0% found this document useful (0 votes)

58 views20 pagesExxon One-Trip Sidetracking System

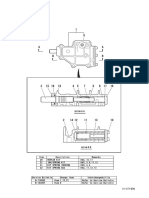

The document provides information about Exxon, an oil and gas services company. It details their products and services which include tools for drilling, completion and production. It describes their design, manufacturing and operational capabilities. Specific tools and systems discussed include a whipstock sidetracking system and polycrystalline diamond compact drill bits.

Uploaded by

farzadmilanCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

58 views20 pagesExxon One-Trip Sidetracking System

The document provides information about Exxon, an oil and gas services company. It details their products and services which include tools for drilling, completion and production. It describes their design, manufacturing and operational capabilities. Specific tools and systems discussed include a whipstock sidetracking system and polycrystalline diamond compact drill bits.

Uploaded by

farzadmilanCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd