Professional Documents

Culture Documents

Work Instruction Template (Operational)

Uploaded by

haaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Work Instruction Template (Operational)

Uploaded by

haaCopyright:

Available Formats

Bandsaw Operation

Date Issued: 22/04/20 Document Owner: Quality Engineer

Scheduled Review Date: 22/04/23 Document Approver: Plant Operations Manager

Contents of this document are confidential and property of Metso Australia Limited (Metso). Unauthorised use or reproduction without written permission is prohibited.

This instruction and risk assessment document has been developed from Metso’s Risk Register in accordance with the Work Instruction Procedure.

If the task being performed differs from this document or changes in any way (e.g. environmental differences/changes) then a JSEA must be completed; unless otherwise

approved by the National HSE Manager.

Where workers are required to sign on to this document, they should do so using the Metso Work Instruction Sign On document.

Department/s: Cutting Location/s: Canning Vale

Critical Risk Management – Critical Risks involved in this task.

Document Requirements and References (e.g. Take 5, Permits, Legislation): Personnel Requirements (e.g. training/competency/license, supervision,

worker numbers):

▪

▪ Operation Training

▪ High Risk Work Licence

▪ COM.AUS.CV2.SWP.2.001 Safely Operate Cutting Tools

▪ COM.AUS.HSE.SWP.2.012 Operate Overhead Crane & Hoist

▪ COM.AUS.HSE.SWP.2.003 Operate a Forklift

▪ COM.AUS.WHS.SWP.1.002 Perform Basic Rigging

PPE Requirements:

Bandsaw Operation Document No: WIN.CV2.CV2.015.8

Date Printed:22/04/2020 Uncontrolled When Printed Page: 1 of 5

Plant/Equipment/Tool Requirements:

Note: All plant/tools/equipment must be inspected prior to use. All electrical equipment and lifting gear must have current test and tag.

▪ Crane

▪ Lifting equipment

Bandsaw Operation Document No: WIN.CV2.CV2.015.8

Date Printed:22/04/2020 Uncontrolled When Printed Page: 2 of 5

Job Steps

Describe task from start to finish including specific hazards and controls

1. Preparation

▪ Check the saw for safe working condition

▪ Check tables are free to move, where fitted, blade is tensioned, coolant can flow, and machine runs without any unusual noise.

▪ Review the Production Order Packet and part drawings

▪ Select the correct saw to use and place parts appropriately for ease of use

▪ Do not block aisles or fire doors or any other work area.

2. Marking

▪ Mark product using templates or from part drawings provided

▪ If template is supplied, then CHECK the template against the drawing before marking.

3. Cutting

▪ Place parts on table and set the blade guide block to suit the thickness of the product

▪ Use crane and lifting equipment wherever necessary

▪ Ensure the blade guide block is close to the product to get the best results from the machine

▪ Place parts on bandsaw table and turn saw on. Ensure coolant is flowing and then push product up to the blade

▪ Use crane and lifting equipment wherever necessary

▪ Line cutting mark up to blade and continue to push the part through the saw until finished.

▪ Ensure that hands are always kept away from the blade

▪ If necessary, use block to keep hands away from the blade

▪ Turn the saw off.

4. Checking

▪ Check the finished cut for correct dimensions against the product drawing

▪ Remove the product from the table and place it on a pallet ready for packing (if finished) or onto a cutting table if more cutting is necessary

▪ Use crane and lifting equipment wherever necessary

▪ Always use the crane when moving headplates or if you do not feel comfortable lifting it.

Bandsaw Operation Document No: WIN.CV2.CV2.015.8

Date Printed:22/04/2020 Uncontrolled When Printed Page: 3 of 5

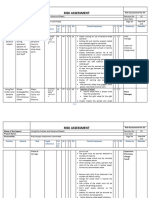

Likelihood

Consequences

Almost Certain Likely Possible Unlikely Rare

Requires

Description Description Expected to Will occur Not expected to

Keyword May Occur unusual chain

Safety Health & Hygiene Environment occur occasionally occur

of events

On site release immediately contained Medium Medium Low Low Low

Minor First aid injury.

with onsite resources 8 7 3 2 1

On site release or off site release

Medically treated injury or High Medium Medium Low Low

Significant immediately contained with on site

illness 14 10 9 5 4

resources

Off site release causing nuisance or

High High Medium Medium Low

Serious Lost time injury or illness community complaint. Breach of licence

16 15 12 11 6

or DA condition

Off site release with detrimental impact to

Fatality or permanently Extreme Extreme High High Medium

Severe environment or community. Repeated

disabling injury or illness 24 22 20 18 13

breach of licence conditions

Multiple fatalities or

Toxic release off site with detrimental Extreme Extreme Extreme High High

Disastrous multiple work related fatal

impact to environment or community 25 23 21 19 17

diseases

Metso HIRAC Risk Level Actions

LEGEND ACTION REQUIRED PERSON

RESPONSIBLE

Low = 1 – 6 Tolerable - Manage by routine procedures

Medium = 7 - 13 Risk reduction required to As Low `As Reasonably Practicable Supervisor

(ALARP)

High = 14 - 20 Immediate action required to reduce risk. JSEA to be signed off by Site/Work Group

Site/Work Group Manager or authorised delegate prior to proceeding Manager

on task

Extreme = 21 - 25 Intolerable. Cease activity and notify senior management. Controls Country SVP

must be implemented in consultation with senior management to

reduce risk prior to recommencement.

Bandsaw Operation Document No: WIN.CV2.CV2.015.8

Date Printed:22/04/2020 Uncontrolled When Printed Page: 4 of 5

Document Revision History

Revision Date Part/Section Details of Changes/Amendments

8 22/04/20 All Document reviewed and amended to ensure compliance with ISO:9001 and the incorporation of WearX and Metso documents.

Document numbering updated to current format

7 21/08/18 All Reformatted to new template

6 30/05/14 All Revised and reissued

5 27/11/12 Checking Directive to “Always use the crane when moving headplates or when you do not feel comfortable lifting it” added to section Checking

4 15/02/12 All Revised and reissued

3 31/05/10 All Revised and reissued

2 25/02/09 All Revised and reissued

1 01/11/00 All New document

Bandsaw Operation Document No: WIN.CV2.CV2.015.8

Date Printed:22/04/2020 Uncontrolled When Printed Page: 5 of 5

You might also like

- SOP-22 AC Compressore Replacement WorkDocument4 pagesSOP-22 AC Compressore Replacement WorkNarendra SinghNo ratings yet

- Safe Working Procedure For Band SawDocument2 pagesSafe Working Procedure For Band SawsizweNo ratings yet

- List Pre-Requisites Here: Importance Ranking Satisfactory or Needs WorkDocument19 pagesList Pre-Requisites Here: Importance Ranking Satisfactory or Needs WorkiZnoGouDmuzicNo ratings yet

- Kuraray America Inc Final Report 2022-12-16Document182 pagesKuraray America Inc Final Report 2022-12-16Ukrit ChansodaNo ratings yet

- Tetra Pak Alex 25 TeMDocument202 pagesTetra Pak Alex 25 TeMMateus MagalhãesNo ratings yet

- PipingDocument9 pagesPipingshamierrul shahliNo ratings yet

- Operating Instructions Flexdip CYA112: Wastewater AssemblyDocument36 pagesOperating Instructions Flexdip CYA112: Wastewater AssemblyLUIS ZAPANANo ratings yet

- Basics of Equipment Guarding: Mining and Petroleum Training ServiceDocument51 pagesBasics of Equipment Guarding: Mining and Petroleum Training ServiceKim Lien TrinhNo ratings yet

- Removal and Replacement of Corroded Mixer Tank Platform Risk AssessmentDocument5 pagesRemoval and Replacement of Corroded Mixer Tank Platform Risk AssessmentPaul ChandaNo ratings yet

- Accident Incident Report ProcedureDocument15 pagesAccident Incident Report ProcedureMouctar GUINDONo ratings yet

- Induction Motors/ Generators: Installation Operation MaintenanceDocument38 pagesInduction Motors/ Generators: Installation Operation Maintenancepatelr123No ratings yet

- Welding Robots Technology System Issues and Applications - J Norberto PiresDocument76 pagesWelding Robots Technology System Issues and Applications - J Norberto PireshetpinNo ratings yet

- Buildsafe AustraliaDocument12 pagesBuildsafe AustraliaRahmat HariNo ratings yet

- 4 5.site Specific Assessment ExampleDocument2 pages4 5.site Specific Assessment ExampleTrustEmmaNo ratings yet

- Usaglasavanje MakazaDocument6 pagesUsaglasavanje MakazaДражен ПетковићNo ratings yet

- Door Window and Roller ShutterDocument7 pagesDoor Window and Roller Shuttershamierrul shahliNo ratings yet

- Baseline Risk Assessment FSDocument17 pagesBaseline Risk Assessment FSStephenNo ratings yet

- Risk Management Report: Type Make Model Serial NumberDocument11 pagesRisk Management Report: Type Make Model Serial NumberdushyantNo ratings yet

- Instructions Hydraulic Table PressDocument26 pagesInstructions Hydraulic Table PressHanna HorváthNo ratings yet

- JSADocument39 pagesJSAAfshin MahdaviNo ratings yet

- Taws Recieving SotreDocument5 pagesTaws Recieving SotresahilNo ratings yet

- 5JTANordberg Cone ReplacementDocument32 pages5JTANordberg Cone ReplacementLmf DanielNo ratings yet

- RA-03-Using Disc Cutters and Abrasive WheelsDocument5 pagesRA-03-Using Disc Cutters and Abrasive Wheelsamritha n krishnaNo ratings yet

- Week 1Document21 pagesWeek 1gaditya17No ratings yet

- SOP Fabrication and Erection and Repairing - PS ..Document28 pagesSOP Fabrication and Erection and Repairing - PS ..Hari NairNo ratings yet

- Kavo 4060 4062 SpindleDocument18 pagesKavo 4060 4062 SpindleKöves IstvánNo ratings yet

- Ksu Band Saw-320 영문 사용설명서Document30 pagesKsu Band Saw-320 영문 사용설명서amri sofyanNo ratings yet

- Machine Guarding EnforcementDocument11 pagesMachine Guarding EnforcementNoe AranelNo ratings yet

- Safe Work Method StatementDocument4 pagesSafe Work Method StatementShahed Facebook100% (1)

- 3954-009-JSA-Cold Field Bending Rev 0Document4 pages3954-009-JSA-Cold Field Bending Rev 0Viron BaxhiaNo ratings yet

- Hydraulic Breaker Guide PDFDocument13 pagesHydraulic Breaker Guide PDFFahri100% (1)

- JSA-003 Fence InstallationDocument5 pagesJSA-003 Fence InstallationMoaatazz Nouisri50% (2)

- 599029W-CAT Manual Partes h5cDocument104 pages599029W-CAT Manual Partes h5cDiego DuranNo ratings yet

- Float SwitchesDocument16 pagesFloat SwitchesSijo JoyNo ratings yet

- BC-5000 BC-5150 Installation Guide - V7.0 - ENDocument41 pagesBC-5000 BC-5150 Installation Guide - V7.0 - ENKevin BravoNo ratings yet

- Bar Bending and Cutting WorkDocument1 pageBar Bending and Cutting WorkAKBAR ALINo ratings yet

- Im01t01b04-01e 003Document20 pagesIm01t01b04-01e 003Bryan NavarreteNo ratings yet

- WSWP For Hamisa Cutting of ConcreateDocument8 pagesWSWP For Hamisa Cutting of ConcreateVictor Thembinkosi MakhubeleNo ratings yet

- JSA (Job Safety Analysis) : PTW #: Job Supervisor: Site / Location: Date: Issued by Client: Job / Task DescriptionDocument3 pagesJSA (Job Safety Analysis) : PTW #: Job Supervisor: Site / Location: Date: Issued by Client: Job / Task DescriptionMeysam DoskiNo ratings yet

- Bizhub c25Document456 pagesBizhub c25Badr Biuo100% (1)

- Bizhub c20-FieldServiceManualDocument495 pagesBizhub c20-FieldServiceManualFrei HerrNo ratings yet

- SWMS - Pedestal DrillDocument3 pagesSWMS - Pedestal DrillMaged AliNo ratings yet

- LOTO Refresher TrainingDocument46 pagesLOTO Refresher TrainingMohd MohdNo ratings yet

- Attachment B (JSA)Document5 pagesAttachment B (JSA)Archana SoorajNo ratings yet

- Stopemate S36IR Manual PDFDocument41 pagesStopemate S36IR Manual PDFRicardo Ramirez EstrelloNo ratings yet

- Induction Motors/ Generators: Installation Operation MaintenanceDocument38 pagesInduction Motors/ Generators: Installation Operation MaintenanceMIGUEL PORTILLA100% (1)

- 333 - Element 5.02.78 Working On Gantries and Heights (EPCM)Document8 pages333 - Element 5.02.78 Working On Gantries and Heights (EPCM)contrax8No ratings yet

- Variador Lte 11625414Document48 pagesVariador Lte 11625414arhescobarNo ratings yet

- New Check ListDocument24 pagesNew Check Listahmed agrodyNo ratings yet

- RA-PROD-013-GALLAF - Hotwork Marking, Cutting, Fit Up On The Rotator MachineDocument8 pagesRA-PROD-013-GALLAF - Hotwork Marking, Cutting, Fit Up On The Rotator MachineidrisNo ratings yet

- EIP 575 Operation ManualDocument78 pagesEIP 575 Operation ManualLuis ContrerasNo ratings yet

- Magicolor 4690MF: Service ManualDocument172 pagesMagicolor 4690MF: Service ManualFrei HerrNo ratings yet

- Drilling and Milling Machine HIRARCDocument1 pageDrilling and Milling Machine HIRARCMahendren Jayapalan0% (1)

- SOP of Bearing ChangeDocument9 pagesSOP of Bearing ChangeDwitikrushna Rout100% (3)

- Hydraulic Press Risk MG T FormDocument10 pagesHydraulic Press Risk MG T FormAndrei VNo ratings yet

- 04 indigoNXT AWN HB enDocument262 pages04 indigoNXT AWN HB enNikolaNo ratings yet

- W0721C I1e 02Document251 pagesW0721C I1e 02orhan kızmazNo ratings yet

- Engineering Principles - PEO 19 2023Document54 pagesEngineering Principles - PEO 19 2023Christopher RedfernNo ratings yet

- Chainsaw Operator's Manual: Chainsaw Safety, Maintenance and Cross-cutting TechniquesFrom EverandChainsaw Operator's Manual: Chainsaw Safety, Maintenance and Cross-cutting TechniquesRating: 5 out of 5 stars5/5 (1)

- Maharishi Language of Gravity - SoS 27Document3 pagesMaharishi Language of Gravity - SoS 27Prof. MadhavanNo ratings yet

- Norman K. Denzin - The Cinematic Society - The Voyeur's Gaze (1995) PDFDocument584 pagesNorman K. Denzin - The Cinematic Society - The Voyeur's Gaze (1995) PDFjuan guerra0% (1)

- The FlyDocument8 pagesThe FlyDrei Tiam Lacadin100% (1)

- Thermal ComfortDocument50 pagesThermal ComfortSSNo ratings yet

- CrumpleZonesSE (Edit)Document12 pagesCrumpleZonesSE (Edit)Dah Unknown MarksmenNo ratings yet

- Lesson Plan Ordinal NumbersDocument5 pagesLesson Plan Ordinal Numbersapi-329663096No ratings yet

- Lesson 7Document6 pagesLesson 7Jeya Plays YTNo ratings yet

- Smart English 2 PDFDocument44 pagesSmart English 2 PDFmishhuana90% (21)

- Operations Management Stevenson 11th Edition Test BankDocument10 pagesOperations Management Stevenson 11th Edition Test BankAries Gonzales Caragan50% (2)

- Finite Element Modeling Analysis of Nano Composite Airfoil StructureDocument11 pagesFinite Element Modeling Analysis of Nano Composite Airfoil StructureSuraj GautamNo ratings yet

- Bo Sanchez-Turtle Always Wins Bo SanchezDocument31 pagesBo Sanchez-Turtle Always Wins Bo SanchezCristy Louela Pagapular88% (8)

- Unit 12 BriefDocument7 pagesUnit 12 Briefapi-477397447No ratings yet

- Final ExamDocument2 pagesFinal ExamblacmsNo ratings yet

- Lesson Plan - Sight Word ObservationDocument2 pagesLesson Plan - Sight Word Observationapi-253277023No ratings yet

- Ruby Onyinyechi Amanze - Werte Magazine - 2019Document2 pagesRuby Onyinyechi Amanze - Werte Magazine - 2019José LaertonNo ratings yet

- Potassium Permanganate CARUSOL CarusCoDocument9 pagesPotassium Permanganate CARUSOL CarusColiebofreakNo ratings yet

- Introduction of Woman Role in SocietyDocument12 pagesIntroduction of Woman Role in SocietyApple DogNo ratings yet

- ADAPT-Builder 2019 GUI Quick Reference GuideDocument103 pagesADAPT-Builder 2019 GUI Quick Reference GuideephremNo ratings yet

- Stamp 07 eDocument6 pagesStamp 07 eDumitru TuiNo ratings yet

- Two Occult Philosophers in The Elizabethan Age: by Peter ForshawDocument10 pagesTwo Occult Philosophers in The Elizabethan Age: by Peter ForshawFrancesco VinciguerraNo ratings yet

- Peter Brandt InterviewDocument38 pagesPeter Brandt InterviewNishant P Kalaskar100% (1)

- Organic Food Business in India A Survey of CompaniDocument19 pagesOrganic Food Business in India A Survey of CompaniShravan KemturNo ratings yet

- Pavlishchuck Addison - 2000 - Electrochemical PotentialsDocument6 pagesPavlishchuck Addison - 2000 - Electrochemical PotentialscomsianNo ratings yet

- PC2000-8 Spec SheetDocument20 pagesPC2000-8 Spec SheetNeeraj ChauhanNo ratings yet

- Module 11 Activity Based CostingDocument13 pagesModule 11 Activity Based CostingMarjorie NepomucenoNo ratings yet

- Datasheet TBJ SBW13009-KDocument5 pagesDatasheet TBJ SBW13009-KMarquinhosCostaNo ratings yet

- Cesars WayDocument20 pagesCesars WayToni TursićNo ratings yet

- Alternatoer Lvsi804s WDG 12 v9 TdsDocument8 pagesAlternatoer Lvsi804s WDG 12 v9 TdsCris_eu09No ratings yet

- Practical Search Techniques in Path Planning For Autonomous DrivingDocument6 pagesPractical Search Techniques in Path Planning For Autonomous DrivingGergely HornyakNo ratings yet

- Valuing Construction Variation by Using PWA, FIDIC, ICWMF and CEDA Fluctuation Formula MechanismDocument5 pagesValuing Construction Variation by Using PWA, FIDIC, ICWMF and CEDA Fluctuation Formula MechanismAzman YahayaNo ratings yet