Professional Documents

Culture Documents

How Ambuja Cement Manufactures and Innovates

Uploaded by

Anand Medical0 ratings0% found this document useful (0 votes)

15 views6 pagesOriginal Title

Fazila Hussain

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

15 views6 pagesHow Ambuja Cement Manufactures and Innovates

Uploaded by

Anand MedicalCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 6

HOW TO MANUFACTURE OF ANMBUJA CEMENT

[ABOUT AMBUJA CEMENT]

Ambuja Cements Ltd., a member of Holcim - global leader in

innovative and sustainable building solutions, is among the leading

cement companies in India. Ambuja Cement has provided hassle-

free, home-building solutions with its unique sustainable

development projects and environment-friendly practices since it

started operations. Currently, Ambuja Cement has a cement capacity

of 31 million tonnes with six integrated cement manufacturing plants

and eight cement grinding units across the country.

The company has many firsts to its credit – a captive port with four

terminals that has facilitated timely, cost-effective, cleaner

shipments of bulk cement to its customers. To further add value to

our customers, the company has launched innovative products like

Ambuja Roof Special, Ambuja Cool Walls, Ambuja Kawach and

Ambuja Cement Compocem. The new products not only fulfil

important customer needs but also help in significantly reducing

caAmbuja Cement is the industry leader in responsible use of

resources, both natural and man-made. The company has been

certified over eight times water positive, a feat achieved through

conservation efforts and increasing water efficiency in its plants. It is

also plastic negative, by burning as much as over 75,000 tonnes of

plastic waste in its kilns, equivalent to 2.5 times of total plastic used.

The company also generated 7.1% of its power needs from

renewable resources.

Sustainable profitable growth is ingrained in the company’s DNA.

Ambuja Cement’s multi-pronged strategy, including triple bottom

line accounting method; True Value; good corporate governance

practices; overarching corporate environment policy; and sustainable

supply chain policy have helped cement the company's credentials as

a sustainable manufacturer. Ambuja Cement's Sustainable

Development Ambition 2030 provides strategic direction to the

company's long-term sustainability vision. All Ambuja Cement plants

are ISO 14001 certified.

Ambuja Knowledge Centres (AKCs), a unique initiative by the

company, serves as a knowledge sharing platform for construction

professionals that includes practical workshops on mix design and

quality supervision. Currently, over 30 AKCs are functional across

India.

The company also works closely with communities that live around

its plants, through its CSR arm, the Ambuja Cement Foundation

(ACF). ACF implements need-based and participatory programmes in

the thematic areas of water resource development, health and

sanitation, women empowerment, rural infrastructure, education

and agro-based/skill-based livelihood creation.

The company's most distinctive attribute is its approach to business.

Ambuja Cement follows a unique homegrown philosophy that

gives people the authority to set their own targets and the freedom

to achieve their goals. Its focus has been consistent on two major

building blocks that has resonated through its daily operations –

Quality (of products) and Safety (of all those involved in the creation

of its products).

PRODUCT & SERVICES

An established brand in India, Ambuja Cement is known for its high

strength, high performance Ordinary Portland Cement (OPC) and

Pozzolana Portland Cement (PPC). OPC & PPC both are high quality

active hydraulic binders & are preferred brands in the market for all

the construction applications. The company currently has a

manufacturing capacity of 29.65 million tonnes.

Innovation – the hallmark of Ambuja Cement since its inception – has

helped it develop technology to produce cement of consistent

quality from diverse raw materials. About 25 per cent of the

company’s production of high strength Portland Pozzolana Cement

(PPC) uses fly ash – a waste produced in thermal power plants – as

raw material. PPC currently constitutes 93 percent of the company’s

product portfolio.

Ambuja was the first to introduce 53-grade cement in the market. By

benchmarking quality standards for the industry, Ambuja became

the first cement company to receive the ISO 9002 quality

certification.

Through use of state-of-the-art technology and strong thrust on

research and development, Ambuja Cement has developed products

to cater to its three customer segments – Individual House Builders,

Masons and Contractors, and Professionals.

Ambuja Compocem

At Ambuja we’ve always looked to create the strongest cement, with

the lightest carbon footprint. By creating an innovative product line,

Ambuja is bringing sustainability to people’s homes.

In February 2017, Ambuja became the first cement company in India

to launch Portland Composite Cement (PCC). The uniqueness of this

product was a formula that contained an optimum combination of fly

ash and slag – both waste products. This allowed the substitution of

natural materials. It was the result of over 18 months of R&D on

cement quality. Yet it began with a challenge, to create a unique

cement that was lighter in colour without compromising on strength.

And the result was a premium product, Compocem, that was

successfully launched in the eastern markets of India.

Ambuja Buildcem

Ambuja developed an innovative way of using fly ash to produce high

strength Portland Pozzolana Cement (PPC) and branded it as Ambuja

Buildcem which helps in building strong and durable structures.

Pozzolana such as fly ash is essentially a siliceous material which

while in itself possessing little or no cementitious properties, will in

finely divided form and in the presence of water, react with calcium

hydroxide at ambient temperature to form compounds possessing

cementitious properties. Ambuja Buildcem meets all applicable

Chemical & Physical requirements as per the IS specification - IS

1489: Product Benefits:

1.Minimum Compressive strength at 28 days is more than 53 MPa –

Economical Construction

2.Dense micro structure (High Strength)

3.Consistent Quality

4.Improved Workability

5.High long term Strength

6.High chemical resistance (sea water, chloride diffusion, sulphate

attack, etc.)

7.Low Permeability (Durable Construction)

8.Improved Pumpability and Compactability

9.Lower heat of hydration

10.Sustainable

- Conservation of natural resources

- Less CO2 production

- Reduction of waste by consumption of fly ash

11.Reduces bleeding and segregation

Uses:

Roads & bridges

Marine & Hydraulic construction

Multi-storied buildings, Residential, Commercial,

Institutional, industrial buildings

Metro rail construction

Massive structure as dams, thick foundation etc.

Pre-cast

Sewers and sewage disposal works, masonry mortars

and grouts

Plastering

Flooring

Repairs & renovation

You might also like

- Ambuja Kawach CementDocument2 pagesAmbuja Kawach CementParshwa ConsultancyNo ratings yet

- Ambuja Cements India's Leading Cement MakerDocument6 pagesAmbuja Cements India's Leading Cement Makeryudhishther100% (1)

- AmbujaDocument46 pagesAmbujashefalikhandelwalNo ratings yet

- Recruitment Process in ACC CEMENTDocument83 pagesRecruitment Process in ACC CEMENTAmit PasiNo ratings yet

- Ambuja Cement Limited ReportDocument76 pagesAmbuja Cement Limited ReportMr. AnikNo ratings yet

- Acc CementDocument30 pagesAcc CementNVNVNVNV43% (7)

- ACC Cement LakheriDocument54 pagesACC Cement Lakherikeshav181100% (4)

- Acc CementDocument30 pagesAcc CementSoumava MitraNo ratings yet

- Project Report: A Study of Channel SatisfactionDocument103 pagesProject Report: A Study of Channel SatisfactionrultheworldNo ratings yet

- Recruitment Process in ACC CEMENTDocument48 pagesRecruitment Process in ACC CEMENTAmit Pasi100% (2)

- Ambuja CementDocument20 pagesAmbuja CementArvindYadavNo ratings yet

- Shivu Company AnalysisDocument37 pagesShivu Company AnalysisSuhail DastanNo ratings yet

- Orient Cements: Company ProfileDocument7 pagesOrient Cements: Company ProfileAkshay SharmaNo ratings yet

- Synopsis of Analysis of Ambuja Cement: Submitted byDocument5 pagesSynopsis of Analysis of Ambuja Cement: Submitted byVividh BansalNo ratings yet

- Tripura University (A Central University) : Material Science & Engineering M. Tech 2 Semester Session-2020-2021Document16 pagesTripura University (A Central University) : Material Science & Engineering M. Tech 2 Semester Session-2020-2021Abhijit RoyNo ratings yet

- Business Marketing Group Assignment Company: ACC Limited: Submitted byDocument11 pagesBusiness Marketing Group Assignment Company: ACC Limited: Submitted byHasan ArmoghanNo ratings yet

- ACC Limited AnalysisDocument10 pagesACC Limited Analysisjawahar_8888No ratings yet

- History: Business Superbrands-2nd Edition (Main) 8/26/08 1:04 AM Page 8Document2 pagesHistory: Business Superbrands-2nd Edition (Main) 8/26/08 1:04 AM Page 8Prafulla TekriwalNo ratings yet

- Value Chain Analysis of Your CompanyDocument39 pagesValue Chain Analysis of Your Companyanon_209752096100% (3)

- M&a Project Group-2Document21 pagesM&a Project Group-2mounicaNo ratings yet

- Capacity Planning-Operations Management ReportDocument30 pagesCapacity Planning-Operations Management Reportnafees39100% (2)

- Thomas Armstrong - Concrete Blocks Brochure Jan 2013 - Web VersionDocument44 pagesThomas Armstrong - Concrete Blocks Brochure Jan 2013 - Web VersionTrilok Chand GuptaNo ratings yet

- Cement: The RightDocument46 pagesCement: The RightSimon ChawingaNo ratings yet

- TT 88Document14 pagesTT 88Kunal KhatriNo ratings yet

- ACC's Ready Mix Mortar Project Management ReportDocument18 pagesACC's Ready Mix Mortar Project Management ReportPiyush Singh PrasannaNo ratings yet

- Media Release: ACC Launches Concrete+'Document1 pageMedia Release: ACC Launches Concrete+'muraliNo ratings yet

- Ambuja Cements: India's Most Profitable Cement CompanyDocument1 pageAmbuja Cements: India's Most Profitable Cement CompanyKartikay VaishnavNo ratings yet

- My Home Industries Limited (MHIL) Summer InternshipDocument36 pagesMy Home Industries Limited (MHIL) Summer InternshipNaveen KumarNo ratings yet

- Ambuja Report 2Document13 pagesAmbuja Report 2JigarNo ratings yet

- Project Report On Summer TrainingDocument60 pagesProject Report On Summer Trainingmittu720No ratings yet

- Operations Management: Operations Excellence of Ambuja Cement LTDDocument6 pagesOperations Management: Operations Excellence of Ambuja Cement LTDPratyus Kumar PandaNo ratings yet

- MarketDocument2 pagesMarketPritish EkkaNo ratings yet

- Industrial Training Report AtulDocument24 pagesIndustrial Training Report AtulShubham100% (3)

- ReportDocument27 pagesReportVital sardharaNo ratings yet

- Concrete SolutionsDocument27 pagesConcrete SolutionsRollyn Mae Garcia BasbañoNo ratings yet

- Report 2Document11 pagesReport 220Soniya BajajNo ratings yet

- Environmental Impact Analysis: A Case Study of Acc Cement Plant AbstractDocument14 pagesEnvironmental Impact Analysis: A Case Study of Acc Cement Plant AbstractMintoo VermaNo ratings yet

- Manipal University Jaipur: Report of Minor Project ONDocument25 pagesManipal University Jaipur: Report of Minor Project ONmanavNo ratings yet

- Total Quality Control in Prism Cement ProductionDocument67 pagesTotal Quality Control in Prism Cement ProductionVickram JainNo ratings yet

- Company ProfileDocument8 pagesCompany ProfileAdnanNo ratings yet

- Autoclaved Aerated Concrete ReportDocument11 pagesAutoclaved Aerated Concrete ReportAbhinavNo ratings yet

- India's Leading Cement Manufacturer ACC Company ProfileDocument2 pagesIndia's Leading Cement Manufacturer ACC Company Profilekaaviya6No ratings yet

- Shah CementDocument10 pagesShah CementKamil Al Ashik 1610289630No ratings yet

- Shah CementDocument10 pagesShah CementKamil Al Ashik 1610289630No ratings yet

- Final Na Inin Jama Sa Feasibility StudyDocument8 pagesFinal Na Inin Jama Sa Feasibility StudyEstiven GierNo ratings yet

- ACC Cement Brand History and AchievementsDocument2 pagesACC Cement Brand History and AchievementsAnurag Singh RathourNo ratings yet

- Catalogue of Products and ServicesDocument89 pagesCatalogue of Products and ServicesdanbelaNo ratings yet

- Quality Control in Birla Cement NewDocument16 pagesQuality Control in Birla Cement NewAman Mishra100% (1)

- Strategic Procurement and SCM Project Report Engro Polymers and ChemicalsDocument15 pagesStrategic Procurement and SCM Project Report Engro Polymers and ChemicalsFareed khan ZKNo ratings yet

- Vision Mission Objectives: Ordinary Portland Cement 43 Grade Cement (OPC 43 Grade)Document2 pagesVision Mission Objectives: Ordinary Portland Cement 43 Grade Cement (OPC 43 Grade)M. HaripriyaNo ratings yet

- ASO-Catalogue CompressedDocument60 pagesASO-Catalogue CompressedAlejandroCalleRuizNo ratings yet

- Transportation Technology On WheelsDocument13 pagesTransportation Technology On Wheelsmariutza_luciaNo ratings yet

- Ambuja Case StudyDocument5 pagesAmbuja Case StudyAkshay GadkariNo ratings yet

- Vision: To Be One of The Most Respected Companies in India Recognized For Challenging Conventions and Delivering On Our PromisesDocument5 pagesVision: To Be One of The Most Respected Companies in India Recognized For Challenging Conventions and Delivering On Our PromisesJasna VasNo ratings yet

- Adding Value To ConcreteDocument16 pagesAdding Value To ConcreteFrancois KokNo ratings yet

- Kishan Cement Report2Document72 pagesKishan Cement Report2Mr. AnikNo ratings yet

- SUPCLAY Builds Eco-Friendly Clay CementDocument2 pagesSUPCLAY Builds Eco-Friendly Clay Cementkoukou kikiNo ratings yet

- Circular Economy: Assessment and Case StudiesFrom EverandCircular Economy: Assessment and Case StudiesNo ratings yet

- Sustainability Management: New Approach in Project Management for Construction ProjectsFrom EverandSustainability Management: New Approach in Project Management for Construction ProjectsNo ratings yet

- Design of CC Pavement For Low Volume Roads As Per IRC SP:62-2014Document5 pagesDesign of CC Pavement For Low Volume Roads As Per IRC SP:62-2014Anyam RambabuNo ratings yet

- ASTM Designations For Steel Properties PDFDocument7 pagesASTM Designations For Steel Properties PDFIlkin hasanovNo ratings yet

- Approved JudgmentDocument42 pagesApproved JudgmentANDRAS Mihaly AlmasanNo ratings yet

- Mobile Crane Operation & SafetyDocument55 pagesMobile Crane Operation & SafetyBhavya ShuklaNo ratings yet

- Describing General ChangesDocument3 pagesDescribing General ChangesNgoc AnhNo ratings yet

- Longitudinal Section Thru "BB" Cross Section Thru "Aa": Proposed 3 Bedroom ResidentialDocument1 pageLongitudinal Section Thru "BB" Cross Section Thru "Aa": Proposed 3 Bedroom ResidentialChristian Sean PaglomutanNo ratings yet

- Taj MahalDocument41 pagesTaj MahalNikunj DwivediNo ratings yet

- Name: Date:: Sentence ConstructionDocument4 pagesName: Date:: Sentence ConstructionMike NgNo ratings yet

- Duct Fitting Loss CoefficientsDocument42 pagesDuct Fitting Loss Coefficientssutejo tejoNo ratings yet

- Risk Assessment and Control Measures for Tunnel Construction WorksDocument3 pagesRisk Assessment and Control Measures for Tunnel Construction WorksGyanendra Narayan NayakNo ratings yet

- Weekly learning activity sheets on tools and equipmentDocument77 pagesWeekly learning activity sheets on tools and equipmentRey Mamat LaguraNo ratings yet

- Parker 4660 56 - Series ConectoresDocument28 pagesParker 4660 56 - Series ConectoresJluisGarcíaMNo ratings yet

- Estimating RCC Culvert CostDocument14 pagesEstimating RCC Culvert CostFunny VinesNo ratings yet

- Typical Slab DetailsDocument1 pageTypical Slab DetailsSrigopi Chand RamineniNo ratings yet

- 06precast ComponentsDocument1 page06precast ComponentsDhanashri MirajkarNo ratings yet

- Ancon EdjPro Lifting SystemsDocument10 pagesAncon EdjPro Lifting Systems12378aNo ratings yet

- The Iveria BrochureDocument31 pagesThe Iveria BrochureRonnie TanNo ratings yet

- Visual rope inspection optimizationDocument88 pagesVisual rope inspection optimizationAlex CallisayaNo ratings yet

- Materi Training Revit StructureDocument1 pageMateri Training Revit StructureSyamsul HasanNo ratings yet

- Amaala Project Permitting DrawingsDocument1 pageAmaala Project Permitting DrawingsJomonNo ratings yet

- NBC Form A-05 Sanitary PermitDocument1 pageNBC Form A-05 Sanitary PermitDarwin CustodioNo ratings yet

- FREE Company Profile (Construction and Mining)Document10 pagesFREE Company Profile (Construction and Mining)Yulianti WarisNo ratings yet

- Rockwool Vs GlasswoolDocument8 pagesRockwool Vs Glasswooly2karein100% (1)

- 35 VinnetSharmaDocument10 pages35 VinnetSharmaSANDALI RATHORENo ratings yet

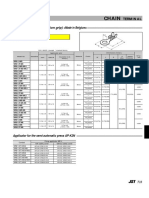

- Chain: SRB Series (With Insulation Grip)Document1 pageChain: SRB Series (With Insulation Grip)shankarNo ratings yet

- Shift Report - November 24, 2023-2nd ShiftDocument4 pagesShift Report - November 24, 2023-2nd Shiftbobowapthree19No ratings yet

- BAP-00-30-SD-0001-R - Rev.0 - Piping Standard Drawing.Document72 pagesBAP-00-30-SD-0001-R - Rev.0 - Piping Standard Drawing.papathsheilaNo ratings yet

- Asme b30 2 2005Document45 pagesAsme b30 2 2005MMillsNo ratings yet

- 30 - Leviste Management System Inc. - v. - Legaspi Towers 2000, Inc.Document2 pages30 - Leviste Management System Inc. - v. - Legaspi Towers 2000, Inc.atNo ratings yet

- 11.NOTES - Introduction - Contemporary Western ArchitectureDocument10 pages11.NOTES - Introduction - Contemporary Western ArchitectureShifa TalathNo ratings yet