Professional Documents

Culture Documents

(Reviewed) How ERP Software Impacts Quality

Uploaded by

sajiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

(Reviewed) How ERP Software Impacts Quality

Uploaded by

sajiCopyright:

Available Formats

SOFT WARE & ANALYSIS

How

ERP Software

Impacts Quality

THE RIGHT SOLUTION ENABLES BUSINESSES TO TRACK AND MEASURE THE

TOTAL COST OF QUALITY. By Genevieve Diesing

Enterprise software is computer software designed to help an entire organization enhance its business and

management reporting. Ideally, such programs enable manufacturers to solve enterprise-wide problems,

rather than a departmental problem. They can boost a business’s productivity and efficiency by helping

organizations display, manage, and store large amounts of often complex data and help organizations process

that data to their advantage.

Dawn Brusseau, product marketing manager, Plex Systems Inc., says ERP software “provides a single source of

truth for an organization” by keeping every member of an organization aware of current operations and

creating traceability and a monitoring process.

“Not only does ERP software allow for real-time updates to help teams quickly pivot when there is an

abnormality, it also provides data consistency because every member of the company has access to the same

numbers when it comes to financial or production reporting, leaving no silos,” Brusseau says.

Maintaining growing quality standards, more demanding customer expectations, and compliance measures

while operating in complex, global supply chains put enormous pressure on manufacturers, says Guido Van

den Broeck, director, product management, QAD.

“Fortunately, ERP solutions can help manufacturers to diminish a lot of these pressures,” Van den Broeck says.

“The goal of ERP systems is to streamline business operations through automation and the consolidation of

business data into one single source of truth.”

Instead of constantly apologizing for returned parts, manufacturers can identify and correct defective parts

before they’re shipped, says Mike Melzer, vice president of service and operations at Global Shop Solutions.

“[Manufacturers] can identify the cost of quality down to the part level, while reducing scrap to equal or better

than the industry standard,” Melzer says. “This gives them the competitive edge to build continued trust with

their customers.”

Because ERP provides the data to easily understand where to focus on continuous improvement — such as by

reducing process waste, or by identifying excesses in transportation, inventory, motion, waiting, over-

processing, overproduction, or other key performance indicators — it enables businesses to track and measure

the total cost of quality, or the cost a manufacturer must bear in terms of utilizing resources to maintain

qualitative outputs to their target customers, Van den Broeck says.

While there are many benefits to employing an ERP solution, Brusseau says, the most important are that it

helps streamline business reporting, secures data, and ultimately drives business growth.

“Before ERP systems, manufacturing operations were run on a paper basis, which would have to go from the

floor to finance executives to invoices,” Brusseau says. “This created an opportunity for human errors that

could negatively impact quality, including lost items, misplaced paperwork, and incorrect data entry. By having

accessible real-time data filed to the cloud, businesses can save time and energy on manual tasks and avoid

costly mistakes in reporting.”

Data confidence and accessibility also streamlines audits and reporting, dramatically reducing this potential

drain on resources. With today’s heightened awareness around cyber and ransomware attacks, organizations

need extra security for their proprietary data, Brusseau says. Organizations that implement ERP solutions

know their data is protected on the cloud, ensuring that the data will not be corrupted and business continuity

will be maintained.

Enterprise software is changing with the times, most notably through the increased use of KPIs and

dashboards, Melzer says. Now more than ever, manufacturers have more data at their fingertips since shop-

floor dashboards show employees’ productivity and executives are privy to ample KPIs.

“With the help of ERP, manufacturers are identifying leading metrics and using that data to make short-term

and long-term decisions,” Melzer says.

Brusseau cites an industrywide push for a cloud-based system for business security and growth as a major

trend.

“Security is a priority concern among customers and isn’t going away anytime soon,” Brusseau says. “The cloud

allows data and business processes to be stored securely, and helps organizations move away from on-premise

solutions that can easily be infiltrated. Manufacturers are also wise to ensure and validate the security

standing of a cloud ERP provider as well.”

The sheer volume and capabilities of ERP software solutions are also relatively new, Brusseau says. While there

are some legacy systems out there, “companies are looking at systems that require intensive IT staff and

comparing them to newer solutions that don’t require heavy lifting and are easier for the IT community to

support,” he explains.

Quality standards, compliance, and customer expectations are increasing while supply chains and operations

are getting more complex and challenging or are being disrupted, Van den Broeck says.

“Getting the right parts from suppliers on time and ensuring the expected quality and features is getting more

challenging,” he explains. “Understanding the impact of these delays on your production and delivery plans

requires seamless integration and synchronization of data and processes in your organization.”

Manufacturers generally need more skilled workers, while products are getting more personalized and

complex to manufacture.

Prices for parts and transporting goods are rising, as are price pressures due to fierce competition.

This leads manufacturers to further invest in prevention and appraisal activities, such as in training, or to

introduce more quality checks in the daily processes integrated with ERP.

These investments ultimately make the tasks easier to execute, helping to compensate for dwindling

workforces and increasingly complex tasks.

“[They provide] proactive guidance, poke yoke checks, easy-to-understand instructions, and workflow tools,

with real-time validations so production can be stopped or adjusted as soon as a problem occurs,” Van den

Broeck says. Prevention and appraisal activities also help to automate tasks as needed, limiting human

interventions.

“More investments are done as well to ensure users have the right (accurate and real-time) insights into

information to make informed decisions faster,” he adds.

As with most enterprise-level technologies, there is a learning curve when it comes to using a new ERP system,

Melzer says.

“These robust systems take time to implement and learn, and most manufacturers are already running

operations on the leaner side,” he says. “While employees may be at capacity, they have to find flexibility in their

day to balance their workload and the undertaking of learning a new system. But with help of dedicated and

experienced ERP experts, you can negate some of that heartburn for a smoother transition and

implementation.”

The biggest challenges organizations face when implementing this type of technology is the cost and time to

implement it among teams, Brusseau says, because it is easy for companies to get overwhelmed when they see

the initial cost these advanced technologies can set them back.

“While it is an investment, organizations need to visualize how they will see an ROI as it pertains to efficiency,

business agility and potential savings in overhead,” Brusseau says.

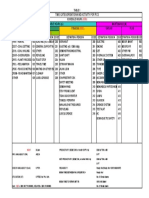

All Images Source: Plex Systems

Genevieve Diesing is a contributing editor of Quality.

MARCH 2022 | VOLUME 61 | NUMBER 3

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5806)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Outsystems Talent Playbook Part2Document11 pagesOutsystems Talent Playbook Part2Ahmad ANo ratings yet

- Optimisation of Cosntruction Process Inspection RatesDocument13 pagesOptimisation of Cosntruction Process Inspection RatessajiNo ratings yet

- Static Equipment in Oil and Gas IndustryDocument93 pagesStatic Equipment in Oil and Gas IndustrysajiNo ratings yet

- INSPECTIONS - FSS of PipelinesDocument2 pagesINSPECTIONS - FSS of PipelinessajiNo ratings yet

- Selection of A Calibration Service Provider (Including Audit Point of View)Document2 pagesSelection of A Calibration Service Provider (Including Audit Point of View)sajiNo ratings yet

- 3 Steps For Effective AutomationDocument2 pages3 Steps For Effective AutomationsajiNo ratings yet

- Remote Visual Inspection - An NDT MethodDocument5 pagesRemote Visual Inspection - An NDT MethodsajiNo ratings yet

- IP11 - Calculation of Min. Allowable Thickness & Test Pressure For Process Furnace TubesDocument2 pagesIP11 - Calculation of Min. Allowable Thickness & Test Pressure For Process Furnace TubessajiNo ratings yet

- IP46 - Guide To Use BAPCO WPS & Welding ProceduresDocument4 pagesIP46 - Guide To Use BAPCO WPS & Welding ProceduressajiNo ratings yet

- IP23 - Procedure For Welder Performance QualificationDocument25 pagesIP23 - Procedure For Welder Performance QualificationsajiNo ratings yet

- IP50 - Pressure Testing of Refinery EquipmentDocument8 pagesIP50 - Pressure Testing of Refinery EquipmentsajiNo ratings yet

- FMEA Errata Sheet ENG AIAG VDA FMEA Handbook 202000602 PDFDocument10 pagesFMEA Errata Sheet ENG AIAG VDA FMEA Handbook 202000602 PDFBonny BonitoNo ratings yet

- Handbook of Project ManagementDocument471 pagesHandbook of Project ManagementG100% (14)

- Quorum's State of Disaster Recovery ReportDocument12 pagesQuorum's State of Disaster Recovery ReportShrijendra ShakyaNo ratings yet

- Sap PS 16 07 2023Document40 pagesSap PS 16 07 2023anand.kumarNo ratings yet

- TikTok Marketing - Cheat SheetDocument4 pagesTikTok Marketing - Cheat Sheetmariomr0890No ratings yet

- Sales Management Literature ReviewDocument5 pagesSales Management Literature Reviewtug0l0byh1g2100% (1)

- Sabsa Risk PracDocument6 pagesSabsa Risk PracMohammed Afzal SiddiquiNo ratings yet

- Business Driven Information Systems Fifth Edition Edition Baltzan Full ChapterDocument67 pagesBusiness Driven Information Systems Fifth Edition Edition Baltzan Full Chapterhelena.williams785100% (3)

- UCBioBSP SDK Programmer's Guide v3.00 (Eng)Document350 pagesUCBioBSP SDK Programmer's Guide v3.00 (Eng)من لخبطهNo ratings yet

- Job Description For Senior .Net Developer Digitain RomaniaDocument1 pageJob Description For Senior .Net Developer Digitain Romanianicolaeionescu91No ratings yet

- Responsabilities: What Are The Core Job Responsibilities of Project Managers? Let's Recap What We Learned in The PreviousDocument37 pagesResponsabilities: What Are The Core Job Responsibilities of Project Managers? Let's Recap What We Learned in The PreviousDemian pflNo ratings yet

- Virtualline: Virtual MachineDocument8 pagesVirtualline: Virtual MachineKurtis FascianoNo ratings yet

- Accounting Information System ActivitiesDocument2 pagesAccounting Information System ActivitiesDarrel SapinosoNo ratings yet

- NikitaDocument64 pagesNikitaNikita BansalNo ratings yet

- Project Planning (Project Quality Management)Document22 pagesProject Planning (Project Quality Management)Stephen VisperasNo ratings yet

- Social Media AnalyticsDocument21 pagesSocial Media AnalyticskushiNo ratings yet

- The State of Ecommerce 2021: Navigating The New World of Omnichannel Commerce and Retail MediaDocument38 pagesThe State of Ecommerce 2021: Navigating The New World of Omnichannel Commerce and Retail MediaDaria B100% (1)

- Bridge and Roof Co. (India) LimitedDocument8 pagesBridge and Roof Co. (India) LimitedBipradip BiswasNo ratings yet

- RPA: The Key To Delivering Automation and Achieving Greater Operational EfficiencyDocument13 pagesRPA: The Key To Delivering Automation and Achieving Greater Operational Efficiencysanjith kNo ratings yet

- Angeli Monica: Work ExperienceDocument2 pagesAngeli Monica: Work ExperienceDivya NinaweNo ratings yet

- Data IntegrityDocument2 pagesData IntegrityThe Peacock FeatherNo ratings yet

- UML Diagram Types GuideDocument17 pagesUML Diagram Types GuideahmedNo ratings yet

- FDocument1 pageFVeronel LunguNo ratings yet

- Anin-Depthview: 1 Cleo - Cleo Harmony - An In-Depth ViewDocument8 pagesAnin-Depthview: 1 Cleo - Cleo Harmony - An In-Depth ViewSturm WolfeNo ratings yet

- Brochure - PESTECH OCPP Charging Management Platform.v3Document1 pageBrochure - PESTECH OCPP Charging Management Platform.v3lkt_pestechNo ratings yet

- Time Categorisation and Activity For PCS: Table 1 Schedule Hours Stand by DelayDocument1 pageTime Categorisation and Activity For PCS: Table 1 Schedule Hours Stand by DelayTommyTriantoTandoNo ratings yet

- Improving The Visibility and Performance of Enterprise ServicesDocument4 pagesImproving The Visibility and Performance of Enterprise ServicesPera PericNo ratings yet

- 7 Guidelines - For - Hoshin - Kanri - Implementation-Development - and - DiscussionDocument18 pages7 Guidelines - For - Hoshin - Kanri - Implementation-Development - and - DiscussionVanessa SantosNo ratings yet

- NetCracker Technology Interview Questions and Answers 45334Document13 pagesNetCracker Technology Interview Questions and Answers 45334neelambika nsNo ratings yet