Professional Documents

Culture Documents

Iis - Ignition System 4.1: Intelligent Ignition System With Microprozessor Controlled Auto Timing

Uploaded by

Bilal Nuraldin EltayebOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Iis - Ignition System 4.1: Intelligent Ignition System With Microprozessor Controlled Auto Timing

Uploaded by

Bilal Nuraldin EltayebCopyright:

Available Formats

IIS - IGNITION SYSTEM 4.

1

intelligent Ignition System with microprozessor controlled auto timing

General

For optimum operation of combustion engines an ignition system with auto timing is necessary. For easy starting up a spark is ideal in the upper

dead point position of the piston. With increasing rpm a pre-ignition timing up to 30 degree is needed. This is achieved with our new system

using a high precision rpm-check by two magnets built-in the hub of the engine. The hall sensor transmits the signal to the microprocessor,

programmed with our engine characteristic.

Technical specifications

o o

Temperature range: - 40 C / + 60 C ambient temperature

Voltage range: 4,8 - 8,4 V

One - cylinder two - cylinder

Operating voltage 6 V NICAD / 7,4 V LiPo can be connected without voltage regulator

Suggested battery capacity 1700 mAh 2400 mAh

Open - circuit current 18 mA 18 mA

Current - consumption 20-25 mA 0 rpm 20-25 mA 0 rpm

80-100 mA* 1000 rpm 90-130 mA* 1000 rpm

700-950 mA* 6000 rpm 800-1000 mA* 6000 rpm

1000-1200 mA* 10.000 rpm 900-1300 mA* 10.000 rpm

Ignition Voltage > 20 kV > 20 kV

Rpm. max 12.000 rpm 12.000 rpm

Magnet red (North Pole) upper dead point upper dead point

o o

Magnet green (South Pole) 55 before upper dead point 55 before upper dead point

*current consumption depends on the voltage of battery used with increasing voltage, current consumption goes down.

Like all other electronic devices the ignition box gets warm under operating conditions. For that reason a simple airflow has to be guaranteed.

Therefore the 4 delivered rubber mounts have to be used for installation, insuring a one millimetre gap underneath the box.

Cable information

Sensor cable multi coloured (4 wires) to sensor

Red / black long with socket to battery

Red / black short with plug connection for red LED, long contact -

Yellow / white with plug connection for 3W tachometer and other options

Info about red LED

a) Ignition battery switched on: LED on

b) Propeller 2 turns (flip): LED off - ignition in standby

c) Propeller not being turned (flipped), after a few seconds: LED on, ignition in standby

This safety function has two reasons:

- The engine cannot be started by coincidence if somebody forgot to switch off the ignition

- Battery will be protected against incidental discharge

d) In case the LED will not get off when propeller is turned (flipped): hall sensor is not connected or other defect

Since June 2003 the operating voltage is 6,0V - 5 cells NiCd or NimH or 2 Lipo cells (2S) can be used without voltage regulators. Ignitions,

wich were built before 2003 need 4,8V (4 cells). The IIS ignition system may not be attached to a voltage regulator. This is already integrated

and regulates the input voltage to 5V. The Ignition is set by factory no adjustment is requiered.

more infos: www.3w-modellmotoren.de

You might also like

- Mind Power SecretsDocument38 pagesMind Power SecretsIan Faian92% (52)

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- Beeswax Craft RecipesDocument19 pagesBeeswax Craft RecipesCpetrean100% (3)

- ECM Terminal Values and Waveforms for 2017 Toyota CorollaDocument15 pagesECM Terminal Values and Waveforms for 2017 Toyota CorollaBilal Nuraldin Eltayeb100% (2)

- Childrens VoiceDocument26 pagesChildrens VoiceMira Alaa100% (2)

- Neonatal Ventilation, Step by StepDocument99 pagesNeonatal Ventilation, Step by StepMarely Ovando Castillo93% (14)

- Hyundai Elantra 1.6 Engine Electrical1Document55 pagesHyundai Elantra 1.6 Engine Electrical1MANUALES2000CLNo ratings yet

- Structural Notes and Specifications for ConcreteDocument1 pageStructural Notes and Specifications for Concreteroger100% (2)

- Life Wealth Mastery EnglishDocument12 pagesLife Wealth Mastery EnglishD.j. Ralmm100% (1)

- Ecu Accent 1Document14 pagesEcu Accent 1Jorge Luis Garcia ArevaloNo ratings yet

- Chapter III Pharmacokinetics: Durge Raj GhalanDocument64 pagesChapter III Pharmacokinetics: Durge Raj GhalanDurge Raj Ghalan100% (3)

- Powmr-MPPT-60A-USER - MANUAL-MakeGreenWorld PDFDocument4 pagesPowmr-MPPT-60A-USER - MANUAL-MakeGreenWorld PDFmarco antonio martinez50% (2)

- Specifications of Avr - SMR (Mosfet)Document4 pagesSpecifications of Avr - SMR (Mosfet)Александр ЩеблыкинNo ratings yet

- Speed Measuring Unit User Manual (ESP-2000-B)Document9 pagesSpeed Measuring Unit User Manual (ESP-2000-B)alexander100% (6)

- TP48200B N20A5 N20A6 L20A5 IndooDocument2 pagesTP48200B N20A5 N20A6 L20A5 IndooАнтон БехтинNo ratings yet

- Effects of Cutting Classes For Grade 11 TEC Students of AMA Computer College Las PiñasDocument5 pagesEffects of Cutting Classes For Grade 11 TEC Students of AMA Computer College Las PiñasGgssNo ratings yet

- MD2278 Microstepping Driver SpecsDocument3 pagesMD2278 Microstepping Driver Specshoangmanh1989No ratings yet

- Can and LinDocument447 pagesCan and Linroopaswamy100% (1)

- SD-2H086MB User ManualDocument10 pagesSD-2H086MB User ManualJohn MiltonNo ratings yet

- 04-20kva Alternator Data Sheet Es10456927-N20g4-D-W212-20Document4 pages04-20kva Alternator Data Sheet Es10456927-N20g4-D-W212-20Muse AFNo ratings yet

- EDRIVE MA860H Stepper Motor Driver Datasheet SummaryDocument7 pagesEDRIVE MA860H Stepper Motor Driver Datasheet Summarymarcyel Oliveira WoliveiraNo ratings yet

- JH 3W14P45Document8 pagesJH 3W14P45martin TorresNo ratings yet

- Low Input Current Photodarlington Coupler: Features DescriptionDocument15 pagesLow Input Current Photodarlington Coupler: Features DescriptionStuxnetNo ratings yet

- Electrical System SpecificationsDocument27 pagesElectrical System SpecificationsVăn HòaNo ratings yet

- SW 80 mono RHA Data SheetDocument2 pagesSW 80 mono RHA Data SheetcelenyNo ratings yet

- Instruction Sheet for S500-A6 ModuleDocument2 pagesInstruction Sheet for S500-A6 ModuleJerson serranoNo ratings yet

- Instruction Sheet For S500-A6: Product SpecificationsDocument2 pagesInstruction Sheet For S500-A6: Product SpecificationsIrfan Taufik SiregarNo ratings yet

- 15.trombetta Elect A6Document2 pages15.trombetta Elect A6Jerson serranoNo ratings yet

- BE8161-Basic Electrical Electronics and Instrumentation Engineering Lab ManualDocument81 pagesBE8161-Basic Electrical Electronics and Instrumentation Engineering Lab ManualAntonio LeonNo ratings yet

- Integrated Starter Generator Assembly (ISG) : Features: Specifica OnsDocument2 pagesIntegrated Starter Generator Assembly (ISG) : Features: Specifica OnsGanapathiNo ratings yet

- BE8161-Basic Electrical Electronics and Instrumentation Engineering Lab ManualDocument162 pagesBE8161-Basic Electrical Electronics and Instrumentation Engineering Lab ManualAntonio LeonNo ratings yet

- String Inverter GTP CX SeriesDocument2 pagesString Inverter GTP CX SeriesBibhuti R DubeyNo ratings yet

- PANEL RAVEL 2554 (4 Zonas)Document4 pagesPANEL RAVEL 2554 (4 Zonas)Alex JanampaNo ratings yet

- Devicecraft: H-Bridge DC Motor Driver / Speed ControllerDocument32 pagesDevicecraft: H-Bridge DC Motor Driver / Speed ControllerGS OLDNo ratings yet

- n05 DC Motors BatteriesDocument38 pagesn05 DC Motors Batteriesvaraprasad93No ratings yet

- GMP 1 0Document4 pagesGMP 1 0rasoolNo ratings yet

- MRT 97-M: Installation and Operating InstructionsDocument15 pagesMRT 97-M: Installation and Operating InstructionsSofyan HadiNo ratings yet

- 1-Axis CNC Motor DriverDocument11 pages1-Axis CNC Motor DriverMarlon PerinNo ratings yet

- 1-Axis CNC Motor DriverDocument11 pages1-Axis CNC Motor DriverMarlon PerinNo ratings yet

- 600KHz, 18V, 2.0A Synchronous Step-Down ConverterDocument8 pages600KHz, 18V, 2.0A Synchronous Step-Down ConverteralfredoNo ratings yet

- Re 2554Document4 pagesRe 2554Brian MirandaNo ratings yet

- Low Voltage Alternators - 4 Pole: Tal A46 - Tal A47 - Tal A49Document15 pagesLow Voltage Alternators - 4 Pole: Tal A46 - Tal A47 - Tal A49Duc Thao VuNo ratings yet

- Dm542 ManualDocument5 pagesDm542 ManualJulio RuizNo ratings yet

- KW948MANUALDocument7 pagesKW948MANUALyarizadehNo ratings yet

- BE8161-Basic Electrical Electronics and Instrumentation Engineering Lab Manual FINAL PDFDocument82 pagesBE8161-Basic Electrical Electronics and Instrumentation Engineering Lab Manual FINAL PDFBHUVANA ARUMUGAMNo ratings yet

- Han-Qi HQD GDL70-24Z Spindle Wire Connection MethodDocument2 pagesHan-Qi HQD GDL70-24Z Spindle Wire Connection MethodNitish GoelNo ratings yet

- Tsup8M60Sh: Taiwan SemiconductorDocument5 pagesTsup8M60Sh: Taiwan Semiconductorn tanevarNo ratings yet

- MC 5x38 CatalogDocument10 pagesMC 5x38 CatalogJose Rolong CNo ratings yet

- MC-5 Series Micro Processor Temperature Controller: ApplicationDocument10 pagesMC-5 Series Micro Processor Temperature Controller: ApplicationJuan David MontoyaNo ratings yet

- Straight Gate DatasheetDocument2 pagesStraight Gate DatasheetDavid BaylissNo ratings yet

- PANEL RAVEL 2558 (8 Zonas)Document4 pagesPANEL RAVEL 2558 (8 Zonas)Alex JanampaNo ratings yet

- InteliLite AMF25 1 2 1 DatasheetDocument4 pagesInteliLite AMF25 1 2 1 DatasheetStanley Florencio100% (1)

- dlp3806 400bmDocument2 pagesdlp3806 400bmWindu SeptianNo ratings yet

- Smartcon 4000Document20 pagesSmartcon 4000செல்வமாரியப்பன் சீனிவாசன்No ratings yet

- TP48200B-N20A5 N20A6 L20A5 Indoor Integrated Power System Datasheet PDFDocument2 pagesTP48200B-N20A5 N20A6 L20A5 Indoor Integrated Power System Datasheet PDFСергей БейлинNo ratings yet

- RCS Capswitch: Rockwill Electric Co., LTDDocument8 pagesRCS Capswitch: Rockwill Electric Co., LTDMahyar MashayekhiNo ratings yet

- Easily Mount Digital Tachometer Panel Instruction ManualDocument8 pagesEasily Mount Digital Tachometer Panel Instruction ManualMatheus AndreoNo ratings yet

- SSVR Three Phase enDocument4 pagesSSVR Three Phase enMallikarjunNo ratings yet

- Stepper Motor Driver SpecificationDocument5 pagesStepper Motor Driver SpecificationMimo AbduNo ratings yet

- TP5000 Auto TranslatedDocument14 pagesTP5000 Auto Translatedlittle sparkNo ratings yet

- 100W LED Converter with IP68 Waterproof DesignDocument8 pages100W LED Converter with IP68 Waterproof DesignReynanNo ratings yet

- SD 32208 enDocument6 pagesSD 32208 enJoão Soares0% (2)

- Solar Charge Controller Specification 2020Document13 pagesSolar Charge Controller Specification 2020hugalesNo ratings yet

- En: Thisdatasheet Ispresentedby Themanufacturer.: Please V Isit Our Websit E F or PR Icing and Av Ailabilit Y atDocument4 pagesEn: Thisdatasheet Ispresentedby Themanufacturer.: Please V Isit Our Websit E F or PR Icing and Av Ailabilit Y atendreminarikNo ratings yet

- XoxoxoxoDocument7 pagesXoxoxoxoAdmin BisnisNo ratings yet

- RECT, Modul SM1600,48V/30A, AEGDocument7 pagesRECT, Modul SM1600,48V/30A, AEGjksiswanto0% (1)

- Datasheet ZCS 1PH 3000 6000TLM V2 ENDocument2 pagesDatasheet ZCS 1PH 3000 6000TLM V2 ENcatalinNo ratings yet

- Devicecraft: H-Bridge DC Motor Driver / Speed ControllerDocument26 pagesDevicecraft: H-Bridge DC Motor Driver / Speed ControllerGS OLDNo ratings yet

- DRX-T7445HD-H: Toshiba X-Ray Tube (Water-Cooled Type)Document4 pagesDRX-T7445HD-H: Toshiba X-Ray Tube (Water-Cooled Type)Advanced Medical Group AMGNo ratings yet

- Catalogue SeDocument5 pagesCatalogue SeSaksham JainNo ratings yet

- Esp-Wrover-Kit V4 1Document1 pageEsp-Wrover-Kit V4 1Bilal Nuraldin EltayebNo ratings yet

- Infineon IRF1404 DataSheet v01 01 enDocument10 pagesInfineon IRF1404 DataSheet v01 01 enAkram KareemNo ratings yet

- Mini Car-Person 103b Gsm-Gprs-Gps Tracking Device - Mk3Document9 pagesMini Car-Person 103b Gsm-Gprs-Gps Tracking Device - Mk3Bilal Nuraldin EltayebNo ratings yet

- GBC232A DatasheetDocument3 pagesGBC232A DatasheetBilal Nuraldin EltayebNo ratings yet

- 74LVC157A: 1. General DescriptionDocument15 pages74LVC157A: 1. General DescriptionBilal Nuraldin EltayebNo ratings yet

- Decoding: Send Filled Form Via Mail To BoschDocument1 pageDecoding: Send Filled Form Via Mail To BoschBilal Nuraldin EltayebNo ratings yet

- ECM Connector End View (A50) : Ymms: Nov 12, 2021 Engine: 2.4L Eng License: Vin: Odometer: 2009 Toyota Corolla XRSDocument20 pagesECM Connector End View (A50) : Ymms: Nov 12, 2021 Engine: 2.4L Eng License: Vin: Odometer: 2009 Toyota Corolla XRSBilal Nuraldin EltayebNo ratings yet

- Transmission Programming Function List for Major Chinese AutomakersDocument93 pagesTransmission Programming Function List for Major Chinese AutomakersBilal Nuraldin Eltayeb0% (1)

- Curriculum Vitae: Personal InformationDocument8 pagesCurriculum Vitae: Personal InformationBilal Nuraldin EltayebNo ratings yet

- WCDT - Current Drain Tester: Ascot II, Wallops Wood, Sheardley Lane, Droxford, Southampton, SO32 3QY, UKDocument1 pageWCDT - Current Drain Tester: Ascot II, Wallops Wood, Sheardley Lane, Droxford, Southampton, SO32 3QY, UKBilal Nuraldin EltayebNo ratings yet

- اكشويتر ازيرا 2014 خليجي ActuatorDocument2 pagesاكشويتر ازيرا 2014 خليجي ActuatorBilal Nuraldin EltayebNo ratings yet

- How anti-lock brakes work in a 2010 Toyota CorollaDocument7 pagesHow anti-lock brakes work in a 2010 Toyota CorollaBilal Nuraldin EltayebNo ratings yet

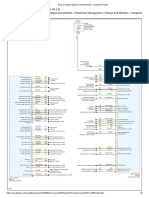

- Engine Controls Powertrain Management ALLDATA RepairDocument6 pagesEngine Controls Powertrain Management ALLDATA RepairBilal Nuraldin EltayebNo ratings yet

- Body Computer (Body Control Module) - ALLDATA RepairDocument2 pagesBody Computer (Body Control Module) - ALLDATA RepairBilal Nuraldin EltayebNo ratings yet

- Elantra 2011 DOHC 2.0Document10 pagesElantra 2011 DOHC 2.0Bilal Nuraldin EltayebNo ratings yet

- Spartan 3EDocument164 pagesSpartan 3Etuxandres82No ratings yet

- SMD Testers with 36V DC Voltage Measurement and Battery TestingDocument1 pageSMD Testers with 36V DC Voltage Measurement and Battery TestingBilal Nuraldin EltayebNo ratings yet

- Micro Proc Lab ProjectDocument4 pagesMicro Proc Lab ProjectBilal Nuraldin EltayebNo ratings yet

- RMO NO. 66-2016 - DigestDocument2 pagesRMO NO. 66-2016 - DigestJuliannaMendozaMaleNo ratings yet

- School and CentreDocument24 pagesSchool and CentreThrilling PrinceNo ratings yet

- The Electrooculogram (EOG)Document34 pagesThe Electrooculogram (EOG)Prasidha PrabhuNo ratings yet

- Understanding Immunomodulatory DrugsDocument4 pagesUnderstanding Immunomodulatory DrugsMark Russel Sean LealNo ratings yet

- ARTIKEL 44 Famuntamah 391-399Document9 pagesARTIKEL 44 Famuntamah 391-399Dandi Aksan MasjudNo ratings yet

- Tugas UNtar 3Document28 pagesTugas UNtar 3Daniel Filemon PosoNo ratings yet

- Broiled Salisbury SteaksDocument29 pagesBroiled Salisbury SteaksCei mendozaNo ratings yet

- 11 Chapter 7Document14 pages11 Chapter 7ParthaSarathyNo ratings yet

- Section - A: Holiday Homework For Grade XiDocument7 pagesSection - A: Holiday Homework For Grade XiGM Ali KawsarNo ratings yet

- Research ProposalDocument10 pagesResearch ProposalRonNo ratings yet

- Piriformis MuscleDocument3 pagesPiriformis MuscleBen CampbellNo ratings yet

- GER Bangladesh EngDocument12 pagesGER Bangladesh Engfarhan.anjum20032004No ratings yet

- Causes of Poverty - Presentation On Poverty - Poverty in PakistanDocument20 pagesCauses of Poverty - Presentation On Poverty - Poverty in PakistanTop_Sledger92% (12)

- WordsDocument11 pagesWordsAref HoseyniNo ratings yet

- 3023 History Cuisine WorksheetDocument6 pages3023 History Cuisine WorksheetFlor HenríquezNo ratings yet

- Nikola Tesla Would Have Celebrated Christmas On January 7thDocument3 pagesNikola Tesla Would Have Celebrated Christmas On January 7thAnonymous DfeajF100% (1)

- Dyna Lift Flyer 500 FL 000010 enDocument20 pagesDyna Lift Flyer 500 FL 000010 enErdinc SenmanNo ratings yet

- National Coalition For The HomelessDocument7 pagesNational Coalition For The HomelessLee GaylordNo ratings yet

- The QuestionnaireDocument3 pagesThe QuestionnaireMaximo C. Nayanga Jr.No ratings yet

- ZinkPower Batam - Company BrochureDocument6 pagesZinkPower Batam - Company BrochureansarALLAAHNo ratings yet

- Broken Access ControlDocument3 pagesBroken Access ControlGlady GladsonNo ratings yet