Professional Documents

Culture Documents

NT Build 141 Adhesives For Floor and Wall Coverings - Long Term Shear Strenght - Nordtest Method

Uploaded by

ironfaceOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

NT Build 141 Adhesives For Floor and Wall Coverings - Long Term Shear Strenght - Nordtest Method

Uploaded by

ironfaceCopyright:

Available Formats

ADHESIVES FOR FLOOR AND WALL COVERINGS: UDC 69.025.35:645.1/.

2

LONG-TERM SHEAR STRENGTH 691.17

620.176

Key words: Adhesives, floor coverings, wall coverings, shear

strength, test method

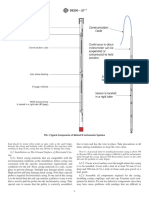

1 SCOPE 6.2 Apparatus

This Nordtest method is intended for the determination of the An arrangement in which a baseplate - dimensions about 200

long-term shear strength which an adhesive is able to transmit. mm x 120 mm to which 3 PVC test specimens may be secured

by adhesive - can be mounted vertically with 2 or 3 weight

underneath, see Fig. 1.6 weights, each with a mass of 2,0 kg.

2 FIELD OF APPLICATION 3 clamping devices to be attached to the PVC test specimens

- see Fig. 1, - so that a load, in form of weights, may be

The method is, in particular, intended for the testing of ad- applied. The clamping device should be of such a weight that

hesives used for securing PVC floor and wall coverings and the mass of the PVC test specimen and clamping device

also skirting board of plastic. together is 2.0 kg.

The method can be used to compare the adhesive and co- If possible an apparatus for recording the time to failure of the

hesive properties of different adhesives. The test result will adhesive joint.

also depend on the properties of the covering and the base- 1 baseplate made of the supporting material to be tested, about

plate. 200 mm x 120 mm.

3 pieces of PVC floor or wall covering, 50 ± 1 mm x 120 ± 1

mm. Putty knife to apply the adhesive.

3 REFERENCES

4 DEFINITIONS

5 SAMPLING

The adhesive is normally delivered by the client, and the Baseplate -

E

I

sample selected for testing must be representative of the b

content of the packing. It is important to follow closely the 0

hl

instructions given by the manufacturer for the use of the x

iI

adhesive.

Piece of floor

covering

xlil-

Clamping device

6 METHOD OF TEST -h;fjv

Weights

6.1 Principle

Small test specimens are suspended vertically. 3 x

The specimens are exposed to shear force for 24 days or until

the joint fails. Fig. 1. Device for testing of long term shear strength.

Published by NORDTEST Tekniikantie 12 FIN-02150 ESPOO FINLAND Phone+35894554600 Fax+35894554272

ISSN 0283-7153 Proj. 136-78 Internet: www.nordtest.org

NORDTEST METHOD NT BUILD 141 2

6.3 Preparation of test samples 6.6 Accuracy

For each test 3 specimens are prepared. No special comments.

If the baseplate is very uneven, it has to be ground with

sandpaper to a maximum deviation of 0,2 mm from an even

plate. 6.7 Test report

The covering and the baseplate shall be conditioned at 296 K The test report shall include the following information, if rele-

± 2 K and 50 ± 5 %RH for 2-3 days. The adhesive must be vant:

kept under these conditions for at least 24 h.

a) Name and address of the testing laboratory

Three areas of 50 mm x 60 mm each on the baseplate shall

be masked by means of tape - see Fig. 1 - and specimen b) Identification number of the test report

areas on the PVC shall also be masked off in the same size.

c) Name and address of the organisation or person who

The PVC specimens shall be secured to the areas marked on ordered the test

the baseplate by means of the adhesive to be tested. The

d) Purpose of the test

adhesive is applied according to the directions for use given

by the manufacturer. Method of sampling and other circumstances (date and

e)

The test specimens shall now be conditioned for 7 days at 296 person responsible for the sampling)

K ± 2 K and 50 ± 5 % RH. Name and address of manufacturer or supplier of the

f)

tested object

6.4 Procedure

g) Name or other identification marks of the tested object

The test is carried out under the same conditions as the test h) Description of the tested object

specimens are stored.

i) Date of supply of the tested object

The baseplate is mounted in such a position that the PVC test Date of the test

j)

specimens can be suspended vertically. The clamping

devices are secured. The test specimens are allowed to re- k) Test method

main in this condition for 4 days. The load is increased by 2,0

kg and the specimens are again left for 4 days. The load is l) Conditioning of the test specimens, environmental data

during the test (temperature, pressure, RH, etc.)

then increased by another 2,0 kg and the total load of 6,0 kg

allowed to remain in position for 16 days or until the joint fails. m) Identification of the test equipment and instruments used

The fracture is then inspected so that it can be determined if Any deviations from the test method

n)

the adhesive has slipped from the covering or from the base-

plate, or if the adhesive itself has been torn apart. 0) Test results (use SI units)

Wall coverings made of flexible foam material should not be p) Inaccuracy or uncertainty of the test results

cut until 72 h after the manufacturing process is completed.

q) Date and signature.

6.5 Expression of results

7 ANNEX

The results of each test is given as the number of whole days

for which the joint is maintained. The long-term strength of the This method has been developed in the laboratory of Tarkett

adhesive is the mean value of the three results. AB and publishing in Bring, C., Roman, B., 1977, Invändiga

ytskikt till väggar och tak (Statens råd för byggnadsforskning,

Any displacement of the remaining test specimens is at the

Rapport R9: 1977, Stockholm).

end of the test decided to the nearest 1 mm according to the

markings.

You might also like

- Applied Weight Per Unit Area of Dried Adhesive Solids: Standard Test Method ForDocument2 pagesApplied Weight Per Unit Area of Dried Adhesive Solids: Standard Test Method ForCris BandaNo ratings yet

- Adhesion of Pressure-Sensitive Tape To Fiberboard at 90° Angle and Constant StressDocument5 pagesAdhesion of Pressure-Sensitive Tape To Fiberboard at 90° Angle and Constant Stressmkaseem74No ratings yet

- Applied Weight Per Unit Area of Dried Adhesive Solids: Standard Test Method ForDocument3 pagesApplied Weight Per Unit Area of Dried Adhesive Solids: Standard Test Method Forgt toniNo ratings yet

- Oil Migration or Plasticizer Bleed-Out of Preformed Tape SealantsDocument2 pagesOil Migration or Plasticizer Bleed-Out of Preformed Tape Sealantssebastian novoaNo ratings yet

- Applied Weight Per Unit Area of Liquid Adhesive: Standard Practice ForDocument2 pagesApplied Weight Per Unit Area of Liquid Adhesive: Standard Practice ForCris BandaNo ratings yet

- Astm d7272Document6 pagesAstm d7272Manuel ContrerasNo ratings yet

- Evaluating The Tear Resistance of A Sealant Under Constant StrainDocument5 pagesEvaluating The Tear Resistance of A Sealant Under Constant Straintejas.winrefNo ratings yet

- NT Build 109 Building Gaskets - Compression Set - Nordtest MethodDocument2 pagesNT Build 109 Building Gaskets - Compression Set - Nordtest MethodironfaceNo ratings yet

- Astm C 772-2003Document2 pagesAstm C 772-2003zeqs9No ratings yet

- NT Build 146 Adhesives For Floor and Wall Coverings - Resistance Against Plasticiser - Nordtest MethodDocument6 pagesNT Build 146 Adhesives For Floor and Wall Coverings - Resistance Against Plasticiser - Nordtest MethodironfaceNo ratings yet

- Astm C297-99Document2 pagesAstm C297-99LIN SONGNo ratings yet

- C 0794 01 Sellantes Adhesion DespellejadoDocument5 pagesC 0794 01 Sellantes Adhesion DespellejadoJuan ZamoraNo ratings yet

- Comparison of Bond Strength or Ply Adhesion of Similar Laminates Made From Flexible MaterialsDocument3 pagesComparison of Bond Strength or Ply Adhesion of Similar Laminates Made From Flexible MaterialslexandroNo ratings yet

- Astm C 907-2008Document3 pagesAstm C 907-2008zeqs9No ratings yet

- D 5641.-11 Prueba de Camara VacioDocument4 pagesD 5641.-11 Prueba de Camara VacioSantiago GonzálezNo ratings yet

- D 906 - 98 R04Document4 pagesD 906 - 98 R04MarceloNo ratings yet

- C 557 - 03 - Qzu1nw - PDFDocument9 pagesC 557 - 03 - Qzu1nw - PDFSamuelNo ratings yet

- ASTM D 1876-2001 - Standard Peel Resistance PDFDocument3 pagesASTM D 1876-2001 - Standard Peel Resistance PDFbcsmurthyNo ratings yet

- Lap Shear Strength of Hot-Applied Sealants: Standard Test Method ForDocument4 pagesLap Shear Strength of Hot-Applied Sealants: Standard Test Method ForSTAFFORDNo ratings yet

- F 2252 - 03 - RjiyntiDocument2 pagesF 2252 - 03 - RjiyntiAndres Camilo Benitez100% (1)

- Adhesion-in-Peel of Elastomeric Joint Sealants: Standard Test Method ForDocument4 pagesAdhesion-in-Peel of Elastomeric Joint Sealants: Standard Test Method Forמשה אביסדריסNo ratings yet

- Astm D 3359-97 (Pruebas de Adherencia)Document6 pagesAstm D 3359-97 (Pruebas de Adherencia)malota2108No ratings yet

- Water Resistance: Rain TestDocument2 pagesWater Resistance: Rain TestJackie Li100% (1)

- NT Build 143 Adhesives For Floor and Wall Coverings - Peel Off Strenght - Nordtest MethodDocument7 pagesNT Build 143 Adhesives For Floor and Wall Coverings - Peel Off Strenght - Nordtest MethodironfaceNo ratings yet

- D 6862 - 03 Rdy4nji - PDFDocument5 pagesD 6862 - 03 Rdy4nji - PDFMarceloNo ratings yet

- Astm D 5064Document2 pagesAstm D 5064Alejandro 20No ratings yet

- Evaluating Adhesive and The Effects of Plasticizer Found Within Polyvinyl Chloride-Backed Floor CoveringsDocument2 pagesEvaluating Adhesive and The Effects of Plasticizer Found Within Polyvinyl Chloride-Backed Floor CoveringsasmaNo ratings yet

- C 1135 00 Sellantes Adhesion TensionDocument3 pagesC 1135 00 Sellantes Adhesion TensionMariano Bonum DieNo ratings yet

- Mar Resistance of Organic Coatings: Standard Test Method ForDocument3 pagesMar Resistance of Organic Coatings: Standard Test Method Formit uotNo ratings yet

- Softness of Preformed Tape Sealants: Standard Test Method ForDocument2 pagesSoftness of Preformed Tape Sealants: Standard Test Method Forsebastian novoaNo ratings yet

- D 1874 - 62 R04 Rde4nzqDocument2 pagesD 1874 - 62 R04 Rde4nzqMarceloNo ratings yet

- D 906 - 98 Rdkwni05oaDocument4 pagesD 906 - 98 Rdkwni05oaMarceloNo ratings yet

- Floating Roller Peel Resistance of Adhesives: Standard Test Method ForDocument4 pagesFloating Roller Peel Resistance of Adhesives: Standard Test Method ForMarceloNo ratings yet

- Kerosine Number of Roofing and Flooring Felt by The Vacuum MethodDocument3 pagesKerosine Number of Roofing and Flooring Felt by The Vacuum MethodDoicielNo ratings yet

- C 879 - 03 - Qzg3oqDocument3 pagesC 879 - 03 - Qzg3oqneophymenNo ratings yet

- Determining Slump Resistance of Carpet Adhesives: Standard Test Method ForDocument2 pagesDetermining Slump Resistance of Carpet Adhesives: Standard Test Method ForFanambinantsoa Eddy RAKOTONDRAZAFYNo ratings yet

- Astm d6230 - Part 2Document4 pagesAstm d6230 - Part 2leegoon82No ratings yet

- AstmDocument5 pagesAstmmohamed abd eldayemNo ratings yet

- Norma D-6904-03 Wind Diven Rain Test PDFDocument3 pagesNorma D-6904-03 Wind Diven Rain Test PDFflorentinoNo ratings yet

- D 4501 - 01 - Rdq1mdeDocument5 pagesD 4501 - 01 - Rdq1mdePRASANTH PRASANTHNo ratings yet

- Cross Cut TestDocument2 pagesCross Cut TestDewiNo ratings yet

- Adhesion-in-Peel of Elastomeric Joint Sealants: Standard Test Method ForDocument4 pagesAdhesion-in-Peel of Elastomeric Joint Sealants: Standard Test Method Forquality staffordNo ratings yet

- Welding Procedure For PVCDocument4 pagesWelding Procedure For PVCVince Tuyulab0% (1)

- Measurement of Masonry Flexural Bond Strength: Standard Test Method ForDocument11 pagesMeasurement of Masonry Flexural Bond Strength: Standard Test Method ForFranky HernandezNo ratings yet

- C367Document5 pagesC367dinhtung2210No ratings yet

- G95.desprendimiento Catodico PDFDocument4 pagesG95.desprendimiento Catodico PDFCoco GalindoNo ratings yet

- 2ASTM C794 - Adhesion-in-Peel of Elastomeric Joint SealantsDocument4 pages2ASTM C794 - Adhesion-in-Peel of Elastomeric Joint SealantsRajeshNo ratings yet

- ASTM C 167 Standard Test Methods For Thickness and Density of Blanket or Batt Thermal InsulationsDocument4 pagesASTM C 167 Standard Test Methods For Thickness and Density of Blanket or Batt Thermal InsulationsRyan LasacaNo ratings yet

- Astm C 557 - 99 - QZU1NY05OQDocument5 pagesAstm C 557 - 99 - QZU1NY05OQSamuel EduardoNo ratings yet

- C 367 - 99 - QZM2NWDocument5 pagesC 367 - 99 - QZM2NWElvis Lionel FLORES ROCANo ratings yet

- Adhesion-in-Peel of Elastomeric Joint Sealants: Standard Test Method ForDocument4 pagesAdhesion-in-Peel of Elastomeric Joint Sealants: Standard Test Method Forquality staffordNo ratings yet

- Tensile Bond Strength of New and RebondedDocument12 pagesTensile Bond Strength of New and RebondedPaola FernandezNo ratings yet

- Astm D 6583 00 - Ensaio Padronizado Porosidade Camada de TintaDocument2 pagesAstm D 6583 00 - Ensaio Padronizado Porosidade Camada de TintaNara CamargoNo ratings yet

- Astm d1184Document3 pagesAstm d1184Cris BandaNo ratings yet

- D 7003 Â " 03 RDCWMDMDocument2 pagesD 7003 Â " 03 RDCWMDMLeón SuárezNo ratings yet

- Astm D2095 PDFDocument3 pagesAstm D2095 PDFTaher Hama AmeenNo ratings yet

- Optimal Design of Flexural Systems: Beams, Grillages, Slabs, Plates and ShellsFrom EverandOptimal Design of Flexural Systems: Beams, Grillages, Slabs, Plates and ShellsNo ratings yet

- Poroelastic StructuresFrom EverandPoroelastic StructuresG. CederbaumNo ratings yet

- NT Mech 033 Combination Packagings - Dangerous Goods.Document2 pagesNT Mech 033 Combination Packagings - Dangerous Goods.ironfaceNo ratings yet

- NT Poly 188 Measurement of Diffusion Coefficients.Document6 pagesNT Poly 188 Measurement of Diffusion Coefficients.ironfaceNo ratings yet

- NT Fire 046 Atrium Roof Construction Fire Resistance.Document3 pagesNT Fire 046 Atrium Roof Construction Fire Resistance.ironfaceNo ratings yet

- NT Fire 038 Building Materials Combustible Content.Document3 pagesNT Fire 038 Building Materials Combustible Content.ironfaceNo ratings yet

- NT Fire 056 Corrosion Test For Fire Retardant Treated Wooden Products.Document4 pagesNT Fire 056 Corrosion Test For Fire Retardant Treated Wooden Products.ironfaceNo ratings yet

- NT Poly 175 Adhesive Compounds Tests For Use in Marine Environments.Document7 pagesNT Poly 175 Adhesive Compounds Tests For Use in Marine Environments.ironfaceNo ratings yet

- NT TR 491 Creep of Granulated Loose-Fil Insulation - Test Method and Round Robin Test (Nordtest Technical Report)Document65 pagesNT TR 491 Creep of Granulated Loose-Fil Insulation - Test Method and Round Robin Test (Nordtest Technical Report)ironfaceNo ratings yet

- NT TR 506a Consensus Meeting On Chemical Testing of Emission From Building Products (Nordtest Technical Report)Document22 pagesNT TR 506a Consensus Meeting On Chemical Testing of Emission From Building Products (Nordtest Technical Report)ironfaceNo ratings yet

- NT NDT 008 Corrosion, Internal Detection and Sizing, Manual Ultrasonics.Document12 pagesNT NDT 008 Corrosion, Internal Detection and Sizing, Manual Ultrasonics.ironfaceNo ratings yet

- NT Vvs 078 Ceiling Cooling Systems Cooling Capacity.Document4 pagesNT Vvs 078 Ceiling Cooling Systems Cooling Capacity.ironfaceNo ratings yet

- NT Build 143 Adhesives For Floor and Wall Coverings - Peel Off Strenght - Nordtest MethodDocument7 pagesNT Build 143 Adhesives For Floor and Wall Coverings - Peel Off Strenght - Nordtest MethodironfaceNo ratings yet

- BS en 572-5-2012 Glass in Building. Basic Soda Lime Silicate Glass Products. Part 5 Patterned Glass.Document14 pagesBS en 572-5-2012 Glass in Building. Basic Soda Lime Silicate Glass Products. Part 5 Patterned Glass.ironfaceNo ratings yet

- NT Build 146 Adhesives For Floor and Wall Coverings - Resistance Against Plasticiser - Nordtest MethodDocument6 pagesNT Build 146 Adhesives For Floor and Wall Coverings - Resistance Against Plasticiser - Nordtest MethodironfaceNo ratings yet

- NT Build 109 Building Gaskets - Compression Set - Nordtest MethodDocument2 pagesNT Build 109 Building Gaskets - Compression Set - Nordtest MethodironfaceNo ratings yet

- NT Build 059 Cladding Materials - Indentation Hardness - Nordtest MethodDocument4 pagesNT Build 059 Cladding Materials - Indentation Hardness - Nordtest MethodironfaceNo ratings yet

- CEN EN 12457 Leaching Test: Comparison of Test Results Obtained by Part 1 and 2 With Test Results Obtained by Part 3Document66 pagesCEN EN 12457 Leaching Test: Comparison of Test Results Obtained by Part 1 and 2 With Test Results Obtained by Part 3ironfaceNo ratings yet

- NT Build 112 Building Gaskets - Contact and Migration Stain - Nordtest MethodDocument2 pagesNT Build 112 Building Gaskets - Contact and Migration Stain - Nordtest MethodironfaceNo ratings yet

- BS en 572-4-2012 Glass in Building. Basic Soda Lime Silicate Glass Products. Part 4 Drawn Sheet Glass.Document14 pagesBS en 572-4-2012 Glass in Building. Basic Soda Lime Silicate Glass Products. Part 4 Drawn Sheet Glass.ironfaceNo ratings yet

- Determining The Potential Alkali-Silica Reactivity of Combinations of Cementitious Materials and Aggregate (Accelerated Mortar-Bar Method)Document6 pagesDetermining The Potential Alkali-Silica Reactivity of Combinations of Cementitious Materials and Aggregate (Accelerated Mortar-Bar Method)ironfaceNo ratings yet

- Durability of WoodDocument40 pagesDurability of WoodSegundo OrilleroNo ratings yet

- BS EN 477-1999 Unplasticized Polyvinylchloride (PVC-U) Profiles For The Fabrication of Windows and Doors. Determination of The Resistance To Impact of Main Profiles by Falling Mass.Document8 pagesBS EN 477-1999 Unplasticized Polyvinylchloride (PVC-U) Profiles For The Fabrication of Windows and Doors. Determination of The Resistance To Impact of Main Profiles by Falling Mass.ironfaceNo ratings yet

- Glass in Building - Basic Soda-Lime Silicate Glass Products: BSI Standards PublicationDocument18 pagesGlass in Building - Basic Soda-Lime Silicate Glass Products: BSI Standards Publicationironface100% (1)

- BS en 317-1993 (1999) Particleboards And. Fibreboards - . Determination Of. Swelling in Thickness. After Immersion In. Water.Document12 pagesBS en 317-1993 (1999) Particleboards And. Fibreboards - . Determination Of. Swelling in Thickness. After Immersion In. Water.ironfaceNo ratings yet

- BS en 322-1993 (1999) Wood-Based Panels - Determination of Moisture Content.Document10 pagesBS en 322-1993 (1999) Wood-Based Panels - Determination of Moisture Content.ironfaceNo ratings yet

- BS en 12697-3-2013 Bituminous Mixtures - Test Methods Part 3 Bitumen Recovery Rotary Evaporator.Document20 pagesBS en 12697-3-2013 Bituminous Mixtures - Test Methods Part 3 Bitumen Recovery Rotary Evaporator.ironfaceNo ratings yet

- BS en 12697-2-2015 Bituminous Mixtures - Test Methods Part 2 Determination of Particle Size Distribution.Document16 pagesBS en 12697-2-2015 Bituminous Mixtures - Test Methods Part 2 Determination of Particle Size Distribution.ironfaceNo ratings yet

- Tesla Coil ProjectDocument8 pagesTesla Coil ProjectShivam singhNo ratings yet

- Fully Automatic Coffee Machine - Slimissimo - IB - SCOTT UK - 2019Document20 pagesFully Automatic Coffee Machine - Slimissimo - IB - SCOTT UK - 2019lazareviciNo ratings yet

- Considerations For Impeller Trimming - Empowering Pumps and EquipmentDocument8 pagesConsiderations For Impeller Trimming - Empowering Pumps and Equipment김기준No ratings yet

- Chapter 7 - Muscular SystemDocument29 pagesChapter 7 - Muscular SystemlNo ratings yet

- Manual PipsDocument5 pagesManual PipsOzzyNo ratings yet

- Semi Finals in Tle 2015Document3 pagesSemi Finals in Tle 2015LoraineTenorioNo ratings yet

- FYP ProposalDocument11 pagesFYP ProposalArslan SamNo ratings yet

- OurCatholicFaith PowerPoint Chapter1Document21 pagesOurCatholicFaith PowerPoint Chapter1VinNo ratings yet

- ZF-FreedomLine TransmissionDocument21 pagesZF-FreedomLine TransmissionHerbert M. Zayco100% (1)

- SP Essay 1Document14 pagesSP Essay 1api-511870420No ratings yet

- Unit 3Document12 pagesUnit 3Erik PurnandoNo ratings yet

- Owner'S Manual: 2023 Chassis CabDocument444 pagesOwner'S Manual: 2023 Chassis CabDmitry DimasNo ratings yet

- June 2021 QP - Paper 1 (H) Edexcel Chemistry GCSEDocument28 pagesJune 2021 QP - Paper 1 (H) Edexcel Chemistry GCSEmiapoppycollinsNo ratings yet

- 3 Tasks and ANS - Gamma Maths PDFDocument6 pages3 Tasks and ANS - Gamma Maths PDFNora ZhangNo ratings yet

- Astm C892 - 00Document5 pagesAstm C892 - 00reneeNo ratings yet

- NAT-REVIEWER-IN-PHYSICAL EDUCATIONDocument4 pagesNAT-REVIEWER-IN-PHYSICAL EDUCATIONMira Rochenie CuranNo ratings yet

- Cross Talk Details and RoutingDocument29 pagesCross Talk Details and RoutingRohith RajNo ratings yet

- Sat Vocabulary Lesson and Practice Lesson 5Document3 pagesSat Vocabulary Lesson and Practice Lesson 5api-430952728No ratings yet

- C.Abdul Hakeem College of Engineering and Technology, Melvisharam Department of Aeronautical Engineering Academic Year 2020-2021 (ODD)Document1 pageC.Abdul Hakeem College of Engineering and Technology, Melvisharam Department of Aeronautical Engineering Academic Year 2020-2021 (ODD)shabeerNo ratings yet

- Electrowetting - Wikipedia, The Free EncyclopediaDocument5 pagesElectrowetting - Wikipedia, The Free EncyclopediaDwane AlmeidaNo ratings yet

- Study The Effect of Postharvest Heat Treatment On Infestation Rate of Fruit Date Palm (Phoenix Dactylifera L.) Cultivars Grown in AlgeriaDocument4 pagesStudy The Effect of Postharvest Heat Treatment On Infestation Rate of Fruit Date Palm (Phoenix Dactylifera L.) Cultivars Grown in AlgeriaJournal of Nutritional Science and Healthy DietNo ratings yet

- SDHI18 - Komparativna Analiza Primene Vodostana I Sinhronih Regulatora TurbinaDocument13 pagesSDHI18 - Komparativna Analiza Primene Vodostana I Sinhronih Regulatora TurbinaAleksandar PetkovicNo ratings yet

- 1962 Gibson Johnny SmithDocument5 pages1962 Gibson Johnny SmithLuisNo ratings yet

- 3-History Rock Cut MonumentDocument136 pages3-History Rock Cut MonumentkrishnaNo ratings yet

- Worksheet Series 5: Answer Any 3 Questions From 1 To 6. (2 Score Each)Document6 pagesWorksheet Series 5: Answer Any 3 Questions From 1 To 6. (2 Score Each)AswithNo ratings yet

- Biophoton RevolutionDocument3 pagesBiophoton RevolutionVyavasayaha Anita BusicNo ratings yet

- CapstoneDocument23 pagesCapstoneA - CAYAGA, Kirby, C 12 - HermonNo ratings yet

- Nivel VV-VW Board User Guide enDocument5 pagesNivel VV-VW Board User Guide enHarveyWishtartNo ratings yet

- DISPOSABLE GLOVES CATALOG 2023npDocument4 pagesDISPOSABLE GLOVES CATALOG 2023npTeodylee CruzNo ratings yet

- Design and Development of Automatic Pneumatic Jack in Four Wheeler Ijariie5374Document5 pagesDesign and Development of Automatic Pneumatic Jack in Four Wheeler Ijariie5374Saravanan ViswakarmaNo ratings yet