Professional Documents

Culture Documents

CatiaV5 Healing Assistant

Uploaded by

Mohamed MerinissiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CatiaV5 Healing Assistant

Uploaded by

Mohamed MerinissiCopyright:

Available Formats

Healing Assistant

Student Notes:

CATIA V5 Training

Foils

Healing Assistant

Copyright DASSAULT SYSTEMES

Version 5 Release 19

August 2008

EDU_CAT_EN_HA1_FF_V5R19

Copyright DASSAULT SYSTEMES 1

Healing Assistant

About this course

Student Notes:

Objectives of the course

Upon completion of this course you will be able to:

- Analyze the imported data

- Repair the imported data

- Compare two versions of a Part

- Customize the workbench

Targeted audience

Tooling Designers, Mechanical Designers, Surface Designers.

Prerequisites

Students attending this course should be familiar with the Wireframe and

Surfaces.

1 day

Copyright DASSAULT SYSTEMES

Copyright DASSAULT SYSTEMES 2

Healing Assistant

Student Notes:

Table of Contents (1/2)

Introduction to Healing Assistant 5

Why Do You Need Healing? 6

Accessing the Workbench 7

User Interface: Healing Assistant Editor 8

Methodology For Healing 10

Information On the Join Operator 11

How To Choose a Merging Distance 15

Model Analysis 17

Face Checker 18

Face Orientation 20

Geometrical Display 22

Repairing Invalid Surfaces 23

Face Smooth 24

Surface Connection Checker 26

Repairing Topology 28

Closing a Join Surface 29

Checking For Free Sides 30

Fixing Free Sides 32

Copyright DASSAULT SYSTEMES

Copyright DASSAULT SYSTEMES 3

Healing Assistant

Student Notes:

Table of Contents (2/2)

Local Join 34

The Healing Operator 36

Local Healing 37

Comparing Models 38

Compare Parts 39

Customizing the Workbench 42

IGES 3D Import 43

CATIA V4 Import 50

Copyright DASSAULT SYSTEMES

Copyright DASSAULT SYSTEMES 4

Healing Assistant

Student Notes:

Introduction to Healing Assistant

In this lesson, you will see general information about Healing Assistant Workbench.

Copyright DASSAULT SYSTEMES

Copyright DASSAULT SYSTEMES 5

Healing Assistant

Student Notes:

Why Do You Need Healing?

Tooling is often done by sub-contractors, who receive data exported by their OEMs

in standard formats such as IGES or STEP. In such situations, Healing Assistant

allows the sub-contractors to make the Parts "V5 compliant".

Healing Assistant is also very useful for data migration, i.e. for companies who need to migrate

data from their previous CAD (including CATIA V4) to their new CATIA V5 environment.

Foreign data: IGES, STEP, CATIA V4, other

Problems linked to imported data:

Accuracy uncontrolled Healing is the process of

creating a valid V5 closed model

Validity criteria different from those of V5 Closed model

out of any type of data, even not

Data quality downgraded during transfer valid.

User mishandling (losses, duplications)

Tooling Design Rapid Prototyping Simulation NC Manufacturing

Copyright DASSAULT SYSTEMES

Copyright DASSAULT SYSTEMES 6

Healing Assistant

Student Notes:

Accessing the Workbench

To access the CATIA Healing Assistant workbench:

Select Start > Mechanical Design > Healing Assistant.

Copyright DASSAULT SYSTEMES

Copyright DASSAULT SYSTEMES 7

Healing Assistant

Student Notes:

User Interface: Healing Assistant Editor (1/2)

The user interface of the Healing Assistant workbench is shown below.

This generic tool bar provides access to display modes

Healing Assistant

workbench icon

Digitized Shape

Editor Tools

Copyright DASSAULT SYSTEMES

Copyright DASSAULT SYSTEMES 8

Healing Assistant

Student Notes:

User Interface: Healing Assistant Editor (2/2)

Seven actions are specific to Healing Assistant, the others are taken from other

workbenches.

Copyright DASSAULT SYSTEMES

Copyright DASSAULT SYSTEMES 9

Healing Assistant

Student Notes:

Methodology For Healing

General process for healing can be seen in the following flow chart.

Optional: measure the gaps Optional: clean all surface

between surfaces to evaluate the boundaries at once to simplify

tolerance of the imported data. the model.

Prepare data: put all surfaces to join

in a geometrical set, remove Join all surfaces with a strict If OK Analyze free sides

unnecessary data. tolerance (for example 0.01mm).

If invalid surfaces If join failure Close free sides

Check all surfaces Check for bad

individually topology situations Create solid

Copyright DASSAULT SYSTEMES

Repair invalid Repair bad topology

surfaces situations

Copyright DASSAULT SYSTEMES 10

Healing Assistant

Student Notes:

Information On the Join Operator (1/4)

JOIN is the main operator for the creation of topology. Joining

surfaces is done in 2 steps.

STEP 1 is done considering a tolerance parameter called

merging distance. All surface boundaries are compared to

find those which are close enough to become shared edges. 1 2

d

d < 0.001mm (system tolerance): edge is shared

(geometrically closed)

0.001mm < d < merging distance: edge is shared

(only topologically closed)

d > merging distance : edge is not shared,

boundaries remain free sides

PROBLEM: surface boundary curves are not always

clean enough to sort out the shared edges.

STEP 2 consists in giving consistent orientations

to faces which have a shared edge.

Surface 2 is included to the Join with a flag 1 2

specifying that the orientation of the face is opposed

to the orientation of the original surface (the surface

Copyright DASSAULT SYSTEMES

itself is not changed)

PROBLEM: Because of some invalid situations it may

be impossible to propagate a consistent orientation

all over the Join.

Copyright DASSAULT SYSTEMES 11

Healing Assistant

Student Notes:

Information On the Join Operator (2/4)

Problem 1: Examples of surfaces with self-intersecting edges

Most common case: surfaces with a thin area.

Depending on the requested merging distance, edges in the thin area

are considered as superimposed (impossible to find a single common vertex).

Other situations which may exist in imported data :

Incorrect boundary (the shaded display is also incorrect)

Very small curves in the boundary (gives a multiple vertex)

multiple vertex: 4 vertices merged into one

Copyright DASSAULT SYSTEMES

Non supported topology (example: surface lying on a closed

surface)

Copyright DASSAULT SYSTEMES 12

Healing Assistant

Student Notes:

Information On the Join Operator (3/4)

Problem 2: Examples of Join failures

Case of duplicated or embedded surfaces

1 2 Impossible to find a consistent orientation except if the join operator

manages to keep some edges as free sides

In some cases you can get a result, if the Join operator has been able

to keep superimposed edges as free edges (boundaries)

3

Case of small overlap Two possible orientations for surface 2, if the “wrong” one is kept, it

will not be possible to add surface 3 to the join.

1 2

3

expected orientation

Expected propagation Incorrect propagation

Copyright DASSAULT SYSTEMES

“wrong” orientation

If possible the Join operator will show the location of orientation

inversions; when it is impossible only Healing Assistant can help

in finding the defects (usually non manifold edges).

Copyright DASSAULT SYSTEMES 13

Healing Assistant

Student Notes:

Information On the Join Operator (4/4)

Problem 2: Examples of Join failures

Case of multiple connections:

Standard non manifold edge is edge shared by more than 2 faces.

2

Impossible to find a consistent orientation except if the join 1

operator manages to keep some edges as free sides.

Moebius type situation:

No inside/outside definition is possible.

Impossible to define a consistent orientation all over the surface

except by keeping a free edge.

Copyright DASSAULT SYSTEMES

Copyright DASSAULT SYSTEMES 14

Healing Assistant

Student Notes:

How To Choose a Merging Distance (1/2)

You must take into account the accuracy of the data to Join: if you choose a strict

tolerance, the Join has many free sides and it takes time to correct them.

merging dist. = 0.001mm merging dist. = 0.01mm merging dist. = 0.1mm

Also sometimes Join does not work with a strict tolerance (Join failure).

On the other hand when you relax the tolerance, some gaps are hidden but the geometry still

has gaps and may be unusable for later processing .

For example gaps may cause visible marks on the manufactured part

remember that a gap may be: or:

Copyright DASSAULT SYSTEMES

Finally Join removes all edges which are smaller than the merging distance, which can cause

problems if the merging distance is too high.

The suppression of small curves may later produce invalid faces (with self-intersecting

edges).

Copyright DASSAULT SYSTEMES 15

Healing Assistant

Student Notes:

How To Choose a Merging Distance (2/2)

Practical tips:

Try a Join with a low value of the merging distance (example 0.001 to 0.01mm).

Increase the value if needed to by-pass failures (example 0.02 to 0.05mm), otherwise use

Connect Checker of Healing Assistant to detect invalid topological situations.

Once you have a Join you may still increase the value of the merging distance to hide gaps; do it

by creating a new Join rather than by modifying the first one, in order to avoid suppressing

small edge curves.

Close remaining gaps using Local Join of Healing Assistant.

START

Join at 0.001mm If OK

If join failure

If too many free sides:

Increase value Create Join of Join with

If OK Closed topology

Limit = 0.01 to 0.05mm bigger value

Limit = 0.01 to 0.05mm

If join failure

Copyright DASSAULT SYSTEMES

Analyze and repair problems If remaining free sides:

with Healing Assistant Analyze and close with

Healing Assistant

Copyright DASSAULT SYSTEMES 16

Healing Assistant

Student Notes:

Model Analysis

In this lesson you will learn about:

Checking surfaces individually

Repairing invalid surfaces

Checking model topology

Repairing invalid topologies

Copyright DASSAULT SYSTEMES

Copyright DASSAULT SYSTEMES 17

Healing Assistant

Student Notes:

Face Checker (1/2)

The purpose of the face checker is:

To find surfaces with an invalid boundary for a given merging distance.

To find surfaces with holes in their boundaries and thin surfaces.

To sort the surfaces by moving the invalid ones to a new geometrical set.

A. Check internal faces of multi-face surfaces; if the

option is not checked only the outside

boundaries are analyzed.

B. Tolerance for the detection of self-intersections:

use the merging distance that you intend to use A

in the Join command.

C. Tolerance for the detection of holes (gaps) in B

surface boundaries: only surfaces with holes C

larger than the given value will be highlighted.

D. Tolerance for the detection of thin faces: faces D

are considered thin when their “width” is F

everywhere smaller than the specified value.

E. Transfer detected surfaces to a new geometrical E

set (see next page).

F. Color used for highlight of detected surfaces

Copyright DASSAULT SYSTEMES

(you can double-click the color slab to change

the color).

WARNING: checking all surfaces with Face Checker and removing the surfaces detected invalid does

not ensure that the Join operator will succeed. New invalidities may appear during the Join process itself.

Copyright DASSAULT SYSTEMES 18

Healing Assistant

Student Notes:

Face Checker (2/2)

The Transfer button lets you transfer detected surfaces to a new

geometrical set.

A. Select a name for the new geometrical set

which will receive the transferred surfaces. The

new set is created directly under the main part:

B. Surfaces detected invalid for the given criterion

(self intersection, hole or thin face). You can

select a site to highlight it on screen or to

transfer it, you can also right-click to reframe

on the site.

C. When the option is checked the operator will try

an automatic repair of the detected surfaces.

If it is possible a new surfaces is created in a A

dedicated geometrical set.

The option is available for self-intersections and

holes only = it is not available for thin faces. B Transfer

selected site

Transfer all

sites

Copyright DASSAULT SYSTEMES

Copyright DASSAULT SYSTEMES 19

Healing Assistant

Student Notes:

Face Orientation (1/2)

Helpful in case of “Bad Topology” in Join operation. The

purpose of the face orientation operator is:

To check surface orientation consistency

To invert the surfaces with a wrong orientation

A. Options:

3

1. While Moving: the colors change dynamically when the

view direction changes.

2. Direction locked: you can change the view while keeping

the same direction for orientation analysis.

A

3. Fly analysis: when direction is locked you can display

orientations on the fly.

B. You can reverse the orientation of a given surface or

propagate the orientation of a given surface (see next page).

C. Each surface is displayed with one of the colors, depending B

on the direction of its normal direction (N) compared to the

view direction (V). Colors can be changed by double-click on

the color tabs. N C

V

V

N D

Copyright DASSAULT SYSTEMES

Orientation 1 Orientation 2

N.V >0 N.V <0

D. Information: current view direction and number of selected

faces.

Copyright DASSAULT SYSTEMES 20

Healing Assistant

Student Notes:

Face Orientation (2/2)

Invert surface

A. Manual: Only some selected surfaces are inverted.

A B

B. Automatic: The orientation of a selected surface is propagated

to all other surfaces of the selection (consistent orientation).

a. Options: same as Connect Checker.

b. Search distance: distance used to pre-select boundary

edges that will be compared (edges candidate for merging).

c. Connection distance: distance below which two candidate

edges are actually considered as merged and the

orientation is propagated.

Copyright DASSAULT SYSTEMES

The processed surfaces

are hidden and the new

surfaces (with inverted

orientations) are created

in a new Geometrical Set.

Copyright DASSAULT SYSTEMES 21

Healing Assistant

Student Notes:

Geometrical Display

The purpose of the Geometrical display is:

To check surface geometric boundaries visually (remember that the

regular surface display shows topological boundaries).

To detect holes in surface boundaries.

Regular shaded display With geometric boundaries With geometric boundaries + holes

A. Internal edges: you can display the internal boundaries of

a multi-face surface.

B. Graphic properties for the display of boundaries. A

C. Threshold for the display of holes in boundaries: only

holes wider than the specified value are highlighted. B

Copyright DASSAULT SYSTEMES

C

Use Remove Geometrical Display to turn OFF

the display of surface geometric boundaries.

Copyright DASSAULT SYSTEMES 22

Healing Assistant

Student Notes:

Repairing Invalid Surfaces

You can repair invalid elements by one of these methods:

Recreate by Split using the boundary and support surface of the invalid surface.

In particular cases, it may be quicker to discard the invalid surface and to create a

new one using the standard surface creation tools of CATIA.

General case: recreate the surface by SPLIT Simple situations: replace the surface by a new

element

Isolate the invalid element

Create its full BOUNDARY (as a datum)

If necessary:

SMOOTH CURVE to the boundary

DISASSEMBLE the boundary, FILL

check and repair the curves and

MULTISECTIONS SURFACE or

JOIN them back

BLEND (specially for ruled surfaces)

UNTRIM the surface

SPLIT the surface back.

Copyright DASSAULT SYSTEMES

Repairing the invalid elements is usually very

easy and quick once they have been located.

Copyright DASSAULT SYSTEMES 23

Healing Assistant

Student Notes:

Face Smooth (1/2)

Invalid surfaces can also be repaired by the Face Smooth command

(mono-face surfaces only).

It modifies the edges of the boundaries within a tolerance in order to:

Fill gaps between edges up to a given length.

Correct small tangency breaks up to a given angle.

Correct curvature discontinuities up to a given % value.

Result

It can also

Copyright DASSAULT SYSTEMES

Suppress very small edges by removing them or concatenating them.

Reduce the number of curves by concatenating edges which are continuous in tangency.

Copyright DASSAULT SYSTEMES 24

Healing Assistant

Student Notes:

Face Smooth (2/2)

A Visualization tab allows to have a feedback on the result. It shows:

The remaining discontinuities between boundary edges (green)

The surfaces which could not be processed (yellow)

The surfaces where the deformation is greater than the system tolerance (red)

Some options are available to

clarify the display when many

surfaces have been processed

together

?

Copyright DASSAULT SYSTEMES

Copyright DASSAULT SYSTEMES 25

Healing Assistant

Student Notes:

Surface Connection Checker (1/2)

You can analyze the connections between several surfaces or inside a

multi-cell surface (internal edges).

You can highlight discontinuities greater than a given value.

You can highlight duplications, overlaps, embedded elements…

Parameter used for pre-selection of edges:

d

Boundary: cannot be If d < Search distance, a more accurate test is

done to find if edges can be shared

d

merged with any

other edge

Distance: geometric gap

(between connection Duplicate: same area

and search distances) with same edges

Tangency: discontinuities Embedded: a surface

along merged edges is totally included

according to Tangency into another one

error criterion

Overlap: merged edges Multiple

with no possible connection: more

consistent orientations than two edges can

Copyright DASSAULT SYSTEMES

be merged together

Tolerance that you intend to use for Join.

Copyright DASSAULT SYSTEMES 26

Healing Assistant

Student Notes:

Surface Connection Checker (2/2)

Discontinuities are identified as sites grouped into connex domains.

You can highlight a site and use Reframe to analyze it.

You can transfer sites to a new geometrical set for later analysis.

A. Domain: domain number for the

selected site

B. Value: distance, angle, number of Transfer

merged edges depending on the A B selected site

type of analysis performed

Transfer all

sites

Copyright DASSAULT SYSTEMES

Copyright DASSAULT SYSTEMES 27

Healing Assistant

Student Notes:

Repairing Topology

Surfaces identified as possible causes for bad topology

situations have to be sorted out using the connection checker.

These surfaces must be carefully analyzed to find out if they

cause a problem or not.

They may simply be adjacent surfaces with opposite

orientations.

Bad topology situations can usually be repaired by:

Deleting unnecessary surfaces

Trimming surfaces

Correcting surfaces which cause an inconsistency in

orientation

Repairing bad topology situations is easy once they have been

precisely located on the model.

Copyright DASSAULT SYSTEMES

Copyright DASSAULT SYSTEMES 28

Healing Assistant

Student Notes:

Closing a Join Surface

Once you have created a topology you have to make it closed (watertight, seamless).

For that you need to analyze and suppress all free sides.

solid created by

Close Surface

Example: molded part

solid created by Split

or Pad/Up to surface

Copyright DASSAULT SYSTEMES

Example: die face

Copyright DASSAULT SYSTEMES 29

Healing Assistant

Student Notes:

Checking For Free Sides (1/2)

You can display the free sides of a surface with the

Surface Boundaries icon of Healing Assistant

You can also use the Boundary function to highlight the free sides.

The Boundary function gives an explicit message when the surface is closed.

Or use the Tools/Options/Display/Visualization menu

The option tool box allows to choose the color and thickness of boundaries to display.

Copyright DASSAULT SYSTEMES

Copyright DASSAULT SYSTEMES 30

Healing Assistant

Student Notes:

Checking For Free Sides (2/2)

There are only 4 possible cases of free sides.

1: Gap (including 2: Duplicated or embedded

overlap) greater than surfaces which have not

Join merging distance been rejected by the join

operator

3: Invalid element 4: Missing

(not detected by the element

Join operator)

Copyright DASSAULT SYSTEMES

Copyright DASSAULT SYSTEMES 31

Healing Assistant

Student Notes:

Fixing Free Sides (1/2)

Missing elements, duplications and invalid elements are easy to correct once

they are located.

Missing element: you can create missing

elements by Fill or any other surface creation

tool.

Duplicated or embedded element: just remove the

unnecessary element from the topology and delete it.

As unnecessary copies of duplicated elements are

included to the Join as non connex domain, you can

also use the Near operator to eliminate all the unwanted

non connex domains in one shot.

Invalid element: remove the invalid element

from the topology and recreate it with Fill or

any other surface creation tool.

Copyright DASSAULT SYSTEMES

Copyright DASSAULT SYSTEMES 32

Healing Assistant

Student Notes:

Fixing Free Sides (2/2)

Once missing elements, duplications and invalid

elements are corrected, only gaps remain

You can measure gaps with the Surface connection

Checker

Gaps can be corrected:

Only at the topological level by increasing the

join merging distance with Join or with Local

Join.

Gaps still exist on the geometry, they are only

hidden Selected face

At both topological and geometrical levels:

by removing the face which is badly

connected to the others and replacing it by

a new one. To remove a face from a

topology, you can use Extract with the

Complementary mode option. The result is

a new surface including all faces except

the selected one. You can also use Multiple

Extract of GSD to remove several faces in

one shot (command not available in HA1

Copyright DASSAULT SYSTEMES

workbench).

by Healing or Local Healing

Copyright DASSAULT SYSTEMES 33

Healing Assistant

Student Notes:

Local Join (1/2)

Local Join can be used to close a gap in a surface or between surfaces.

The concept is to release the tolerance locally, only for the selected edges.

You can also select a boundary to process all gaps in one shot.

You can close the gap on the topological level only or both on the topological

and geometrical levels.

A. List of selected edges or boundary curves.

B. Automatically sets the Join merging

distance as equal to the maximum gap size. A

C. Choose a simple Join (topological level) or

a Join + Healing (topological and

geometrical levels). Automatic Join/Heal will

do both: join up to the Join tolerance and

Heal for bigger gaps. B

D. Tolerance for Join.

C

E. Tolerance for healing when different from

join tolerance (in case of Automatic

Join/Heal). D

E

Copyright DASSAULT SYSTEMES

Copyright DASSAULT SYSTEMES 34

Healing Assistant

Student Notes:

Local Join (2/2)

Join and Healing parameters are available to control the result.

Copyright DASSAULT SYSTEMES

Copyright DASSAULT SYSTEMES 35

Healing Assistant

Student Notes:

The Healing Operator

The concept of Healing is to measure connections between faces (same as Join)

and to modify the faces when the distance is not within a given tolerance (merging

distance).

The distance is reduced to the user specified Distance Objective.

Healing = Join + modification of surfaces to close geometry at shared edges.

• d < 0.001mm (system tolerance): both geometry and topology are

closed.

• 0.001mm < d < merging distance: the geometry is not closed but

the topology is closed => HEALING modifies the surfaces to close

the geometry. 1 2

• d > merging distance : the geometry is not closed but HEALING d

does not modify anything because the topology is also not closed.

surfaces with a gap a new common edge is computed a smart modification is applied to both surfaces

Copyright DASSAULT SYSTEMES

The process is totally automatic: the whole surface is processed.

HEALING fills gaps but can also make surfaces tangent (G1), this can be useful for offset surfaces

The deformation preserves the shape tendency.

Specific faces can be frozen so that they are not deformed (examples: planar faces, canonic shapes).

Copyright DASSAULT SYSTEMES 36

Healing Assistant

Student Notes:

Local Healing

Local Healing lets you select shared edges of a surface, and all the faces

which share a selected edge are geometrically corrected.

It does not include a Join computation, selected edges must be shared, no

healing will be applied to free sides.

List of selected shared edges

(all of them must belong to

the same surface).

Same parameters as

global Healing operator

Copyright DASSAULT SYSTEMES

The input gap widths can be

displayed, with a warning flag when

the objective distance is not reached.

Copyright DASSAULT SYSTEMES 37

Healing Assistant

Student Notes:

Comparing Models

In this lesson, you will learn about:

Comparing two versions of a part.

Finding differences between them.

Sorting out the unchanged and the modified areas of the part.

Copyright DASSAULT SYSTEMES

Copyright DASSAULT SYSTEMES 38

Healing Assistant

Student Notes:

Compare Parts (1/3)

Two versions of a same part can be compared with Compare Parts.

You can easily display both parts in synchronized windows and,

find the surfaces or faces which are the same in both parts

find the surfaces or faces which are different

find embedded surfaces in a part

The command performs a geometric comparison face to face or surface to surface,

it does not compare features or specification trees.

Comparison methods

Tolerance

Copyright DASSAULT SYSTEMES

View synchronization options :

- Synchronize commands = apply same

command to both views (ex: Hide/Show)

- Synchronize views for zoom and pan

Copyright DASSAULT SYSTEMES 39

Healing Assistant

Student Notes:

Compare Parts (2/3)

You can Select the comparison methods like

Quick: It enables a quicker detection of the faces that are different.

Detailed: It is a precise comparison.

You can use the Merge button to sort the surfaces

Quick

Detailed

Copyright DASSAULT SYSTEMES

Copyright DASSAULT SYSTEMES 40

Healing Assistant

Student Notes:

Compare Parts (3/3)

You can sort the surfaces by

Geometrical set: choose names for the geometrical

sets to create

Selection Set: choose names for the sets to create

Color: choose colors

Full name: Displays full name of the surfaces in the

specification tree

Destination: Choose the destination CatPart

Copyright DASSAULT SYSTEMES

Copyright DASSAULT SYSTEMES 41

Healing Assistant

Student Notes:

Customizing the Workbench

You will learn about:

Controlling and improving the results of IGES 3D import.

Controlling and improving the results of CATIA V4 import.

Copyright DASSAULT SYSTEMES

Copyright DASSAULT SYSTEMES 42

Healing Assistant

Student Notes:

IGES 3D Import (1/7)

The conversion of an IGES file is started by File/Open.

There are related parameters in the Tools/Options box:

Copyright DASSAULT SYSTEMES

Copyright DASSAULT SYSTEMES 43

Healing Assistant

Student Notes:

IGES 3D Import (2/7)

The general parameter can be used to activate or deactivate the

display of the completion dialog box at the end of each file import.

This is specially useful when converting several IGES files together. You do

not have to close the message box at the end of the conversion of each file.

Copyright DASSAULT SYSTEMES

Copyright DASSAULT SYSTEMES 44

Healing Assistant

Student Notes:

IGES 3D Import (3/7)

If the Join option is activated, all the surfaces of the IGES file will be joined during

the conversion, using the specified tolerance as a merging distance.

Copyright DASSAULT SYSTEMES

Copyright DASSAULT SYSTEMES 45

Healing Assistant

Student Notes:

IGES 3D Import (4/7)

The option may be necessary to reduce the

amount of data resulting from the conversion.

In CATIA V5, a single-cell curve or surface must be C2. If the IGES file contains a curve or surface

which is not C2 enough, CATIA will cut it at each C2 discontinuity to create a multi-cell curve or

surface. In case of poor quality IGES data, this may cause a drastic increase of the model size.

To prevent this, curves and surfaces of the IGES file can be re-approximated by exactly C2 curves

or surfaces, within a specified tolerance, so that they can be converted into single-cell elements.

Copyright DASSAULT SYSTEMES

No C2 optimization: many faces C2 optimization: one single face

Copyright DASSAULT SYSTEMES 46

Healing Assistant

Student Notes:

IGES 3D Import (5/7)

Besides, boundaries of IGES surfaces can be made of an unnecessarily high

number of curves. The topological reduction option allows to re-approximate the

boundaries with a smaller number of curves.

support

surface

6 2

5

2 4 1

1 3

trimmed angle > limit

surface

No reduction: 6 curves Topological reduction: 2 curves

Automatic optimization: the tolerance for the approximation of

curves and surfaces is 0.001mm, no topological reduction is done

Advanced optimization: you choose the type of data reduction to

perform and the parameters to take into account for approximation.

Copyright DASSAULT SYSTEMES

Copyright DASSAULT SYSTEMES 47

Healing Assistant

Student Notes:

IGES 3D Import (6/7)

It is also possible to analyze the IGES data to find out the invalid surfaces if any.

If the option is activated, all surfaces of the IGES file are analyzed to detect:

holes in boundary loops: if a hole is wider than the specified tolerance

the surface is declared invalid,

boundaries out of support surface: if the curves are further than the

specified tolerance from the support surface the element is declared

invalid.

The resulting CATIA part contains an individual geometrical set for each invalid

element. These bodies contain the support surface and boundary curves of the

element. Annotations are also created to describe the detected invalidities.

Copyright DASSAULT SYSTEMES

Copyright DASSAULT SYSTEMES 48

Healing Assistant

Student Notes:

IGES 3D Import (7/7)

In 3D IGES, trimmed surfaces are described by entity types 143 (Bounded Surface) or 144

(Trimmed Surface). In both cases, the trimmed surface is given by a support surface, 3D

curves, 2D curves (P-curves).

The 2D and 3D descriptions of the boundaries are redundant. Normally the emitting system

specifies in the header of the IGES file which one is best. This information is not always

relevant, and CATIA still lets you choose which one will be used for the conversion:

Option = keep file preference: CATIA will use the type of curves specified in the header (2D or

3D representation),

Option = Force 3D representation: CATIA will use the 3D curves even if the header specifies

that 2D curves are preferable; the 2D curves are then computed by projection.

Finally you can choose whether you want to create Selections Sets when

Copyright DASSAULT SYSTEMES

importing IGES groups (entity type 402).

Copyright DASSAULT SYSTEMES 49

Healing Assistant

Student Notes:

CATIA V4 Import (1/2)

The import of a CATIA V4 model file is started by File/Open.

There are related parameters in the Tools/Options box:

You can deactivate this option to

simplify the display:

Option ON:

Option OFF:

You can activate this option to

avoid reading 2D drawing data

whenever it is not necessary.

Copyright DASSAULT SYSTEMES

Copyright DASSAULT SYSTEMES 50

Healing Assistant

Student Notes:

CATIA V4 Import (2/2)

With this option the internal control points of the V4

NURBS surfaces are modified in order to improve the

curvature continuity between segments and avoid

cutting into faces when the continuity is not C2.

The parameter gives the maximum displacement

value for a control point. The corresponding

deformation of the surface is strictly smaller, usually

much smaller.

Option OFF:

Deactivate the option to let the

system reduce the segmentation

when possible. Option ON with value 0.005 mm:

Option ON with value 0.01 mm:

Copyright DASSAULT SYSTEMES

Copyright DASSAULT SYSTEMES 51

Healing Assistant

Student Notes:

To Sum Up

In this course you have seen:

How to analyze an imported model

How to repair invalid data

How to repair invalid topological configurations

How to create a valid CATIA V5 topology

How to analyze the free sides of a surface

How to fix free sides topologically and geometrically

How to compare versions of a same part

Copyright DASSAULT SYSTEMES

Copyright DASSAULT SYSTEMES 52

You might also like

- Wurood Shaher. An Introduction To Integrated Media Communication Campaign Development Ebook AssignmentDocument24 pagesWurood Shaher. An Introduction To Integrated Media Communication Campaign Development Ebook AssignmentWurood ShaherNo ratings yet

- Needham Bank - A BYOD Case StudyDocument8 pagesNeedham Bank - A BYOD Case StudyMitzi SantosNo ratings yet

- IKM Online Assessment ResultDocument1 pageIKM Online Assessment ResultpattabhikvNo ratings yet

- Viewpoint 6 Getting StartedDocument42 pagesViewpoint 6 Getting StartedNitin ChandruNo ratings yet

- Resume Tyrique Hynes 22 FinalDocument2 pagesResume Tyrique Hynes 22 Finalapi-3401103680% (1)

- Assembly Language 8086 Candy CrushDocument41 pagesAssembly Language 8086 Candy Crushaleena0% (1)

- Working With Time - Lab Solutions Guide: Index Type Sourcetype Interesting FieldsDocument10 pagesWorking With Time - Lab Solutions Guide: Index Type Sourcetype Interesting FieldsPreet GadhiyaNo ratings yet

- Data Sheet: SAW DuplexerDocument24 pagesData Sheet: SAW DuplexerHongdang DinhNo ratings yet

- Bhatty 2008 (Falling Through The Cracks) PDFDocument4 pagesBhatty 2008 (Falling Through The Cracks) PDFrozgarNo ratings yet

- Science Webquest 2Document3 pagesScience Webquest 2Maleah GossaiNo ratings yet

- 11 Molecular DockingDocument6 pages11 Molecular DockingCarissa IslaNo ratings yet

- Global Plastic Recycling Solution Converts Waste into Profitable ProductsDocument31 pagesGlobal Plastic Recycling Solution Converts Waste into Profitable ProductsDawit SolomonNo ratings yet

- Syllabus - BUA 102-170 - FALL22Document11 pagesSyllabus - BUA 102-170 - FALL22Brooke HartNo ratings yet

- ReliabilDocument23 pagesReliabilAmit ANo ratings yet

- Dell Premium DES-4121 by - VCEplus 60q-DEMO PDFDocument19 pagesDell Premium DES-4121 by - VCEplus 60q-DEMO PDFDinaj AttanayakaNo ratings yet

- Lab Assignment 6 ViewsDocument52 pagesLab Assignment 6 ViewsRienzi Adrienne VillenoNo ratings yet

- Developper CASE en APIDocument26 pagesDevelopper CASE en APIrigobertoz9No ratings yet

- E-commerce security teaching guideDocument11 pagesE-commerce security teaching guideBura ArsenalNo ratings yet

- Sundar Pichai PDFDocument6 pagesSundar Pichai PDFHimanshi Patle100% (1)

- Block 1 - MBSC-4.1G Software Project Management PDFDocument88 pagesBlock 1 - MBSC-4.1G Software Project Management PDFSRIram sriramNo ratings yet

- DSTL - Lab ManualDocument28 pagesDSTL - Lab ManualGud GuyNo ratings yet

- Sun NXT: Available For Android and Ios Devices, Smart Tvs and Other DevicesDocument2 pagesSun NXT: Available For Android and Ios Devices, Smart Tvs and Other DevicesChandan SrivastavaNo ratings yet

- Sublingual Tablet Tapentadol HCL 2Document80 pagesSublingual Tablet Tapentadol HCL 2Maharshi PandyaNo ratings yet

- Ipru Pension 10 Year X 2 LacDocument5 pagesIpru Pension 10 Year X 2 LacHK Option LearnNo ratings yet

- Climate Change and Its Impact (CCI-2023) Climate Change and Its Impact (CCI-2023)Document9 pagesClimate Change and Its Impact (CCI-2023) Climate Change and Its Impact (CCI-2023)hksachinNo ratings yet

- Mci 1Document34 pagesMci 1NAMITHA M RNo ratings yet

- 05 SST Parallels and Meridians WS PDFDocument4 pages05 SST Parallels and Meridians WS PDFVinita SahuNo ratings yet

- HB 1379Document12 pagesHB 1379Jeremy TurleyNo ratings yet

- UTech Jamaica Program GuideDocument28 pagesUTech Jamaica Program GuideAkiem JarrettNo ratings yet

- Compal Confidential: UMA MB Schematic Document Eh7Lw/Eh5Lw/Fh5Tw/Eh7Lc/Eh5LcDocument46 pagesCompal Confidential: UMA MB Schematic Document Eh7Lw/Eh5Lw/Fh5Tw/Eh7Lc/Eh5LcAlisson PereiraNo ratings yet

- General Purpose Application SoftwareDocument24 pagesGeneral Purpose Application SoftwareBabar ZafarNo ratings yet

- Problems of Management in The 21st Century, Vol. 3, 2012Document137 pagesProblems of Management in The 21st Century, Vol. 3, 2012Scientia Socialis, Ltd.No ratings yet

- MBA 8 Year 2 Managerial Finance January 2020Document269 pagesMBA 8 Year 2 Managerial Finance January 2020weedforlifeNo ratings yet

- Week 5Document12 pagesWeek 5Askall ThapaNo ratings yet

- Non - Bank Financial Institutions and Economic Growth in NigeriaDocument57 pagesNon - Bank Financial Institutions and Economic Growth in Nigeriajayeoba oluwaseyi100% (1)

- Contactless Doorbell System Rasoa KatakaDocument32 pagesContactless Doorbell System Rasoa KatakaChalo NdikoNo ratings yet

- Linux Lab CSC 371L 2 - MergedDocument23 pagesLinux Lab CSC 371L 2 - MergedGopran albashaNo ratings yet

- WWW BBC Com Worklife Article 20220311 The Complicated Truth of Post Traumatic GRDocument12 pagesWWW BBC Com Worklife Article 20220311 The Complicated Truth of Post Traumatic GRCipo LlettiNo ratings yet

- Infineon CYW43439 DataSheet v03 - 00 ENDocument88 pagesInfineon CYW43439 DataSheet v03 - 00 ENDenes MarschalkoNo ratings yet

- CIT 202 - Fundamentals of Multimedia System - Unit 2Document30 pagesCIT 202 - Fundamentals of Multimedia System - Unit 2Noe Jhon SionilloNo ratings yet

- 2017-08 Analytic Success Stories - Results of A Business Case SeminarDocument20 pages2017-08 Analytic Success Stories - Results of A Business Case SeminarBrahim EL AZZOUZINo ratings yet

- (Institute of Social Studies, The Hague) S. Parasuraman (Auth.) - The Development Dilemma - Displacement in India-Palgrave Macmillan UK (1999)Document316 pages(Institute of Social Studies, The Hague) S. Parasuraman (Auth.) - The Development Dilemma - Displacement in India-Palgrave Macmillan UK (1999)rik49450No ratings yet

- EG Actuator Tester Models 8909-041 and 8909-059: Product Manual 55021 (Revision F, 10/2021)Document28 pagesEG Actuator Tester Models 8909-041 and 8909-059: Product Manual 55021 (Revision F, 10/2021)MussardNo ratings yet

- UDSM Postgraduate Programmes 2022-2023 Academic Year FINALDocument18 pagesUDSM Postgraduate Programmes 2022-2023 Academic Year FINALdeus nyangokoNo ratings yet

- A Wearable Electrochemical Biosensor For The Monitoring of Metabolites and NutrientsDocument13 pagesA Wearable Electrochemical Biosensor For The Monitoring of Metabolites and NutrientsBAUTISTA DIPAOLA100% (1)

- Value - Creation - and - The - Impact - (CD)Document27 pagesValue - Creation - and - The - Impact - (CD)Jummy BMSNo ratings yet

- Tónová Korekce S TDA1524 - RumunskoDocument3 pagesTónová Korekce S TDA1524 - Rumunskoquad electronicsNo ratings yet

- TDA7449Document21 pagesTDA7449Sambhu Dharmadevan VU3KQFNo ratings yet

- Ardonagh Group Investor Presentation q4 2021Document32 pagesArdonagh Group Investor Presentation q4 2021Glori ortuNo ratings yet

- Computer Answer Key of Class 8thDocument27 pagesComputer Answer Key of Class 8thIshaan SharmaNo ratings yet

- Bennet-Kaine Medicare-X Choice Act SummaryDocument1 pageBennet-Kaine Medicare-X Choice Act SummaryU.S. Senator Michael F. BennetNo ratings yet

- DSCE Lab Manual: Computer Aided Building Planning & DrawingDocument35 pagesDSCE Lab Manual: Computer Aided Building Planning & DrawingSupritha KNo ratings yet

- How To Cut Down Your PortfolioDocument2 pagesHow To Cut Down Your PortfolioabhishekNo ratings yet

- COLORSDocument21 pagesCOLORSAna Cristina Castro-CayabyabNo ratings yet

- Quezon City University 673 Quirino Highway Novaliches, Quezon CityDocument55 pagesQuezon City University 673 Quirino Highway Novaliches, Quezon CityKianne ChanNo ratings yet

- TCW Chapter 1Document17 pagesTCW Chapter 1Via Eileen Madonna JamesNo ratings yet

- STD 7 Sample PapersDocument31 pagesSTD 7 Sample Papersdivya kapoorNo ratings yet

- E-commerce Marketing and Advertising StrategiesDocument52 pagesE-commerce Marketing and Advertising StrategiesShahinur FerdoushNo ratings yet

- Vireo Fact Sheet - MinnesotaDocument4 pagesVireo Fact Sheet - MinnesotaFluenceMediaNo ratings yet

- HealthifyPro Information CollateralDocument11 pagesHealthifyPro Information CollateralMaheshwar ReddyNo ratings yet

- Name To Be Added To Le Roy War Memorial: Lamb Farms IncDocument8 pagesName To Be Added To Le Roy War Memorial: Lamb Farms IncWatertown Daily TimesNo ratings yet

- IFC-Based 4D Construction Management Information Model of Prefabricated Buildings and Its Application in Graph DatabaseDocument26 pagesIFC-Based 4D Construction Management Information Model of Prefabricated Buildings and Its Application in Graph DatabaseBenz CivilNo ratings yet

- 3D Functional Tolerancing and Annotation PDFDocument154 pages3D Functional Tolerancing and Annotation PDFLuis Angel GonzálezNo ratings yet

- Kelompok 6 membahas biaya layanan distribusiDocument12 pagesKelompok 6 membahas biaya layanan distribusiezar zacharyNo ratings yet

- GOST Regulations GuideDocument10 pagesGOST Regulations Guidehemant1886No ratings yet

- User ManualDocument60 pagesUser Manuallilya mohNo ratings yet

- AutoLaser UM enDocument151 pagesAutoLaser UM enCristian LopezNo ratings yet

- Mitsui Cranes & SystemsDocument12 pagesMitsui Cranes & SystemsKhang ElvisNo ratings yet

- Cisco Small Form-Factor Pluggable Modules For Gigabit Ethernet ApplicationsDocument6 pagesCisco Small Form-Factor Pluggable Modules For Gigabit Ethernet ApplicationsCarlos Eduardo Flores SilvaNo ratings yet

- Benbri ProfileDocument32 pagesBenbri ProfileOlusola OluwaseunNo ratings yet

- 3 Pureballast 3.2/ Pureballast 3.2 Compact Flex 3Document11 pages3 Pureballast 3.2/ Pureballast 3.2 Compact Flex 3TamNo ratings yet

- Cursor Movement Using Hand Gestures in Python and Arduino UnoDocument7 pagesCursor Movement Using Hand Gestures in Python and Arduino UnoIJRASETPublicationsNo ratings yet

- Lab Task3 PHP IntroDocument3 pagesLab Task3 PHP IntroRahful Hasan ShawonNo ratings yet

- Apple - Clean Energy and Recycled Products.Document15 pagesApple - Clean Energy and Recycled Products.Sumanyu AgrawalNo ratings yet

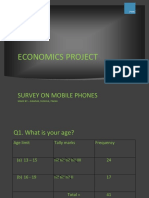

- Economics Project: Survey On Mobile PhonesDocument16 pagesEconomics Project: Survey On Mobile PhonesmanikNo ratings yet

- Skimming and ScanningDocument4 pagesSkimming and ScanningRayene MedabisNo ratings yet

- Valtek Handwheels and Limit Stops (Flow Serve)Document12 pagesValtek Handwheels and Limit Stops (Flow Serve)dharmendrabholeNo ratings yet

- 3G3PV Series Advanced General-Purpose Inverter Users Manual - I537-E2-01 PDFDocument320 pages3G3PV Series Advanced General-Purpose Inverter Users Manual - I537-E2-01 PDFАлександрNo ratings yet

- Law Made Simple Intellectual Property Law Note 1 0f 7 Notes: Musbri Mohamed Dil Adil (Itm) MBL (Ukm)Document50 pagesLaw Made Simple Intellectual Property Law Note 1 0f 7 Notes: Musbri Mohamed Dil Adil (Itm) MBL (Ukm)musbri mohamedNo ratings yet

- A Study On Consumer Behaviour Towards Led TV: in Comibatore DistrictDocument11 pagesA Study On Consumer Behaviour Towards Led TV: in Comibatore DistrictNithishNo ratings yet

- Tda 7850Document18 pagesTda 7850Adrian AguilarNo ratings yet

- Yealink Hybrid-mode Feature Compatible with AudioCodes SBC V15.3Document13 pagesYealink Hybrid-mode Feature Compatible with AudioCodes SBC V15.3jtzondoNo ratings yet

- CC Unit4Document8 pagesCC Unit4Harsh RajputNo ratings yet

- Global USS - Inside Sales Account ManagerDocument2 pagesGlobal USS - Inside Sales Account Managerneeraj viharNo ratings yet

- Data Processing Addendum SummaryDocument20 pagesData Processing Addendum SummaryJacimar JuniorNo ratings yet

- 09 - Configuring Cisco ASADocument8 pages09 - Configuring Cisco ASAMorad Alabsy100% (1)

- E-Tech ReviewerDocument10 pagesE-Tech ReviewerPsalm De VeraNo ratings yet

- Bibler Tempest SetupDocument3 pagesBibler Tempest SetupmriffaiNo ratings yet

- Thesis Generator AppDocument6 pagesThesis Generator Appafcnenabv100% (1)

- XR-200 Manual Pos-X PrinterDocument17 pagesXR-200 Manual Pos-X Printerlvincent7No ratings yet