100% found this document useful (7 votes)

46K views4 pagesSpring Constant Experiment

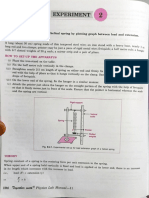

To determine the force constant of a helical spring, weights were added to extend the spring and measurements were recorded. A graph of force versus extension produced a straight line, and the slope equaled the force constant. The experiment found the force constant of the spring to be 100 g per cm.

Uploaded by

RacCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

100% found this document useful (7 votes)

46K views4 pagesSpring Constant Experiment

To determine the force constant of a helical spring, weights were added to extend the spring and measurements were recorded. A graph of force versus extension produced a straight line, and the slope equaled the force constant. The experiment found the force constant of the spring to be 100 g per cm.

Uploaded by

RacCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

- Experiment Aim: Describes the objective of the experiment, focusing on finding the force constant of a helical spring by plotting a graph between load and extension.

- Theory: Explains the theoretical background of the experiment, including the concept of proportionality and calculating the spring constant.

- Apparatus: Lists the equipment and materials needed to perform the experiment, including spring, weights, scale, and others.

- Procedure: Outlines the step-by-step experimental procedure for measuring and recording the effect on the spring under varying loads.

- Observations: Describes the observations made during the experiment, emphasizing data on load and extension.

- Graph: Details the method of plotting a graph between force and extension to visually determine the spring constant.

- Result: Presents the calculated force constant of the spring based on experimental data and graph analysis.

- Sources of Error: Identifies potential sources of error in the experiment that could impact data accuracy.

- Precautions: Provides precautionary measures to ensure accurate results and maintain the integrity of the experiment.