Professional Documents

Culture Documents

Saic D 2002

Saic D 2002

Uploaded by

Abdul HannanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Saic D 2002

Saic D 2002

Uploaded by

Abdul HannanCopyright:

Available Formats

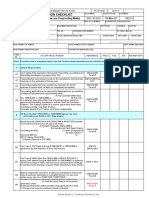

SAUDI ARAMCO ID/PIEU - 15-Nov-2017 - REV. 2016.06.00 (Standards Cutoff -June 30, 2016) Rev. 2016.06.

00 30-Jun-16

SAUDI ARAMCO INSPECTION CHECKLIST SAIC NUMBER DATE APPROVED QR NUMBER

Receiving Inspection of Pressure Vessels- External SAIC-D-2002 15-Nov-17 MECH-

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

EQUIPMENT ID NUMBER(S) EQUIPMENT DESCRIPTION EQPT CODE SYSTEM ID. PLANT NO.

LAYOUT DRAWING NUMBER REV. NO. PURCHASE ORDER NUMBER EC / PMCC / MCC NO.

SCHEDULED INSPECTION DATE & TIME ACTUAL INSPECTION DATE & TIME QUANTITY INSP. MH's SPENT TRAVEL TIME

SAUDI ARAMCO USE ONLY

SAUDI ARAMCO TIP NUMBER SAUDI ARAMCO ACTIVITY NUMBER WORK PERMIT REQUIRED?

SAUDI ARAMCO INSPECTION LEVEL CONTRACTOR INSPECTION LEVEL

ITEM RE-INSP

ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A

No. DATE

Following inspection records are provided with the vessel received:

1) Inspection Release Certificates Schedule Q,

A1 2) Contractor's Inspection Reports Attach. III

3) Test reports specified in Form 175-321900 Para 3.14

Verify that requirements of Purchase Order are complied with.

Final Disposition Report comprising of the following documents as

minimum is provided:

1. Details of Quality activities performed during manufacturing and

fabrication of equipment.

2. Copies of Saudi Aramco approved Waivers to SA requirements. Schedule -Q

A2 3. All SA -175-325100 contractor witnessed inspections. Attachment-III

4. Copies of Quality Records as specified in SA -175-321900 Para 3.15

5. Copies of all NCR's with final disposition and resolutions (If any)

6. Out standing punch items from pre-shipment inspection (If any)

Schedule Q

Delivered vessel showed no signs of improper handling and no physical

A3 Attachment IV

damage.

Para 7.1

Vessel Safety Instruction Sheet (SIS), Form-2694-ENG or Form-2694-M- SAES-A-005,

A4

ENH is available and has been approved. Par. 5.1

Non-material Requirements for Pressure Vessels (NMR-7919-1) was 32-SAMSS-004,

A5

provided and verified per SAIC-D-2022. Par. 20.1

The quantities, sizes and ratings, facings, elevations and orientation of

32-SAMSS-004,

A6 nozzles and manways conform with the Vessel Data Sheet

Par. 8.1.1

and Approved drawings.

Unless otherwise specified on the data sheet, the minimum projections for

nozzles and manway necks, as measured from the outside surface of the

shell or head to the face of a flange, shall meet the following reqmts:

a) 6 inches for NPS 6 nozzles and smaller.

b) 8 inches for NPS 8 nozzles and larger and manways necks. 32-SAMSS-004,

A7

c) For insulated vessels, projection shall be sufficient to allow Par. 8.1.2

bolting of studs without interference with the insulation.

d) For vessel drain connections and other connections, where a

process stream is likely to be stagnant, the projection shall not

exceed three times the connection nominal diameter.

Pressure ratings for standard flanges are per the following:

32-SAMSS-004,

A8 1) ASME B16.5 for flanges NPS 24 and smaller.

Par. 8.3.3

2) ASME B16.47, Series A for flanges larger than NPS 24.

Gasket seating surfaces complies with the following:

a) Spiral wound gasket = 125 to 250 AARH (except for hydrogen service.

b) For spiral wound gaskets in hydrogen service, 125 to 150 AARH. 32-SAMSS-004,

A9

c) The side-walls of rings joint flanges in all services, 63 AARH. Par. 8.3.4

d) For Nonmetallic gaskets, 250 to 500 AARH.

Special care shall be taken to prevent damage.

Saudi Aramco: Company General Use

Gasket Installed types and material specifications of gaskets are as 32-SAMSS-004,

A10

specified in the data sheet. Par. 12.1.27

32-SAMSS-004,

A3 Type of head used is ASME 2:1-Ellipsoidal or ASME Hemispherical. Design

Par. 7.10.2

One piece construction is used for heads of vessels with wall thickness

32-SAMSS-004,

A4 greater than 50 mm, and for heads of vessels in cyclic, hydrogen or lethal Design

Par. 7.10.4

services.

Reinforcing for conical transition sections in vessels with design thickness

32-SAMSS-004,

A5 greater than 50mm shall be provided by increased plate thickness. Use of Design

Par. 7.10.7

reinforcing rings is prohibited.

Flanges, nozzles & manways shall be as follows (all services):

a) Forged steel long welding neck.

b) Forged steel welding neck flange with seamless pipe, or rolled

plate with 100% radiography. The bores of nozzle flanges shall

match the nozzle neck bore.

c) Studded nozzles and proprietary designs may be offered as

alternatives provided their design is in accordance with the Codes

32-SAMSS-004, Procureme

A8 and approved by the Saudi Aramco Engineer.

Par. 8.1.3 nt

d) Slip-on type flanges with seamless pipe nozzle necks or rolled

plate with 100% radiography are permissible for vessels, which are

integral parts of skid-mounted packaged equipment units, in only non-

cyclic air and water services with design temperature and design

pressure not exceeding 121ºC (250ºF)

and 1.7 MPA (245 psi), respectively. Slip-on flange shall be welded on the

front or face and at the back of the hub.

32-SAMSS-004,

A body flange shall be constructed of a single-piece forging. Nozzles shall

A9 Par. 8.1.4 Par. Design

not be less than 2-inch NPS. Only flanged nozzles shall be used.

8.1.5 Par. 8.1.6

Vessels in services other than air and water shall be provided with a 32-SAMSS-004,

A10 Design

minimum 2-inch NPS flanged steam-out connection Par. 8.1.8

Nozzles supporting mechanical mixers shall be designed to include the

32-SAMSS-004,

additional loads and dimensional tolerances as specified on the data

A11 Par. 8.1.10 & par. Design

sheet. Minimum four gusset plates for the reinforcement of nozzles

8.1.11

supporting mixers shall be provided.

Saudi Aramco: Company General Use

SAUDI ARAMCO ID/PIEU - 15-Nov-2017 - REV. 2016.06.00 (Standards Cutoff -June 30, 2016) Rev. 2016.06.00 30-Jun-16

SAUDI ARAMCO INSPECTION CHECKLIST SAIC NUMBER DATE APPROVED QR NUMBER

Receiving Inspection of Pressure Vessels- External SAIC-D-2002 15-Nov-17 MECH-

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

ITEM RE-INSP

ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A

No. DATE

All manways are circular. The manway covers shall be hinged or provided

32-SAMSS-004,

A12 with handling davits as specified on the data sheet and shown in approved

Par. 8.4.2

drawings.

1/4-inch telltale vent holes drilled and tapped for 1/8-inch NPT shall be

provided in reinforcing pads for welded attachments, including nozzles

and manways, per the following: 1) one hole in a single piece reinforcing

32-SAMSS-004,

A13 pad. 2) where a pad is split, each segment shall have at least one hole.

Par. 13.2.7

Tell tale holes in reinforcing pads for external welded attachments shall be

plugged with grease or other materials adequate for the operating

temperature but not capable of retaining pressure.

All supports and structural attachments (clips) are continuously welded to 32-SAMSS-004,

A14

the vessel. 10.1.4

Vessel skirts are provided with access openings as follows:

a. Minimum of 500 mm diameter opening for vessels with diameters

32-SAMSS-004,

A15 equal to and larger than 1200 mm.

Par. 10.2.6

b. Minimum of one half of the vessel diameter for vessels with

less than 1200 mm.

Horizontal pressure vessel are supported by two saddles. The vessel is

32-SAMSS-004,

A16 fixed at one saddle support and free to slide at the other saddle.Saddle

Par. 10.3.1

baseplates shall be in full direct contact with the foundation.

Wear pads supplied at the junction of the saddle of horizontal vessels

conforms with all of the following:

a) A minimum thickness of 10 mm. 32-SAMSS-004,

A17

b) Continuously welded to the shell. Par. 10.3.4

c) All corners are rounded to a 50 mm minimum radius, and

d) One ¼ inch NPT vent hole at the lowest elevation.

The anchor bolt holes on the sliding-end saddle are slotted. 32-SAMSS-004,

A18

Par. 10.3.5

Anchor bolts shall straddle vessel centerlines on the north-south, east- 32-SAMSS-004,

A19

west axes. Par. 10.4.2

32-SAMSS-004,

A20 Anchor bolts shall not be less than 19 mm minimum nominal diameter.

Par. 10.4.3

Vessels supported on skirts, lugs or legs shall be provided with an even

32-SAMSS-004,

number of anchor bolts with a minimum of four anchor bolts. Vessels

A21 Par. 10.4.5 & Par.

supported on saddles shall be provided with an even number of anchor

10.4.6

bolts with a minimum of two anchor bolts per saddle.

Pressure vessel is provided with a grounding lug connection that is 32-SAMSS-004,

A22

welded to the vessel support. Par. 11.5

A davit for the lifting of equipment shall be supplied when specified on the 32-SAMSS-004,

A23

data sheet & shall be in accordance with PIP VEFV1100. Par. 11.6

Arc strikes, gouges, and other indications of careless workmanship (such

SAES-W-010,

A24 as surface porosity, uneven weld profiles, and undercut) and temporary

Par. 11.6

welded attachments shall be removed by grinding.

Saudi Aramco: Company General Use

SAUDI ARAMCO ID/PIEU - 15-Nov-2017 - REV. 2016.06.00 (Standards Cutoff -June 30, 2016) Rev. 2016.06.00 30-Jun-16

SAUDI ARAMCO INSPECTION CHECKLIST SAIC NUMBER DATE APPROVED QR NUMBER

Receiving Inspection of Pressure Vessels- External SAIC-D-2002 15-Nov-17 MECH-

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

ITEM RE-INSP

ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A

No. DATE

Vessel shall be identified by a nameplate and marked with the information

required by the applicable Code and the requirements of this

32-SAMSS-004,

A25 Specification.

Par. 17.1& 17.3

Note: The nameplate markings shall be stamped or engraved such that

the nameplate material is permanently deformed with the symbols.

Nameplate of vessels are installed as follows:

a) Nameplates and nameplate mounting brackets are not covered

by insulation and are easily readable from grade or a platform.

b) Brackets extend from the outside of vessel to clear insulation,

and with sufficient access for surface preparation, and

painting.

c) Nameplates are 3-mm minimum thickness and manufactured from 32-SAMSS-004,

A26 type 304 stainless steel or Monel and continuously welded to Par. 17.3,

the mounting bracket according to PIP VEFV1100. 17.4,17.5 & 17.6

d) The mounting bracket material shall conform to Para12.1.19.

The brackets are continuously seal welded and

positioned such as not to allow for collection of moisture or rain. d)

Nameplate for internally coated vessels shall show: the Saudi Aramco

Painting system Numbers, type of coating, brand name, and date of

application.

External coating has no physical damage (gouge, cracks, runs, sags,

drips, dry spray, porous, foreign matter) or pre-mature breakdown/rusting

and meet the DFT requirements as follows:

a) APCS-1A&B -----275-400 microns

b) APCS-1C ---------250-375 microns

c) APCS-1D&F -----190-315 microns SAES-H-001

A27 d) APCS-1E ---------175-315 microns Par. 9.3.5 & Sec

e) APCS-2A/B/C ---275-375 microns 11

f) APCS-2D ---------200-250 microns

g) APCS-4 ----------115-180 microns

h) APCS-22A ---------300-400 microns

i) Others ------------- as specified by in SAES-H-001 Sec 11 & the

Purchase Order

Support for insulation system shall be according to the data sheet. The 32-SAMSS-004,

A28 Vessel Manufacturer shall supply and install supports required for Par. 11.2.1 & Par.

insulation 11.2.2

The bottom heads of vertical vessels that are externally insulated are

32-SAMSS-004,

A29 provided with 12 mm blank nuts. Blank nuts are welded on edge and

Par. 11.2.3

located on 300 mm square centers.

For Vessels that were insulated, insulations are not damaged and meets

the following:

a) Stainless steel, galvanized steel, or aluminized steel jackets

for insulation systems that require fireproofing

b) Aluminum metal jackets for non-fire hazardous areas within SAES-N-001,

A30

process plant battery limits. Par. 7.7.2

c) Elastomeric coatings used for weatherproofing on plastic foam

and cellular glass when there is no requirement for metal

jackets.

d) Corrugated jacketing shall not be used to cover cold insulation.

Removable insulated covers are provided for manways and designed so

SAES-N-001,

A31 that their removal shall not disturb the surrounding permanently fixed

Par. 8.2.1

insulation.

Saudi Aramco: Company General Use

SAUDI ARAMCO ID/PIEU - 15-Nov-2017 - REV. 2016.06.00 (Standards Cutoff -June 30, 2016) Rev. 2016.06.00 30-Jun-16

SAUDI ARAMCO INSPECTION CHECKLIST SAIC NUMBER DATE APPROVED QR NUMBER

Receiving Inspection of Pressure Vessels- External SAIC-D-2002 15-Nov-17 MECH-

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

ITEM RE-INSP

ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A

No. DATE

Removable insulation plugs are provided to permit on-stream ultrasonic

inspection when required by the operating proponent. Plugs shall be SAES-N-001,

A32

vapor tight, ultra violet resistant and be such that they can be opened & Par. 8.2.2

reclosed without disturbing adjacent insulation.

All metallic protrusions through insulation systems are caulked with a SAES-N-001,

A33

sealant. Par. 7.4.4

REMARKS:

REFERENCE DOCUMENTS:

1- SAES-A-005, Safety Instruction Sheet (21 March 2010)

2- 32-SAMSS-004 -- Manufacture of Pressure Vessels,(29 June 2015)

3- SAES-W-010 -- Welding Requirements for Pressure Vessels, (15 May 2016)

4- SAES-N-001 -- Basic Criteria, Industrial Insulation, (6 September 2008)

5- SAES-H-001 --Coating Selection and Application Requirements for Industrial Plants and Equipment (5 April 2016)

6- ASME -- Section VIII, Applicable Edition as per Equipment Drawing's Design Data

Contractor / Third-Party Saudi Aramco

Construction Representative* PMT Representative

Work is Complete and Ready for Inspection: T&I Witnessed QC Record Reviewed Work Verified

Name, Initials and Date: Name, Initials and Date:

Saudi Aramco: Company General Use

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5810)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- 12e-C01 Rfis & Hprs Log Updated 28-Jan-2024Document30 pages12e-C01 Rfis & Hprs Log Updated 28-Jan-2024Abdul HannanNo ratings yet

- RFI HPR FORM - 12E-C01-CE-0084 - 3rd LAYER BACFILLING AT PROJECT F 9 AROUND OFFICE AND LAY DOWN AREADocument4 pagesRFI HPR FORM - 12E-C01-CE-0084 - 3rd LAYER BACFILLING AT PROJECT F 9 AROUND OFFICE AND LAY DOWN AREAAbdul Hannan100% (1)

- SKBR HR NP 19111712022Document4 pagesSKBR HR NP 19111712022Abdul HannanNo ratings yet

- 01-SAMSS-017 Auxiliary Piping For Mechanical EquipmentDocument13 pages01-SAMSS-017 Auxiliary Piping For Mechanical EquipmentAbdul HannanNo ratings yet

- 09-SAMSS-068 Qualification Requirements For Coal Tar Epoxy in Buried or Immersion Services (APCS-3) For Steel and ConcreteDocument7 pages09-SAMSS-068 Qualification Requirements For Coal Tar Epoxy in Buried or Immersion Services (APCS-3) For Steel and ConcreteAbdul HannanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument3 pagesSaudi Aramco Inspection ChecklistAbdul HannanNo ratings yet

- Saudi Aramco Inspection Checklist: Foam Generating Equipment - Installation Insp & Testing SAIC-B-2014 15-Nov-17 MechDocument5 pagesSaudi Aramco Inspection Checklist: Foam Generating Equipment - Installation Insp & Testing SAIC-B-2014 15-Nov-17 MechAbdul HannanNo ratings yet

- Saudi Aramco Inspection Checklist: Top Coating Application (Intumescent Fireproofing Matls) 15-Nov-17Document5 pagesSaudi Aramco Inspection Checklist: Top Coating Application (Intumescent Fireproofing Matls) 15-Nov-17Abdul HannanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument2 pagesSaudi Aramco Inspection ChecklistAbdul HannanNo ratings yet