Professional Documents

Culture Documents

1.5 Sample Systems: Table 1 Below Lists Some Background Gases That Can Interfere With The

Uploaded by

Miquiztli SpillingOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1.5 Sample Systems: Table 1 Below Lists Some Background Gases That Can Interfere With The

Uploaded by

Miquiztli SpillingCopyright:

Available Formats

Chapter 1.

Features and Capabilities

1.5 Sample Systems

In addition to the standard features and options, GE offers a full line

of sample handling systems for a variety of applications. If needed,

GE can design and build a sample conditioning system to meet

unique application requirements. Please contact GE for details.

Table 1 below lists some background gases that can interfere with the

oxygen sensor.

Table 1: Oxygen Sensor Interference Gases

OX-1 & 5 ppm OX-2 ppm OX-3 % OX-4 %

Gas Cont. Cont. Cont. Int. (1) Cont. Int.

H2S <5 ppm <10 ppm 0.0005 % 0.01 % 0.001 % 0.1 %

SO3 <10 ppm <10 ppm 0.01 % 0.1 % 0.01 % 0.1 %

SO2 <10 ppm (3) 0.01 % 0.1 % (3) (3)

HCl <1000 ppm (3) 0.1 % 1.0 % (3) (3)

HCN <1000 ppm (3) 0.1 % 1.0 % (3) (3)

CO2 <1000 ppm (3) 0.1 % 20 & (3) (3)

NO2 (2) (2) (2) (2) (2) (2)

Cl2 (2) (2) (2) (2) (2) (2)

Cont. = Continuous, Int. = Intermittent

(1) Recommended maximum exposure 30 minutes, followed by flushing

with ambient air for an equal period.

(2) Minimal effect on sensor performance, but produces signal interference

of 1:2 ratio for ppm levels only (e.g., 100 ppm NO2 looks like 200 ppm

O2).

(3) Minimal effect on sensor performance

4 oxy.IQ User’s Manual

Chapter 2. Installation

Chapter 2. Installation

2.1 Mounting the oxy.IQ

To install the oxy.IQ into the process or sample system, refer to

Figure 9 on page 38 and/or Figure 2 below and proceed to the next

page.

CONNECTOR

1.58 2.05

Note: All dimensions are inches [mm]. [52.1]

[40.3]

2.75

B

[69.8] C

4.10

[104.2]

0.32

1.33 [8.25]

[33.9]

2X 2X 1.03 A

1/8-27NPT-2B 8-32 UNC-2B [26.27]

.27 [6.9] .51 [12.9] MAX

0.53

[13.57]

1.00

[25.40]

Ø1.75

[44.3]

Figure 2: Outline and Dimensions (ref. dwg. 712-1840)

Note: To avoid collecting condensate that may damage the oxygen

sensor, mount the oxy.IQ in an upright position, with the sensor

manifold below the electronics module.

oxy.IQ User’s Manual 5

Chapter 2. Installation

2.1 Mounting the oxy.IQ (cont.)

Install the oxy.IQ by completing the following steps:

1. Remove the oxy.IQ and the separately-packaged oxygen sensor

(see Figure 3 below) from the shipping container. Keep the

shipping container and packaging material for possible future

use.

IMPORTANT: DO NOT open the oxygen sensor package until you are

ready to install the sensor.

Figure 3: Packaged Oxygen Sensor

2. Remove the sensor manifold by unscrewing it from the blue

knurled nut on the sensor base at the bottom of the electronics

module.

6 oxy.IQ User’s Manual

Chapter 2. Installation

2.1 Mounting the oxy.IQ (cont.)

IMPORTANT: The maximum operating pressure for the oxy.IQ is 10

psi, and the burst pressure of the unit is 200 psi. Be sure

the sample conditioning system is designed to maintain

the oxy.IQ pressure below these limits, and that the

oxy.IQ outlet is vented to atmosphere during operation

and calibration.

3. Using PTFE tape as a sealant, connect the sample gas inlet and

outlet to the 1/8” NPT ports on the sensor manifold (see Figure 4

below). Either port may be used as the inlet or the outlet, as the

direction of flow does not matter.

Sensor Manifold

PTFE Tape

Sample Inlet Sample Outlet

Figure 4: Sensor Manifold Installation

oxy.IQ User’s Manual 7

Chapter 2. Installation

2.2 Wiring the oxy.IQ

To wire the oxy.IQ, refer to Figure 14 on page 43, then proceed as

follows:

WARNING! For IS (Intrinsically Safe) applications, the oxy.IQ

must be installed with a Zener barrier (see the

top of Figure 14 on page 43). Also, for

installations in a hazardous location, the blue IS

cable (p/n 704-1318-02, 10) must be used.

1. Attach the appropriate cable to the oxy.IQ (see Figure 5 below). Be

sure to align the white arrow on the cable connector with the

white arrow on the oxy.IQ connector, and then push the top of the

cable connector straight down onto the mating connector on the

rear of the electronics module until you hear it click into place.

IMPORTANT: Do not rotate the cable connector during installation (it is

not threaded) and do not hold the connector by its

bottom section while pushing it down into place.

IMPORTANT: To remove the cable, grasp the bottom section of the

connector (the part with the white arrow) and pull it

straight up until the cable comes loose. DO NOT twist the

connector either by hand or with any tool during

removal.

Blank Label

Std. Cable

Cable Connector Alignment Arrow

8 oxy.IQ User’s Manual

You might also like

- Practical Embedded Controllers: Design and Troubleshooting with the Motorola 68HC11From EverandPractical Embedded Controllers: Design and Troubleshooting with the Motorola 68HC11No ratings yet

- Electronics for Technicians: The Commonwealth and International Library: Electrical Engineering DivisionFrom EverandElectronics for Technicians: The Commonwealth and International Library: Electrical Engineering DivisionRating: 5 out of 5 stars5/5 (1)

- Panametrics - O2X1 Manual PDFDocument37 pagesPanametrics - O2X1 Manual PDFCamilo MartinezNo ratings yet

- Crankcase Breather - Install - Filtered Breather (KENR6081-15)Document6 pagesCrankcase Breather - Install - Filtered Breather (KENR6081-15)Anderson Oliveira SilvaNo ratings yet

- Model Name: T420HW09 V1: Issue Date: 2011/1/11 Preliminary Specifications (!) Final SpecificationsDocument31 pagesModel Name: T420HW09 V1: Issue Date: 2011/1/11 Preliminary Specifications (!) Final SpecificationsSertan YasanNo ratings yet

- Datasheet 3010103Document11 pagesDatasheet 3010103Miguel Angel Pachas CaychoNo ratings yet

- T390HVN02 2-AuoDocument28 pagesT390HVN02 2-AuoposiliNo ratings yet

- M215HW03 V1 Auo PDFDocument28 pagesM215HW03 V1 Auo PDFAlfa alfaNo ratings yet

- Data Sheet AO 02 Oxygen SensorDocument5 pagesData Sheet AO 02 Oxygen SensorKaio QueirozNo ratings yet

- Pasolink MaintenanceDocument41 pagesPasolink MaintenanceNiall Slattery67% (3)

- T320XVN02.0 SKD AuoDocument23 pagesT320XVN02.0 SKD AuoVenkatesh SubramanyaNo ratings yet

- KB Manual v5Document26 pagesKB Manual v5nathanaelsilva076No ratings yet

- T320XVN01.0 K AuoDocument25 pagesT320XVN01.0 K AuoRizky GultomNo ratings yet

- T315HW07 V8 PDFDocument31 pagesT315HW07 V8 PDFJose GargaglioneNo ratings yet

- Hitachi VSP Hardware Installation GuideDocument2,358 pagesHitachi VSP Hardware Installation GuideFebbin Rajan100% (2)

- TDLS200 Tunable Diode Laser Gas Analyzer and Its Application To Industrial ProcessDocument4 pagesTDLS200 Tunable Diode Laser Gas Analyzer and Its Application To Industrial ProcessIJNo ratings yet

- AB36Document19 pagesAB36Amr AlshamloolNo ratings yet

- Design and Fabrication of Exhaust Gas AnalyzerDocument6 pagesDesign and Fabrication of Exhaust Gas AnalyzerVIVA-TECH IJRINo ratings yet

- B156XW01 V0Document33 pagesB156XW01 V0Павел Пашко-ПащенкоNo ratings yet

- Sps Siot Citytech 7oxv Sensor DatasheetDocument3 pagesSps Siot Citytech 7oxv Sensor DatasheetShanmugamoorthyNo ratings yet

- Kobold Echoking Neo-500 3 Series Ultrasonic Level Transmitter User InstructionsDocument22 pagesKobold Echoking Neo-500 3 Series Ultrasonic Level Transmitter User Instructionsroberto cheuquepanNo ratings yet

- Proposal - VBot210 - Floor Cleaning Robot - Vatsal Shah - EC - 7th SemDocument5 pagesProposal - VBot210 - Floor Cleaning Robot - Vatsal Shah - EC - 7th SemMarcela DobreNo ratings yet

- B156XW02 V.2 PDFDocument31 pagesB156XW02 V.2 PDFvimaro24No ratings yet

- DatasheetDocument29 pagesDatasheetGabrielNo ratings yet

- Product Specification: Preliminary Specifications (V) Final SpecificationsDocument31 pagesProduct Specification: Preliminary Specifications (V) Final Specificationsbarlow00No ratings yet

- Lab2 EE130P Spring2022 20220306Document9 pagesLab2 EE130P Spring2022 20220306Cat ABCDENo ratings yet

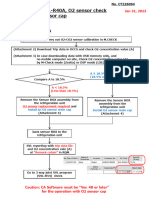

- Jan 31 2023) CT226094 SVL-R40A O2 Sensor CheckDocument13 pagesJan 31 2023) CT226094 SVL-R40A O2 Sensor CheckchristiamNo ratings yet

- 3.3 NODEMCU:: Fig 3.3 Pin DefinitionDocument6 pages3.3 NODEMCU:: Fig 3.3 Pin DefinitionHareesh HarshaNo ratings yet

- Nickel ElectroplatingDocument9 pagesNickel ElectroplatingHoang TanNo ratings yet

- Full Paper - Breakthrough in Pulsed Eddy Current Detection and Sizing - June 29 2019 PDFDocument16 pagesFull Paper - Breakthrough in Pulsed Eddy Current Detection and Sizing - June 29 2019 PDFTYO WIBOWONo ratings yet

- GE Infrastructure: SensingDocument37 pagesGE Infrastructure: SensingNguyen VuNo ratings yet

- Water in Fuel SensorDocument11 pagesWater in Fuel Sensornachof1No ratings yet

- DT600 User Manua 2014Document16 pagesDT600 User Manua 2014AgisMaulidiNo ratings yet

- Wavelet Denoising: Jacob FainguelerntDocument41 pagesWavelet Denoising: Jacob FainguelerntSANTIAGONo ratings yet

- DPI 610 / 615 IS: Intrinsically Safe Portable Pressure CalibratorDocument76 pagesDPI 610 / 615 IS: Intrinsically Safe Portable Pressure Calibratorengineer080602No ratings yet

- C-15 Electronic Unit Injector - InstallDocument6 pagesC-15 Electronic Unit Injector - InstallCEVegaONo ratings yet

- Mitsubishi - AA101TA12 - DatasheetDocument25 pagesMitsubishi - AA101TA12 - DatasheetaylinaykanNo ratings yet

- Product Specification: (V) Preliminary Specifications Final SpecificationsDocument29 pagesProduct Specification: (V) Preliminary Specifications Final SpecificationsahmedcoNo ratings yet

- Panel T315HDocument31 pagesPanel T315HJan Carlos RodriguezNo ratings yet

- CO2 Sensor Module - SE8000 Series Room Controller - Installation SheetDocument4 pagesCO2 Sensor Module - SE8000 Series Room Controller - Installation SheetRaul CARRASQUERO DIAZNo ratings yet

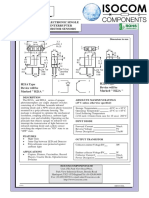

- 1Mm Aperture Opto-Electronic Single Channel Slotted Interrupter Switches With Transistor SensorsDocument3 pages1Mm Aperture Opto-Electronic Single Channel Slotted Interrupter Switches With Transistor SensorsAry MmNo ratings yet

- Minor Project ReportDocument30 pagesMinor Project ReporthimanshuNo ratings yet

- M5329-R0 Dead Line AnchorDocument26 pagesM5329-R0 Dead Line Anchorandrei20041100% (2)

- IQScanner-i GeneralDocument8 pagesIQScanner-i GeneralDeva RajanNo ratings yet

- June 1, 2010: Automotive Electronics CouncilDocument6 pagesJune 1, 2010: Automotive Electronics Councilsean_mcfaddenNo ratings yet

- B116XW03 V2 PDFDocument29 pagesB116XW03 V2 PDFValentin SevostjanovNo ratings yet

- Product Description: T315Xw02 TFT-LCD Panel With Rohs GuaranteeDocument28 pagesProduct Description: T315Xw02 TFT-LCD Panel With Rohs GuaranteeLgDvdNo ratings yet

- Audiolab 8000S Service Manual PDFDocument36 pagesAudiolab 8000S Service Manual PDFMarcelo IpolitoNo ratings yet

- Datasheet MKDocument25 pagesDatasheet MKFaisal IrsyadNo ratings yet

- Sps Siot Citytech 5fo Sensor DatasheetDocument3 pagesSps Siot Citytech 5fo Sensor DatasheetIdris FirdausNo ratings yet

- Automatic Room Light Controller With Bidirectional Visitor CounterDocument59 pagesAutomatic Room Light Controller With Bidirectional Visitor CounterakshayamrapaliNo ratings yet

- Crankcase Breather - Install - Unfiltered Breather (KENR6081-15)Document5 pagesCrankcase Breather - Install - Unfiltered Breather (KENR6081-15)Anderson Oliveira SilvaNo ratings yet

- S6 ManualDocument81 pagesS6 ManualAlexander BudnikNo ratings yet

- Grove - Gas Sensor (O2) : Release Date 9/20/2015Document12 pagesGrove - Gas Sensor (O2) : Release Date 9/20/2015Prasika DroidNo ratings yet

- OTC103206 OptiX BWS 1600G V100R001 Commissioning Guide ISS PDFDocument18 pagesOTC103206 OptiX BWS 1600G V100R001 Commissioning Guide ISS PDFAnonymous Cx5zpf8No ratings yet

- 1 Safety Instructions: Bluetooth Low Energy Radio TransmitterDocument4 pages1 Safety Instructions: Bluetooth Low Energy Radio TransmitterMohamed Tahar BoussahaNo ratings yet

- Electronic Unit Injector - Install (KENR6081-15)Document12 pagesElectronic Unit Injector - Install (KENR6081-15)Anderson Oliveira SilvaNo ratings yet

- TEC32-1664-002 - OceanTRx7 ACUDocument22 pagesTEC32-1664-002 - OceanTRx7 ACUAntonio Bragança MartinsNo ratings yet

- B101ew04 V0Document31 pagesB101ew04 V0максим герцовNo ratings yet

- The Engineering of Microprocessor Systems: Guidelines on System DevelopmentFrom EverandThe Engineering of Microprocessor Systems: Guidelines on System DevelopmentNo ratings yet

- 3.3.4 Span Gas CalibrationDocument5 pages3.3.4 Span Gas CalibrationMiquiztli SpillingNo ratings yet

- Chapter 1. Features and CapabilitiesDocument5 pagesChapter 1. Features and CapabilitiesMiquiztli SpillingNo ratings yet

- Instructions To Change Filter Material For LCPWDocument5 pagesInstructions To Change Filter Material For LCPWMiquiztli SpillingNo ratings yet

- Chapter 5. The Service MenuDocument5 pagesChapter 5. The Service MenuMiquiztli SpillingNo ratings yet

- What Happens in The Dark Knight: Spoilers, ObviouslyDocument1 pageWhat Happens in The Dark Knight: Spoilers, ObviouslyMiquiztli SpillingNo ratings yet

- Instruction Manual: MS200/300/400 Magnetic StirrerDocument6 pagesInstruction Manual: MS200/300/400 Magnetic StirrerMiquiztli SpillingNo ratings yet

- (Cutting Edge - Lesbian LifeDocument307 pages(Cutting Edge - Lesbian Lifepruebameotravezyotra100% (3)

- Sylvia Marcos - Taken From The Lips. Gender and Eros in Mesoamerican ReligionsDocument177 pagesSylvia Marcos - Taken From The Lips. Gender and Eros in Mesoamerican ReligionsMiquiztli Spilling100% (1)

- Grupos Answer 1Document17 pagesGrupos Answer 1Juay del ArcoNo ratings yet

- 4G Alarms TroubleshootingDocument22 pages4G Alarms TroubleshootingNirdosh Chhasatiya100% (2)

- Standards LED's FINALDocument5 pagesStandards LED's FINALRudy StanciuNo ratings yet

- Road Safety-Basic Rules of The RoadDocument14 pagesRoad Safety-Basic Rules of The RoadGlobal EHSNo ratings yet

- 620 Vector Drive S/W Release 2.X: User ManualDocument185 pages620 Vector Drive S/W Release 2.X: User ManualtadyNo ratings yet

- ATV600 Getting Started Annex EAV64300 12Document8 pagesATV600 Getting Started Annex EAV64300 12rabia akramNo ratings yet

- Dimensiones de Bomba Viking L124Document1 pageDimensiones de Bomba Viking L124nerio gerardinoNo ratings yet

- Best Performance For Mid-Range Cylinders and Tools: Shown: PEJ-1401BDocument4 pagesBest Performance For Mid-Range Cylinders and Tools: Shown: PEJ-1401BGleynder IraricaNo ratings yet

- Wright HD356B LHD Operating and Maintenance NEWDocument113 pagesWright HD356B LHD Operating and Maintenance NEWChester Dalitso Mwanza50% (2)

- Estimation and Analysis of VFTO in 420kV Gas Insulated SubstationDocument8 pagesEstimation and Analysis of VFTO in 420kV Gas Insulated SubstationboopelectraNo ratings yet

- 2010 Porsche 911 gt3 84287 PDFDocument251 pages2010 Porsche 911 gt3 84287 PDFas1546224No ratings yet

- Engines (M52TU)Document27 pagesEngines (M52TU)Leonard 'Leo' Ng100% (1)

- SCE Part Catalogue All R4 OLG Logo 030919Document189 pagesSCE Part Catalogue All R4 OLG Logo 030919Anonymous IQJwSTNo ratings yet

- 2N6ADocument4 pages2N6Ajackson singhNo ratings yet

- BLCOMD09CDDocument288 pagesBLCOMD09CDasifaliabidNo ratings yet

- Lec - 5 GPIODocument47 pagesLec - 5 GPIOjarvis 1011No ratings yet

- Tms2 GRS895/R HEV With ECA 2.0 2019-06 - : GMS - Gearbox Management SystemDocument1 pageTms2 GRS895/R HEV With ECA 2.0 2019-06 - : GMS - Gearbox Management Systemali wardanaNo ratings yet

- Service Manual: Split TypeDocument123 pagesService Manual: Split TypeSơn PhạmNo ratings yet

- Merlin Gerin HV Circuit BreakerDocument4 pagesMerlin Gerin HV Circuit BreakerAmerico Guerrero100% (1)

- Skema Rangkaian Long Range ..Document3 pagesSkema Rangkaian Long Range ..dedy kurniawanNo ratings yet

- Gulfstream g150 Pilot Training Manual Volume 2 Aircraft Syst PDFDocument474 pagesGulfstream g150 Pilot Training Manual Volume 2 Aircraft Syst PDFrubenaris100% (3)

- Baudouin 4M11-6M11 Engine ManualDocument35 pagesBaudouin 4M11-6M11 Engine ManualAntonio MartinNo ratings yet

- Manual-TRACTEL-Tirak Passenger Wire Rope Hoists Elevator Installations-EN PDFDocument36 pagesManual-TRACTEL-Tirak Passenger Wire Rope Hoists Elevator Installations-EN PDFamcneelaNo ratings yet

- Info Pompe Pistonase PDFDocument44 pagesInfo Pompe Pistonase PDFMarin GarazNo ratings yet

- Computer Architecture Unit 1 MCQDocument6 pagesComputer Architecture Unit 1 MCQRaagavi VNo ratings yet

- Medium Voltage SubstationsDocument5 pagesMedium Voltage SubstationsAnh Tú NguyễnNo ratings yet

- Quincy QGD 30 HPDocument80 pagesQuincy QGD 30 HPLuis Fernando Bravo100% (1)

- Athena Controller 4000 SeriesDocument17 pagesAthena Controller 4000 SeriesMichel RigaudNo ratings yet

- TK 51916-18-OP Direct Drive DSR Operators Manual Rev 12 06-16 - ML PDFDocument334 pagesTK 51916-18-OP Direct Drive DSR Operators Manual Rev 12 06-16 - ML PDFRaphael GamaNo ratings yet

- REDFOX-SERIES - SvičDocument24 pagesREDFOX-SERIES - SvičIgor NikodijevicNo ratings yet

- WEG cfw50x Kpcs Guia 10002517476 Guia de Instalacao Portugues BRDocument12 pagesWEG cfw50x Kpcs Guia 10002517476 Guia de Instalacao Portugues BRRodrigoNo ratings yet