Professional Documents

Culture Documents

Microtips 01 27 2021 REX012832AWPP3N00000 RevD 201-1984173

Uploaded by

vicio tarOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Microtips 01 27 2021 REX012832AWPP3N00000 RevD 201-1984173

Uploaded by

vicio tarCopyright:

Available Formats

Model No: REX012832AWPP3N00000

Approved By

Tel: 1 (888) 499-8477

Fax: (407) 273-0771

E-mail: mtusainfo@microtipsusa.com

Web: www.microtipsusa.com

Page 1 , Total 27 Pages

OLED SPECIFICATION

Model No:

REX012832AWPP3N00000

CUSTOMER:

APPROVED BY

PCB VERSION

DATE

FOR CUSTOMER USE ONLY

SALES BY APPROVED BY CHECKED BY PREPARED BY

APPROVAL FOR SPECIFICATIONS ONLY

APPROVAL FOR SPECIFICATIONS AND SAMPLE

Page 2 , Total 27 Pages

1. Revision History

VERSION DATE REVISED PAGE NO. Note

0 2015/07/24 First release

A 2015/12/07 Modify Life Time

B 2016/06/01 Modify Static

electricity test

C 2017/10/30 Modify Reliability test

Condition

D 2018/11/28 Modify Static

electricity test

Content of Test

Page 3 , Total 27 Pages

Contents

1.General Specification

2.Module Classification Information

3.Interface Pin Function

4.Contour Drawing & Block Diagram

5.Absolute Maximum Ratings

6.Electrical Characteristics

7.Optical Characteristics

8.OLED Lifetime

9.Reliability

10.Inspection specification

11.Precautions in use of OLED Modules

Page 4 , Total 27 Pages

1.General Specification

The Features is described as follow:

Module dimension: 62.0 × 24.0 × 2.35 (MAX) mm

View area: 57.02 × 15.10 mm

Active area: 55.018 × 13.098 mm

Dot Matrix: 128*32

Dot size: 0.408 × 0.388 mm

Dot pitch: 0.43 × 0.41 mm

Duty: 1/32

Display Color: Monochrome (White)

Page 5 , Total 27 Pages

2.Module Classification information

1 2 3 4 5 6 7 8 9 10 11 12 13 14

R E X 012832 A W P P 3 N 0 0 0 00

1 Brand:Microtips Technology.

2 E:OLED

C:COB Character G:COB Graphic

X:COG H:COG + FR

3 Display Type

P:COG + FR + PCB T:TAB

A:COG + PCB

4 Dot Matrix: 128*32

5 Series

A:Amber R:Red C:Full Color

B:Blue W:White

6 Emitting Color

G:Green Y:Yellow

S:Sky Blue X:Dual Color

P:With Polarizer; N: Without Polarizer

7 Polarizer

A:Anti-glare Polarizer

8 Display Mode P:Passive Matrix ; N:Active Matrix

9 Driver Voltage 3:3.0~3.3V ; 5:5.0V

10 Touch Panel N:Without touch panel; T: With touch panel

0:Standard

1:Daylight Readable

Product type

11 2:Transparent OLED (TOLED)

3:Flexible OLED (FOLED)

4:OLED Lighting

0:Standard

2:B grade

12 Inspection Grade

C:Automotive grade

Y:Consumer grade

13 Option 0:Default ; F:ZIF FPC ; H:Hot bar FPC; D:Demo Kit

14 Serial No. Serial number(00~ZZ)

Page 6 , Total 27 Pages

3.Interface Pin Function

No. Symbol Function

1 N.C.(GND) No connection

This is an analog ground pin. It should be connected to VSS

2 VLSS

externally.

3 VSS Ground.

4 N.C. No connection

5 VDD Power supply pin for core logic operation

Communicating Protocol Select

6 BS1 These pins are MCU interface selection input. See the following

table:

68XX-parallel 80XX-parallel Serial I2C

7 BS2 BS1 0 1 0 1

BS2 1 1 0 0

8 CS# This pin is the chip select input. (active LOW)

This pin is reset signal input. When the pin is LOW, initialization

of the chip is executed.

9 RES#

Keep this pin HIGH (i.e. connect to VDDIO) during normal

operation.

This is Data/Command control pin. When it is pulled HIGH (i.e.

connect to VDDIO), the data at D[7:0] is treated as data. When it

10 D/C# is pulled LOW, the data at D[7:0] will be transferred to the

command register.

In I2C mode, this pin acts as SA0 for slave address selection.

This is read / write control input pin connecting to the MCU

interface.

When interfacing to a 6800-series microprocessor, this pin will be

used as Read/Write (R/W#) selection input. Read mode will be

carried out when this pin is pulled HIGH (i.e. connect to VDDIO)

11 R/W# and write mode when LOW. When 8080 interface mode is

selected, this pin will be the Write (WR#) input. Data write

operation is initiated when this pin is pulled LOW and the chip is

selected.

When serial interface is selected, this pin must be connected to

VSS.

When interfacing to a 6800-series microprocessor, this pin will be

used as the Enable (E) signal. Read/write operation is initiated

when this pin is pulled HIGH (i.e. connect to VDDIO)

and the chip is selected.

12 E/RD#

When connecting to an 8080-microprocessor, this pin receives

the Read (RD#) signal. Read operation is initiated when this pin

is pulled LOW and the chip is selected.

When serial interface is selected, this pin must be connected to

Page 7 , Total 27 Pages

VSS.

13 D0

14 D1 These are 8-bit bi-directional data bus to be connected to the

15 D2 microprocessor’s data bus.

When serial interface mode is selected, D0 will be the serial

16 D3

clock input: SCLK; D1 will be the serial data input: SDIN and D2

17 D4

should be left opened. When I2C mode is selected, D2, D1

18 D5 should be tied together and serve as SDAout, SDAin in

19 D6 application and D0 is the serial clock input, SCL.

20 D7

This is segment output current reference pin.

21 IREF A resistor should be connected between this pin and VSS to

maintain the IREF current at 10uA.

The pin for COM signal deselected voltage level.

22 VCOMH

A capacitor should be connected between this pin and VSS.

Power supply for panel driving voltage. This is also the most

23 VCC

positive power voltage supply pin.

24 N.C.(GND) No connection

Page 8 , Total 27 Pages

4.Contour Drawing & Block Diagram

MAX 2.35

62.00±0.2 1 N.C.(GND)

2.05±0.2

2.491 57.02 VA 2 VLSS

0.50±0.5

3.491 55.018 AA 0.70±0.07 3 VSS

2.00

3.00

10.00 5.00 1.10±0.1 4 N.C.

5 VDD

6 BS1

7 BS2

8.00

"A" 8 CS#

13.098 AA

15.10 VA

20.10±0.2

Remove tape Shading plate

24.00±0.2

9 RES#

T=0.15 Max T=0.2 10 D/C#

11 R/W#

12 E/RD#

Glue 13 D0

Protect tape 14 D1

15*3.5*0.05 15 D2

8.50±0.1 2.00±0.15 16 D3

19.60±0.3

Stiffener side 17 D4

2- 0 Contact side

.80± 18 D5

0.1

19 D6

1 24 20 D7

0.30±0.03 21 IREF

W=0.30±0.03

0.43 22 VCOMH

3.00±0.3

8.60±0.15

4.50±0.5

0.388

0.50 P0.5*23=11.50±0.05 23 VCC

0.41

0.408

24 N.C.(GND)

(24.75) 12.50±0.2

Detail "A"

Scale(5/1)

The non-specified tolerance of dimension is 0.3mm.

Page 9 , Total 27 Pages

FUNCTION BLOCK DIAGRAM

*For more information, please refer to Application Note provided by Microtips Technology.

Page 10 , Total 27 Pages

5.Absolute Maximum Ratings

Parameter Symbol Min Max Unit Notes

Supply Voltage for Logic VDD -0.3 4 V 1, 2

Supply Voltage for Display VCC 0 15 V 1, 2

Operating Temperature TOP -40 +80 °C -

Storage Temperature TSTG -40 +85 °C -

Note 1: All the above voltages are on the basis of “VSS = 0V”.

Note 2: When this module is used beyond the above absolute maximum ratings, permanent

breakage of the module may occur. Also, for normal operations, it is desirable to use this

module under the conditions according to Section6 “Electrical Characteristics”. If this module is

used beyond these conditions, malfunctioning of the module can occur and the reliability of the

module may deteriorate

Page 11 , Total 27 Pages

6.Electrical Characteristics

Item Symbol Condition Min Typ Max Unit

Supply Voltage for Logic VDD - 2.8 3.0 3.3 V

Supply Voltage for Display VCC - 10 12 15 V

High Level Input VIH - 0.8×VDD - VDD V

Low Level Input VIL - 0 - 0.2×VDD V

High Level Output VOH - 0.9×VDD - VDD V

Low Level Output VOL - 0 - 0.1×VDD V

50% Check Board operating VCC =12V 22 23 25 mA

Current

Page 12 , Total 27 Pages

7.Optical Characteristics

Item Symbol Condition Min Typ Max Unit

(V)θ - 160 - - deg

View Angle

(H)φ - 160 - - deg

Contrast Ratio CR Dark 2000:1 - - -

T rise - - 10 - µs

Response Time

T fall - - 10 - µs

Display with 50% check Board Brightness 100 120 - cd/m2

CIEx(White) (CIE1931) 0.26 0.28 0.30 -

CIEy(White) (CIE1931) 0.30 0.32 0.34 -

Page 13 , Total 27 Pages

8.OLED Lifetime

ITEM Conditions Min Typ Remark

Ta=25℃

Operating

/ Initial 50% check board 20,000 Hrs - Note

Life Time

brightness 100cd/m2

Notes:

1. Life time is defined the amount of time when the luminance has decayed to <50% of the

initial value.

2. This analysis method uses life data obtained under accelerated conditions to extrapolate

an estimated probability density function (pdf) for the product under normal use conditions.

3. Screen saving mode will extend OLED lifetime.

Page 14 , Total 27 Pages

9.Reliability

Content of Reliability Test

Environmental Test

Applicable

Test Item Content of Test Test Condition

Standard

High

Endurance test applying the high 85℃

Temperature ——

storage temperature for a long time. 240hrs

storage

Low

Endurance test applying the low storage -40℃

Temperature ——

temperature for a long time. 240hrs

storage

Endurance test applying the electric

High

stress (Voltage & Current) and the 80℃

Temperature ——

thermal stress to the element for a long 240hrs

Operation

time.

Low Endurance test applying the electric

-40℃

Temperature stress under low temperature for a long ——

240hrs

Operation time.

High

Endurance test applying the high

Temperature/ 60℃,90%RH

temperature and high humidity storage ——

Humidity 240hrs

for a long time.

Storage

High

Endurance test applying the high

Temperature/ 60℃,90%RH

temperature and high humidity

Humidity 120hrs

Operation for a long time.

Operation

Endurance test applying the low and

high temperature cycle.

Temperature -40℃ 25℃ 80℃ -40℃/80℃

——

Cycle 30 cycles

30min 5min 30min

1 cycle

Mechanical Test

Frequency:10~55Hz

Endurance test applying the vibration amplitude:1.5mm

Vibration test ——

during transportation and using. Time:0.5hrs/axis

Test axis:X,Y,Z

Others

Static Endurance test applying the electric Air Discharge model

——

electricity test stress to the finished product housing. ±4kv,10 times

*** Supply voltage for OLED system =Operating voltage at 25℃

Page 15 , Total 27 Pages

Test and measurement conditions

1. All measurements shall not be started until the specimens attain to temperature stability.

After the completion of the described reliability test, the samples were left at room

temperature for 2 hrs prior to conducting the failure test at 23±5°C; 55±15% RH.

2. All-pixels-on is used as operation test pattern.

3. The degradation of Polarizer are ignored for High Temperature storage, High Temperature/

Humidity Storage, Temperature Cycle

Evaluation criteria

1. The function test is OK.

2. No observable defects.

3. Luminance: > 50% of initial value.

4. Current consumption: within ± 50% of initial value.

APPENDIX:

RESIDUE IMAGE

Because the pixels are lighted in different time, the luminance of active pixels

may reduce or differ from inactive pixels. Therefore, the residue image will occur.

To avoid the residue image, every pixel needs to be lighted up uniformly.

Page 16 , Total 27 Pages

10.Inspection specification

NO Item Criterion AQL

01 Electrical 1.1 Missing vertical, horizontal segment, segment contrast

Testing defect.

1.2 Missing character , dot or icon.

1.3 Display malfunction.

1.4 No function or no display.

0.65

1.5 Current consumption exceeds product specifications.

1.6 OLED viewing angle defect.

1.7 Mixed product types.

1.8 Contrast defect.

02 Black or 2.1 White and black spots on display ≦ 0.25mm, no more than

white three white or black spots present.

spots on 2.2 Densely spaced: No more than two spots or lines within

2.5

OLED 3mm.

(display

only)

03 OLED 3.1 Round type : As

black following drawing SIZE Acceptable Q

spots, Φ=( x + y ) / 2 TY

white Φ≦0.10 Accept no

spots, dense

contamina 0.10< 2 2.5

tion Φ≦0.20

(non-displ 0.20< 1

ay)

Φ≦0.25

0.25<Φ 0

3.2 Line type : (As following drawing)

Length Width Acceptable Q TY

--- W≦0.02 Accept no dense

L≦3.0 0.02<W≦0.03 2.5

2

L≦2.5 0.03<W≦0.05

--- 0.05<W As round type

04 Polarizer

bubbles If bubbles are visible, Size Φ Acceptable Q TY

judge using black spot Φ≦0.20 Accept no dense

specifications, not easy 0.20<Φ≦0.50 3 2.5

to find, must check in

0.50<Φ≦1.00 2

specify direction.

1.00<Φ 0

Total Q TY 3

Page 17 , Total 27 Pages

NO Item Criterion AQL

05 Scratches Follow NO.3 OLED black spots, white spots, contamination

Symbols Define:

x: Chip length y: Chip width z: Chip thickness

k: Seal width t: Glass thickness a: OLED side length

L: Electrode pad length:

6.1 General glass chip :

6.1.1 Chip on panel surface and crack between panels:

z: Chip thickness y: Chip width x: Chip length

Z≦1/2t Not over viewing x≦1/8a

Chipped area

06 2.5

glass 1/2t<z≦2t Not exceed 1/3k x≦1/8a

☉If there are 2 or more chips, x is total length of each chip.

6.1.2 Corner crack:

z: Chip thickness y: Chip width x: Chip length

Z≦1/2t Not over viewing x≦1/8a

area

1/2t<z≦2t Not exceed 1/3k x≦1/8a

☉If there are 2 or more chips, x is the total length of each chip.

Page 18 , Total 27 Pages

NO Item Criterion AQL

Symbols :

x: Chip length y: Chip width z: Chip thickness

k: Seal width t: Glass thickness a: OLED side length

L: Electrode pad length

6.2 Protrusion over terminal :

6.2.1 Chip on electrode pad :

y: Chip width x: Chip length z: Chip thickness

y≦0.5mm x≦1/8a 0 < z≦t

6.2.2 Non-conductive portion:

Glass

06 2.5

crack

y: Chip width x: Chip length z: Chip

thickness

y≦ L x≦1/8a 0 < z≦t

☉If the chipped area touches the ITO terminal, over 2/3 of the ITO

must remain and be inspected according to electrode terminal

specifications.

☉If the product will be heat sealed by the customer, the alignment

mark not be damaged.

6.2.3 Substrate protuberance and internal crack.

y: width x: length

y≦1/3L x≦a

Page 19 , Total 27 Pages

NO Item Criterion AQL

Cracked

07 The OLED with extensive crack is not acceptable. 2.5

glass

8.1 Illumination source flickers when lit. 0.65

Backlight 8.2 Spots or scratched that appear when lit must be judged. 2.5

08

elements Using OLED spot, lines and contamination standards.

8.3 Backlight doesn’t light or color wrong. 0.65

9.1 Bezel may not have rust, be deformed or have

2.5

09 Bezel fingerprints, stains or other contamination.

0.65

9.2 Bezel must comply with job specifications.

10.1 COB seal may not have pinholes larger than 0.2mm or 2.5

contamination.

10.2 COB seal surface may not have pinholes through to the 2.5

IC. 0.65

10.3 The height of the COB should not exceed the height

indicated in the assembly diagram. 2.5

10.4 There may not be more than 2mm of sealant outside the

seal area on the PCB. And there should be no more than

10 PCB、COB three places. 2.5

10.5 No oxidation or contamination PCB terminals. 0.65

10.6 Parts on PCB must be the same as on the production

characteristic chart. There should be no wrong parts,

missing parts or excess parts. 0.65

10.7 The jumper on the PCB should conform to the product

characteristic chart. 2.5

10.8 If solder gets on bezel tab pads, OLED pad, zebra pad

or screw hold pad, make sure it is smoothed down.

11.1 No un-melted solder paste may be present on the PCB. 2.5

11.2 No cold solder joints, missing solder connections, 2.5

11 Soldering oxidation or icicle.

11.3 No residue or solder balls on PCB. 2.5

11.4 No short circuits in components on PCB. 0.65

Page 20 , Total 27 Pages

NO Item Criterion AQL

12.1 No oxidation, contamination, curves or, bends on 2.5

interface Pin (OLB) of TCP.

12.2 No cracks on interface pin (OLB) of TCP. 0.65

12.3 No contamination, solder residue or solder balls on 2.5

product. 2.5

12.4 The IC on the TCP may not be damaged, circuits. 2.5

12.5 The uppermost edge of the protective strip on the

interface pin must be present or look as if it cause the 2.5

General interface pin to sever.

12

appearance 12.6 The residual rosin or tin oil of soldering (component or 2.5

chip component) is not burned into brown or black color. 0.65

12.7 Sealant on top of the ITO circuit has not hardened. 0.65

12.8 Pin type must match type in specification sheet. 0.65

12.9 OLED pin loose or missing pins.

12.10 Product packaging must the same as specified on 0.65

packaging specification sheet.

12.11 Product dimension and structure must conform to

product specification sheet.

Page 21 , Total 27 Pages

Check Item Classification Criteria

No Display Major

Missing Line Major

Pixel Short Major

Darker Short Major

Wrong Display Major

Un-uniform

B/A x 100% < 70% Major

A/C x 100% < 70%

Page 22 , Total 27 Pages

11.Precautions in use of OLED Modules

(1) Avoid applying excessive shocks to module or making any alterations or modifications to it.

(2) Don’t make extra holes on the printed circuit board, modify its shape or change the

components of OLED display module.

(3) Don’t disassemble the OLED display module.

(4) Don’t operate it above the absolute maximum rating.

(5) Don’t drop, bend or twist OLED display module.

(6) Soldering: only to the I/O terminals.

(7) Storage: please storage in anti-static electricity container and clean environment.

(8) It's pretty common to use "Screen Saver" to extend the lifetime and Don't use fix

information for long time in real application.

(9) Don't use fixed information in OLED panel for long time, that will extend "screen burn"

effect time.

(10) Microtips has the right to change the passive components, including R2and R3 adjust

resistors. (Resistors, capacitors and other passive components will have different

appearance and color caused by the different supplier.)

(11) Microtips have the right to change the PCB Rev. (In order to satisfy the supplying

stability, management optimization and the best product performance...etc, under the

premise of not affecting the electrical characteristics and external dimensions, Microtips

have the right to modify the version.)

11.1 Handling Precautions

(1) Since the display panel is being made of glass, do not apply mechanical impacts such us

dropping from a high position.

(2) If the display panel is broken by some accident and the internal organic substance leaks

out, be careful not to inhale nor lick the organic substance.

(3) If pressure is applied to the display surface or its neighborhood of the OLED display

module, the cell structure may be damaged and be careful not to apply pressure to these

sections.

(4) The polarizer covering the surface of the OLED display module is soft and easily scratched.

Please be careful when handling the OLED display module.

(5) When the surface of the polarizer of the OLED display module has soil, clean the surface. It

takes advantage of by using following adhesion tape.

* Scotch Mending Tape No. 810 or an equivalent

Never try to breathe upon the soiled surface nor wipe the surface using cloth containing

solvent Also, pay attention that the following liquid and solvent may spoil the polarizer:

* Water

* Ketone

* Aromatic Solvents

(6) Hold OLED display module very carefully when placing OLED display module into the

System housing. Do not apply excessive stress or pressure to OLED display module. And,

do not over bend the film with electrode pattern layouts. These stresses will influence the

display performance. Also, secure sufficient rigidity for the outer cases.

Page 23 , Total 27 Pages

(7) Do not apply stress to the LSI chips and the surrounding molded sections.

(8) Do not disassemble nor modify the OLED display module.

(9) Do not apply input signals while the logic power is off.

(10) Pay sufficient attention to the working environments when handing OLED display modules

to prevent occurrence of element breakage accidents by static electricity.

* Be sure to make human body grounding when handling OLED display modules.

* Be sure to ground tools to use or assembly such as soldering irons.

* To suppress generation of static electricity, avoid carrying out assembly work under dry

environments.

* Protective film is being applied to the surface of the display panel of the OLED display

module. Be careful since static electricity may be generated when exfoliating the protective

film.

(11) Protection film is being applied to the surface of the display panel and removes the

protection film before assembling it. At this time, if the OLED display module has been

stored surface of the display panel after removed of the film. In such case, remove the

residue material by the method introduced in the above Section 5.

(12) If electric current is applied when the OLED display module is being dewed or when it is

placed under high humidity environments, the electrodes may be corroded and be careful

to avoid the above.

11.2 Storage Precautions

(1) When storing OLED display modules, put them in static electricity preventive bags avoiding

exposure to direct sun light nor to lights of fluorescent lamps. And, also, avoiding high

temperature and high humidity environment or low temperature (less than 0°C)

environments.(We recommend you to store these modules in the packaged state when

they were shipped from Microtips Technology. At that time, be careful not to let water drops

adhere to the packages or bags nor let dewing occur with them.

(2) If electric current is applied when water drops are adhering to the surface of the OLED

display module, when the OLED display module is being dewed or when it is placed under

high humidity environments, the electrodes may be corroded and be careful about the

above.

Page 24 , Total 27 Pages

11.3 Designing Precautions

(1) The absolute maximum ratings are the ratings which cannot be exceeded for OLED display

module, and if these values are exceeded, panel damage may be happen.

(2) To prevent occurrence of malfunctioning by noise, pay attention to satisfy the VIL and VIH

specifications and, at the same time, to make the signal line cable as short as possible.

(3) We recommend you to install excess current preventive unit (fuses, etc.) to the power

circuit (VDD). (Recommend value: 0.5A)

(4) Pay sufficient attention to avoid occurrence of mutual noise interference with the

neighboring devices.

(5) As for EMI, take necessary measures on the equipment side basically.

(6) When fastening the OLED display module, fasten the external plastic housing section.

(7) If power supply to the OLED display module is forcibly shut down by such errors as taking

out the main battery while the OLED display panel is in operation, we cannot guarantee the

quality of this OLED display module. Connection (contact) to any other potential than the

above may lead to rupture of the IC.

(8) The limitation of FPC and Film bending.

Page 25 , Total 27 Pages

Page: 1

Module Sample Estimate Feedback Sheet

Module Number:

1、Panel Specification:

1. Panel Type: □ Pass □NG ,

2. Numbers of Pixel: □ Pass □NG ,

3. View Area: □ Pass □NG ,

4. Active Area: □ Pass □NG ,

5.Emitting Color: □ Pass □NG ,

6.Uniformity: □Pass □NG ,

7.Operating □ Pass □NG ,

Temperature:

8.Storage Temperature: □ Pass □NG ,

9.Others:

2、Mechanical Specification:

1. PCB Size: □Pass □NG ,

2.Frame Size: □Pass □NG ,

3.Materal of Frame: □Pass □NG ,

4.Connector Position: □Pass □NG ,

5.Fix Hole Position: □Pass □NG ,

6. Thickness of PCB: □Pass □NG ,

7. Height of Frame to □Pass □NG ,

PCB:

8.Height of Module: □Pass □NG ,

9.Others: □Pass □NG ,

3、Relative Hole Size:

1.Pitch of Connector: □Pass □NG ,

2.Hole size of □Pass □NG ,

Connector:

3.Mounting Hole size: □Pass □NG ,

4.Mounting Hole Type: □Pass □NG ,

5.Others: □Pass □NG ,

>> Go to page 2 <<

Page 26 , Total 27 Pages

Page: 2

Module Number:

4、Electronic Characteristics of Module:

1.Input Voltage: □Pass □NG ,

2.Supply Current: □Pass □NG ,

3.Driving Voltage for □Pass □NG ,

OLED:

4.Contrast for OLED: □Pass □NG ,

5.Negative Voltage □Pass □NG ,

Output:

6.Interface Function: □Pass □NG ,

7.ESD test: □Pass □NG ,

8.Others: □Pass □NG ,

5、Summary:

Sales signature:

Customer Signature: Date: / /

MICROTIPS TECHNOLOGY USA

3504 Lake Lynda Dr, Suite 110, Orlando, Florida, 32817, TEL: 407-273-0204, FAX: 407-273-0771

Page 27 , Total 27 Pages

Mouser Electronics

Authorized Distributor

Click to View Pricing, Inventory, Delivery & Lifecycle Information:

Microtips Technology:

REX012832AWPP3N00000

You might also like

- Raystar Optronics OLED Module Specification SheetDocument28 pagesRaystar Optronics OLED Module Specification Sheetmarius.chitigaNo ratings yet

- Ym12864p-Dalian Good Display PDFDocument10 pagesYm12864p-Dalian Good Display PDFEvgeniyNo ratings yet

- 2.13inch E-Paper DatasheetDocument26 pages2.13inch E-Paper Datasheetvjspd hppNo ratings yet

- Rfc570p Eiw DbsDocument26 pagesRfc570p Eiw DbscarlitinhadeNo ratings yet

- Dem 20487 Syh-LyDocument14 pagesDem 20487 Syh-LyPreda AndreiNo ratings yet

- TFT LCD Module Product Specification: 7.0" (800 (RGB) X 480 DOTS) TFT Module With Resistive Touch PanelDocument14 pagesTFT LCD Module Product Specification: 7.0" (800 (RGB) X 480 DOTS) TFT Module With Resistive Touch PanelSehrishNo ratings yet

- Oled Specification: Vishay Dale Electronics, Inc. Information Display Products OLED Product Data SheetDocument22 pagesOled Specification: Vishay Dale Electronics, Inc. Information Display Products OLED Product Data SheetMuhammad Rayhan ArdaniNo ratings yet

- LCD Module SpecificationDocument12 pagesLCD Module SpecificationGratian RealNo ratings yet

- 3.5'' TFT DisplayDocument5 pages3.5'' TFT DisplayBen sayari Mohamed AmineNo ratings yet

- Dem128064o1fgh PWDocument17 pagesDem128064o1fgh PWRadu MititeluNo ratings yet

- Kuman 3.5 Inch Touch Screen DatasheetDocument15 pagesKuman 3.5 Inch Touch Screen DatasheetMarcGarciaNo ratings yet

- KlockDocument42 pagesKlockUmair HameedNo ratings yet

- GDE060BA-T V2.1 SpecificationDocument17 pagesGDE060BA-T V2.1 SpecificationHolopNo ratings yet

- XK3118K8 Manul BookDocument25 pagesXK3118K8 Manul BookEka Nugraha67% (3)

- Digital ClockDocument42 pagesDigital ClockPuneet Jain100% (2)

- Digital Thermometer ReportDocument23 pagesDigital Thermometer ReportAbhilash Krishna100% (1)

- Round OLED 37mm - 128x128 Dots: Incl. Controller SSD1327ZBDocument28 pagesRound OLED 37mm - 128x128 Dots: Incl. Controller SSD1327ZBvicio tarNo ratings yet

- Winstar Display Co., LTD: Specification Customer: Atlas Electronic Module No.: WG12864A-YYH-VDocument17 pagesWinstar Display Co., LTD: Specification Customer: Atlas Electronic Module No.: WG12864A-YYH-VElvis SilvaNo ratings yet

- Part Number: Date:: SpecificationDocument38 pagesPart Number: Date:: SpecificationLakshmanan SethupathiNo ratings yet

- JW Series Maintenance Manual GuideDocument40 pagesJW Series Maintenance Manual GuideLuis Alberto Garcia CaychoNo ratings yet

- Wg240128a Tmi VZ#Document25 pagesWg240128a Tmi VZ#حمزة صباحNo ratings yet

- LCD 128x64 Tech12864GDocument10 pagesLCD 128x64 Tech12864GMarlon PerinNo ratings yet

- Specification For LCD Module: Model NoDocument22 pagesSpecification For LCD Module: Model NoNasir UddinNo ratings yet

- 6969057Document24 pages6969057Андрій БілявськийNo ratings yet

- LCD Module Spec SheetDocument14 pagesLCD Module Spec Sheetflo72afNo ratings yet

- Wo12864h TFH#Document27 pagesWo12864h TFH#Paulina HozhoNo ratings yet

- LCD 4x20 Large Digit DatasheetDocument29 pagesLCD 4x20 Large Digit DatasheetthuanNo ratings yet

- Display LCD 40 Caracteres 2 Linhas Backlight Verde 182x33,5x13,6mm WH4002A YYH JTDocument25 pagesDisplay LCD 40 Caracteres 2 Linhas Backlight Verde 182x33,5x13,6mm WH4002A YYH JTFelipeMeloNo ratings yet

- LM32019DFW-C-TOPWAYDocument15 pagesLM32019DFW-C-TOPWAYJudá RibeiroNo ratings yet

- Winstar Display 12864A1-TFH# Specification SheetDocument24 pagesWinstar Display 12864A1-TFH# Specification SheetHalit YalçınkayaNo ratings yet

- Winstar - WH2004A YGH JTDocument25 pagesWinstar - WH2004A YGH JTPhong DoNo ratings yet

- Lc1622 Smlyh6 EtcDocument26 pagesLc1622 Smlyh6 EtcsaumyakanthaNo ratings yet

- toyota_cn-ts6270kDocument14 pagestoyota_cn-ts6270kPoon Electronic Training CentreNo ratings yet

- Dem 128064G FGH-PW PDFDocument16 pagesDem 128064G FGH-PW PDFEdisson Alarcon MoraNo ratings yet

- DS8 User's Manual - V 1.10Document39 pagesDS8 User's Manual - V 1.10Julio MerijNo ratings yet

- Winstar Display Specification for WH1604A-TMI-CT# LCD ModuleDocument26 pagesWinstar Display Specification for WH1604A-TMI-CT# LCD ModuleСергейNo ratings yet

- Datasheet Display WH-2004L-YYHDocument25 pagesDatasheet Display WH-2004L-YYHmarcioNo ratings yet

- LCD Module Specification: Multi-Inno Technology Co., LTDDocument19 pagesLCD Module Specification: Multi-Inno Technology Co., LTDLuis MejiaNo ratings yet

- AT090TN10 - ManualDocument22 pagesAT090TN10 - ManualRazvan FlorinNo ratings yet

- GBE043WQH09RT SpecificationDocument19 pagesGBE043WQH09RT SpecificationFabiano SanchesNo ratings yet

- Specification For TFT LCD Module: (With Touch Panel Controller) 3.5", 320 (RGB) X 240 TFT LCM With Mcu InterfaceDocument17 pagesSpecification For TFT LCD Module: (With Touch Panel Controller) 3.5", 320 (RGB) X 240 TFT LCM With Mcu InterfacexColdwarNo ratings yet

- ATM12232B-FL-YBW: Graphic Dot Matrix LCD ModulesDocument2 pagesATM12232B-FL-YBW: Graphic Dot Matrix LCD Modulesvanhuong87No ratings yet

- Product SpecificationDocument18 pagesProduct Specification罗冬杰No ratings yet

- AMC1602AI2CDocument21 pagesAMC1602AI2CArmand PopaNo ratings yet

- LCD Display RC2002C-FHW-ESXDocument28 pagesLCD Display RC2002C-FHW-ESXionutNo ratings yet

- Pin No. Name Description VSS VCC Power Supply (+5V) VEE RS R/W EN D0 D1 D2Document25 pagesPin No. Name Description VSS VCC Power Supply (+5V) VEE RS R/W EN D0 D1 D2suryateja247100% (1)

- Data Sheet: Graphics Displays and Interface/adaptor CardsDocument8 pagesData Sheet: Graphics Displays and Interface/adaptor CardsSergey DNo ratings yet

- rc1602b Biw EsxDocument28 pagesrc1602b Biw EsxIoan TudosaNo ratings yet

- Dem16215syh LyDocument17 pagesDem16215syh Lyflo72afNo ratings yet

- Tm162vca6 SpecDocument23 pagesTm162vca6 SpecMarius FerdyNo ratings yet

- MT215DW01 V0Document24 pagesMT215DW01 V0ivanivz62No ratings yet

- DEM 128048A FGH: LCD ModuleDocument13 pagesDEM 128048A FGH: LCD ModulePreciso AprenderNo ratings yet

- RG12864C Biw VDocument24 pagesRG12864C Biw V31482No ratings yet

- Winstar Display Specification SheetDocument26 pagesWinstar Display Specification SheetQuarmina HesseNo ratings yet

- Arduino 16x2LCD 5vDocument28 pagesArduino 16x2LCD 5vKing TranNo ratings yet

- Mitsubishi 8-Bit 8-Channel Multiplying DAC with Buffer Amps M62364FPDocument6 pagesMitsubishi 8-Bit 8-Channel Multiplying DAC with Buffer Amps M62364FPquinquinoNo ratings yet

- Exploring Arduino: Tools and Techniques for Engineering WizardryFrom EverandExploring Arduino: Tools and Techniques for Engineering WizardryRating: 4.5 out of 5 stars4.5/5 (5)

- CompTIA A+ CertMike: Prepare. Practice. Pass the Test! Get Certified!: Core 1 Exam 220-1101From EverandCompTIA A+ CertMike: Prepare. Practice. Pass the Test! Get Certified!: Core 1 Exam 220-1101No ratings yet

- Round OLED 37mm - 128x128 Dots: Incl. Controller SSD1327ZBDocument28 pagesRound OLED 37mm - 128x128 Dots: Incl. Controller SSD1327ZBvicio tarNo ratings yet

- LM61 2.7-V, SOT-23 or TO-92 Temperature Sensor: 1 Features 3 DescriptionDocument27 pagesLM61 2.7-V, SOT-23 or TO-92 Temperature Sensor: 1 Features 3 Descriptionvicio tarNo ratings yet

- Features General Description: PWM/PFM Dual Mode Step-Up DC/DC ConverterDocument9 pagesFeatures General Description: PWM/PFM Dual Mode Step-Up DC/DC Convertervicio tarNo ratings yet

- Atmel 2549 8 Bit AVR Microcontroller ATmega640 1280 1281 2560 2561 DatasheetDocument435 pagesAtmel 2549 8 Bit AVR Microcontroller ATmega640 1280 1281 2560 2561 Datasheetpototo1234567No ratings yet

- LM556 ST PDFDocument10 pagesLM556 ST PDFkurtm22No ratings yet

- Talea: IssueDocument60 pagesTalea: IssueNickNo ratings yet

- Electrical Engineering Portal Com Electrical Thumb Rules You Must Follow Part 3Document8 pagesElectrical Engineering Portal Com Electrical Thumb Rules You Must Follow Part 3m khNo ratings yet

- Cover Letter For Electromotives PVT LTDDocument1 pageCover Letter For Electromotives PVT LTDhamza aslamNo ratings yet

- Transformer Inspection Checklist: DepartmentDocument18 pagesTransformer Inspection Checklist: DepartmentADEN LIU100% (1)

- .NG EEC115 Electrical Engineering Science 1Document29 pages.NG EEC115 Electrical Engineering Science 1archibong dominicNo ratings yet

- IGS Hyd Chapter-GEOPRACTICES-2021-SymposiumDocument1 pageIGS Hyd Chapter-GEOPRACTICES-2021-SymposiumjitendraNo ratings yet

- Foshan Sunmart Electronic Co.,Ltd: 2KW On Off Grid Solar Power System ModelDocument2 pagesFoshan Sunmart Electronic Co.,Ltd: 2KW On Off Grid Solar Power System ModelDamian Cando0% (1)

- Silicon NPN Power Transistors: Inchange Semiconductor Product SpecificationDocument3 pagesSilicon NPN Power Transistors: Inchange Semiconductor Product SpecificationSebastian CorreaNo ratings yet

- Energy vs Voltage CapacitorDocument4 pagesEnergy vs Voltage CapacitorV Sree Suswara SuswaraNo ratings yet

- Osram Dim Mcu Inst PDFDocument2 pagesOsram Dim Mcu Inst PDFeduardskNo ratings yet

- International Standard: Norme InternationaleDocument67 pagesInternational Standard: Norme InternationaleDischargerNo ratings yet

- Service: ManualDocument168 pagesService: Manualcamila y rosario contrerasNo ratings yet

- JFET Characteristics and ConfigurationsDocument15 pagesJFET Characteristics and ConfigurationsSAHIL SATYAMNo ratings yet

- ATR 72-600F: Born to be the Versatile Regional FreighterDocument2 pagesATR 72-600F: Born to be the Versatile Regional Freighterالزاوي الشيخNo ratings yet

- Tutorial of Non-Isolated DC/DC Converters in Continuous ModeDocument15 pagesTutorial of Non-Isolated DC/DC Converters in Continuous ModeSudip MondalNo ratings yet

- AP183772 Azur 540 C&640 CV2 Multilingual Users ManualDocument116 pagesAP183772 Azur 540 C&640 CV2 Multilingual Users ManualKevinNo ratings yet

- Cable On The Reel: Section 13Document20 pagesCable On The Reel: Section 13BolboNo ratings yet

- Engineering Circuit Analysis 8th Edition SolutionsDocument62 pagesEngineering Circuit Analysis 8th Edition SolutionsRanz Kopacz77% (13)

- Project Report on Multistage BJT Amplifier DesignDocument7 pagesProject Report on Multistage BJT Amplifier DesignAlex Ferguson0% (1)

- Horizon Drucker Spectra ManualDocument12 pagesHorizon Drucker Spectra ManualService BlockNo ratings yet

- Chapter 36 Series and Parallel Networks: EXERCISE 169, Page 377Document11 pagesChapter 36 Series and Parallel Networks: EXERCISE 169, Page 377DanialNo ratings yet

- CHAPTER-1EC II Feedback AmpDocument14 pagesCHAPTER-1EC II Feedback Ampabdi gmNo ratings yet

- ASTM F496-20 Standard Specification For In-Service Care of Insulating Gloves and Sleeves1Document8 pagesASTM F496-20 Standard Specification For In-Service Care of Insulating Gloves and Sleeves1OSCAR MAURICIO GUTIERREZ GOMEZNo ratings yet

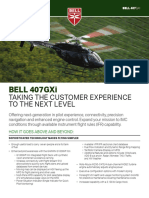

- Bell 407gxi: Taking The Customer Experience To The Next LevelDocument2 pagesBell 407gxi: Taking The Customer Experience To The Next LevelJUAN CARLOS HENRIQUEZNo ratings yet

- SCR and Its Applications in Power ElectronicsDocument8 pagesSCR and Its Applications in Power Electronicsf yNo ratings yet

- User Manuel: Dcb-I Folding Door Control BoardDocument10 pagesUser Manuel: Dcb-I Folding Door Control BoardMohd Abu AjajNo ratings yet

- Polytechnic University of The Philippines Sta. Mesa, Manila Computer Engineering Computer Engineering DepartmentDocument3 pagesPolytechnic University of The Philippines Sta. Mesa, Manila Computer Engineering Computer Engineering DepartmentBryan Michael B. MonterozoNo ratings yet

- splices-WPS OfficeDocument4 pagessplices-WPS OfficeSal McGaundieNo ratings yet

- Top 100 companies in TimisoaraDocument35 pagesTop 100 companies in TimisoaraSabin IvascuNo ratings yet

- General Specifications: Model DY Model DYA Vortex FlowmetersDocument24 pagesGeneral Specifications: Model DY Model DYA Vortex FlowmetersSayed Ibrahim GhanemNo ratings yet