Professional Documents

Culture Documents

Saudi Aramco Inspection Checklist: Foam Generating Equipment - Installation Insp & Testing SAIC-B-2014 15-Nov-17 Mech

Uploaded by

Abdul HannanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Saudi Aramco Inspection Checklist: Foam Generating Equipment - Installation Insp & Testing SAIC-B-2014 15-Nov-17 Mech

Uploaded by

Abdul HannanCopyright:

Available Formats

SAUDI ARAMCO ID/PIEU - 15-Nov-2017 - REV. 2016.06.00 (Standards Cutoff -June 30, 2016) Rev. 2016.06.

00 30-Jun-16

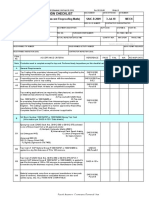

SAUDI ARAMCO INSPECTION CHECKLIST SAIC NUMBER DATE APPROVED QR NUMBER

Foam Generating Equipment - Installation Insp & Testing SAIC-B-2014 15-Nov-17 MECH

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

EQUIPMENT ID NUMBER(S) EQUIPMENT DESCRIPTION EQPT CODE SYSTEM ID. PLANT NO.

LAYOUT DRAWING NUMBER REV. NO. PURCHASE ORDER NUMBER EC / PMCC / MCC NO.

SCHEDULED INSPECTION DATE & TIME ACTUAL INSPECTION DATE & TIME QUANTITY INSP. MH's SPENT TRAVEL TIME

SAUDI ARAMCO USE ONLY

SAUDI ARAMCO TIP NUMBER SAUDI ARAMCO ACTIVITY NUMBER WORK PERMIT REQUIRED?

SAUDI ARAMCO INSPECTION LEVEL CONTRACTOR INSPECTION LEVEL

ITEM

ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A RE-INSP DATE

No.

A General Requirements (As Applicable)

Prior to entering service, all new foam generating equipment is inspected,

GI-1781.001,

A1 commissioned & tagged by the Local Fire Control Unit

Section 5.12.1

NCRs (damages upon receipt) are resolved or detail final disposition & Sch Q, Att III,

A2

resolution. Punch list items (on receipt) are identified for follow-up Para. 3.24

Fire Protection Equipment Layout Drawings for onshore & offshore

GI-1781.001,

A3 facilities show all fire protection equipment locations with an assigned item

Section 2.20

number or unit number.

A 95 Liter/second combination water/foam mobile truck (NFPA 1901,

NFPA 11C) is provided when large quantities of foam are needed in a SAES-B-019,

A4

high risk area (hydrocarbon plant, large tank farm). Para. 5.4

A 4-wheel combination light water/dry chemical trailer mounted

extinguishing unit is provided where lesser amounts of foam are needed

SAES-B-019,

A5 such as Standby first aid protection for maintenance & repair operations

Para. 5.5

of hydrocarbon equipment.

When water is available at a facility, fluoroprotein foam concentrate in 20

SAES-B-019,

A6 L or 210 L containers is used with foam monitors or playpipes equipped

Para. 5.5

with pickup tubes installed.

Protect oil loading piers, platforms, sea islands, oil tankers, & other craft in

harbor, offshore producing operations & associated cargo piers (Use

SAES-B-019,

A7 SAES-B-060 & SAES-B-009 as detailed checklists). Firefighting tug

Para. 5.6

boats and other selected launches are equipped with foam

monitors/tanks to supplement installed system facilities.

B Foam Requirements

Fluoroprotein foam meets 21-SAMSS-011 (onshore application) unless

alternate foams are approved by the Chief Fire Prevention Engineer & SAES-B-019,

B1

General Supervisor, TS&TD Div., Fire Protection Dept. Para. 5.1

Foam concentrate is supplied in 208 liter (55 U.S. gallon) mild steel with

polyethylene lined drums as follows:

A) Each container shall have three labels written in English.

21-SAMSS-011,

B2 B) Two labels are centrally positioned, directly

Section 6

opposite each other.

C) The third label is located centrally on the top of the container.

D) The labels are clearly legible & permanently attached to container

Label information is as follows:

A) SAMS Stock Number 21-111-510-00 (55 gallon)

B) Type of Foam & Concentrate Percentage 21-SAMSS-011,

B3

C) Manufacturer Name & Address Section 6

D) Date of Manufacture

E) Batch/Stock Number

Saudi Aramco: Company General Use

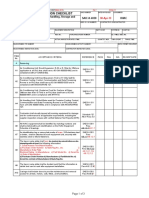

SAUDI ARAMCO ID/PIEU - 15-Nov-2017 - REV. 2016.06.00 (Standards Cutoff -June 30, 2016) Rev. 2016.06.00 30-Jun-16

SAUDI ARAMCO INSPECTION CHECKLIST SAIC NUMBER DATE APPROVED QR NUMBER

Foam Generating Equipment - Installation Insp & Testing SAIC-B-2014 15-Nov-17 MECH

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

ITEM RE-INSP

ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A

No. DATE

Inspection of concentrate was performed per Saudi Aramco Inspection 21-SAMSS-011,

B5

Requirements Form 175, attached to purchase order. Section 7

Current Manufacturer's lab test results on the concentrate is available 21-SAMSS-011,

B6

and acceptable (as submitted by the manufacturer). Section 7

Foam concentration has one of the following proportions:

NFPA 11,

A) Not less than the rated concentration

B7

B) No more than 30 percent above the rated concentrate, or 1 percentage

Section 11.6.4

point above the rated concentration (whichever is less)

C NFPA 11 Requirements for Installations

Foam systems are examined visually to determine that they have been

properly installed as follows:

A) They conform with installation plans

B) Continuity of piping exists

NFPA 11,

to assure system operability C)

C1

Removal of temporary blinds has been accomplished

Section 11.1

D) Valves, controls & gauges (for operation) are accessible.

E) Vapor seals (where applicable) have

been properly installed. F) Devices have

proper identification and operating instructions.

NFPA 11,

Flush all foam system piping after installation using normal water supply

C2

(foam-forming materials are shut off)

Section 11.2

Flushing to remove foreign materials in both underground (UG) and NFPA 11,

C3 aboveground (AG) water supply mains during installation is completed

before connection is made to system piping Section 11.2

NFPA 11,

Minimum rate of flow for flushing is not less than the water demand

C4

rate of the system, as determined by system design.

Section 11.2

NFPA 11,

During flushing, flow is continued for enough time to ensure thorough

C5

cleaning of lines.

Section 11.2

NFPA 11,

Where flushing cannot be accomplished, pipe interiors are carefully

C6

visually examined for cleanliness during installation.

Section 11.2

Equipment is tested by qualified personnel that perform a complete check NFPA 11,

C7 of control circuits & systems to ensure proper operation & supervision in

the event of failure. Section 11.5

NFPA 11,

Tests are adequate to determine that the system has been properly

C8

installed and that it functions as intended. Section 10.3

Section 11.3

Hydrotest all equipment piping for 2-hour hydrostatic pressure gauge NFPA 11,

C9 test at 200 psi or 50 psi in excess of the maximum pressure anticipated,

whichever is greater. Hydrotest has been accepted. Section 11.4

NFPA 11,

Normally dry horizontal piping has proper drainage pitch (slope) per

C10

approved drawings to permit self drainage.

Section 11.4

Functional Test ensures proper operation (devices & equipment):

Total flood system automatic closing devices (doors, NFPA 11,

C11 windows) conveyor openings, automatic equipment interlocks, automatic

opening of heat smoke vents or ventilators function properly. Section 11.5

Saudi Aramco: Company General Use

SAUDI ARAMCO ID/PIEU - 15-Nov-2017 - REV. 2016.06.00 (Standards Cutoff -June 30, 2016) Rev. 2016.06.00 30-Jun-16

SAUDI ARAMCO INSPECTION CHECKLIST SAIC NUMBER DATE APPROVED QR NUMBER

Foam Generating Equipment - Installation Insp & Testing SAIC-B-2014 15-Nov-17 MECH

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

ITEM RE-INSP

ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A

No. DATE

NFPA 11,

Operating instructions (from supplier) are followed. Device identification

C12

is checked and found to be correct.

Section 11.5

Flow tests ensure the hazard is fully protected with data required:

A) Static water pressure

B) Residual water pressure at control valve & remote reference point in

the system NFPA 11,

C13 C) Actual discharge rate

D) Consumption rate of foam-producing material Section 11.6

E) Concentration of the foam solution

F) Foam quality (expansion & 1/4 drain time) or foam discharge is

conducted or the foam discharge is visually inspected

NFPA 11,

After completion of acceptance tests using foam, systems are flushed &

C14

restored to operational condition.

Section 11.7

D GI-1781.001 Supplement 13.0 Checklists (Trailer)

Inspect the Twin Agent Four-Wheeled Unit (Trailer):

A) Storage area is not exposed to direct sunlight or corrosive

atmospheres or in environments exceeding 120°F.

B) Unit has a Mfg's cover (or will be housed in shed, sunshade).

C) No obvious corrosion or physical damage.

D) Tires are properly inflated and in good condition.

E) Seal and safety pin are intact.

GI-1781.001,

D1 F) Hoses are free from cracks, unplugged, & in good condition.

Supplement 12.0

G) Dry chemical level and type is correct with no caking.

H) Nitrogen pressure gauge reads at least 2000 psi.

i) CO2 cartridge disc is intact.

J) Foam (light water) solution is used.

K) Cap gasket in good condition.

L) Hydrotest date from manufacturer is shown on label.

M) Inspection tag exists showing last inspection date.

E GI-1781.001 Supplement 27.0 (Foam System Checklist)

Manifold installations are checked as follows:

A) Clapper valves are installed & operational. GI-1781.001,

E1

B) Caps are installed on hose inlets. Supplement 24

C) Manifold has the proper female fittings.

Bladder installations are checked as follows:

A) Bladder bags are free of leaks. GI-1781.001,

E2

Follow manufacturer instruction manual for leak detection. Supplement 24

B) Bladder condition is good & exhibits no dry rot or defects.

Balanced Pressure installations are checked as follows:

A) Free from defects in piping. (No leaks will occur). GI-1781.001,

E3

B) Foam pump is in automatic mode. Supplement 24

C) All valves are car-sealed in correct position (open or closed).

Piping installations are checked as follows:

A) Free from corrosion and leaks.

B) Piping is self-draining properly. GI-1781.001,

E4

C) All valves are car-sealed in correct position. Supplement 24

D) Pipe hangers are not damaged, loose, or missing.

E) Pipe is not loaded and a 50 mm clearance exists.

Saudi Aramco: Company General Use

SAUDI ARAMCO ID/PIEU - 15-Nov-2017 - REV. 2016.06.00 (Standards Cutoff -June 30, 2016) Rev. 2016.06.00 30-Jun-16

SAUDI ARAMCO INSPECTION CHECKLIST SAIC NUMBER DATE APPROVED QR NUMBER

Foam Generating Equipment - Installation Insp & Testing SAIC-B-2014 15-Nov-17 MECH

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

ITEM RE-INSP

ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A

No. DATE

Foam System Discharge outlet installation (3 types) as follows:

A) Floating roof intstallations

B) Cone Roof installations GI-1781.001,

E5

C) High Expansion Foam Generator installations Supplement 24

Check these installations as shown below (as

applicable)

Floating roof discharge outlet intstallations are checked:

A) Air inlet screen on foam chamber is clean & in good condition.

B) Foam dam is installed and in good condition.

C) Foam deflectors are installed & in good condition. GI-1781.001,

E6

D) Floating roof seal & shunts are installed & in good condition. Supplement 24

E) Rain drains are installed, open and clear.

F) Caps are installed on 1 1/2" hose outlets.

G) Fire Department connection is free from damage and accessible

Cone roof discharge outlet intstallations are checked:

GI-1781.001,

E7 A) Rubber hose is installed & free from cracks.

Supplement 24

B) No obvious damage to the foam chamber exists.

High Expansion Foam Generator installations are checked:

A) Foam generator is properly installed & unobstructed. GI-1781.001,

E8

B) Foam screen is installed, clean & unobstructed. Supplement 24

C) Foam generator is operable.

Calibration stickers are affixed on pressure gauges with a valid GI-1781.001,

E9

calibration date (Validity is 5 years). Supplement 21

System alarm and associated equipment is checked:

A) Alarm is activated &

GI-1781.001,

E10 operates properly. B) Alarm

Supplement 27

signals to building fire alarm control panel & remote monitoring stations

are verified, test results recorded

GI-1781.001,

E11 Inspection tags have been installed on all equipment

Supplement 27

REMARKS:

REFERENCE DOCUMENTS:

1- Schedule Q, Project Specific (Mar 2013)

2- Saudi Aramco GI-1781.001 -- Inspection, Test, and Maintenance of Fire Protection Equipment, 3 January 2009

3- SAES-B-019 -- Portable, Mobile and Special Fixed Firefighting Equipment, (10 December 2013)

4- 21-SAMSS-011 -- Fluroprotein Foam Concentrate for MTBE Hydrocarbon Fires, 28 November 2011

5- NFPA 11 -- Standards for Low, Medium & High Expansion Foam & Mobile Foam Apparatus, 2016 Edition

Contractor / Third-Party Saudi Aramco

Construction Representative* PMT Representative

Work is Complete and Ready for Inspection:

T&I Witnessed QC Record Reviewed Work Verified

Name, Initials and Date: Name, Initials and Date:

QC Inspector PID Representative

Performed Inspection Work / Rework May Proceed T&I Witnessed QC Record Reviewed Work Verified

Name, Initials and Date: Name, Initials and Date:

Saudi Aramco: Company General Use

SAUDI ARAMCO ID/PIEU - 15-Nov-2017 - REV. 2016.06.00 (Standards Cutoff -June 30, 2016) Rev. 2016.06.00 30-Jun-16

SAUDI ARAMCO INSPECTION CHECKLIST SAIC NUMBER DATE APPROVED QR NUMBER

Foam Generating Equipment - Installation Insp & Testing SAIC-B-2014 15-Nov-17 MECH

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

ITEM RE-INSP

ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A

No. DATE

QC Supervisor Proponent and Others

Quality Record Approved:

T&I Witnessed QC Record Reviewed Work Verified

Name, Organization,

Name, Sign and Date:

Initials and Date:

*Person Responsible for Completion of Quality Work / Test Y = YES N = NO F = FAILED

Saudi Aramco: Company General Use

You might also like

- 737 Performance Reference Handbook - EASA EditionFrom Everand737 Performance Reference Handbook - EASA EditionRating: 4.5 out of 5 stars4.5/5 (3)

- Helicopter Pilot Oral Exam Guide: When used with the corresponding Oral Exam Guide, this book prepares you for the oral portion of the Private, Instrument, Commercial, Flight Instructor, or ATP Helicopter CheckrideFrom EverandHelicopter Pilot Oral Exam Guide: When used with the corresponding Oral Exam Guide, this book prepares you for the oral portion of the Private, Instrument, Commercial, Flight Instructor, or ATP Helicopter CheckrideNo ratings yet

- KT Chaser Product ManualDocument47 pagesKT Chaser Product Manualzx7blurr6239No ratings yet

- Saic B 2014Document5 pagesSaic B 2014mohammadNo ratings yet

- Saudi Aramco Inspection Checklist: Foam Generating Equipment - Installation Insp & Testing SAIC-B-2014 30-Apr-13 MechDocument5 pagesSaudi Aramco Inspection Checklist: Foam Generating Equipment - Installation Insp & Testing SAIC-B-2014 30-Apr-13 Mechpookkoya thangalNo ratings yet

- Saic B 2014Document4 pagesSaic B 2014usmanNo ratings yet

- Saudi Aramco Inspection Checklist: Top Coating Application (Intumescent Fireproofing Matls) 15-Nov-17Document5 pagesSaudi Aramco Inspection Checklist: Top Coating Application (Intumescent Fireproofing Matls) 15-Nov-17Abdul HannanNo ratings yet

- Saudi Aramco Inspection Checklist: Top Coating Application (Intumescent Fireproofing Matls) SAIC-B-2009 30-Apr-13 MechDocument5 pagesSaudi Aramco Inspection Checklist: Top Coating Application (Intumescent Fireproofing Matls) SAIC-B-2009 30-Apr-13 Mechpookkoya thangalNo ratings yet

- Saudi Aramco Inspection ChecklistDocument1 pageSaudi Aramco Inspection ChecklistSardar Muhamad RashidNo ratings yet

- Saudi Aramco Inspection Checklist: Top Coating Application (Intumescent Fireproofing Matls) SAIC-B-2009 3-Jul-18 MechDocument5 pagesSaudi Aramco Inspection Checklist: Top Coating Application (Intumescent Fireproofing Matls) SAIC-B-2009 3-Jul-18 Mechkarthi51289No ratings yet

- Saic B 4001Document2 pagesSaic B 4001usmanNo ratings yet

- Saic N 2026Document3 pagesSaic N 2026jerinNo ratings yet

- Saudi Aramco Inspection Checklist: Receiving Inspection of Centrifugal Pumps SAIC-G-2002 29-Dec-16 MechDocument32 pagesSaudi Aramco Inspection Checklist: Receiving Inspection of Centrifugal Pumps SAIC-G-2002 29-Dec-16 MechAbdul Hafeez SoomroNo ratings yet

- Saic G 2002Document32 pagesSaic G 2002jerinNo ratings yet

- Saic H 2060Document11 pagesSaic H 2060jerinNo ratings yet

- Saudi Aramco Inspection ChecklistDocument8 pagesSaudi Aramco Inspection ChecklistsureshNo ratings yet

- Saic D 2025Document12 pagesSaic D 2025Md ShariqueNo ratings yet

- Saic H 1002Document4 pagesSaic H 1002NASIR SYEDNo ratings yet

- Saic H 2011Document2 pagesSaic H 2011Ansar Ali VemmullyNo ratings yet

- Saudi Aramco Inspection Checklist: Storage Handling & Presevation of Heat Exchangers. SAIC-E-2003 15-Nov-17 MechDocument7 pagesSaudi Aramco Inspection Checklist: Storage Handling & Presevation of Heat Exchangers. SAIC-E-2003 15-Nov-17 MechmominNo ratings yet

- Saic B 2013Document4 pagesSaic B 2013mohammadNo ratings yet

- Saic B 2017Document7 pagesSaic B 2017mohammadNo ratings yet

- Saic D 2022Document7 pagesSaic D 2022sureshNo ratings yet

- Saic L 2139Document9 pagesSaic L 2139Kumar RNo ratings yet

- Saudi Aramco Inspection Checklist: Reinstatement of Portable Fire Protection Systems SAIC-B-2017 3-Jul-18 MechDocument7 pagesSaudi Aramco Inspection Checklist: Reinstatement of Portable Fire Protection Systems SAIC-B-2017 3-Jul-18 Mechkarthi51289No ratings yet

- SAIC-L-2038 Rev 7 - Final Inspection For Release of Fabricated PipinDocument2 pagesSAIC-L-2038 Rev 7 - Final Inspection For Release of Fabricated PipinLipika GayenNo ratings yet

- Saic F 2008Document4 pagesSaic F 2008usmanNo ratings yet

- Saudi Aramco Inspection Checklist: Relief Valve Installation SAIC-J-2009 24-Jul-18 MechDocument2 pagesSaudi Aramco Inspection Checklist: Relief Valve Installation SAIC-J-2009 24-Jul-18 Mechnisha_khanNo ratings yet

- Saudi Aramco Inspection Checklist: Pre-Application Insp of Intumescent Fireproofing Mat'ls SAIC-B-2006 30-Apr-13 MechDocument4 pagesSaudi Aramco Inspection Checklist: Pre-Application Insp of Intumescent Fireproofing Mat'ls SAIC-B-2006 30-Apr-13 Mechpookkoya thangalNo ratings yet

- Saic-M-1012 Rev 7 (Final)Document3 pagesSaic-M-1012 Rev 7 (Final)Satheesh Rama SamyNo ratings yet

- Saic H 2011Document2 pagesSaic H 2011zuknesedriNo ratings yet

- SAIC-H-2014 Rev 7Document3 pagesSAIC-H-2014 Rev 7mohammed siddiqNo ratings yet

- SAIC-K-4001 Rev 7Document3 pagesSAIC-K-4001 Rev 7Rohit BassNo ratings yet

- Saudi Aramco Inspection Checklist: Post-Application Insp of Intumescent Fireproofing Mat'l SAIC-B-2008 30-Apr-13 MechDocument2 pagesSaudi Aramco Inspection Checklist: Post-Application Insp of Intumescent Fireproofing Mat'l SAIC-B-2008 30-Apr-13 Mechpookkoya thangalNo ratings yet

- Saudi Aramco Inspection Checklist: In-Process Welding Inspection (API Tanks) SAIC-W-2086 31-Aug-11 WeldDocument3 pagesSaudi Aramco Inspection Checklist: In-Process Welding Inspection (API Tanks) SAIC-W-2086 31-Aug-11 WeldAnonymous 4e7GNjzGWNo ratings yet

- Saic e 2008Document4 pagesSaic e 2008usmanNo ratings yet

- Saic L 2007 PDFDocument7 pagesSaic L 2007 PDFHesham HelalNo ratings yet

- Saic H 2015Document4 pagesSaic H 2015jerinNo ratings yet

- Saudi Aramco Inspection Checklist: Final Insp / Walkthrough of Diesel Engine Installation SAIC-K-2020 25-Apr-18 MechDocument2 pagesSaudi Aramco Inspection Checklist: Final Insp / Walkthrough of Diesel Engine Installation SAIC-K-2020 25-Apr-18 MechjunaidNo ratings yet

- Saic e 2005Document13 pagesSaic e 2005jerinNo ratings yet

- Saic H 2002Document3 pagesSaic H 2002NASIR SYEDNo ratings yet

- Saudi Aramco Inspection Checklist: Receiving Inspection of Positive Displacement Pumps SAIC-G-2009 29-Dec-16 MechDocument18 pagesSaudi Aramco Inspection Checklist: Receiving Inspection of Positive Displacement Pumps SAIC-G-2009 29-Dec-16 MechAbdul HafeezNo ratings yet

- 26 Saic A 2009Document5 pages26 Saic A 2009Naveed ShahNo ratings yet

- Saudi Aramco Inspection Checklist: Receiving Inspection of Positive Displacement Pumps SAIC-G-2009 30-Apr-17 MechDocument18 pagesSaudi Aramco Inspection Checklist: Receiving Inspection of Positive Displacement Pumps SAIC-G-2009 30-Apr-17 Mechkarthi51289No ratings yet

- SAIC-H-2032 Rev 7Document4 pagesSAIC-H-2032 Rev 7Satheesh Rama SamyNo ratings yet

- SAIC-G-2012 NMR Verif Visual Insp-Sxs-Rlc-FDocument8 pagesSAIC-G-2012 NMR Verif Visual Insp-Sxs-Rlc-FKirubhakarPooranamNo ratings yet

- Saudi Aramco Inspection Checklist: Receiving Inspection of Air-Cooled Heat Exchanger SAIC-E-2005 15-Nov-17 MechDocument13 pagesSaudi Aramco Inspection Checklist: Receiving Inspection of Air-Cooled Heat Exchanger SAIC-E-2005 15-Nov-17 MechmominNo ratings yet

- SAIC-H-1002 - Coatings and Repair Materials Receiving, InspectionDocument2 pagesSAIC-H-1002 - Coatings and Repair Materials Receiving, InspectionzuknesedriNo ratings yet

- Saudi Aramco Inspection Checklist: Pre-Application Insp of Intumescent Fireproofing Mat'ls SAIC-B-2006 3-Jul-18 MechDocument3 pagesSaudi Aramco Inspection Checklist: Pre-Application Insp of Intumescent Fireproofing Mat'ls SAIC-B-2006 3-Jul-18 Mechkarthi51289No ratings yet

- Saudi Aramco Inspection ChecklistDocument2 pagesSaudi Aramco Inspection ChecklistAbdul HannanNo ratings yet

- SAIC-K-4038 Rev 7Document3 pagesSAIC-K-4038 Rev 7shahzadaNo ratings yet

- Saudi Aramco Inspection ChecklistDocument9 pagesSaudi Aramco Inspection ChecklistMainuddin AliNo ratings yet

- SAIC-L-2112 Rev 7Document7 pagesSAIC-L-2112 Rev 7Jaseel KanhirathingalNo ratings yet

- SAIC-E-2005 Recvg Insp of AirCooled Heat ExchDocument5 pagesSAIC-E-2005 Recvg Insp of AirCooled Heat ExchAnonymous S9qBDVkyNo ratings yet

- Saic B 4001Document2 pagesSaic B 4001mohammadNo ratings yet

- Saudi Aramco Inspection Checklist: Inspection of Furnace Dryout SAIC-N-2030 25-May-05 MechDocument4 pagesSaudi Aramco Inspection Checklist: Inspection of Furnace Dryout SAIC-N-2030 25-May-05 MechAnonymous S9qBDVky0% (1)

- SAIC-B-2001 Rev 6Document6 pagesSAIC-B-2001 Rev 6pookkoya thangalNo ratings yet

- Saudi Aramco Inspection Checklist: Material Receiving Insp - Portable Fire Protection Equip SAIC-B-2011 30-Apr-13 MechDocument4 pagesSaudi Aramco Inspection Checklist: Material Receiving Insp - Portable Fire Protection Equip SAIC-B-2011 30-Apr-13 Mechpookkoya thangalNo ratings yet

- Saudi Aramco Inspection Checklist: Post Weld Heat Treatment (PWHT) For On-Plot Piping SAIC-W-2004 15-Dec-09 WeldDocument19 pagesSaudi Aramco Inspection Checklist: Post Weld Heat Treatment (PWHT) For On-Plot Piping SAIC-W-2004 15-Dec-09 WeldIrshad IqbalNo ratings yet

- Saic B 2011Document4 pagesSaic B 2011mohammadNo ratings yet

- 12e-C01 Rfis & Hprs Log Updated 28-Jan-2024Document30 pages12e-C01 Rfis & Hprs Log Updated 28-Jan-2024Abdul HannanNo ratings yet

- Saep 13 PDFDocument25 pagesSaep 13 PDFAnonymous 4IpmN7OnNo ratings yet

- Saes Z 004Document40 pagesSaes Z 004nadeem100% (1)

- Saes Z 008Document47 pagesSaes Z 008nadeemNo ratings yet

- Saes Z 010Document16 pagesSaes Z 010nadeemNo ratings yet

- RFI HPR FORM - 12E-C01-CE-0084 - 3rd LAYER BACFILLING AT PROJECT F 9 AROUND OFFICE AND LAY DOWN AREADocument4 pagesRFI HPR FORM - 12E-C01-CE-0084 - 3rd LAYER BACFILLING AT PROJECT F 9 AROUND OFFICE AND LAY DOWN AREAAbdul Hannan100% (1)

- 12e-C01 Rfis & Hprs Log Updated 28-Jan-2024Document30 pages12e-C01 Rfis & Hprs Log Updated 28-Jan-2024Abdul HannanNo ratings yet

- RFI HPR FORM - 12E-C01-CE-0084 - 3rd LAYER BACFILLING AT PROJECT F 9 AROUND OFFICE AND LAY DOWN AREADocument4 pagesRFI HPR FORM - 12E-C01-CE-0084 - 3rd LAYER BACFILLING AT PROJECT F 9 AROUND OFFICE AND LAY DOWN AREAAbdul Hannan100% (1)

- Saes A 005 PDFDocument32 pagesSaes A 005 PDFAdnanAtifNo ratings yet

- Saes A 100Document6 pagesSaes A 100nadeemNo ratings yet

- Saes A 102Document22 pagesSaes A 102nadeemNo ratings yet

- 01 Samss 010Document12 pages01 Samss 010Ahmed Shaban KotbNo ratings yet

- Saes A 010Document32 pagesSaes A 010hyderabadNo ratings yet

- Saes A 007 PDFDocument29 pagesSaes A 007 PDFsindalisindiNo ratings yet

- Saes A 011 PDFDocument20 pagesSaes A 011 PDFcywahaNo ratings yet

- 01 Samss 012 2014Document10 pages01 Samss 012 2014lhanx2No ratings yet

- 01 Samss 010Document12 pages01 Samss 010Ahmed Shaban KotbNo ratings yet

- 09-SAMSS-060 Packaging Requirements For CoatingsDocument4 pages09-SAMSS-060 Packaging Requirements For CoatingsAbdul HannanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument1 pageSaudi Aramco Inspection ChecklistAbdul HannanNo ratings yet

- 01-SAMSS-016 Qualification of Plates For Storage Tanks and Pressured Equipment For Resistance To Hydrogen-Induced CrackingDocument14 pages01-SAMSS-016 Qualification of Plates For Storage Tanks and Pressured Equipment For Resistance To Hydrogen-Induced CrackingJoni Carino SuniNo ratings yet

- 01-SAMSS-017 Auxiliary Piping For Mechanical EquipmentDocument13 pages01-SAMSS-017 Auxiliary Piping For Mechanical EquipmentAbdul HannanNo ratings yet

- 01 Samss 005 PDFDocument5 pages01 Samss 005 PDFjojo_323No ratings yet

- Samss 023Document10 pagesSamss 023Subin RoshanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument3 pagesSaudi Aramco Inspection ChecklistAbdul HannanNo ratings yet

- Saudi Aramco Inspection Checklist: Post-Application Insp of Intumescent Fireproofing Mat'l SAIC-B-2008 15-Nov-17 MechDocument2 pagesSaudi Aramco Inspection Checklist: Post-Application Insp of Intumescent Fireproofing Mat'l SAIC-B-2008 15-Nov-17 MechAbdul HannanNo ratings yet

- Saudi Aramco Inspection Checklist: Final Inspection of Intumescent Fireproofing Application SAIC-B-2010 15-Nov-17 MechDocument2 pagesSaudi Aramco Inspection Checklist: Final Inspection of Intumescent Fireproofing Application SAIC-B-2010 15-Nov-17 MechAbdul HannanNo ratings yet

- 01 Samss 005 PDFDocument5 pages01 Samss 005 PDFjojo_323No ratings yet

- 02 Samss 010Document7 pages02 Samss 010balajiNo ratings yet

- Saudi Aramco Inspection ChecklistDocument2 pagesSaudi Aramco Inspection ChecklistAbdul HannanNo ratings yet

- Catalouge For Cenlub ProductDocument34 pagesCatalouge For Cenlub ProductUdaya Manju50% (2)

- Fdez. Jove - Valvula 3 Vías - (SFERACO)Document12 pagesFdez. Jove - Valvula 3 Vías - (SFERACO)Pedro VarelaNo ratings yet

- Installation and Maintenance Instructions Ball Valves, Fully WeldedDocument6 pagesInstallation and Maintenance Instructions Ball Valves, Fully WeldedvictorbirlanNo ratings yet

- HCR910-DS 917600-D302020 enDocument174 pagesHCR910-DS 917600-D302020 enSantiago Bonilla100% (3)

- Bomba Hidraulica EatonDocument8 pagesBomba Hidraulica EatonLuis Enrique PeñaNo ratings yet

- IPCSD0602CA004M - Refrigeratore IPC 602 SIDEL R134a 440/3/60Document2 pagesIPCSD0602CA004M - Refrigeratore IPC 602 SIDEL R134a 440/3/60Joel Coaguila CosiNo ratings yet

- Nimco Monoblock Control ValvesDocument66 pagesNimco Monoblock Control ValvesHui ChenNo ratings yet

- Process Safety Lopa Sil Hazop 1662875531Document92 pagesProcess Safety Lopa Sil Hazop 1662875531richardNo ratings yet

- Hägglunds Viking: Radial Piston Hydraulic MotorDocument68 pagesHägglunds Viking: Radial Piston Hydraulic MotorYo Jimenez PardoNo ratings yet

- Vaf Lorcon ManilaDocument61 pagesVaf Lorcon ManilaJamie ColemanNo ratings yet

- AVK Dams - Reservoirs - HydroPower BrochureDocument15 pagesAVK Dams - Reservoirs - HydroPower Brochureindra putraNo ratings yet

- Solutions: TankersDocument7 pagesSolutions: TankersKirtishbose ChowdhuryNo ratings yet

- Tanker Checklist Incoming EmptyDocument4 pagesTanker Checklist Incoming Emptybuddy-20087751No ratings yet

- Grove T41Document6 pagesGrove T41Den AbbasNo ratings yet

- 2010 Cameron Barton Tecnova HTDocument23 pages2010 Cameron Barton Tecnova HTDeji AdesiyanNo ratings yet

- Standard Operating Procedure DistillationDocument2 pagesStandard Operating Procedure DistillationGaurav Sharma60% (5)

- Piping Training Course - Part - 1Document162 pagesPiping Training Course - Part - 1Ibrahim Braneci100% (1)

- 27.multipurpose Sheet Metal Cutting and Bending MachineDocument5 pages27.multipurpose Sheet Metal Cutting and Bending MachineMaruthi JacsNo ratings yet

- Operator'S Manual & Sales and Engineering Data: AF0450LXXXXXX-XX-X Basic Grease PumpDocument4 pagesOperator'S Manual & Sales and Engineering Data: AF0450LXXXXXX-XX-X Basic Grease PumpDiego Nicolas Figueroa QuirozNo ratings yet

- 422-02027-11 SA-252F-5個燈英文操作手冊Document18 pages422-02027-11 SA-252F-5個燈英文操作手冊pham vuNo ratings yet

- TS Fire Hydrant Wet SystemDocument9 pagesTS Fire Hydrant Wet System123agattarNo ratings yet

- Deep Well Water PumpDocument36 pagesDeep Well Water PumpMartin-Garcia Guayubin-Montecristi100% (1)

- Catálogo Cast Iron ValvesDocument40 pagesCatálogo Cast Iron ValvesAlvaro Jhoel Quinteros RNo ratings yet

- Festo Fittings Brochure 2006Document24 pagesFesto Fittings Brochure 2006bad_mariussNo ratings yet

- PLANT Material Codification StructureDocument8 pagesPLANT Material Codification StructureAjay Kumar MohiniNo ratings yet

- Engineering Standards For Fire Sprinkler Protection SystemsDocument71 pagesEngineering Standards For Fire Sprinkler Protection SystemsRodwell ChiraraNo ratings yet

- Mechanic Machine Tool Maintenance-Nsqf PDFDocument63 pagesMechanic Machine Tool Maintenance-Nsqf PDFUjjwal Chauhan100% (3)

- Cylinder Blocks 11-00-2 (Hino Engine Type J08etm-Ksda)Document3 pagesCylinder Blocks 11-00-2 (Hino Engine Type J08etm-Ksda)Oecox Cah DjadoelNo ratings yet

- IPS-46 - Flare DesignDocument57 pagesIPS-46 - Flare DesignalizareiforoushNo ratings yet