Professional Documents

Culture Documents

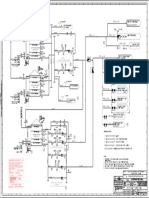

BFP & Pipelines

BFP & Pipelines

Uploaded by

PMG Bhuswal Project0 ratings0% found this document useful (0 votes)

12 views4 pagesOriginal Title

2. BFP & PIPELINES

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

12 views4 pagesBFP & Pipelines

BFP & Pipelines

Uploaded by

PMG Bhuswal ProjectCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 4

BFP Design Parameters

Parameters MDBFP TDBFP

No of pumps 2x30% duty 2x50% duty

Type of Operation Continuous for 2 TD Intermittent for 2 MD

BFPs BFP

Type of Pump MDG346; 6 stage, double MDG405; 5 stage, double

casing type with a casing type with a

simple cylindrical simple cylindrical

outer casing & casing outer casing & casing

cover and horizontally cover horizontally

split inner volute split inner volute

casing, o[[osed casing, opposed

impellers. impellers.

Temp. of feed water 189.6°C

(Suction)

Suction Flow 780 m³/hr 1300m³/hr

Rate(including Inter

Stage tap off)

Speed 6100 rpm 5685 rpm

Power Input to Pump 7183 kW 11955 kW

BFP Suction Pressure 33.57kg/cm2 29.89kg/cm2

Common discharge line 470 KH/cm2 / 470 kg/cm2 /

design pressure/ 200 degrees 200 degrees

temp

Discharge line pipe 355.6x64 457x82

size

BFD Line Design Parameters:

Parameter Pipe Size Desn Press Desn Temp Thermal

(kg/cm2) (degrees) Insulation

(mm)

Feed 559x72 330 200 100

discharge

inlet to HPH-6

Feed 559x72 330 230 115

discharge

from HPH 6 to 7

Feed 559x72 330 280 155

discharge

from HPH 7 to 8

Feed 559x72 330 300 175

discharge

from HPH 8 to

HPH 6

Desuperheater

HPH 6 323.9x42 330 300 155

Desuperheater

inlet

HPH 6 323.9x42 330 310 165

Desuperheater

outlet

Feed 559x72 330 310 175

Discharge

Header to Eco

Inlet

Condensate Piping/ Critical Piping Details

PGMA/ Line Size Weight Design Design Temp Material

Drawing No Description (ODxThk in (Kg/m) Pressure (Degree

mm) (Kg/Cm2) Centigrade)

80-402 CEP 457x12.7, 123 to 139 47 60 SA106GR-C

Discharge 406x12.7

(LPH#1 to

LPH#4)

80-403 CEP 406x73, 600.2 47 60 SA106GR-C

Discharge 457.2x82, 758.7

(LPH#4 to 660x116 1556.1

Deaerator)

80-420 BFP Suction

80-421 Recirculation 219.1x40 176.66 470 200 SA106GR-C

piping from 168.3x7.11 28.26 20

MDBFP

80-423 BFP 355.6x64 460.2 470 200 SA106GR-C

Discharge 406.4x73 600.2

Pipeline 457.2x82 758.7

660x116 1556.1

80-424 BFD Piping 559x72 864.6 330 230/280/300 SA106GR-C

between HP 457x60 584.4

Heaters

80-425 BFD Piping 559x72 864.6 330 300/310 SA106GR-C

to Eco. Inlet 457x60 587.4

323.9x42 291.96

Status of Condensate/ Critical Piping Work:

PGMA Total Joints Fit up Welding R.T U.T

Involved

80-402 122 33 26 5/12.5 NA

80-403 72 28 24 0/7.2 NA

80-420 -- 4 -- -- --

80-423 194 24 23 23/194 NA

80-424 102 06 06 6/102 0

80-425 104 07 07 7/104 0

Heaters Details

Heaters LPH#1 LPH#2 LPH#3 LPH#4 HPH#6 HPH#7 HPH#8

Heat 1248 1350.5 1365.99 1431.33 2833.46 3507.39 2864.62

Exchanger

Area

(sq.M)

Shell Side 150 153 153 173 235 290 305

Design

Temp

(degC)

Shell Side 3.5 3.5 3.5 6.5 30 74 92

Design

Press

Kg/Sqcm

(g)

Tube Side 150 153 153 173 235/255 290/310 305/325

Design

Temp

degC

Tube Side 46.3 47 47 47 350 350 350

Design

Press

Kg/Sqcm

(g)

Location +9.55 +9.745 +9.72 +9.695 +18.85 +18.85 +18.85

(metre)

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5819)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- National Smart Grid Mission OMDocument12 pagesNational Smart Grid Mission OMPMG Bhuswal ProjectNo ratings yet

- TGE 3668 - Rev-01 - Write-Up of Generator Primary Water SystemDocument11 pagesTGE 3668 - Rev-01 - Write-Up of Generator Primary Water SystemPMG Bhuswal ProjectNo ratings yet

- Smart Grid Kumud WadhwaDocument52 pagesSmart Grid Kumud WadhwaPMG Bhuswal ProjectNo ratings yet

- Bharati Krsna Tirthaji, V. S. Agrawala (Editor) - Vedic Mathematics - Sixteen Simple Mathematical Formulae From The Vedas-Motilal Books (1970)Document424 pagesBharati Krsna Tirthaji, V. S. Agrawala (Editor) - Vedic Mathematics - Sixteen Simple Mathematical Formulae From The Vedas-Motilal Books (1970)PMG Bhuswal ProjectNo ratings yet

- Commissioning of DAVRDocument70 pagesCommissioning of DAVRPMG Bhuswal Project100% (1)

- DocScanner Jul 14, 2023 4-53 PM-5Document1 pageDocScanner Jul 14, 2023 4-53 PM-5PMG Bhuswal ProjectNo ratings yet

- Notes For SCH ReadingDocument7 pagesNotes For SCH ReadingPMG Bhuswal ProjectNo ratings yet

- MERC Brief InfoDocument51 pagesMERC Brief InfoPMG Bhuswal ProjectNo ratings yet

- RCD Presentation On MERC MYT Regulations, 2019Document18 pagesRCD Presentation On MERC MYT Regulations, 2019PMG Bhuswal ProjectNo ratings yet

- Bhusawal 1X660 CO 106 R03 PDFDocument1 pageBhusawal 1X660 CO 106 R03 PDFPMG Bhuswal ProjectNo ratings yet

- DocScanner Jul 14, 2023 4-53 PM-4Document1 pageDocScanner Jul 14, 2023 4-53 PM-4PMG Bhuswal ProjectNo ratings yet

- SyllabusDocument1 pageSyllabusPMG Bhuswal ProjectNo ratings yet

- Pre CommisioningDocument7 pagesPre CommisioningPMG Bhuswal ProjectNo ratings yet

- Exe Sum Eng Tangedco 251121Document10 pagesExe Sum Eng Tangedco 251121PMG Bhuswal ProjectNo ratings yet

- Bhusawal HPH Rev02 PDFDocument26 pagesBhusawal HPH Rev02 PDFPMG Bhuswal ProjectNo ratings yet

- Single Line Diagram of Generator Transformer Unit#4 Bay: 400KV Bus I 400KV Bus IIDocument7 pagesSingle Line Diagram of Generator Transformer Unit#4 Bay: 400KV Bus I 400KV Bus IIPMG Bhuswal ProjectNo ratings yet

- Bhusawal - 1X660 - HPBP LP - 102 - R02 PDFDocument1 pageBhusawal - 1X660 - HPBP LP - 102 - R02 PDFPMG Bhuswal ProjectNo ratings yet

- PA00KWSNDocument13 pagesPA00KWSNPMG Bhuswal ProjectNo ratings yet

- Bhusawal 1X660 DMS 110 R01Document1 pageBhusawal 1X660 DMS 110 R01PMG Bhuswal ProjectNo ratings yet

- MCQ On Power Systems 5eea6a0f39140f30f369e734 PDFDocument20 pagesMCQ On Power Systems 5eea6a0f39140f30f369e734 PDFPMG Bhuswal ProjectNo ratings yet

- Detailed Application Process PDFDocument4 pagesDetailed Application Process PDFPMG Bhuswal ProjectNo ratings yet

- Field and Stator Ground Fault Protection Modules: Grid SolutionsDocument64 pagesField and Stator Ground Fault Protection Modules: Grid SolutionsPMG Bhuswal ProjectNo ratings yet

- UntitledDocument1 pageUntitledPMG Bhuswal ProjectNo ratings yet

- UntitledDocument186 pagesUntitledPMG Bhuswal ProjectNo ratings yet

- Normal 5f8df2d11da63Document3 pagesNormal 5f8df2d11da63PMG Bhuswal ProjectNo ratings yet

- UntitledDocument2 pagesUntitledPMG Bhuswal ProjectNo ratings yet

- CRS - SLD-Turbine Valve MCC - 6KB-R02Document2 pagesCRS - SLD-Turbine Valve MCC - 6KB-R02PMG Bhuswal ProjectNo ratings yet

- Mexican Spanish: Words & Phrases For Ordering FoodDocument7 pagesMexican Spanish: Words & Phrases For Ordering FoodPMG Bhuswal ProjectNo ratings yet

- UntitledDocument8 pagesUntitledPMG Bhuswal ProjectNo ratings yet

- English Alphabets Reading Writing Worksheets PDFSevaDocument10 pagesEnglish Alphabets Reading Writing Worksheets PDFSevaPMG Bhuswal ProjectNo ratings yet