Professional Documents

Culture Documents

Recommended Maintenance Intervals For Continuous Duty Reciprocating Compressors

Uploaded by

Manuel LiñeiroOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Recommended Maintenance Intervals For Continuous Duty Reciprocating Compressors

Uploaded by

Manuel LiñeiroCopyright:

Available Formats

ER-8.

2 ECN: 201900889 VER: 30 - 03-02-2020

Recommended Maintenance Intervals for Continuous

Duty Reciprocating Compressors

Ariel compressors, like all industrial equipment, require maintenance. The severity of compressor service dir-

ectly influences the frequency and amount of maintenance needed. Below are recommended intervals for

inspections and replacements to help determine appropriate intervals for a given compressor application.

Careful documentation of inspection results is critical to establish whether recommended intervals are

adequate or require more or less frequency.

Continuous Duty: The compressor operates continuously, 24 hours a day, shutting down only for short

durations, usually for maintenance and unexpected shut-downs.

Short-Term Intermittent Duty: The compressor operates for short durations, starting and stopping per-

haps several times per day, such as in many CNG filling station applications that require operation based on

consumer demand.

Long-Term Intermittent Duty: The compressor operates continuously for extended durations, with exten-

ded shut-down periods, such as in some storage/withdrawal applications and fuel gas booster applications.

Many factors affect bearing life including number of starts, starting conditions, and run hours. Consider site-

specific conditions when adjusting maintenance intervals.

NOTE: For intermittent duty service, see ER-8.2.2.

As part of your maintenance program, Ariel recommends:

l Consistent adherence to safety policies, procedures, and equipment warning labels.

l Daily operational checks.

l Routine trending and review of operational parameters.

l Routine oil analysis and trending.

l Detailed records of all maintenance.

To avoid contamination, keep all covers in place where access is not required. Use paper towels during

internal maintenance.

CAUTION: Gas compressors are complicated and dangerous pieces of equipment. Only

trained operators and mechanics familiar with unit operation should attempt any main-

tenance. Read and thoroughly understand the appropriate manual and always wear appro-

priate personal protection equipment during maintenance. Never adjust any fastener

torques while the unit is operating or pressurized.

To reduce the risk of serious personal injury or death, verify driver or compressor cylinder

gas pressure cannot turn compressor crankshaft during maintenance. Before any main-

tenance or component removal, relieve all pressure from compressor cylinders. See pack-

ager information to completely vent the system or call the packager for assistance. After

maintenance, purge the entire system with gas prior to operation to avoid a potentially

explosive air/gas mixture.

ER-8.2, Ver. 30 888-397-7766 (toll free USA & Canada) or Page 1 of 8

740-397-3602 (International)

www.arielcorp.com | arc@arielcorp.com

Initial Maintenance

Comply with Ariel Packager Standards and the com-

pressor Start Up Check List. Adhere to all items

before and after start-up.

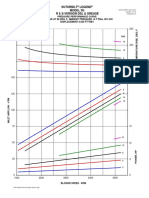

For cold alignment, account for the difference in

thermal growth height between the compressor and

driver. TABLE 1 lists compressor centerline height

change based on 6.5 x 10-6/°F (11.7 x 10-6/°C).

NOTE: Thermal growth numbers were cal-

culated using 170°F (77°C) as the frame oper-

ating temperature. Initial frame temperature is

the temperature of the frame during cold align-

ment. Obtain driver thermal growth pre-

dictions from the driver manufacturer.

Center the coupling between the driver and com-

pressor so it does not thrust or force the crankshaft FIGURE 1 Thermal Growth

against either thrust face.

To ensure parallel and concentric drive

train alignment, position connected equip-

ment so misalignment is as close to zero

as possible. Limits for Total Indicator

Reading (TIR):

l Maximum rim (outside diameter),

(parallel) misalignment is 0.005 inch

(0.13 mm).

l Face (angular) misalignment must be

within 0.005 inch (0.13 mm) for hub

diameters up to 17 inches (430 mm).

For hubs greater than 17 inches (430

mm), use the following formula: Hub

O.D. x 0.0003 = max angular

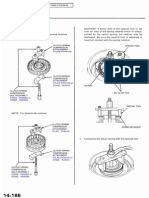

misalignment. See FIGURE 2.

For laser alignment tools:

FIGURE 2 Angular Coupling-Hub Face Alignment Limits

l Maximum parallel misalignment is

0.0025 inch (0.064 mm).

l Maximum angular misalignment is 0.0003 inch/1 inch (0.03mm/100mm)

NOTE: If laser is adjusted to display TIR, use TIR limits.

After running a new, relocated, reconfigured, or overhauled compressor for 24 hours, shut down, vent the

gas system, and perform the following maintenance:

1. Perform a hot alignment check within 30 minutes of shutdown as described above. Adjust discharge

bottle supports and head end supports, if applicable. NOTE: To avoid cylinder distortion, lift

discharge bottles only 0.003 to 0.005 inch (0.08 to 0.13 mm) using the supports.

2. Check fastener torque on gas nozzle flanges, valve caps, cylinder heads, piston rod packing flanges,

crosshead guide hold down, frame hold down, crosshead guide to cylinder, and crosshead guide to

frame bolting, if applicable. See appropriate ER-96.2.x series document for correct torques.

ER-8.2, Ver. 30 888-397-7766 (toll free USA & Canada) or Page 2 of 8

740-397-3602 (International)

www.arielcorp.com | arc@arielcorp.com

3. Repeat torque check after 750 hours. Recheck fasteners found loose in any of these intervals after an

additional 750 hours. If loosening continues, contact your package supplier immediately.

TABLE 1 Thermal Growth of Compressors

Initial THERMAL GROWTH, INCH (MM)

Frame

Temp. JGM:P:N:Q JGH:E:K:T JGZ:U

JG:JGA JGJ:R JGC:D:F JGB:V KBB:V

°F (°C) KB100 KBE:K:T KBZ:U

0 (-18) 0.011 (0.29) 0.010 (0.26) 0.013 (0.34) 0.019 (0.48) 0.024 (0.62) 0.027 (0.68) 0.033 (0.85) 0.030 (0.76)

10 (-12) 0.011 (0.27) 0.010 (0.25) 0.012 (0.32) 0.018 (0.45) 0.023 (0.58) 0.025 (0.64) 0.031 (0.79) 0.028 (0.71)

20 (-7) 0.010 (0.26) 0.009 (0.23) 0.012 (0.30) 0.017 (0.42) 0.021 (0.55) 0.023 (0.60) 0.029 (0.75) 0.026 (0.67)

30 (-1) 0.009 (0.24) 0.008 (0.21) 0.011 (0.28) 0.015 (0.39) 0.020 (0.51) 0.022 (0.56) 0.027 (0.70) 0.025 (0.63)

40 (4) 0.009 (0.22) 0.008 (0.20) 0.010 (0.26) 0.014 (0.37) 0.019 (0.48) 0.020 (0.52) 0.025 (0.65) 0.023 (0.59)

50 (10) 0.008 (0.20) 0.007 (0.18) 0.009 (0.24) 0.013 (0.34) 0.017 (0.44) 0.019 (0.48) 0.023 (0.60) 0.021 (0.54)

60 (16) 0.007 (0.19) 0.007 (0.17) 0.009 (0.22) 0.012 (0.31) 0.016 (0.40) 0.017 (0.44) 0.021 (0.54) 0.019 (0.49)

70 (21) 0.007 (0.17) 0.006 (0.15) 0.008 (0.20) 0.011 (0.28) 0.014 (0.37) 0.016 (0.40) 0.020 (0.50) 0.018 (0.45)

80 (27) 0.006 (0.15) 0.005 (0.14) 0.007 (0.18) 0.010 (0.25) 0.013 (0.33) 0.014 (0.36) 0.018 (0.45) 0.016 (0.40)

90 (32) 0.005 (0.14) 0.005 (0.12) 0.006 (0.16) 0.009 (0.23) 0.011 (0.29) 0.012 (0.32) 0.016 (0.40) 0.014 (0.36)

100 (38) 0.005 (0.12) 0.004 (0.11) 0.005 (0.14) 0.008 (0.20) 0.010 (0.26) 0.011 (0.28) 0.014 (0.35) 0.012 (0.31)

110 (43) 0.004 (0.10) 0.004 (0.09) 0.005 (0.12) 0.007 (0.17) 0.009 (0.22) 0.009 (0.24) 0.012 (0.30) 0.011 (0.27)

120 (49) 0.003 (0.09) 0.003 (0.08) 0.004 (0.10) 0.006 (0.14) 0.007 (0.18) 0.008 (0.20) 0.010 (0.25) 0.009 (0.23)

130 (54) 0.003 (0.07) 0.002 (0.06) 0.003 (0.08) 0.004 (0.12) 0.006 (0.15) 0.006 (0.16) 0.008 (0.21) 0.007 (0.19)

Daily Maintenance

1. Log and trend the following:

l Operating RPM, gas pressure and temperatures - determine if the unit is operating within design

parameters and expectations. NOTE: Verify high and low pressure shutdowns are set as close

as practical to normal operating conditions. Set points must protect the machine from

exceeding compressor limits.

l Bearing temperatures - if the unit is equipped with main bearing temperature sensors.

l Compressor frame oil pressure - at operating temperature (190°F (88°C) max. inlet oil temperature),

it should be 50 to 60 psig (3.5 to 4.2 barg) at the filter gauges. If pressure falls below 50 psig (3.5

barg), shut down the compressor then determine and correct the cause.

l Compressor frame inlet oil temperature.

l Cylinder valve cap temperatures.

l Compressor frame oil filter differential pressure - differential pressure exceeding the filter change

value indicates a need for a filter change. See filter information plate on top cover or ER-96.5.16 for

procedure.

ER-8.2, Ver. 30 888-397-7766 (toll free USA & Canada) or Page 3 of 8

740-397-3602 (International)

www.arielcorp.com | arc@arielcorp.com

2. Check compressor frame oil level. It should be about mid-level in the sight glass and free of foam when

running. If not, determine and correct the cause. Do not overfill. Check oil makeup tank for sufficient oil

supply. For dry sump frames, check the package sump oil level. Do not add oil to the crankcase through

the breather hole while the unit runs. This causes oil foaming and unnecessary no-flow shutdowns in the

force feed lubrication system.

3. Check force feed lubricator box oil level. It should be full to the overflow line.

4. Log and trend piston rod packing vent/drain temperature and check distance piece vents for leakage. If

the piston rod packing vent/drain temperature is trending high, then verify leak rate before performing

maintenance.

5. If applicable, check suction valve unloader actuator vents for leakage.

6. If applicable, check head end clearance pocket vents for leakage.

7. Verify all cylinder high discharge gas temperature shutdowns are set to within 10% or as close as

practical above the normal operating discharge temperature. Do not exceed the maximum discharge

temperature shutdown setting for the application.

8. Check lubricator block cycle time. See lubricator box data plate for correct cycle time. Changes in gas

composition may require a review of cycle time. Check lube sheet for units not running at the speed on

the data tag. If applicable, verify auto relief valve indicator does not show sign of over-pressurization.

9. Check for gas, oil, and coolant leaks.

CAUTION: Do not attempt to repair leaks while the unit is operating or pressurized.

10. Check for unusual noises or vibrations.

11. See packager documentation for additional recommended checks, i.e. scrubber liquid levels, dump valve

operation, cooler louver positions, etc.

Monthly Maintenance

1. Perform all Daily maintenance.

2. Verify safety shutdown functionality.

3. Sample compressor frame oil and send it to a reputable lubricant lab for analysis. See ER-56.06 for a list

of what an oil analysis should provide. If analysis results indicate increasing levels of lead, tin, or copper

particles in the oil, shut down unit. Remove frame top cover and crosshead guide side covers. Visually

inspect for debris. Do not disassemble further without good reason. If debris indicates, replace affected

parts, then change oil, oil filter, and clean the strainer with a suitable solvent. NOTE: Operate the unit

to bring oil temperature to a minimum operating temperature of 150°F (66°C) to drive off any

entrained water.

4. Check and log cylinder clearance devices in use and their settings.

Six-Month (4,000-Hour) Maintenance

1. Perform all Daily and Monthly maintenance.

2. Shut down unit and allow sufficient time for components to cool.

3. Inspect crankcase breather filter and clean with suitable solvent.

4. Drain and replace force feed lubricator box oil.

ER-8.2, Ver. 30 888-397-7766 (toll free USA & Canada) or Page 4 of 8

740-397-3602 (International)

www.arielcorp.com | arc@arielcorp.com

5. Where applicable, clean sintered element in the small oil filter on the force feed lubrication system now or

at every main oil filter change. Use a suitable solvent. Where applicable, replace force feed lubricator

inlet filter in independent supply system.

6. Change compressor oil filter. See top cover filter information plate or ER-96.5.16 for procedure. NOTE:

For replaceable element style filters, drain the canister completely before removing the

element. Inspect elements for cleanliness and damage. Do not install dirty or damaged

elements.

7. Change compressor oil. Extremely dirty environments, oil supplier recommendations, or oil analysis

results may dictate a different oil change interval. Follow these steps:

l Drain oil from frame, associated piping, and oil cooler.

l Clean oil strainer with a suitable solvent. In dry sump applications, the strainer is located at the oil

reservoir.

l Remove frame top cover and crosshead guide side covers. Visually inspect for debris. Do not

disassemble further without good reason. If debris indicates, replace affected parts, then change the

oil filter and clean the strainer with a suitable solvent.

l Refill compressor frame with fresh, clean oil.

8. Check for adequate cylinder lubrication. See ER-96.5.9 for procedure.

9. Re-tighten hold down fasteners to proper torque (compressor frame feet and crosshead guide/distance

piece support feet). Inspect for frame twist or bending to verify main bearing bore alignment. See Ariel

document ER-82 for flatness and soft foot requirements.

10. Perform a coupling alignment (see "Initial Maintenance").

11. Remove and inspect inlet screens on each stage; clean if clogged with debris or replace if damaged.

Clean inlet screens regularly to avoid increased pressure that may collapse them. More debris in the

screen may dictate more frequent inspections. Inlet screens may be removed if they catch little or no

debris and the gas stream is clean (optional).

ER-8.2, Ver. 30 888-397-7766 (toll free USA & Canada) or Page 5 of 8

740-397-3602 (International)

www.arielcorp.com | arc@arielcorp.com

One-Year (8,000-Hour) Maintenance

1. Perform all Daily, Monthly, and Six-Month maintenance.

2. Grease VVCP stem threads at grease fitting, with 2 to 3 pumps of cylinder lube compatible grease using

a standard manual grease pump. Turn VVCP adjustment handle all the way in and all the way out to

lubricate the threads. Measure or count turns to return the handle to its original position.

3. Open force feed lubricator box and visually inspect pump followers, cams, and gears for wear.

4. Pressure test distribution blocks. See ER-96.5.4 for procedure.

5. Measure, log, and trend the following:

l Main bearing, connecting rod bearing, and crankshaft jack and thrust clearances. See ER-96.5.6 .

NOTE: Clearance trends along with oil analysis and crankcase visual inspection can

indicate the need for bearing replacement. Do not disassemble to check clearances.

Disassemble only if clearance checks indicate excessive clearance. Contact Ariel for

original assembly clearances.

l Crosshead to guide clearances. See ER-96.5.10.

l Piston rod runout. See ER-96.5.3.

If any of the above items are outside limits listed in the specified document, find the cause and correct

it. It may require part replacement.

6. Remove valves and valve gaskets:

a. Visually inspect valve pockets for damage. Verify all old valve seat gaskets are removed.

b. Have a qualified valve repair shop disassemble, visually inspect, and refurbish the valves where

needed. Provide the valve repair shop an Ariel torque chart and valve service guide.

c. Visually inspect cylinder gas passages and clean them of all debris.

7. If applicable, visually inspect suction valve unloader actuator stems for damage or wear. Visually inspect

stem seals for damage or wear and confirm that the actuator moves freely.

8. If applicable, visually inspect pneumatic clearance pockets for damage or wear (seating surface and

stems/stem seals). Confirm that actuator moves freely.

9. Inspect cylinder bores for damage or wear. Replace the cylinder body or restore the bore if any of the

following conditions exist:

l Bore surface blemishes or gouges.

l Bore out of round more than 0.001 inch per inch of bore diameter (0.001 mm/mm) or tapered.

l Main bore is worn to counterbore diameter or larger.

10. Inspect piston rings and wearband:

a. Measure and log piston ring condition, end gap, side clearance, and piston groove width.

b. Replace rings that are damaged or outside limits listed in the appropriate ER-96.3.x series

document.

c. When replacing rings, re-measure and log ring side clearance to check for groove wear.

d. Measure and log radial projection of wear band.

ER-8.2, Ver. 30 888-397-7766 (toll free USA & Canada) or Page 6 of 8

740-397-3602 (International)

www.arielcorp.com | arc@arielcorp.com

11. Inspect piston rods for damage and excessive wear. Replace rod if any of these conditions exist (see

ER-96.5.3):

l Gouges or scratches on the rod.

l Under size more than 0.005 inch (0.13 mm).

l In the packing travel length, out of round more than 0.001 inch (0.03 mm).

l Anywhere in the packing travel area, tapered more than 0.002 inch (0.05 mm) for

JG:A:M:P:N:Q:R:J:H:E:K:T:C:D:F, KBE:K:T, and KB100 or 0.005 inch (0.1 mm) for Z:U:B:V.

12. Rebuild piston rod pressure packing cases. See ER-96.5.8 for procedure.

13. Re-install valves, retainers, and valve caps using new valve seat gaskets and valve cap O-rings/seals.

See ER-96.5.2. Use proper installation techniques and torque procedures for valve caps.

14. Check and re-calibrate all required instrumentation.

15. Clean crankcase breather filter with suitable solvent.

16. Check and, if needed, adjust drive chains. See ER-96.5.12 for procedure.

17. If the compressor is equipped with crankcase over-pressure relief valves, visually inspect and exercise

valves to manufacturer recommendations.

18. Check fastener torques of gas nozzle flanges, head end head or unloader, valve caps, piston rod

packings, crosshead pin thru- bolts, crosshead guide to frame, frame hold down, crosshead guide to

cylinder, cylinder mounting flange to forged steel cylinder, distance piece to cylinder, distance piece to

crosshead guide, and tandem cylinder to cylinder.

Two-Year (16,000-Hour) Maintenance

1. Perform all Daily, Monthly, Six-Month, and One-Year maintenance.

2. Rebuild oil wiper cases.

3. If applicable, use new piston and stem seals to rebuild actuators on suction valve unloaders and fixed

volume pneumatic pockets. Replace piston stem assemblies where stem is damaged or worn.

4. Check auxiliary end chain drive for undercut sprocket teeth and chain for excessive stretching. Replace

as required.

Three-Year (24,000-Hour) Maintenance

1. Perform all Daily, Monthly, Six-Month, and One-Year maintenance.

2. Replace non-ELP connecting rod bearings for JGE:T:C:D:U:Z:B:V and KBB:V models. See ER-96.5.6

for procedure. NOTE: Main and connecting rod bearing wear and replacement intervals are

heavily dependent on many factors including speed, load, oil temperature, oil cleanliness,

and oil quality. Depending on the severity of service, the bearing maintenance interval may

be longer or shorter.

ER-8.2, Ver. 30 888-397-7766 (toll free USA & Canada) or Page 7 of 8

740-397-3602 (International)

www.arielcorp.com | arc@arielcorp.com

Four-Year (32,000-Hour) Maintenance

1. Perform all Daily, Monthly, Six-Month, One-Year, and Two-Year maintenance.

2. Remove crosshead pins. Measure and log crosshead pin to crosshead pin bore and connecting rod

bushing bore clearances. Check crosshead pin end caps and thru-bolt for wear. Replace if needed.

3. Check for bushing wear in the auxiliary end drive chain tightener.

4. Check for ring groove wear in pistons.

Six-Year (48,000-Hour) Maintenance

1. Perform all Daily, Monthly, Six-Month, One-Year, Two-Year, and Three-Year maintenance.

2. Replace lubricator distribution blocks.

3. Replace crosshead bushings and connecting rod bushings. See ER-96.5.10 and ER-96.5.14 for

procedures.

4. Replace connecting rod bearings. See ER-96.5.6 for procedure.

5. Replace main bearings. See ER-96.5.6 for procedure.

6. Replace auxiliary end torsional damper, if applicable. See assembly drawing in compressor build book

for procedure.

Document contents are proprietary and confidential. They are the property of Ariel Corporation and may not be dis-

closed, reproduced, or used for manufacture in part or in whole without written permission from Ariel Corporation.

DATE: VER: ECN: DESCRIPTION:

03-02-2020 30 201900889 Table 1, heading: "KBE:K:T" was "KBK:T". "One Year Maintenance", #11: "KBE:K:T" was

"KBK:T".

ER-8.2, Ver. 30 888-397-7766 (toll free USA & Canada) or Page 8 of 8

740-397-3602 (International)

www.arielcorp.com | arc@arielcorp.com

You might also like

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Recommended Maintenance Intervals For Continuous Duty Reciprocating CompressorsDocument7 pagesRecommended Maintenance Intervals For Continuous Duty Reciprocating Compressorsgustavofx21No ratings yet

- 2000 Nissan Frontier KA24DE LCDocument16 pages2000 Nissan Frontier KA24DE LCDavid CervantesNo ratings yet

- ARIEL Maint intervalSEK PDFDocument7 pagesARIEL Maint intervalSEK PDFMargaret Daugherty100% (1)

- R32.engine - Manual Ca18i, Rb20e, Rb20de, Rb20det, Rb25de & Rb26dettDocument580 pagesR32.engine - Manual Ca18i, Rb20e, Rb20de, Rb20det, Rb25de & Rb26dettNick Viccajee100% (1)

- CAT 3412 Air Inlet and Exhaust SystemDocument8 pagesCAT 3412 Air Inlet and Exhaust SystemCEVegaO100% (2)

- Hyundai Exel 89 1.5l.mantenimientoDocument18 pagesHyundai Exel 89 1.5l.mantenimientoAlexander cesar neyra sotoNo ratings yet

- Brake Accumulator: PART NO. 1529749 1800 SRM 1036Document12 pagesBrake Accumulator: PART NO. 1529749 1800 SRM 1036oleg-spbNo ratings yet

- 78 Dt400e DT250E ManualDocument18 pages78 Dt400e DT250E Manualdisgustipate0% (1)

- Partes y Piezas Compresor Schultz - MSI-2.6MLDocument2 pagesPartes y Piezas Compresor Schultz - MSI-2.6MLWinca MantezNo ratings yet

- Valve Lash 1Document4 pagesValve Lash 1Daniel TekleNo ratings yet

- OJ02 - Maintenance (Engine)Document20 pagesOJ02 - Maintenance (Engine)Thong TranNo ratings yet

- Calibracion Valvulas C15Document4 pagesCalibracion Valvulas C15luismf14No ratings yet

- 8369382-Mercury Mariner 200hp Optimax Jet Drive Service ManualDocument364 pages8369382-Mercury Mariner 200hp Optimax Jet Drive Service ManualIvan Zorn90% (10)

- Rcoa1806 03 03Document36 pagesRcoa1806 03 03Fernando Sabino100% (1)

- Valve LashDocument4 pagesValve Lashrafkaalika627No ratings yet

- C4 4 CalibracionDocument5 pagesC4 4 CalibracionJaya Abadi100% (1)

- Adjusting Valve Cummins QSBDocument4 pagesAdjusting Valve Cummins QSBMoch Imron100% (1)

- A 1753 ADocument44 pagesA 1753 AMauricio03No ratings yet

- C4.4 CalibracionDocument5 pagesC4.4 Calibracionecaph24488% (8)

- 3007a Je0m f9q Special FeaturesDocument101 pages3007a Je0m f9q Special FeaturesAdam JohnsonNo ratings yet

- Lubricating System - Primera P11Document42 pagesLubricating System - Primera P11Ishmael WoolooNo ratings yet

- Maintain Reciprocating CompressorsDocument4 pagesMaintain Reciprocating CompressorsCarlos MantillaNo ratings yet

- Ajuste de ValvulaDocument4 pagesAjuste de ValvulaVictor NoschangNo ratings yet

- ТКDocument4 pagesТКАндрей ДубовецNo ratings yet

- 1995 - 1998 Acura 2.5TL 3.2TL Service Manual - Part3Document200 pages1995 - 1998 Acura 2.5TL 3.2TL Service Manual - Part3CandieApple100% (1)

- Gi PDFDocument34 pagesGi PDFdunesNo ratings yet

- Image Server HandlerDocument12 pagesImage Server Handlerbobcat1810No ratings yet

- 3406C+Industrial+Engines Maintenance+IntervalsDocument32 pages3406C+Industrial+Engines Maintenance+Intervalsfoxtrot12100% (1)

- Model D4BDocument165 pagesModel D4BTorque100% (13)

- KiaOptima Seccion 002Document7 pagesKiaOptima Seccion 002Luis Enrique PeñaNo ratings yet

- ManualDocument8 pagesManualSanchai ProgaeewNo ratings yet

- Procedimiento de Ajuste de Freno de Motor C-15, C-16 and C-18 EnginesDocument10 pagesProcedimiento de Ajuste de Freno de Motor C-15, C-16 and C-18 EnginesJose MontoyaNo ratings yet

- 2003-2006 Kia Opirus - Engine Mechanical System PDFDocument131 pages2003-2006 Kia Opirus - Engine Mechanical System PDFprueba2No ratings yet

- 701Document35 pages701tmtt44100% (1)

- Folga Valvula c9Document4 pagesFolga Valvula c9Victor NoschangNo ratings yet

- Foote-Jones 8000 Series Gear Reducer ManualDocument20 pagesFoote-Jones 8000 Series Gear Reducer ManualbwelzNo ratings yet

- MSB 97e55 001 PDFDocument12 pagesMSB 97e55 001 PDFAutof FerreiraNo ratings yet

- Governor (Types I, II, and Some III) - AdjustDocument8 pagesGovernor (Types I, II, and Some III) - AdjustDaniel TekleNo ratings yet

- 456 FourstrkeDocument260 pages456 FourstrkeAndrew WilliamsNo ratings yet

- Powerroc T50 Start Up and Drilling Setting ProcedureDocument7 pagesPowerroc T50 Start Up and Drilling Setting ProcedurerolandNo ratings yet

- Maintenance ScheduleDocument16 pagesMaintenance ScheduleSiska0806No ratings yet

- Toyota Forklift Service ManualDocument43 pagesToyota Forklift Service ManualKamrul Islam JashimNo ratings yet

- Special Features of The f5r 740 EngineDocument146 pagesSpecial Features of The f5r 740 EngineBen Van Der MerweNo ratings yet

- Outboard Manual 70-75-80-90-100-115Document391 pagesOutboard Manual 70-75-80-90-100-115Possis76% (74)

- ME Manual AppendixDocument641 pagesME Manual AppendixAnonymous uTO1WI0% (1)

- Engine Mechanical PDFDocument115 pagesEngine Mechanical PDFAndrey GladyshevNo ratings yet

- Calibracion Valvulas Motor c12 CaterpillarDocument5 pagesCalibracion Valvulas Motor c12 CaterpillarOmar Diaz Segura100% (1)

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- VW Volkswagen Transporter T4 [ Powered By 1.8, 2.4 & 2.9 Diesel engines ]: Workshop Manual Diesel Models Years 2000-2004From EverandVW Volkswagen Transporter T4 [ Powered By 1.8, 2.4 & 2.9 Diesel engines ]: Workshop Manual Diesel Models Years 2000-2004Rating: 3 out of 5 stars3/5 (1)

- VW Transporter T4 ( Diesel - 2000-2004) Workshop Manual: Owners Edition (Owners' Workshop Manuals)From EverandVW Transporter T4 ( Diesel - 2000-2004) Workshop Manual: Owners Edition (Owners' Workshop Manuals)Rating: 1 out of 5 stars1/5 (3)

- Mercedes - Benz Vito & V-Class Petrol & Diesel Models: Workshop Manual - 2000 - 2003From EverandMercedes - Benz Vito & V-Class Petrol & Diesel Models: Workshop Manual - 2000 - 2003Rating: 5 out of 5 stars5/5 (1)

- GM Automatic Overdrive Transmission Builder's and Swapper's GuideFrom EverandGM Automatic Overdrive Transmission Builder's and Swapper's GuideRating: 4.5 out of 5 stars4.5/5 (8)

- Mercedes Benz & Dodge Sprinter CDI 2000-2006 Owners Workshop ManualFrom EverandMercedes Benz & Dodge Sprinter CDI 2000-2006 Owners Workshop ManualRating: 2.5 out of 5 stars2.5/5 (2)

- Mercedes Benz & Dodge Sprinter CDI 2000-2006 Owners Workshop ManualFrom EverandMercedes Benz & Dodge Sprinter CDI 2000-2006 Owners Workshop ManualNo ratings yet

- Diesel Engine Care and Repair: A Captain's Quick GuideFrom EverandDiesel Engine Care and Repair: A Captain's Quick GuideRating: 5 out of 5 stars5/5 (1)

- PipeCalc - Friction LossDocument1 pagePipeCalc - Friction LossManuel LiñeiroNo ratings yet

- Endress-Hauser Proline T-Mass F 300 6F3B enDocument5 pagesEndress-Hauser Proline T-Mass F 300 6F3B enManuel LiñeiroNo ratings yet

- Endress-Hauser Proline T-Mass F 300 6F3B enDocument5 pagesEndress-Hauser Proline T-Mass F 300 6F3B enManuel LiñeiroNo ratings yet

- PipeCalc - Friction LossDocument1 pagePipeCalc - Friction LossManuel LiñeiroNo ratings yet

- Friction loss calculation for single head pump water systemDocument1 pageFriction loss calculation for single head pump water systemManuel LiñeiroNo ratings yet

- Fuel Metering Valve - Test: Localización y Solución de ProblemasDocument21 pagesFuel Metering Valve - Test: Localización y Solución de ProblemasManuel Liñeiro100% (1)

- Ariel J. Lubrication System-03 04 04Document43 pagesAriel J. Lubrication System-03 04 04Manuel LiñeiroNo ratings yet

- Compressor Selection GuidelineDocument46 pagesCompressor Selection Guidelinemohammad basuki0% (1)

- CAT Manual Raptor Woodward 26090BDocument40 pagesCAT Manual Raptor Woodward 26090BManuel Liñeiro90% (10)

- Quote 25260 PDFDocument1 pageQuote 25260 PDFManuel LiñeiroNo ratings yet

- Water Draw PresentationDocument52 pagesWater Draw PresentationManuel Liñeiro100% (1)

- Ariel E. Valves 3.2Document48 pagesAriel E. Valves 3.2Manuel Liñeiro100% (1)

- Vibraciones3 PDFDocument6 pagesVibraciones3 PDFManuel LiñeiroNo ratings yet

- Vibraciones PDFDocument9 pagesVibraciones PDFManuel LiñeiroNo ratings yet

- Vibraciones 3Document6 pagesVibraciones 3Manuel LiñeiroNo ratings yet

- Vibraciones 1Document10 pagesVibraciones 1Manuel LiñeiroNo ratings yet

- Pumps, Valves, Seals and Packing materials - 2010 directoryDocument36 pagesPumps, Valves, Seals and Packing materials - 2010 directoryAvijitSinharoyNo ratings yet

- Package ACDocument52 pagesPackage ACWee WeeNo ratings yet

- Zuidberg Pricelist Update September 2013Document157 pagesZuidberg Pricelist Update September 2013emmanolan100% (1)

- CASE 7 32621 PreviewDocument41 pagesCASE 7 32621 PreviewDiego Alejandro QuinteroNo ratings yet

- Design of Power ScrewsDocument19 pagesDesign of Power ScrewsSOURAV JADHAVNo ratings yet

- Truztaksi0ebhb Y007570 1 en 006Document506 pagesTruztaksi0ebhb Y007570 1 en 006Bùi Xuân ĐứcNo ratings yet

- Suspension Bushing Service Tool: Go The DistanceDocument2 pagesSuspension Bushing Service Tool: Go The DistancePatricio G. ArrienNo ratings yet

- Assignment 1 (LAB)Document7 pagesAssignment 1 (LAB)Zain NajamNo ratings yet

- Catalago Toyota Sas 25 8fg25bDocument316 pagesCatalago Toyota Sas 25 8fg25bMatheus VilsonNo ratings yet

- White Fork Lift Wc30 Thru 60 Fork Lift Trucks Parts CatalogDocument10 pagesWhite Fork Lift Wc30 Thru 60 Fork Lift Trucks Parts Catalogalyssa100% (45)

- JGK-T ArielDocument4 pagesJGK-T Arielrsilayen951No ratings yet

- CanastillasDocument3 pagesCanastillasMiguel Jorge Chavez ChavezNo ratings yet

- TDS LWA High Speed GensetDocument5 pagesTDS LWA High Speed GensetMuhammad SheryNo ratings yet

- Seltec AC Compressor Catalog 2010Document39 pagesSeltec AC Compressor Catalog 2010Erisson100% (1)

- UL 508A ScopeDocument3 pagesUL 508A ScopeKirk WaterworthNo ratings yet

- Assignment 2 PP PDFDocument21 pagesAssignment 2 PP PDFjamesplanetearthNo ratings yet

- CD150M Pump CurveDocument1 pageCD150M Pump CurveUrgent HiringNo ratings yet

- Spare Parts Manual 059459 - LTM - 1070!4!1Document960 pagesSpare Parts Manual 059459 - LTM - 1070!4!1Dmitrij Lukin100% (1)

- Iseki Th4260 4290 4330 Parts ManualDocument20 pagesIseki Th4260 4290 4330 Parts Manualreva100% (45)

- 1520-01 en PDFDocument57 pages1520-01 en PDFjohan ruizNo ratings yet

- Eaton Fuller Heavy-Duty Transmissions TRDR0515: Driver InstructionsDocument22 pagesEaton Fuller Heavy-Duty Transmissions TRDR0515: Driver InstructionsDaniel Marin MoralesNo ratings yet

- Sutorbilt Legend Model 3H R & S-Version DSL & GreaseDocument1 pageSutorbilt Legend Model 3H R & S-Version DSL & GreaseJosue UrgilésNo ratings yet

- Engine Controls (Powertrain Management) - ALLDATA RepairDocument8 pagesEngine Controls (Powertrain Management) - ALLDATA RepairXavier AlvarezNo ratings yet

- Great Benefits of Using Bhs Econtors Single Diaphragm CouplingsDocument6 pagesGreat Benefits of Using Bhs Econtors Single Diaphragm CouplingslubricacionNo ratings yet

- Volume 5 Design and Manufacturing of Hydraulic PressesDocument64 pagesVolume 5 Design and Manufacturing of Hydraulic PressesBaihaki St100% (1)

- Weg Motor ManualDocument56 pagesWeg Motor ManualOrbeneSantosNo ratings yet

- Machines Lab II QuestionsDocument4 pagesMachines Lab II QuestionsAbhiram DonNo ratings yet

- PAES 222 - Chipping Machine - Specifications (Circulated)Document7 pagesPAES 222 - Chipping Machine - Specifications (Circulated)Jerard BalalaNo ratings yet

- DC Motor Speed Regulation and CharacteristicsDocument120 pagesDC Motor Speed Regulation and CharacteristicsEvan KanigaraNo ratings yet

- Piping Sensing Line Layout of Fire Pump and Jockey PumpDocument1 pagePiping Sensing Line Layout of Fire Pump and Jockey Pumpاحمد الجزار200750% (2)

![VW Volkswagen Transporter T4 [ Powered By 1.8, 2.4 & 2.9 Diesel engines ]: Workshop Manual Diesel Models Years 2000-2004](https://imgv2-1-f.scribdassets.com/img/word_document/282876773/149x198/5fb74bd6e1/1675169638?v=1)