Professional Documents

Culture Documents

Solvoya D5936-X TDS

Uploaded by

Osama GabrOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Solvoya D5936-X TDS

Uploaded by

Osama GabrCopyright:

Available Formats

Technical Datasheet Liquid Coating Resins and Additives

Solvoya® D5936-X Edition 04-2020

Solvoya® D5936-X is a standard short oil air-dry alkyd resin based on Soya bean oil or Soya Fatty Acid - available in solids from 60% to 70 ± 1% in Xylene

Mode of application: Air physical dry, Bake, NC and/or catalyzed dry.

PERFORMANCE & APPLICATIONS

▪ Good weathering & color retention durability ▪ Used for undercoat enamels, stoving enamels (100°C - 140°C)

▪ Excellent adhesion properties ▪ Recommended 2K PU for wood finish

▪ Excellent drying properties with tough film and abrasion resistance ▪ Recommended for Structural steel paints & NC – lacquers

SUPPLY SPECIFICATIONS

▪ Delivery form 60.0 ± 1%

▪ Dilution form 60.0 ± 1%

▪ Acid value mg KOH/gm solid 12.0 max.

▪ Gardner viscosity at 25°C Approx. Z2 at 60%

▪ Brookfield approx. viscosity at 25°C Approx. 3,600 CP at 60%

▪ OH-Content (Per solids) 2.90%

▪ Gardner Color Scale DIN EN ISO 6271-1 5.0 max.

TYPICAL COMPOSITION

▪ Phthalic anhydride content 40%

▪ Type of oil Soya bean oil or Soya Fatty Acid

▪ Oil Content 41%

▪ Type of Polyol Glycerin

▪ Type of Solvent(s) Xylene

SPECIFIC PROPERTIES

▪ Aliphatic hydrocarbon Insoluble ▪ Zinc white Incompatible

▪ Aromatic hydrocarbon Soluble ▪ Red Lead Incompatible

▪ Chlorinated hydrocarbon Soluble ▪ Nitrocellulose Compatible

▪ Alcohols Limited solubility ▪ Chlorinated rubber Incompatible

▪ Esters Soluble ▪ Stand oil Limited compatibility

▪ Ketones Soluble ▪ Isocyanate Compatible

▪ Glycol-ethers & esters Soluble ▪ Urea/melamine resins Limited compatibility

STORAGE

Solvoya® D5936-X is stable at temperatures up to 30 °C when packed in original containers, Exposure to sun shine should be avoided.

STABILITY

Solvoya® D5936-X is stable for more than 24 months from the date of production mentioned on the pack of each patch, with reference to the above

mentioned storage conditions.

REMARKS

▪ For Ideal Drying time test results, EBCA recommends testing after 48 hours from adding the driers to the paint (min. 24 hours).

▪ The combinations must be tested for their compatibility

Egyptian British Company maintains Material Safety Data sheets (MSDS) on all of its products. These contain important information that you may need to protect your employees and customers against any known health

and safety hazards associated with our products. We recommend you obtain copies of MSDS for our products, from our technical representative, and obtain copies of MSDS from your suppliers of other raw materials used

with our products.

All rights are reserved for Egyptian British Co.

You might also like

- MSDSTransocean Alkyd Thinner 6.00 (EGY) - EN48Document9 pagesMSDSTransocean Alkyd Thinner 6.00 (EGY) - EN48Osama GabrNo ratings yet

- Paintex Acico GlossDocument3 pagesPaintex Acico GlossOsama GabrNo ratings yet

- Acico Matt 30300Document3 pagesAcico Matt 30300Osama GabrNo ratings yet

- PAINTEX ACICO Matt 2Document3 pagesPAINTEX ACICO Matt 2Osama GabrNo ratings yet

- Paintex Acico Gloss 2Document3 pagesPaintex Acico Gloss 2Osama GabrNo ratings yet

- PuttyDocument2 pagesPuttyOsama GabrNo ratings yet

- Solvoya® D6518-X: Technical DatasheetDocument1 pageSolvoya® D6518-X: Technical DatasheetOsama GabrNo ratings yet

- Solvoya l3865-Wk TdsDocument1 pageSolvoya l3865-Wk TdsOsama GabrNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5796)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Chem Trend Thermoplastics-Product-Selector-Guide PDFDocument5 pagesChem Trend Thermoplastics-Product-Selector-Guide PDFbap06No ratings yet

- DPF Lab Report (8-13)Document25 pagesDPF Lab Report (8-13)Jisun AhmedNo ratings yet

- 20 Jul 2018 153328220AELG1KSWAnnexure-Pre-feasibilityReport (PFR) FileDocument56 pages20 Jul 2018 153328220AELG1KSWAnnexure-Pre-feasibilityReport (PFR) FileMohitNo ratings yet

- Journal of Food Engineering: Andrea Mahn, Constanza Martin, Alejandro Reyes, Aldo SaavedraDocument7 pagesJournal of Food Engineering: Andrea Mahn, Constanza Martin, Alejandro Reyes, Aldo SaavedraAchmad NaufalNo ratings yet

- Aatcc TM20-2021Document20 pagesAatcc TM20-2021Kunal ShingalaNo ratings yet

- Beta-Vulgares Lab ReportDocument9 pagesBeta-Vulgares Lab Reportadamnahar24No ratings yet

- Physical Properties and Chemical Reactions ofDocument9 pagesPhysical Properties and Chemical Reactions ofTUANA DURMAYÜKSELNo ratings yet

- 2113 PharmacognosyDocument36 pages2113 Pharmacognosypankaj chaudhary100% (1)

- BUZIL SD G481 en-GB V4-1Document9 pagesBUZIL SD G481 en-GB V4-1JeSuSkopjeNo ratings yet

- Guidance Materials For Organic Crop Production: Acetic Acid AlcoholDocument24 pagesGuidance Materials For Organic Crop Production: Acetic Acid AlcoholEcoAgricola ConsultoresNo ratings yet

- 1001 CPC-Quick CouplingsDocument51 pages1001 CPC-Quick CouplingsSanthoshNo ratings yet

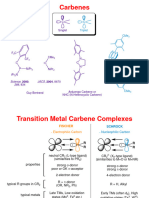

- 7 - Carbene Carbyne Carbide ComplexesDocument8 pages7 - Carbene Carbyne Carbide ComplexesNandini GattadahalliNo ratings yet

- Inorganic and Organic ChemistryDocument8 pagesInorganic and Organic ChemistryValerie BorrioNo ratings yet

- Metamino: Dl-Methionine, Feed Grade 99 %Document2 pagesMetamino: Dl-Methionine, Feed Grade 99 %Ricardo Diaz NiñoNo ratings yet

- Rudolf Hausmann Auth. To Grasp The Essence of Life A History of Molecular BiologyDocument342 pagesRudolf Hausmann Auth. To Grasp The Essence of Life A History of Molecular BiologyJúnior MagalhãesNo ratings yet

- P Block 13 - 14 - Eklavya (Q)Document12 pagesP Block 13 - 14 - Eklavya (Q)Dhruv KuchhalNo ratings yet

- Biojet - Palm OilDocument13 pagesBiojet - Palm Oilscorpion2001glaNo ratings yet

- Molecules: Biodiversity, Biochemical Profiling, and Pharmaco-Commercial Applications of Withania Somnifera: A ReviewDocument27 pagesMolecules: Biodiversity, Biochemical Profiling, and Pharmaco-Commercial Applications of Withania Somnifera: A ReviewWinny KemNo ratings yet

- 1 Identification of Organic and Inorganic CompoundsDocument3 pages1 Identification of Organic and Inorganic CompoundsJuan Pablo Carrasco Ferra MartínezNo ratings yet

- Biochemistry McqsDocument19 pagesBiochemistry McqsMuskan warisNo ratings yet

- Abjna 3 4 145 149Document5 pagesAbjna 3 4 145 149chunibyoxdelusionsNo ratings yet

- General Organic ChemistryDocument29 pagesGeneral Organic ChemistryBombay TechnologyNo ratings yet

- Protein BiokimiaDocument44 pagesProtein BiokimiaAdnindya JeehanNo ratings yet

- Lesson 6 Limiting ReactantsDocument23 pagesLesson 6 Limiting ReactantsJabeguero Marvelyn Jessica100% (1)

- The Chemistry of LifeDocument113 pagesThe Chemistry of LifeDeron C. De CastroNo ratings yet

- Vertical Farming: A Revolution To Sustainable Agriculture: Cps41@pitt - Edu Iss33@pitt - EduDocument9 pagesVertical Farming: A Revolution To Sustainable Agriculture: Cps41@pitt - Edu Iss33@pitt - EduShilpa MaratheNo ratings yet

- 06 Assign-57 To 67 Grignard Reagent OC JEE TEASDocument18 pages06 Assign-57 To 67 Grignard Reagent OC JEE TEASMOKSH AGARWALNo ratings yet

- Word Sarcina TermicaDocument3 pagesWord Sarcina TermicaSergiu AlupoaeNo ratings yet

- Chapter 7 TEST BANK Chapter 7 TEST BANKDocument61 pagesChapter 7 TEST BANK Chapter 7 TEST BANKangelineNo ratings yet

- Exam Final SugralionaDocument1 pageExam Final SugralionaDaniyar TemirovNo ratings yet