Professional Documents

Culture Documents

Kennedy Guardian Submittal k81d K81a K81am

Uploaded by

Alfredo BravoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Kennedy Guardian Submittal k81d K81a K81am

Uploaded by

Alfredo BravoCopyright:

Available Formats

The Kennedy Guardian Kennedy Valve

Fire hydrants have been used in fire protection for over 100 years. A.W.W.A. C502 was developed in 1913 as a standard for the

manufacture and use of dry barrel hydrants. Kennedy has established itself as a leader in the industry with manufacturing experience dating back to

1905. Many of the early hydrants are in use today.

Kennedy’s most recent design is the Guardian. Based on a simple design, it is easy to install, maintain and repair. The Guardian sets a

standard for quality in the industry and meets or exceeds all requirements for A.W.W.A. C502 latest revision, and is UL listed and FM approved.

K81D Meets or exceeds requirements of A.W.W.A. C-502 and is

UL listed and FM approved.

Guardian Features K-81A Meets or exceeds requirements of A.W.W.A. C-502.

Weather Shield

Fig. K81D Weather

To protect Shield

exposed

To protect exposed operating

operating area from

area from freezing rain and dirt.

OneBonnet

Piece Bonnet freezing rain and dirt.

One Piece

Newlyfor

Newly designed designed for Thrust Washer

Thrust Washer

easier maintenance.

easier maintenance. For easy turning operation.

For easy turning

operation.

Sealed Grease Cavity

Sealed For easier operation

Grease Cavity TwoTwo O-Rings

O-Rings

To protect operating threads from corrosion.

and maintenance.

For easier operation To protect operating threads from corrosion.

and maintenance.

O-Ring

O-Ring

To seal between

To seal brassbrass

between ferrule and and

ferrule stem.stem.

Nozzle

Nozzle

Temper resistant.

Tamper resistant.

Breakable Coupling

Breakable Coupling

Traffic Flange

Traffic Flange Minimizes

Minimizesdamage

damage from traffic

from accident.

traffic

Full

Full360

360˚ degree adjustment.

adjustment. New design makes repairs more efficient.

NewBreaking

breakingRing

ring on

on top accident. New design makes

New

forfor

top easy replacement

easy replacementand repairs more efficient.

andinterchangeability

interchangeabilityononall

O-Ring

all K-81 models.K-81 models. O-Ring

For For

easeease

of repait

of repair and nozzle facing.

Corrosion Resistant and nozzle facing.

Bronze Drain Valve.

AWWA ULFM

500 psi test pressure 500 psi test pressure

250 psi working pressure 175 psi working pressure

Easy to install—Even easier to maintain

• Tamper resistant quarter turn hose and steamer nozzles.

Corrosion Resistant For those who know how, replacement is easy.

Bronze to Bronze Seating

Bronze drain valve. • Easy to use, short, simple, inexpensive and lightweight

This standard feature assures seat removal wrench.

easy seat removal.

• Unique pressure-activated drain valve assures positive

Bronze to Bronze Seating

shut off.

This standard feature

The higher the pressure, the tighter the seal.

assures easy

Full Cover seat removal.

Bottom Plate Automatically compensates for wear due to usage.

Prevents corrosion to the

lower stem threads and

Does not rely on interference fit.

Full Cover

prevents Bottom

main valve Plate

distortion. • Two sizes available, 51/4” valve opening and 41/2” valve

Prevents

Provides corrosion

a positive stop to the opening to best meet your needs.

againstlower stem threads and

the elbow. • Fully and easily lubricated operating threads for

prevents main valve corrosion protection and ease of operation.

distortion. Provides a • The Guardian K-81D Hydrant meets or exceeds all the

positive stop against latest provisions of AWWA, and UL 246-FM 1510

the elbow. specifications (options are limited on UL/FM models)

Kennedy Valve 7/16/20 Hydrants 2-1

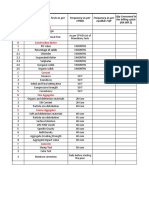

Guardian K81D Technical / Dimensional Data (AWWA-UL/FM)

DETAIL & PART MATERIAL ASTM SPEC (or as stated)

K8101 ALEMITE FITTING STAINLESS STEEL A276 (304)

† K8102 OPERATING STEM NUT BRONZE B584 C87850

K8103 DIRT SHIELD CAST IRON A126 CLASS B

K8101 K8104 STEM LOCK NUT BRONZE B584 C87850

† K8105 O-RING BUNA-N (SYN. RUBBER) D2000

K8102 † K8106 THRUST WASHER NYLATRON GS MIL LP-410

K8107 HYDRANT CAP CAST IRON A126 CLASS B

K8146 K8108 CAP BOLTS & NUTS STAINLESS STEEL F593C/F594

K8103 † K8109 CAP O-RING BUNA-N (SYN. RUBBER) D2000

K8104 * K8110 STEM FERRULE BRASS B135 C26000

K8105 † K8111 O-RING BUNA-N (SYN. RUBBER) D2000

K8106 * K8112 O-RING BUNA-N (SYN. RUBBER) D2000

K8114 UPPER STEM C.R. STEEL A108

K8107 K8115 UPPER BARREL CAST IRON A126 CLASS B

K8116 STEM BREAKING COUPLING CAST IRON A126 CLASS B

K8118 BOLTS & NUTS STAINLESS STEEL F593C/F594

K8108 K8119 BREAKING RING CAST IRON A126 CLASS B

K8120 O-RING BUNA-N (SYN. RUBBER) D2000

K8109

K8122R COUPLING PINS STAINLESS STEEL 410

K8110 K8145 K8123 LOWER STEM C.R. STEEL A108

K8111 K8124 LOWER BARREL DUCTILE IRON ANSI 21.50, 21.51

K8144 † K8125 ELBOW O-RING BUNA-N (SYN. RUBBER) D2000

K8112

† K8126A O-RING BUNA-N (SYN. RUBBER) D2000

K8143 * K8127 SEAT RING INSERT BRONZE B584/C87850

† K8128 SEAT RING BRONZE B584/C87850

K8129 DRAIN TUBE BRASS B135 C23000

† K8130 O-RING BUNA-N (SYN. RUBBER) D2000

† K8131 MAIN VALVE EPDM

K8132 BOTTOM PLATE CAST IRON A126 CLASS B

K8133 DRAIN VALVE PIN STAINLESS STEEL 410/416

K8142 K8134 ELBOW DUCTILE IRON A536 10 70 50 05

K8135 ELBOW BOLTS AND NUTS STEEL-302/304 STAINLESS ASTM F593

K8141 K8136 DRAIN VALVE BRONZE B806 C95400/C95500

† K8137 DRAIN VALVE FACING W/INSERT BUNA-N W/STAINLESS STEEL D2000/A276 (304)

K8138 NOZZLE CHAIN 'S' HOOK STEEL A108

K8138

K8139 NOZZLE CAP CHAIN STEEL A108

K8140 NOZZLE CHAIN BAND STEEL A108

K8114 † K8141 NOZZLE RETAINING SCREW STAINLESS STEEL A276 (304)

# K8142 NOZZLE: HOSE / STEAMER BRONZE B806C95400/B584C87850

K8115 †# K8143 NOZZLE CAP GASKET RUBBER D2000 TYPE AA

# K8144 NOZZLE CAP CAST IRON A126 CLASS B

K8116 †# K8145 O-RING BUNA-N (SYN. RUBBER) D2000

K8156 K8146 ALLEN HEAD SET SCREW STAINLESS STEEL A276 (410)

K8147 SEAT REMOVAL WRENCH

K8118

K8148 NOZZLE REMOVAL TOOLS

K8119 † K8149 COLLISION REPAIR KIT

K8120 K8150 GRADE EXTENSION KIT

K8156 BREAKING RING STRAPS

* Denotes that part is available only as part of an assembl

# Must specify type of Nozzle, Hose or Steamer.

K8122R † Recommended spare parts.

NOTE: Also available in DI 350 PSI.

K8123

K8124

Accessories

STYLE SHOE SIZE A

MARKINGS

M.J. 4 7 3/4

FRONT: BACK:

K8126 M.J. 6 8

YEAR K.V. MONOGRAM

K8137 KENNEDY KENNEDY

ELMIRA, N.Y ELMIRA, N.Y. Flange 4 7 7/8

K8135

SIZE SIZE Flange 6 8 1/8

K8125 TYPE UL/FM

250CWP 250 Tyson 6 9

Contact Factory for UL/FM

Tyton ends available only in 5 1/4” Main Valve Hydrants.

K8126A Limitations

4” shoe dimensions apply to 4 1/2” Main Valve Hydrants only.

K8127

K8128

K8129

K8130

COTTER

PIN

K8131

COUPLING

PINS

K8132 NOZZLE REMOVING

TOOLS K8148 BRIDGE

K8133 (ORDER BY NOZZLE I.D.)

PIN

COLLISION REPAIR

K8134 KIT K8149

(Includes pins and seals)

EXTENSION KIT K8150

SEAT REMOVING

WRENCH K8147

STOP NUT WRENCH K8155

Kennedy Valve 7/16/20 Hydrants 2-2

Guardian K81A with “Storz” Outlet

Technical / Dimensional Data (AWWA)

DETAIL & PART MATERIAL ASTM SPEC (or as stated)

K8101 ALEMITE FITTING STAINLESS STEEL A276 (304)

K8101 | K8102 OPERATING STEM NUT BRONZE B584 C87850

K8102 K8103 DIRT SHIELD CAST IRON A126 CLASS B

K8104 STEM LOCK NUT BRONZE B584 C87850

K8146 | K8105 O-RING BUNA-N (SYN. RUBBER) 02000

| K8108 CAP BOLTS & NUTS STAINLESS STEEL F593C/F594

K8103

K8107 HYDRANT CAP

K8104 K8108 CAP BOLTS & NUTS STAINLESS STEEL F593C/F594

K8105 | K8109 CAP O-RING BUNA-N (SYN. RUBBER) D20000

K8106 * K8110 STEM FERRULE BRASS B135 C26000

K8107 | K8111 O-RING BUNA-N (SYN. RUBBER) 02000

* K8112 O-RING BUNA-N (SYN. RUBBER) 02000

K8114 UPPER STEM C.R. STEEL A108

K8115 UPPER BARREL CAST IRON A126 CLASS B

K8108

K8116 STEM BREAKING COUPLING CAST IRON A126 CLASS B

K8109 K8118 BOLTS & NUTS STAINLESS STEEL F593C/F594

K8119 BREAKING RING CAST IRON A126 CLASS B

K8110

K8120 O-RING BUNA-N (SYN. RUBBER) D2000

K8111 K8122R COUPLING PINS STAINLESS STEEL 410

K8145

K8112 K8123 LOWER STEM C.R. STEEL A108

K8124 LOWER BARREL DUCTILE IRON ANSI 21.50, 21.51

K8144 | K8125 ELBOW O-RING BUNA-N (SYN. RUBBER) D2000

| K8126A O-RING BUNA-N (SYN. RUBBER) 02000

* K8127 SEAT RING INSERT BRONZE B584/C87850

| K8128 SEAT RING BRONZE B584/C87850

K8129 DRAIN TUBE BRASS B135 C23000

| K8130 O-RING BUNA-N (SYN. RUBBER) D2000

| K8131 MAIN VALVE EPDM

K8132 BOTTOM PLATE CAST IRON A126 CLASS B

K8133 DRAIN VALVE PIN STAINLESS STEEL 410/416

K8142 K8134 ELBOW DUCTILE IRON A536 10 70 50 05

K8141 | K8135 ELBOW BOLTS AND NUTS STEEL-302/304 STAINLESS ASTM F593

| K8136 DRAIN VALVE BRONZE B806 C95400/C95500

K8137 DRAIN VALVE FACING D2000 / A276 (304)

w/INSERT

K8114 K8138 NOZZLE CHAIN 'S' HOOK STEEL A108

* K8139 NOZZLE CAP CHAIN STEEL A108

K8115 * K8140 NOZZLE CAP BAND STEEL A108

| K8141 NOZZLE RETAINING SCREW STAINLESS STEEL A276 (304)

K8116

-*# K8142 NOZZLE: HOSE / STEAMER BRONZE B806 C95400 / B584 C87850

K8156 -*# K8143 NOZZLE CAP GASKET RESILIENT B2000

K8118 (INTEGRAL)

-*# K8144 NOZZLE CAP AIRCRAFT ALUMINUM A126 CLASS B

K8119 |# K8145 O-RING BUNA-N (SYN. RUBBER) 02000

K8120 K8146 ALLEN HEAD SET SCREW STAINLESS STEEL A276 (410)

| K8147 SEAT REMOVAL WRENCH

K8148 NOZZLE REMOVAL TOOLS

| K8149 COLLISION REPAIR KIT

K8122R

K8150 GRADE EXTENSION KIT

K8156 BREAKING RING STRAPS

* Denotes that part is available only as part of an assembly.

# Must specify type of Nozzle, Hose or Steamer.

| Recommended spare parts.

K8123 -Special for this Customer Only.

“Storz” Features

K8124

K8126 STYLE SHOE SIZE A

K8137 • No more M.J. 4 7 3/4

K8135 time consuming M.J. 6 8

K8125 threading and

Flange 4 7 7/8

tightening

Flange 6 8 1/8

K8126A

K8127

• Only 1/4 turn Tyson 6 9

K8128 connects hose Tyton ends available only in 5 1/4” Main Valve Hydrants.

K8129

K8130

to hydrant 4” shoe dimensions apply to 4 1/2” Main Valve Hydrants only.

K8131 • Alleviates confusion if multiple

steamer threads are used in your area

K8132

K8133 • Available in 4” and 5” connections

K8134

Kennedy Valve 7/16/20 Hydrants 2-3

Tamper-Resistant Guardian Shield Lock Nut

INSTRUCTIONS PARTS LIST

DETAIL PART MATERIAL ASTM SPEC PART CODE

1. Remove the cast iron shield, K8103. Use a large (6”) K8101 ALEMITE FITTING STAINLESS STEEL A276 (304) - 4-41670P

pipe wrench to remove the dirt shield & a hydrant K8102 OPERATING STEM NUT BRONZE B584 C87850 - -VARIES

wrench to prevent the hydrant from being opened. K8103 DIRT SHIELD CAST IRON A 126 CLASS B OPEN LEFT 3212132

OPEN RIGHT 3212133

2. Remove the allen head, cone point set screw K8146.

K8104 STEM LOCK NUT BRONZE B584 C87850 - 3-185944

Use a 1/8” allen wrench.

K8103 s ANTI TAMPER LOCK NUT DUCTILE IRON A536 OPEN LEFT 3212114

3. Remove the stem hold down or lock nut K8104. Use a OPEN RIGHT 3212112

large (4”) monkey or crescent wrench. Note that the K8105 O-RING BUNA-N D 735 - 442905P

hold down nut has a left hand thread & is turned K8106 THRUST WASHER NYLATRON GS (TO MIL LP-410) - 445843P

clockwise to remove it. K8107 HYDRANT CAP OR DOME CAST IRON A 126 CLASS B 5 1/4” 3185962

K8146 ALLEN HEAD SET SCREW STAINLESS STEEL A 276 - 4-44438P

4. Inspect the thrust bearing, K8106. If necessary replace it. K8146 s ALLEN HEAD SET SCREW STAINLESS STEEL A 276 - 4-44449P

5. Inspect the anti tamper combination. Hold down nut\

dirt shield K8103 s to be certain that the arrow points

in the correct direction.

6. Start the anti tamper combination hold down nut\dirt

shield into the dome by hand. (It may be difficult to

force it over the ‘O’-ring.) And then tighten it firmly.

(i.e. 200 lb-ft).

7. Replace the set screw and tighten the screw tight (i.e. 80 lb-ft).

8. If possible operate the hydrant to check the installation.

Kennedy Valve 7/16/20 Hydrants 2-4

Guardian Insert for users of WOOD-MATHEWS HYDRANTS

A True Guardian Insert Replacement

Save the cost of digging to replace that tried and true, but aging friend.

Merely unscrew Mathews insert and replace it with a Guardian Insert, and

for normal maintenance, never do it again.

Check These Benefits

1. All working parts are Guardian.

2. Fully maintainable through the bonnet, using light weight wrench.

3. Available to replace 4” former type and Modernized Wood-Mathews.

Additional Parts for Guardian Insert

Fig. K81AW

Adaption Method Chart Corresponds to

above illustrations

M.V.O. 5 1/4” 4 1/2” 4”

MATHEWS

6” BRONZE LINED 1 - -

6” REGULAR 1 - -

5 1/4” BRONZE LINED 1 - -

5 1/4” REGULAR 2 - -

4 1/2” BRONZE LINED - 1 -

4 1/2” REGULAR - 2 -

4” REGULAR - - 2

Kennedy Valve 7/16/20 Hydrants 2-5

Ordering Information

Guardian Hydrant NATIONAL STANDARD HOSE COUPLING THREAD SPECIFICATIONS (NST)

A. Nominal inside diameter 2 1/2” 3” 3 1/2” 4” 4 1/2”

Number of threads per inch 7 1/2 6 6 4 4

When ordering, indicate the following: B. Major diameter nozzle thread Max. 3.0686 3.6239 4.2439 5.0109 5.7609

1. Size of main valve opening Min. 3.0366 3.5879 4.2079 4.9609 5.7109

2. Quantity and threading details of hose nozzles. C. Pitch diameter nozzle thread Max. 2.9820 3.5156 4.1356 4.8485 5.5985

3. Threading details of steamer nozzle. Min. 2.9660 3.4976 4.1176 4.8235 5.5735

4. Size and type of inlet connection (mechanical joint, flanged,

D. Minor diameter nozzle thread Max. 2.8954 3.4073 4.0273 4.6861 5.4361

asbestos-cement, bell, or tyton).

E. Diameter pilot nozzle 2.8500 3.3540 3.9730 4.6100 5.3570

5. Depth of bury (from bottom of pipe to ground line).

F. Length of thread - nozzle

6. Color (National standard yellow will be furnished unless 1” 1 1/8” 1 1/8” 1 1/4” 1 1/4”

otherwise indicated). G. Face to start of second turn 1/4” 5/16” 5/16” 7/16” 7/16”

7. Size and shape of operating nut. H. Major diameter coupling thread Min. 3.0836 3.6389 4.2639 5.0359 5.7859

8. Direction to open. I. Pitch diameter coupling thread Max. 3.0130 3.5486 4.1736 4.8985 5.6485

9. Regular or Bronze Lined (for Mathews-Guardian Insert only). Min. 2.9970 3.5306 4.1556 4.8735 5.6235

Parts

J. Minor diameter coupling thread Max. 2.9424 3.4583 4.0833 4.7611 5.5111

Min. 2.9104 3.4223 4.0473 4.7111 5.4611

K. Depth of coupling 5/16” 1 1/16” 1 1/16” 1 3/16” 1 3/16”

Also available: Figure 109 Hose Gate Valve (2 1/2”).

When ordering parts, indicate the following:

Estimated Weights

1. Part number

2. Part description

3. Type of hydrant

4. Size of main valve opening DEPTH OF TRENCH

2'6" 3'0" 3'6" 4'0" 4'6" 5'0" 5'6" 6'0" 6'6" 7'0"

4 / " 336 351 366 381 396 411 426 441 456 534

1

K-81A

2

ELBOW - We must have the size and type of connection to main. Main Valve

5 / " 380 409 427 444 460 480 502 523 542 560

1

4

3-way configuration with M.J. shoe less accessories

Opening 4" 281 297 316 333 350 365 381 396 414 429

OPERATING STEM NUT - Give directions to open (cast on cap) K-81AW 4 / " 278 295 313 330 347 362 378 393 411 426

1

2

5 / " 328 335 355 375 395 415 430 445 468 489

and size and shape of operating nut. 4-sided nut, give flat to flat

1

4

3-way configuration

dimension. 5-sided nut, give point to opposite flat dimension. 6-sided

nut, give flat to flat dimension to eliminate any doubt as to where the NOZZLE CAP CHAIN - Tell us the nozzle type, hose or steamer.

measurement was taken.”

NOZZLE CAP - Exact threading and nut size and shape.

Note: Dual rated hydrants are UL/FM approved for 1-1/2 P and

1-1/4” sq. nut sizes. UPPER BARREL - Furnish all information cast on the barrel and

the number of hose and steamer connections.

STEM - Furnish the direction the hydrant opens as cast on the cap

and furnish the depth of trench (distance from groundline to bottom

of connecting pipe). If the stem can be measured, complete overall

SQUARE PENTAGON HEXAGON OCTAGON dimensions including diameter will help. The diameter should

(4-Sided) (5-Sided) (6-Sided) (8-Sided) always be measured on the smooth (unthreaded) portion.*

CAP - Give direction the hydrant opens. This is indicated by an LOWER BARREL - Furnish depth of trench (distance from

arrow cast on the cap. Indicate the direction the arrow points. groundline to bottom of connecting pipe) or dimension from flange

face to flange face (overall). The outside and inside diameters

NOZZLE CAP GASKET - Indicate size of nozzle and whether are also a help.

hose or steamer.

SEAT RING - As with all parts you order we must have size of

NOZZLE - Give exact threading details, outside (major) diameter, main valve opening and type of hydrant. This is cast on

pitch diameter, root (minor) diameter and exact number of threads the upper barrel.

per inch (TPI) or send in a gauge or sample in good condition.

Kennedy Valve 7/16/20 Hydrants 2-6

Kennedy Guardian Monitor Hydrant

K8101

K8102

K8103

K8104 K8146

K8105

K8106

K8107

K8108

K8109

K8110

K8111

K8142

K8141

K8151

K8114

K8115

K8116

Features

K8118 STYLE SHOE SIZE A

K8119 1. Meets or exceeds all M.J. 4 7 3/4

K8120

requirements of M.J. 6 8

K8122R

AWWA C-502.

Flange 4 7 7/8

K8123 2. 5 1/4” Main Flange 6 8 1/8

Valve Opening Tyson 6 9

K8124 3. Excellent flow characteristics.

4. Existing hydrants can be retrofitted easily and affordably.

Approvals:

K8126 3” & 4” Flange - UL/FM Approved

K8137

K8135 Monitor hydrant can be maintained through the hydrant cap

K8125 without excavation.

NOTE: Hydrant also available in DI 350 PSI.

K8126A

K8127

K8128

K8129

K8130

K8131

K8132

K8133

K8134

Kennedy Valve 7/16/20 Hydrants 2-7

5-1/4” K81AM AWWA Guardian Monitor Hydrant

Options Parts List

DETAIL & PART MATERIAL ASTM SPEC (or as stated)

Upper Barrel Configurations K8101 ALEMITE FITTING STAINLESS STEEL A276 (304)

† K8102 OPERATING STEM NUT BRONZE B584 C87850

• 1 Steamer & 2 Hose Nozzles K8103 DIRT SHIELD CAST IRON A126 CLASS B

• 2 Hose Nozzles K8104 STEM LOCK NUT BRONZE B584 C87850

† K8105 O-RING BUNA-N (SYN. RUBBER) D2000

• 2 Steamer Nozzles † K8106 THRUST WASHER NYLATRON GS MIL LP-410

• 1 Steamer & 3 Hose Nozzles K8107 HYDRANT CAP CAST IRON A126 CLASS B

K8108 CAP BOLTS & NUTS STAINLESS STEEL F593C/F594

† K8109 CAP O-RING BUNA-N (SYN. RUBBER) D20000

Handwheel Operation - 16” ø * K8110 STEM FERRULE BRASS B135 C26000

† K8111 O-RING BUNA-N (SYN. RUBBER) D20000

* K8112 O-RING BUNA-N (SYN. RUBBER) D20000

Inlet Connections K8114 UPPER STEM C.R. STEEL A108

• 6” Mechanical Joint, Flanged, Push-on or K8115

K8116

UPPER BARREL

STEM BREAKING COUPLING

CAST IRON

CAST IRON

A126 CLASS B

A126 CLASS B

Ring Tite Elbows K8118 BOLTS & NUTS STAINLESS STEEL F593C/F594

• 6” ANSI Straight Shoe K8119 BREAKING RING CAST IRON A126 CLASS B

K8120 O-RING BUNA-N (SYN. RUBBER) D2000

• 6” 250# Raised Face Elbow K8122R COUPLING PINS STAINLESS STEEL 410

• 8” Mechanical Joint or Flanged Elbow K8123 LOWER STEM C.R. STEEL A108

K8124 LOWER BARREL DUCTILE IRON ANSI 21.50, 21.51

† K8125 ELBOW O-RING BUNA-N (SYN. RUBBER) D2000

2-1/2” Size Independent Hose Gate Valves † K8126A O-RING BUNA-N (SYN. RUBBER) D2000

* K8127 SEAT RING INSERT BRONZE B584 / C87850

• Bolt-on/Figure 109XNS † K8128 SEAT RING BRONZE B584 / C87850

• Screw-on/Figure 109XMN K8129 DRAIN TUBE BRASS B135 C23000

† K8130 O-RING BUNA-N (SYN. RUBBER) D2000

† K8131 MAIN VALVE EPDM

Salt Water Protection K8132 BOTTOM PLATE CAST IRON A126 CLASS B

• Fusion Bonded Coatings K8133

K8134

DRAIN VALVE PIN

ELBOW

STAINLESS STEEL

DUCTILE IRON

410/416

A536 10 70 50 05

• Stainless Steel Stems & Fasteners K8135 ELBOW BOLTS AND NUTS STEEL-302/304 STAINLESS ASTM F593

K8136 DRAIN VALVE BRONZE B806 C95400/C95500

† K8137 DRAIN VALVE FACING W/INSERT BUNA-N W/STAINLESS STEEL D2000/A276 (304)

Operating Details K8138 NOZZLE CHAIN 'S' HOOK STEEL A108

• “Open” Clockwise or Counter Clockwise K8139 NOZZLE CAP CHAIN STEEL A108

K8140 NOZZLE CHAIN BAND STEEL A108

• Any Size & Shape of Operating Nuts † K8141 NOZZLE RETAINING SCREW STAINLESS STEEL A276 (304)

• Any Nozzle Outlet Threads # K8142 NOZZLE: HOSE / STEAMER BRONZE B806 C95400 / B584 C87850

†# K8143 NOZZLE CAP GASKET RUBBER D20000 TYPE AA

# K8144 NOZZLE CAP CAST IRON A126 CLASS B

†# K8145 O-RING BUNA-N (SYN. RUBBER) D20000

K8146 ALLEN HEAD SET SCREW STAINLESS STEEL A276 (410)

K8147 SEAT REMOVAL WRENCH

K8148 NOZZLE REMOVAL TOOLS

† K8149 COLLISION REPAIR KIT

K8150 GRADE EXTENSION KIT

K8151 MONITOR ELBOW-SPECIAL

K8156 BREAKING RING STRAPS

* Denotes that part is available only as part of an assembly.

# Must specify type of Nozzle, Hose or Steamer.

† Recommended spare parts.

3" & 4" SIZED DRILL PATTERNS

PROVIDED PER ANSI B16.1-125#

17.50

Kennedy Valve 7/16/20 Hydrants 2-8

Iron Hose Gate Valves

Working Pressures Parts List

PART NO. NAME OF PART MATERIAL ASTM SPEC

2-1/2” Cold Water, Non-Shock 175 lbs. 1 HEX NUT STEEL A-108 C-1018

• Non-Rising Stem 2 HANDWHEEL MALL. IRON A-47

• Bronze Mounted 3 STUFFING BOX BRONZE B-62

• Rubber Seat

4 HX. HD. SCR. & NUT STEEL A-108 C-1018

5 O-RINGS SYN. RUBBER D-735

Hydrostatic Test Pressure: 2-1/2” - Seat & Shell - 300 psi.

6 CAP BUSHING BRONZE B-135 ALLOY A

7 SEAT & GSKT. FLG. NEOPRENE ---

8 NOZZLE BRONZE B-61

9 CAP CAST IRON A-126 GRADE B

10 STEM MANG. BRZ B-132 ALLOY A

11 GASKET GARLOCK 1591 ---

12 BODY CAST IRON A-126 GRADE B

13 DISC BRONZE B-62

14 PIN BRZ. ROD B-16

FIG. 109XNS SHOWN

FIG. 109XMN (Screwed ends also available)

Kennedy Valve 7/16/20 Hydrants 2-9

K81-A Extension Stem Installation Spool Installation

Extension Coupling

Part No. 4-40776P

(Steel)

Extension Stem

Dwg A-15843

Clevis Pin(s)

Part No. 4-43022P

(2)-Required

(18-8 S’STL)-K8122R

NOTE:

1. All K81 Stems

1.250 DIA

NOTE: It is preferable to be able to turn the water pressure on and off. If the water

pressure is low, it is possible that the hydrant will be opened when removing the upper.

1. Make certain that the hydrant is closed. The water may remain on, but

see above note.

2. Remove the eight 1/2-UNC bolts & nuts that retain the breaking rings.

3. Turn the Operating Nut in the opening direction until the threaded stem disengages

from the Operating Nut. (This will lift the Upper away from the flange).

4. Lift the complete hydrant upper stand-pipe assembly and done from the stem.

List this assembly straight up about 12” to avoid damaging the O-Rings that seal the

stem and remove the complete upper assembly.

5. Disengage the Lower Stem from the Upper Stem. Remove the lower Clevis Pin that

retains the Lower Stem to the Breaking Coupling.

6. Wire brush the exposed flange of the lower stand-pipe until all dirt and

built up rust is removed.

7. Wire brush the end of the Lower Stem and attach the Extension Stem Coupling to

the Lower Stem exactly as illustrated below.

8. Attach the Upper Stem to the Extension Stem in exactly the same way that it was

previously attached to the Lower Stem.

9. Place the Gasket for the Extension Spool on the exposed flange of the

Lower Stand-Pipe. Retain the gasket with grease to keep it from shifting.

10. Place the Extension Spool on the Lower Stand-Pipe and align the bolt holes.

11. Insert the bolts provided in the holes. Start the nuts provided on the bolts. Tighten

the bolts wrist tight only then tighten them securely (70 ft-lb), proceeding in a side

to side pattern that assures that the pressure on the gasket is uniform.

12. Carefully lift the complete upper assembly up above the Upper Stem and lower

it onto the Upper Stem, taking care not to cut the O-Rings in the dome.

13. Turn the Operating Nut in the closed direction until the bottom of the

Stand Pipe just touched the flange.

14. Align the hydrants and replace the breaking rings in the original position.

15. Replace the bolts in the breaking rings in the original position.

16. Start the nuts on the bolts and tighten the bolts per step 11 exept that the

torque should be 40 ft-lb.

Kennedy Valve 7/16/20 Hydrants 2-10

Product / Capability Listing

Suggested Specifications

• Hydrants shall be UL listed and FM approved

• Hydrants shall conform to A.W.W.A. Standard C-502 latest revision and as specified herein.

• Hydrants shall be of the compression type, closing with line pressure.

• Hydrants shall be of the traffic model breakaway type.

• Hydrant cap and stuffing box shall be of a unitized, one piece design creating a water tight

cavity without the use of gaskets. The combination of 3 O-Rings to a crimped brass ferrule

around the stem shall seal the cavity from contact with water. An alemite fitting shall be

supplied for periodic lubrication of the operating threads with grease.

• Operating nut shall be of one piece bronze construction.

• A dirt shield shall be provided to protect the operating mechanism from grit buildup and

corrosion due to moisture.

• A thrust washer shall be supplied between the operating nut and stem lock nut to

facilitate operation.

• Nozzles shall be of the tamper resistant, 1/4 turn type with O-ring seals and stainless

steel retaining screws.

• An O-ring shall be provided to seal between the upper and lower barrels.

• The main valve shall be of synthetic rubber reinforced with steel.

• The seat shall be of a bronze ring threaded to a bronze insert in the hydrant shoe, with O-rings

to seal the drainway and barrel from leakage of water in the shoe.

• Hydrant drain valve shall momentarily force flush with each operation. Drainway shall be of

bronze. Drain valve facing shall be of synthetic rubber with a stainless steel retaining pin.

• Hydrants shall be Guardian as manufactured by Kennedy Valve or approved equal.

Kennedy Valve

Division of McWane

1021 E. Water Street

Elmira, New York 14902-1516

607-734-2211 | Fax: 800-952-4771

Kennedy Valve 7/16/20 Hydrants 2-11

You might also like

- Fire HydrantsDocument22 pagesFire HydrantsRaduNo ratings yet

- KennedyDocument18 pagesKennedyHimat KhimaniNo ratings yet

- Submittal Sheet Kennedy Guardian k81d K81a and K81am 89dfbd8f PDFDocument18 pagesSubmittal Sheet Kennedy Guardian k81d K81a and K81am 89dfbd8f PDFvicvic34No ratings yet

- CAT 3905 en - Triple-Sealed - Bearings - For - Bearing - UnitsDocument15 pagesCAT 3905 en - Triple-Sealed - Bearings - For - Bearing - UnitsJesusNo ratings yet

- 04 Amortiguadores de Rotación ContinuaDocument11 pages04 Amortiguadores de Rotación ContinuajaraozvNo ratings yet

- ROBA-stop - M: Electromagnetic Safety BrakesDocument20 pagesROBA-stop - M: Electromagnetic Safety BrakesRafael LinarezNo ratings yet

- ROBA Stop M General CatalogueDocument20 pagesROBA Stop M General CatalogueBang OchimNo ratings yet

- Flygt 2620 EnglishDocument2 pagesFlygt 2620 Englishedwin martinezNo ratings yet

- THE Manway: Feature Highlights Feature Highlights Feature HighlightsDocument2 pagesTHE Manway: Feature Highlights Feature Highlights Feature HighlightsFelipe OliveiraNo ratings yet

- Catalog TechnorollDocument24 pagesCatalog TechnorollSummA Learning CenterNo ratings yet

- V Ring PDFDocument26 pagesV Ring PDFAnonymous D5QForitcNo ratings yet

- Brands You Trust.: CENTER LINE® - Resilient Seated Butterfly Valves Now All Ductile Iron Body Standard On Series 200Document8 pagesBrands You Trust.: CENTER LINE® - Resilient Seated Butterfly Valves Now All Ductile Iron Body Standard On Series 200Yamil Diaz SantosNo ratings yet

- Butterfly Valve Q 011Document4 pagesButterfly Valve Q 011JOHNNo ratings yet

- MA Stewart L-D-4-S-E-LH Butterfly Valves Drawings and SpecificationsDocument8 pagesMA Stewart L-D-4-S-E-LH Butterfly Valves Drawings and SpecificationsFawn DixonNo ratings yet

- Flygt 2670 Dewatering Pump: Designed Without CompromiseDocument2 pagesFlygt 2670 Dewatering Pump: Designed Without CompromiseEdy Renato Zapeta100% (1)

- Series 2200 Butterfly Valve Product BrochureDocument18 pagesSeries 2200 Butterfly Valve Product BrochureSandesh KambleNo ratings yet

- BSF - CT 4281-8 in - 36-5 PDFDocument6 pagesBSF - CT 4281-8 in - 36-5 PDFHugh O'Brien GwazeNo ratings yet

- Mayr K - 891 - v17 - en - 26 - 03 - 2018Document32 pagesMayr K - 891 - v17 - en - 26 - 03 - 2018David ArgentinNo ratings yet

- Type Butterfly Valve (Wafer Type)Document34 pagesType Butterfly Valve (Wafer Type)rizkydjonhansemitNo ratings yet

- Ductile Iron/Stainless Steel Cylinders Quarter-Turn Spring Return and Double Acting Actuators Output Torques To 238,000 LB - inDocument12 pagesDuctile Iron/Stainless Steel Cylinders Quarter-Turn Spring Return and Double Acting Actuators Output Torques To 238,000 LB - inCapacitacion TodocatNo ratings yet

- Diamond Power IR-3Z: Furnace Wall SootblowerDocument4 pagesDiamond Power IR-3Z: Furnace Wall SootblowerGỗ MộcNo ratings yet

- E101 3236 IR 3Z SootblowerDocument4 pagesE101 3236 IR 3Z SootblowerKartika SuryawanNo ratings yet

- Rex DWC Catalogue IS-14930..Document2 pagesRex DWC Catalogue IS-14930..ajeetNo ratings yet

- Thern Ta2 Air Winch PressDocument2 pagesThern Ta2 Air Winch PressKiat LimNo ratings yet

- CORTEC Compact Valves - Critical ServiceDocument2 pagesCORTEC Compact Valves - Critical ServiceAndresNo ratings yet

- PM PRO Non-AdjustableDocument26 pagesPM PRO Non-AdjustableKarimZianiNo ratings yet

- Flygt Bs 2640 MT 226 5 6 KW 7 5 HP Salida 4Document2 pagesFlygt Bs 2640 MT 226 5 6 KW 7 5 HP Salida 4MartinTPNo ratings yet

- Durilock Marketing Bulletin PELJ0343Document7 pagesDurilock Marketing Bulletin PELJ0343Patricio AlvaradoNo ratings yet

- ROBA-stop - M: Your Reliable PartnerDocument28 pagesROBA-stop - M: Your Reliable PartneruripssNo ratings yet

- 2022 Meteor GMA - CompressedDocument5 pages2022 Meteor GMA - CompressedIngrid Trindade , Acessorios Royal Enfield VINo ratings yet

- Technical Insight: Bearings SealsDocument4 pagesTechnical Insight: Bearings SealsRitche Lim BragaisNo ratings yet

- Louvre DamperTandem DamperengfinDocument16 pagesLouvre DamperTandem DamperengfinDan PascaruNo ratings yet

- GT S 8000 BrochureDocument8 pagesGT S 8000 Brochurea100acomNo ratings yet

- 8290 SERIES: Angle Body Piston ValvesDocument12 pages8290 SERIES: Angle Body Piston ValvesCarlos Giovanni Camperos GaitanNo ratings yet

- Auslite Iii Gate Valves-Handwheel: Resilient Seated - DN 80 To DN 400Document3 pagesAuslite Iii Gate Valves-Handwheel: Resilient Seated - DN 80 To DN 400Akshat JainNo ratings yet

- NelesfinetrolDocument14 pagesNelesfinetrolsan21No ratings yet

- Spare Ring Is Easily Activated Without DisassemblingDocument2 pagesSpare Ring Is Easily Activated Without DisassemblingKjsNo ratings yet

- L&J 94020-2BDocument8 pagesL&J 94020-2BBureau VeritasNo ratings yet

- D-Series Rack & Pinion Pneumatic ActuatorsDocument6 pagesD-Series Rack & Pinion Pneumatic ActuatorsJandri JacobNo ratings yet

- NSK PreventingCreepOnSubmersiblePumpBearings PDFDocument2 pagesNSK PreventingCreepOnSubmersiblePumpBearings PDFSaikat PurkaitNo ratings yet

- Ace Sanitary 2010 CatalogDocument16 pagesAce Sanitary 2010 CatalogJosh LeBlancNo ratings yet

- OME Application Guide - Katalog Zawieszenia OME - 10-2017Document165 pagesOME Application Guide - Katalog Zawieszenia OME - 10-2017promuxaiicNo ratings yet

- Catalogo OMEDocument168 pagesCatalogo OMEDiego Pineda100% (1)

- Triple-Sealed Bearings For Bearing Units: CAT. No. 3905-@ EDocument16 pagesTriple-Sealed Bearings For Bearing Units: CAT. No. 3905-@ ELuis Carlos FerréNo ratings yet

- Asco Series 290 Angle Body Full CatalogDocument12 pagesAsco Series 290 Angle Body Full CatalogJuan Sebastián BustosNo ratings yet

- Omega-ITT Goulds Argumentation enDocument5 pagesOmega-ITT Goulds Argumentation enAlvialvarezNo ratings yet

- N Lockscrew Assembly - PDS0070 - REVDocument2 pagesN Lockscrew Assembly - PDS0070 - REVvinayakbankarNo ratings yet

- 12 - Cast Iron Tapping MachinesDocument14 pages12 - Cast Iron Tapping MachinesaurabloodNo ratings yet

- I-Tork PDS CatalogDocument12 pagesI-Tork PDS CatalogAnisVisuNo ratings yet

- Roba - Stop - M: Your Reliable PartnerDocument20 pagesRoba - Stop - M: Your Reliable PartnerCaio DiasNo ratings yet

- Inverter Drive and Vector Drive Motors: Made in The U.S.ADocument24 pagesInverter Drive and Vector Drive Motors: Made in The U.S.APedroNo ratings yet

- Rotary Seals Vrings - PD PDFDocument25 pagesRotary Seals Vrings - PD PDFAnonymous D5QForitcNo ratings yet

- Data AL Series Threaded Insert DataDocument3 pagesData AL Series Threaded Insert DataJuan RamirezNo ratings yet

- BMV Brochure 4 Page Web - 2019Document4 pagesBMV Brochure 4 Page Web - 2019Velibor StokicNo ratings yet

- Baier-Rail-Brochure-V2 r4 2022 ProtectedDocument2 pagesBaier-Rail-Brochure-V2 r4 2022 ProtectedFelipe OliveiraNo ratings yet

- Pressure SwitchesDocument4 pagesPressure SwitcheshaggNo ratings yet

- Plastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965From EverandPlastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965No ratings yet

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsFrom EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsRating: 5 out of 5 stars5/5 (1)

- Geotextiles and Geomembranes HandbookFrom EverandGeotextiles and Geomembranes HandbookT.S. IngoldRating: 5 out of 5 stars5/5 (1)

- KW900WFPDocument1 pageKW900WFPAlfredo BravoNo ratings yet

- Manual Bristle Blaster Electric DoubleDocument76 pagesManual Bristle Blaster Electric DoubleAlfredo BravoNo ratings yet

- Asme Sección Viii d1 IndexDocument9 pagesAsme Sección Viii d1 IndexAlfredo BravoNo ratings yet

- ASME B31.4 Design Minimum Wall ThicknessDocument6 pagesASME B31.4 Design Minimum Wall ThicknessAlfredo BravoNo ratings yet

- Asme9 AppendicesDocument30 pagesAsme9 Appendiceskmas1612No ratings yet

- MECH - Valvula de Compuerta OSY XZ41XDocument1 pageMECH - Valvula de Compuerta OSY XZ41XAlfredo BravoNo ratings yet

- Mantenimiento de Brazos de CargaDocument38 pagesMantenimiento de Brazos de CargaAlfredo BravoNo ratings yet

- PFI ES 24 2001 Pipe Bending MethodsDocument9 pagesPFI ES 24 2001 Pipe Bending MethodsAlfredo BravoNo ratings yet

- Pfi-Es-3 (2000) PDFDocument4 pagesPfi-Es-3 (2000) PDFBarnum Pebble Darrel100% (1)

- Api 5L / Astm A53: RIF J295368682Document7 pagesApi 5L / Astm A53: RIF J295368682OPAZOSCNo ratings yet

- Astm A 962 16aDocument12 pagesAstm A 962 16aDaryna KupriianovaNo ratings yet

- BridasDocument3 pagesBridasClaudio Jara EncaladaNo ratings yet

- BS EN ISO 13920-1997 Welding-General Tolerances For Welded Constructions Dimensions For Lengths and Angles-Shape and PositionDocument14 pagesBS EN ISO 13920-1997 Welding-General Tolerances For Welded Constructions Dimensions For Lengths and Angles-Shape and PositionAlfredo Bravo0% (1)

- Guia de Autoevaluacion AmbientalDocument6 pagesGuia de Autoevaluacion AmbientalSergio LorenzoNo ratings yet

- Catalogo de Reducciones Excentricas y ConcentricasDocument1 pageCatalogo de Reducciones Excentricas y ConcentricasAlfredo BravoNo ratings yet

- Catalogo de Reducciones Excentricas y ConcentricasDocument1 pageCatalogo de Reducciones Excentricas y ConcentricasAlfredo BravoNo ratings yet

- Cat 17Document1 pageCat 17Alfredo BravoNo ratings yet

- Safety Data SheetDocument9 pagesSafety Data SheetAlfredo BravoNo ratings yet

- Nema Ab 1-1986Document45 pagesNema Ab 1-1986Ulysses OreiroNo ratings yet

- Guia de Autoevaluacion AmbientalDocument6 pagesGuia de Autoevaluacion AmbientalSergio LorenzoNo ratings yet

- 400Y Torrent Engineering - v27 PDFDocument16 pages400Y Torrent Engineering - v27 PDFKrishna N HNo ratings yet

- Nema Ab 1-1986Document45 pagesNema Ab 1-1986Ulysses OreiroNo ratings yet

- FM Global Property Loss Prevention Data Sheets: List of FiguresDocument8 pagesFM Global Property Loss Prevention Data Sheets: List of Figuresthongtn2007No ratings yet

- Ga DrawingDocument37 pagesGa DrawingRey OchavilloNo ratings yet

- 100 Series PyroDocument8 pages100 Series PyroomkarvadlooriNo ratings yet

- HDUDADocument126 pagesHDUDAAbhishek DalabanjanNo ratings yet

- Diferrent Lubrication Techniques Being Adopted in Wire DrawingDocument5 pagesDiferrent Lubrication Techniques Being Adopted in Wire DrawingRaghu ChowdaryNo ratings yet

- July 2022 Past Board (Similar Questions)Document15 pagesJuly 2022 Past Board (Similar Questions)Harold GarciaNo ratings yet

- H 002 CRDocument12 pagesH 002 CRmra1982No ratings yet

- Catalogo RICAMBI SPARE PARTS Catalogue Catalogo de Piezas de Repuesto Catalogue de PIECES DETACHEES ErsatzteilkatalogDocument168 pagesCatalogo RICAMBI SPARE PARTS Catalogue Catalogo de Piezas de Repuesto Catalogue de PIECES DETACHEES ErsatzteilkatalogАлексей100% (1)

- VIBROFLOTATIONDocument39 pagesVIBROFLOTATIONSOLOMON T. OMITOGUNNo ratings yet

- 1994 Lee & Lee - Local Buckling of Steel Sections Under Cyclic LoadingDocument16 pages1994 Lee & Lee - Local Buckling of Steel Sections Under Cyclic LoadingAKNo ratings yet

- Asme BPVC - Ssc.iv - Ii.v.ix - Xiii-2023Document42 pagesAsme BPVC - Ssc.iv - Ii.v.ix - Xiii-2023mmendozagNo ratings yet

- 19 - Beam ColumnsDocument95 pages19 - Beam ColumnsArfan HaiderNo ratings yet

- Section 4. Bidding FormsDocument24 pagesSection 4. Bidding Formsfilomeno martinsNo ratings yet

- The Modern Field Development ApproachDocument9 pagesThe Modern Field Development ApproachEyoma Etim100% (2)

- Quality Tests RequirementDocument6 pagesQuality Tests RequirementSandip PaulNo ratings yet

- E272 PDFDocument4 pagesE272 PDFsreemoy123100% (1)

- Measurement of Payment (Insulation Work)Document4 pagesMeasurement of Payment (Insulation Work)Steven JosephNo ratings yet

- Aa 036322 001 PDFDocument1 pageAa 036322 001 PDFErin JohnsonNo ratings yet

- Elev. Penthouse Plan: Mechanical Hvac For G/F, 2/F, 3/F and Upper 3Rd FloorDocument1 pageElev. Penthouse Plan: Mechanical Hvac For G/F, 2/F, 3/F and Upper 3Rd FloorJan Kenneth BarazonNo ratings yet

- Link BeamDocument8 pagesLink BeamNeil SonNo ratings yet

- RCD Module 2 NSCP Updates and OthersDocument47 pagesRCD Module 2 NSCP Updates and OthersHannylet OcateNo ratings yet

- Muhammad Awais: ContactDocument1 pageMuhammad Awais: ContactMian AwaisNo ratings yet

- Material SpecificationDocument12 pagesMaterial SpecificationmehrNo ratings yet

- A. Hardened Concrete (Non-Destructive Tests) : The SAC Programme Is Managed by Enterprise SingaporeDocument2 pagesA. Hardened Concrete (Non-Destructive Tests) : The SAC Programme Is Managed by Enterprise Singaporeng chee yongNo ratings yet

- CIAP Document 102 - PrimerDocument18 pagesCIAP Document 102 - Primerfreanne_0527No ratings yet

- A Case Study of TanzaniaDocument9 pagesA Case Study of Tanzaniaaklilu ayalewNo ratings yet

- Polypropylene (PP) Corrugated Wall Stormwater Collection ChambersDocument7 pagesPolypropylene (PP) Corrugated Wall Stormwater Collection Chambersastewayb_964354182No ratings yet

- Guidelines For Telecommunications Structures v1.0 - NSW GovernmentDocument29 pagesGuidelines For Telecommunications Structures v1.0 - NSW GovernmentruayoNo ratings yet

- MTF Organic Agriculture ProductionDocument16 pagesMTF Organic Agriculture ProductionJeanivy Maneja100% (2)

- Mumbai Port Trust: Tender No.Document246 pagesMumbai Port Trust: Tender No.suji91No ratings yet

- Valvulas de Bola PDFDocument9 pagesValvulas de Bola PDFChristian VegaNo ratings yet