BOARD EXAM PAPERSnewDocument26 pagesCHAPTERWISE QUESTIONS FROM BOARD EXAM PAPERSnewSriramNo ratings yet

- Memory Subsystem and Memory HierarchyDocument44 pagesMemory Subsystem and Memory Hierarchyvivek srivastavNo ratings yet

- R 4360c 36 Series Gas Valve Cross Reference en 5239824Document28 pagesR 4360c 36 Series Gas Valve Cross Reference en 5239824pandahiuNo ratings yet

- An 4137SCDocument13 pagesAn 4137SCYung SangNo ratings yet

- Bipolar Junction Transistors (BJTS)Document28 pagesBipolar Junction Transistors (BJTS)Musa MagaulaNo ratings yet

- Questionaires No. 03Document18 pagesQuestionaires No. 03Er Raushan Kumar Yadav0% (1)

- Single Phase RectificationDocument13 pagesSingle Phase RectificationMariusNo ratings yet

- Manual TLM 103 - 617718Document2 pagesManual TLM 103 - 617718FabrícioNo ratings yet

- Ultra Low Drop Linear RegulatorDocument2 pagesUltra Low Drop Linear RegulatorJose Helio PalmaNo ratings yet

- Samsung Le32a65 Le37a65 Le40a65 Le46a65 Le52a65 Le37a616a 40a616a Chassis N46aDocument425 pagesSamsung Le32a65 Le37a65 Le40a65 Le46a65 Le52a65 Le37a616a 40a616a Chassis N46aenerjay80% (5)

- EEE-251 Digital Logic Design Laboratory Adder-Subtractor ExperimentDocument3 pagesEEE-251 Digital Logic Design Laboratory Adder-Subtractor ExperimentModel Ship CompetitionNo ratings yet

- Basic Electrical Engineering: 3110005 Mr. Devang ShahDocument10 pagesBasic Electrical Engineering: 3110005 Mr. Devang ShahAbhay RanpariyaNo ratings yet

- Innovations O2D Image Sensor: Fluid Sensors and Diagnostic SystemsDocument4 pagesInnovations O2D Image Sensor: Fluid Sensors and Diagnostic SystemssandeshshivaNo ratings yet

- Wolf Hazardous Area Portable Temporary Lighting Brochure 2 PDFDocument23 pagesWolf Hazardous Area Portable Temporary Lighting Brochure 2 PDFMohammed MustafaNo ratings yet

- vr7000 Brochure PDFDocument4 pagesvr7000 Brochure PDFvangNo ratings yet