Professional Documents

Culture Documents

Qualiy Plan-Stack-shop Inspection

Qualiy Plan-Stack-shop Inspection

Uploaded by

widi0 ratings0% found this document useful (0 votes)

7 views5 pagesOriginal Title

Qualiy Plan-Stack-shop inspection

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

7 views5 pagesQualiy Plan-Stack-shop Inspection

Qualiy Plan-Stack-shop Inspection

Uploaded by

widiCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 5

FERBECK

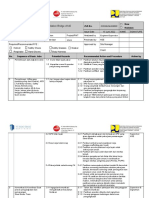

QUALITY PLAN for lowe: DNECIOA on

INTERNATIONAL STACK (Shop Inspection) evn

ane 105

owNeR AIT STEIN GROUP

PROJECTINAME |: CO17-20 DOUBLE SKIN STEEL STACK, AL JUBAIL, SAUD ARABIA

‘QUALITY PLAN

FOR

STACK ( Shop Inspection)

7 — [ora fee ora

ls ceo

cing Br] ao

CRCRPTON

PREPARED

‘Giecxeo | —TEPROWED

‘esa Manat & Can Bhd

‘ust Pan

Procedure Ho: DNEC/OA-001

Revision No:

Page <1 of

‘Sco

This Quality Plans applicable to the abication of ne unit oF 5 metre double skin Stack or

A AL ball ia KSA.

2.0 REFERENCES

= Ferbeck Purchase Order No 001 / C047 -20,

Spectcation and Qualification of welding procedures for mettle materials 180 15616-1/ASME

= Qualfcation for testing oF welders: IO 9606 1 / ASK

General tolerance for welded construction: 18012920,

Metalic Products Type of inspection documents: 10208,

Hot rolled produets of structural steels £10025 -2

Hot rolled steel lates Tolerance on almensions and shape EN 10029.

Welding consumable EN 756 / ASME

Visual and dimensional examination ESO 1763 / EN SE17/ ASME IN OV

Radiography examination : ASME V/ ASME DW 1

Painting System 25-1

$3.0 DEFINITIONS, ABBREVIATIONS AND INITIALS

TP Inspection and Test Pla,

WPS: Welding Procedure Speciation.

NOT: Non Destructive Testing

NCR Non Conformance Report

‘WP: Welding Plan

PAR : Procedure Qualification Recor

10 PROCEDURES

‘Special processes ike welding, painting ete salle donein accordance with the ulesof

Specification issued according tothe applicable codes

‘All welds wil be made according the instructions of the welding procedure speciation

{15 andthe welding plan (WP supported by approved welding procedure {POR and

by certified welders according to the applicable code,

Nondestructive test shall be performed by certified operators (evel II-ASNTSHT-IC-14

‘or EN 473/80 9712 and according to the applicable code

‘Ainspction steps shal be indicated nthe Inspection and Test Plan (1.

Desa Nikmat & €Sdn Bhd

‘ualty Pan

Procedure No:DNEC/QA-001

rage : of 4

‘0: DOCUMENTS AND DATA CONTROL

The company possess of the methodologies forthe contol ofthe documents and das as

er the duality Control Manual

‘The Manwal served as. upport forthe documents and register of Qual ar elaborte and

approved according tothe imputed respons.

The documents are elaborated, approves, Issued, distributed, gathered and reviewed by

sauthodzed eat

0 PURCHASING

‘Te company possess ofthe methodologies in order to assure thatthe purchased preuc i

Inconformity withthe specified requisites. The methodologies are in accordance with the

‘uty Control Manual

‘2.0 IDENTIFICATION AND TRACEABILITY OF THE PRODUCT

‘Te company possess ofthe methodologies for the products entication from theta

tage unt is completion. These are in accordance with the QualtyContol Mana

8.0 PROCESS CONTROL

‘he company dentils and organizes its production methods and installation methods that

alecs the quay ofthe products

‘The main methods of production are

Cut and conformation of pats, profs an pipes.

Welding

“Assembly

“surface treatments painting)

Machin.

the processes are cared outin accordance withthe procedures that define the method

nd practices wed which assures the control ofthe sme processes

For some processes, namely welding the company guarantees the operator's ualifeaton.

Desa hikmat & Cdn Bhd

‘vatty Pan

Procedure No:DNEC/QA-001

Revision No: A

Page : 1 of

a

{CTION AND TEST PLAN

‘he company wil prepare inspection and Test Plan (TP) that define the quality contol

Inspections actions tobe performed to the product during the diverse phased of production

‘The lnspecton actives wil cried out rom the receipt of rw materials onwards inorder

to make sure that purchased materials willbe used ony ster the verification of conformity

ofthe spectied requirements

Inspection and tex actions are performed according ta inspection and Test Plans, sing to

Ceri the utflment of the product in each of its procedure phase.

Final inepection and test wil be cared aut to confem the conformity of he final product

with the spectied requisites.

Inspection ane test plan record shall be eatabished and maintain records which provide

evidence thatthe product has been inspected

10.0 CONTROL OF INSPECTION, MEASURING AND TEST EQUIPMENT

‘The company will ensure al Inspection, measuring and est equipment have been calbated

Callration records shal be maintained

‘The company wl ensure thatthe preservation an storage handing of inspection, measuring,

and test equipments such thatthe accuracy and tings for use are maintained.

111.0 INSPECTION AND TEST STATUS

‘The identification of inspection and tes status shall be maintained as defined in the quay

plan and document procedure to ensue that ony product that has passed the required

Inspection and test,

2.

CONTROL OF NON CONFORMANCE REPORT | NCR:

‘The company possess the methodologies forthe identification and treatment ofon

conformance report as per the Quality Control Manu

Provict which doesnot conform to specified requirement sis prevented from using for

production.

Desa Nikmat€ & Cdn hd

uatty Pan

Procedure No:ONEC(QR-0O1

fevislon No: A

Page 21 of 4

Ton conforming product sal be reworked ta meet the speolied requrements acaable

with or without repair by concession regraded appeation or eject or scrapped

‘Repaired and ceworked product shale inspected in accordance with the Inpetion& Test

13.0 CORRECTIVE AND PREVENTIVE ACTIONS

“The company possess the methodologies fr corrective and preventive ations as pethe

‘Quality Control Manual

‘The company ill ensue of application corrective actions taken and that effect

‘The company wil take necessary preventive action, to ensure the potential of man-

conforment not repeated

a0 (ING PRESERVATION AND DELIVERY.

Handling The company wll ensure methods of handing produc that prevent damage oF

deterioration

Storage Designated storage area to prevent damaged or deterioration of products

Packing & Preservation - Shall done according to customer requirement.

Delivery: Upon completion af testing ad inspection, the quality produc shall be devered

with protection as per customar's requirement

15.0. CONTROL OF QUALITY RECORD

‘The company wil ensure that ll quality record shall be legible and stored, an retained in

Such a way that they are readily retrievable in facts that provide a suitable environment

te prevent damaged o deterioration and os

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5811)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- HSE JSA Lifting Jembatan Rangka Baja A140Document5 pagesHSE JSA Lifting Jembatan Rangka Baja A140widiNo ratings yet

- ENG BC 01 Officer NoRestrictionDocument1 pageENG BC 01 Officer NoRestrictionwidiNo ratings yet

- Welding Schedule A.100-CAMCHE 1Document4 pagesWelding Schedule A.100-CAMCHE 1widiNo ratings yet

- Pengenalan Jembatan Baja Dan Bagian Bagian NyaDocument25 pagesPengenalan Jembatan Baja Dan Bagian Bagian NyawidiNo ratings yet

- PRD - JD - 03 - Production OfficerDocument1 pagePRD - JD - 03 - Production OfficerwidiNo ratings yet

- Diagram Pre Chamber Jembatan Rangka Baja ADocument1 pageDiagram Pre Chamber Jembatan Rangka Baja AwidiNo ratings yet

- MDR C40 Pt. DmiDocument14 pagesMDR C40 Pt. DmiwidiNo ratings yet

- PRD - JD - 01 - Works ManagerDocument1 pagePRD - JD - 01 - Works ManagerwidiNo ratings yet

- ITK-II-HSE-07 Prosedure APDDocument11 pagesITK-II-HSE-07 Prosedure APDwidiNo ratings yet

- ITK-II-HSE-26 Prosedur Bekerja Diketinggian.Document4 pagesITK-II-HSE-26 Prosedur Bekerja Diketinggian.widiNo ratings yet

- Alur Utama Divisi ProjectDocument4 pagesAlur Utama Divisi ProjectwidiNo ratings yet

- ITK II HSE 20 Prosedur Kalibrasi AlatDocument4 pagesITK II HSE 20 Prosedur Kalibrasi AlatwidiNo ratings yet

- Metode Fabrikasi Jembatan Rangka C50Document25 pagesMetode Fabrikasi Jembatan Rangka C50widiNo ratings yet

- 04 IK Stamping & FinishingDocument5 pages04 IK Stamping & FinishingwidiNo ratings yet

- ITK-II-HSE-22 Prosedur Tanggap Darurat Gempa BumiDocument4 pagesITK-II-HSE-22 Prosedur Tanggap Darurat Gempa BumiwidiNo ratings yet

- ITK-II-HSE-24 Prosedur Penanganan Kebakaran Dan PencegahanDocument6 pagesITK-II-HSE-24 Prosedur Penanganan Kebakaran Dan PencegahanwidiNo ratings yet

- Flow Aktivitas ProyekDocument12 pagesFlow Aktivitas ProyekwidiNo ratings yet

- ITK-II-HSE-23 Prosedur Penanganan Huru HaraDocument3 pagesITK-II-HSE-23 Prosedur Penanganan Huru Harawidi100% (1)

- 01 IK Blasting Painting& GalvanizingDocument4 pages01 IK Blasting Painting& GalvanizingwidiNo ratings yet

- 05 Ik Perakitan & PengelasanDocument5 pages05 Ik Perakitan & PengelasanwidiNo ratings yet

- 03 IK INSP Pelaksanaan Non Destructif TestDocument4 pages03 IK INSP Pelaksanaan Non Destructif TestwidiNo ratings yet

- B. Training MatrixDocument5 pagesB. Training MatrixwidiNo ratings yet

- Sop Teknis Pemeliharaan Jembatan 1Document12 pagesSop Teknis Pemeliharaan Jembatan 1widiNo ratings yet

- Painting Procedure-Stack-shop InspectionDocument32 pagesPainting Procedure-Stack-shop InspectionwidiNo ratings yet

- Metode Erection Jembatan Pipa R2 - Pak Edi - 10 Jan 2022Document84 pagesMetode Erection Jembatan Pipa R2 - Pak Edi - 10 Jan 2022widiNo ratings yet

- Jsa Pekerjaan PengelasanDocument6 pagesJsa Pekerjaan PengelasanwidiNo ratings yet

- Itp For Piping Fabrication and InstallationDocument10 pagesItp For Piping Fabrication and InstallationwidiNo ratings yet

- Itp For Penstock InstalationDocument2 pagesItp For Penstock InstalationwidiNo ratings yet

- ANALISA METODE KONSTRUKSI JEMBATAN JOGLO v4Document39 pagesANALISA METODE KONSTRUKSI JEMBATAN JOGLO v4widiNo ratings yet

- E. Prosedure Laporan Kinerja K3LDocument5 pagesE. Prosedure Laporan Kinerja K3LwidiNo ratings yet