Professional Documents

Culture Documents

Sheets Vaijayanti Mundada

Uploaded by

khushiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sheets Vaijayanti Mundada

Uploaded by

khushiCopyright:

Available Formats

PRODUCED BY AN AUTODESK STUDENT VERSION

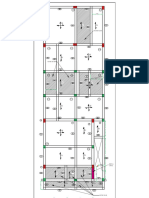

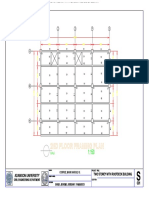

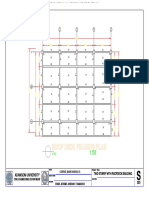

FRAMING PLAN WITH STRUCTURAL REINFORCEMENT C4

C1 C2

C3

B1 B2 B3 DIST. BAR

6 MM DIA

100 MM C-C

C1 C2 C3 C4

B1 B2 B3

A A' S3

B4 S1 B9 S2 B10 B4

B9 B10

B8

B8 C7 C6

C5

C8

B7 B6 B5

MAIN BAR

12 MM DIA

125 MM C-C B11 B12 B13

S5 B14

C6 S4

C5

C8 B7 C7 B6 B5 C9

B16 C10 C11

B15 C12

2.0

MAIN BARS

12 MM DIA

DIST. BAR 125 MM C-C

6 MM DIA ALTERNATE BENT UP B17

S7 B18 B20 S6 B21

100 MM C-C

4.0

B11 B12 B13 B14

C16

B19 C15 C14

1 2 3 4 5

B22

6 7 8 9 10

C13

B25

UP MAIN BAR

12 MM DIA

125 MM C-C

MAIN BAR B23

S8 B24 S9 B26

20 19 18 17 16 15 14 13 12 11

B27

12 MM DIA DIST. BAR

6 MM DIA

100 MM C-C

125 MM C-C C17

C18

B29 B28

C19

PLAN C20

SUNK

SUNK

B16

PRODUCED BY AN AUTODESK STUDENT VERSION

C9 C10

B15

PRODUCED BY AN AUTODESK STUDENT VERSION

C12

C11

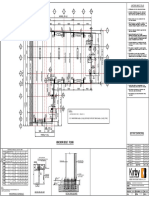

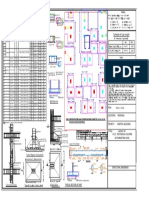

GROUND FLOOR PLAN

SUNK

SUNK

KEY PLAN

DIST. BAR

6 MM DIA

100 MM C-C B21

B18 B20 MAIN BARS

4.0

B17

12 MM DIA

125 MM C-C

MAIN BAR

12 MM DIA

ALTERNATE BENT UP

125 MM C-C

B19 C14

B22

C13

C16 C15 B25 1 2 3 4 5 6 7 8 9 10

UP

B23 B24 B26 B27

20 19 18 17 16 15 14 13 12 11 10

C17 C18

B29 C19 B28 C20

FIRST FLOOR PLAN

MAIN BAR DIST. BAR

MAIN BAR

DIST. BAR 12 MM DIA 6 MM DIA MAIN BAR

12 MM DIA

6 MM DIA 125 MM C-C DIST. BAR 100 MM C-C 12 MM DIA

125 MM C-C

100 MM C-C 6 MM DIA 125 MM C-C

S5 100 MM C-C

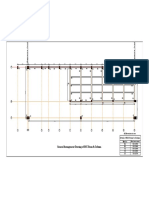

6.7 6.7 6.7 3D VIEW OF SLAB REINFORCEMENT

SECTION AT AA'

SIGN BVDU COLLEGE OF ARHITECTURE, PUNE STAMP

RCC SLABS

EVISHA G. GAURAV P. SAMPADA K. VAIJAYANTI M.

T. Y . B. ARCH SEM VI 2020-2021

BUILDING CONSTRUCTION MATERIAL

DATE ROLL NO. SHEET NO.

PRODUCED BY AN AUTODESK STUDENT VERSION

PRODUCED BY AN AUTODESK STUDENT VERSION

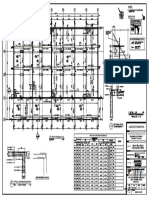

FIRST FLOOR PLAN

C1 C2 C4

C3 C1 C2 C3 C4

B1 B2 B3

B1 B2 B3 DIST. BAR

6 MM DIA

100 MM C-C

S1 S2 S3 B4

5.0 B8

B9 B10

C7 C6

C5

B6

5.0 B4 C8

B7 B5

B9 B10

B8

MAIN BAR

B11

S4

B12 B13

S5 B14

12 MM DIA

125 MM C-C

C6

C5

C9 C10

B16 C11

B15 C12

C8 B7 C7 B6 B5

1.5 MAIN BARS

12 MM DIA

DIST. BAR 125 MM C-C

6 MM DIA

100 MM C-C

ALTERNATE BENT UP B17

S7 B18 B20 S6 B21

A

3.0

B11 B12 B13 B14 A' C16

B19 C15 C14

B22

C13

1 2 3 4 5 6 7 8 9 10

MAIN BAR MAIN BARS B25

12 MM DIA

125 MM C-C

12 MM DIA

125 MM C-C B23

S8 B24 S9

UP

B26

20 19 18 17 16 15 14 13 12 11

B27

MAIN BAR

12 MM DIA

125 MM C-C

SIMPLY SUPPORTED BEAM BALCONY

ALTERNATE BENT UP DIST. BAR

6 MM DIA

100 MM C-C

C17

SUNK C18

B29 B28

SUNK C19

PLAN C20

C9

B16 C10

C11

B15 C12

SUNK

SUNK

GROUND FLOOR PLAN

DIST. BAR

PRODUCED BY AN AUTODESK STUDENT VERSION

6 MM DIA

PRODUCED BY AN AUTODESK STUDENT VERSION

100 MM C-C B18 B21

B17 B20 MAIN BARS

MAIN BAR

3.0

12 MM DIA

125 MM C-C KEY PLAN

ALTERNATE BENT UP

12 MM DIA

125 MM C-C B19 C14

B22

C13

C16 C15 B25 1 2 3 4 5 6 7 8 9 10

UP

B23 B24 B26 B27

20 19 18 17 16 15 14 13 12 11 10

B29 B28

CANTILEVER BEAM BALCONY

C17 C18 C20

C19

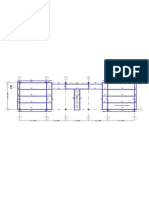

SECTION AA'

CANTILEVER BEAM SLAB

CANTILEVER SLAB BALCONY

SIGN BVDU COLLEGE OF ARHITECTURE, PUNE STAMP

RCC BALCONIES

EVISHA G. GAURAV P. SAMPADA K. VAIJAYANTI M.

T. Y . B. ARCH SEM VI 2020-2021

BUILDING CONSTRUCTION MATERIAL

DATE ROLL NO. SHEET NO.

PRODUCED BY AN AUTODESK STUDENT VERSION

PRODUCED BY AN AUTODESK STUDENT VERSION

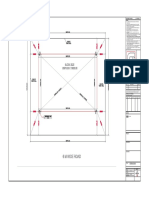

C1 C2 C3 C4

B1 B2 B3

PLAN

S1 S2 S3 C14 C13

B4

B8

B9 B10

1 2 3 4

B22

5 6 7 8 9 10

MAIN BAR

DETAIL AT A

12 MM DIA

125 MM C-C

C7 C6

C5

C8

B7 B6 B5 UP

S5 S4 B28

B11 B12 B13 B14

B26 20 19 18 17 16 15 14 13 12 11

DIST. BAR

8 MM DIA

100 MM C-C

C9 C10

B16 C11

B15 C12

C19 B27 C20

PRODUCED BY AN AUTODESK STUDENT VERSION

PRODUCED BY AN AUTODESK STUDENT VERSION

S6 B18

S7 B21

B17 B20 DIST. BAR

8 MM DIA

100 MM C-C

C16

B19 C15 C14

B22

C13

TREAD

1 2 3 4 5 6 7 8 9 10

B25

DISTRIBUTION STEEL RISER

UP 0.30

8MM DIA

B23 B24 S9 B26 B27

S8 20 19 18 17 16 15 14 13 12 11

1.50 1.50 MID - LANDING

MAIN BAR

A

C17

C18

B29 12 MM DIA MAIN BAR

B28

125 MM C-C

C19

PLAN C20 12 MM DIA

125 MM C-C

1.50 DIST. BAR

6 MM DIA

100 MM C-C

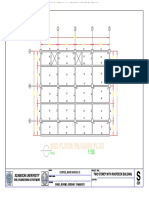

GROUND FLOOR PLAN

5.27 0.30

0.15

2.85

MAIN BAR

12 MM DIA

SECTION

0.30 125 MM C-C

BEAM

ISOMETRIC VIWE OF DOG

SECTION

LEGGED STAIRCASE

*DIMENSIONS IN M

SIGN BVDU COLLEGE OF ARHITECTURE, PUNE STAMP

CHAITRALI J. EVISHA G. GAURAV P. SAMPADA K. VAIJAYANTI M.

T. Y . B. ARCH SEM VI 2020-2021

STAIRCASE REINFORCEMENT BUILDING CONSTRUCTION MATERIAL

DATE ROLL NO. SHEET NO.

PRODUCED BY AN AUTODESK STUDENT VERSION

COMPOUND FINK TRUSS RIDGE

COMPOUND FINK TRUSS

PURLIN

RIDGE

PRINCIPAL RAFTER RIDGE

POLYCARBONATE SHEET

PRINCIPAL RAFTER PRLINCIPLE RAFTER

KING POST

KING POST

STRUT PURLIN

STRUT 3000.0

GUSSET PLATE STRUT

CLEAT

TIE BEAM 3.95

TIE BEAM SHEET

45 MM GUSSET PLATE

STEEL COLUMN

WEB MEMBER

( CHANNEL= L.)

TIE MEMBER

INDUSTRIAL TRUSS :- 15000X20000 CENTRE LINE

OF COLUMN

SPACING OF TRUSS :-15000

3000 = 5000

PITCH :- SPAN / 4000 = 15000

4000 =3.75

5.0

PROJECTION :- 600

SLOPE :- 7414.9 COMPRESSION

I CHANNEL

COLUMN

TENSION

BASE

RIDGE G.L 0.6

STEEL COLUMN

SECTION

(SCALE 1:100)

CALCULATIONS

· SPAN OF THE TRUSS :- 15 .0 M

20.00

· LENGTH OF THE TRUSS :-18.0 M

· DISTANCE BETWEEN TWO TRUSSES

:- SPAN/ 5= 3 OR SPAN / 3= 5

· PITCH :-24 DEGREE

20.0000

15.0000

· LENTH OF COMMON RAFTER :-

8.234(SPAN/5)

5.0000 9.013(SPAN /3)

5.00

11.74

11.74

15.00

3.34 3.45

DOBLE HOWE TRUSS RIDGE

PURLIN

3.52

PLAN

3.52

WEB MEMBER

( CHANNEL= L SECTION)

15.0

PRLINCIPLE RAFTER

0.33 1.10 3.52

4.5 0.86

TIE MEMBER

FOUINDATION PLAN (SCALE 1:100)

ISOMETRIC VIEW OF COMPOUND FOUINDATION PLAN (SCALE 1:100)

FINK TRUSS (SCALE 1:20) FOUINDATION PLAN

SIGN BVDU COLLEGE OF ARCHITECTURE STAMP

(SCALE 1:100)

GROUP SHEET

TYPES OF TRUSS T.Y.B.ARCH DIV - B SEM -6

BUILDING CONSTRUCTION AND MATERIAL

ROLL NO - 10

ALL DIMENSIONS ARE IN M DATE - SHEET NO - 04

TYPE 3 - PORTAL FRAMES TYPE 4 - WARREN TRUSS

· Generally Low rise structures consisting of columns and horizontal pitched

rafters

· Connected by moment resisting connections

· Resistance to lateral and vertical actions is provided by the rigidity of the

connections and the bending stiffness of members. · In this type of truss , the diagonal members are alternatively in tension and

compression.

· This form of continuous frame structure is stable in its plane and provides a

clear span that is unobstructed by bracing. · The Warren Truss has equal length compression and tension web members ,

MOULDED G.I RIDGE PIECE

and fewer members than a Pratt truss.

20 MM THK M.S BASE PLATE

50 MM DIA HINGE PIN

G.I SHEET M.S HOLDING DOWN BOLTS

FABRICATED SECTIONS AS RAFTERS

20 MM THK M.S BASE PLATE

100 MM THK P.C.C BED

· This type of truss is also used for horizontal truss of gantry / crane girders .

FABRICATED SECTIONS AS POSTS

scale-1:10

PURLIN

SCALE= 1:200 ROOF PLAN · A modified Warren truss may be adopted where additional members

introduced to provide a node at (for example) purlin location.

· Warren Trusses are

commonly used in long

PIN JOINT

span buildings ranging

B

G.I ROOFING SHEET from 20 m to 100 m in

SPANNING MEMBER span.

ANGLE CLEATS AS PURLINS

G.I GUTTER MOULDED RIDGE PIECE

I SECTION TIE BEAM B/W PORTAL FRAMES

STIFFENER PLATES

RAFTERS

J- BOLT

HINGE PLATE WELDED

TO THE SPANNING MEMBER

HINGED END

STEEL BOLT

A

FOUNDATION

ISOMETRIC VIEW (B)

SCALE= 1:200 KEY SECTION

SIGN BVDU COLLEGE OF ARCHITECTURE, PUNE

SAMPADA KULKARNI

2020-2021

T.Y.B.ARCH SEM - 6

BUILDING CONSTRUCTION AND MATERIALS

ROLL

DATE NO. SHEET NO.

PRODUCED BY AN AUTODESK STUDENT VERSION

PIN JOINT

G.I ROOFING SHEET

B

SPANNING MEMBER 20 MM THK M.S BASE PLATE HINGE PLATE WELDED TO THE

50 MM DIA HINGE PIN SPANNING MEMBER(RAFTER)

ANGLE CLEATS AS PURLINS

G.I GUTTER M.S HOLDING DOWN BOLTS

I SECTION TIE BEAM B/W PORTAL FRAMES

STIFFENER PLATES 20 MM THK M.S BASE PLATE STEEL BOLT AS PIN

J- BOLT 100 MM THK P.C.C BED

DETAIL AT B scale-1:10

HINGED END

A

FOUNDATION

KEY SECTION SCALE= 1:200

DETAIL AT A scale-1:10

FISH PLATES TO TOP AND BOTTOM FLANGE

MOULDED RIDGE PIECE

BASE OF THE FOUNDATION SPANNING MEMBERS BUTT JOINTED

RAFTERS POST OF THE PORTAL

HINGE PLATE WELDED M.S PLATE WEB PLATES

PRODUCED BY AN AUTODESK STUDENT VERSION

TO THE SPANNING MEMBER \AS REQUIRED

PRODUCED BY AN AUTODESK STUDENT VERSION

HOLDING DOWN BOLTS

STEEL BOLT

PLAN scale-1:10 BOLTED SPLICE JOINT scale-1:10

ISOMETRIC VIEW (B)

FABRICATED SECTION

M.S PLATE

2 LEAF PIN

3 LEAF PIN

M.S BASE PLATE

PIN 20 MM DIA

THREE DIMENSIONAL PERSPECTIVE

OF PORTAL FRAME STRUCTURES

ISOMETRIC VIEW (A)

SIGN BVDU COLLEGE OF ARCHITECTURE STAMP

ADITI PADIYAR, JASMITA MARELLA, BHAVYA TRIPATHI, EVISHA GUPTA,SAMPADA KULKARNI, SHRUTI PANGARE,SWARNNIM JAISWAL,VAIJAYANTI MUNDADA

1- PORTAL FRAMES (II) TY B. ARCH. , SEM-VI, 2020-21

BUILDING CONSTRUCTION & MATERIALS (VI)

DATE, SHEET, ROLL. NO.

31/5/21, 1 08

PRODUCED BY AN AUTODESK STUDENT VERSION

PRODUCED BY AN AUTODESK STUDENT VERSION

PORTAL FRAMES:

MOULDED G.I RIDGE PIECE

· generally low-rise structures

G.I SHEET

· comprising of columns & horizontal/ pitched rafters,

6000 mm

FABRICATED SECTIONS AS RAFTERS

· connected by moment-resisting connections.

· Resistance to lateral & vertical actions is provided by the rigidity of the

connections & the bending stiffness of the members (which is increased FABRICATED SECTIONS AS POSTS

by a suitable haunch/ deepening of the rafter sections).

PURLIN

6000 mm

· This form of continuous frame structure is stable in its plane & provides

a clear span that is unobstructed by bracing.

· Following are the common types of portal frames:

6000 mm

12000 mm

PRODUCED BY AN AUTODESK STUDENT VERSION

PRODUCED BY AN AUTODESK STUDENT VERSION

ROOF PLAN SCALE= 1:200

PIN JOINT

G.I ROOFING SHEET

B

SPANNING MEMBER

ANGLE CLEATS AS PURLINS

G.I GUTTER

I SECTION TIE BEAM B/W PORTAL FRAMES

STIFFENER PLATES

J- BOLT

HINGED END

A

FOUNDATION

KEY SECTION SCALE= 1:200

SIGN BVDU COLLEGE OF ARCHITECTURE STAMP

ADITI PADIYAR, JASMITA MARELLA, BHAVYA TRIPATHI, EVISHA GUPTA,SAMPADA KULKARNI, SHRUTI PANGARE,SWARNNIM JAISWAL,VAIJAYANTI MUNDADA

1- PORTAL FRAME (I) TY B. ARCH. , SEM-VI, 2020-21

BUILDING CONSTRUCTION & MATERIALS (VI)

DATE, SHEET, ROLL. NO.

31/5/21, 1 08

PRODUCED BY AN AUTODESK STUDENT VERSION

STEEL COLUMN TO BASE INCLUDING GUTTER STYLES

FOUNDATION DEATIL · SEAMED & SECTIONAL GUTTER

· SEAMLESS GUTTERS

COLUMN TOP PLATE

900 mm X 300 mm X 12 mm LATTICE STEEL

2 NOS. BOLTS GUTTER SHAPES

ROOF TRUSS

6 - 12 mm DIA. · K SHAPE

ANGLES · HALF ROUNDED

60 X 60 X 6

STEEL CAP GUSSET PLATE · FASCIA SHAPE TYPES OF FLASHING, TRIMS & GUTTERS

COLUMN PLATE WELDED · BOX

900 mm X 300 mm TO COLUMN OR ANGLE CLEATS BOLTED

FIXED WITH TO GUSSET PLATE AND

· HIGH BACK

ANGLE BOLTED TO CAP PLATE

GUTTER MATERIAL

STEEL BASE

COLUMN TOP PLATE DETAIL PLATE

ANGLE CLEATS BOLTED · ALUMINIUM

TO COLUMN AND

BASE PLATE

· STEEL

· ZINC

· VINYL

· COPPER

I SECTION COLUMNS

HOLDING DOWN

HOLDING DOWN BOLTS BASE PLATE (15MM)

BOLT

ON CLEARENCE BOLTS CONCRETE

BASE ANGLE IRON FRAME

CAST INTO CONCRETE

STEEL PACKING BEEDING SPACE 50 MM

LOCATION TUBE

CAP AND BASE OF STEEL COLUMN SUPPORT FOR

CONCRETE FOUNDATION LATTICE STEEL AND TRUSS

ANCHOR PLATE

FOUNDATION DETAIL

SMALL WEB 60X60X6 2.5MM THICK GI CORRUGATED

SHEET

CENTRE LINE PRINCIPAL RAFTER 70X70X6

PURLIN 50X100X6MM

BOLTS 12MM DIA

CENTRE LINE

GUSSET PLATE 8MM THICK BOLTS 12MM DIA

BOTTOM CHORD 80X80X8

GUSSET PLATE 8MM THICK

SMALL WEB 40X40X6

Web and Chord Connection SAG TIE

BOLTS 12MM DIA

Detail Of Purlin

RIVETS

GUSSET PLATE 8MM THICK TWO ANGLE SECTIONS

GUSSET PLATE BACK TO BACK

CENTROIDAL AXES

SINGLE ANGLE

Strut junction details

SIGN BVDU COLLEGE OF ARCHITECTURE STAMP

GROUP SHEET

TY B. ARCH DIB B SEM 6

BUILDING CONSTRUCTION & MATERIAL

SHEET NO.4

PRODUCED BY AN AUTODESK STUDENT VERSION

PRESTRESSING OVERVIEW

Post-tensioning enables the construction & refurbishment of concrete structures; improving structural performance & also reducing construction time,

costs, materials & environmental impact.

PRESTRESSING IS THE PROCESS OF INTRODUCTION OF COMPRESSIVE STRESSES IN IMPLEMENTATION:

Post-tensioning is a method of reinforcing concrete. High-strength steel tendons are positioned in ducts/ sleeves before the concrete is placed. Once the

THE STRUCTURE BEFORE IT IS PUT TO ACTUAL USE. concrete has gained strength, tension is then applied, pulling the tendons & anchoring them against the outer edges of the concrete, before service loads

are applied.

PRESTRESSED CONCRETE MEMBER IS A MEMBER OF CONCRETE IN WHICH INTERNAL

ELEMENTS OF POST TENSIONING SYSTEM:

STRESSES ARE INTRODUCED IN A PLANNED MANNER , SO THAT THE STRESSES · Tendon: one/more pieces of prestressing steel, coated with a protective coating, housed within a duct/sheathing. It has anchors (intermediate

anchors too for long tendons) on ends to transmit the forces into the structure.

RESULTING FROM THE SUPERIMPOSED LOADS ARE COUNTERACTED TO A DESIRED · Internal bonded tendons: where one/more strands are inserted into a metal/plastic duct embedded in concrete.

· Internal unbonded tendons: where the prestressing steel isn't bonded to the concrete around it, except at the anchorages.

DEGREE. · External unbonded tendons: on the outer surface of concrete structures, allows access for maintenance, hence used for bridge enhancements &

refurbishments.

· Hydraulic tension jack: Tension is applied to prestressing steel by using this. The jack bears against one of the anchors embedded in the concrete &

TENDON BEAM TENDON REINFORCEMENT BARS pulls the steel to a predetermined force. As the steel elongates, the concrete / masonry elementcompresses.

ANCHORAGE TENDON · Bearing Plate: transfers prestressing force from the tendon to the concrete.

R.C.C.

JACK ADVANTAGES: Post-tensioning allows :

· longer clear spans, thinner slabs, fewer beams & more slender, dramatic elements.

PRESTRESSED TENDON

· Thinner slabs mean less concrete is needed i.e. a lower overall building height for the same floor-to-floor height.

· Allows a significant reduction in building weight vs a conventional concrete building with the same number of floors.

PRESTRESSED CONCRETE WITH DEAD LOAD · This reduces the foundation load & can be a major advantage in seismic areas.

· Lower building height translates to considerable savings in mechanical systems & façade costs.

UNCRACKED WITH SERVICE LOAD · Beams & slabs can be continuous, i.e. a single beam can run continuously from one end of the building to the other.

· Post-tensioning is the system of choice for parking structures since it allows a high degree of flexibility in the column layout, span lengths & ramp

PRESTRESSED CONCRETE WITH FULL SERVICE configurations.

LOAD · In areas with expansive soils (low bearing capacity), post-tensioned slabs-on-ground & mat foundations reduce problems (cracking & differential

settlement).

· Post-tensioned rock & soil anchors are used in tunneling & slope stabilization & as tie-backs for excavations. Post-tensioning can also be used to

produce crack-free concrete for water-tanks.

APPLICATIONS: Post tensioning system of construction is ideal in the cases of:

PRODUCED BY AN AUTODESK STUDENT VERSION

·

PRODUCED BY AN AUTODESK STUDENT VERSION

Office and apartment buildings

· Multi storey parking

· Stadiums/auditoriums (buildings which require long spans and/or heavy loads)

· Bridges, Water tanks.

· tunnels & slope stabilisation projects/ embankments.

FLOORING FOUNDATION STONE CLADDING

COMPOSITE FLOOR SYSTEMS- After the concrete foundation has setup, steel base plates are anchored and

The basic concept of composite beam lies in the fact that the concrete is stronger in attached to the foundation with four anchoring bolts. the plates are levelled on a bed Stone veneer is a thin layer of any stone used as decorative facing material that is not meant to be load bearing.

compression than steel which is susceptible to buckling under compression & steel is of non- shrinking grout. In India, granite, sandstone and slate are the most common choices for stone wall cladding. Marble is another

stronger in tension. The steel columns are lowered and welded to those base. the plates are used to

transfer concentrated load from the columns to the ground.

option for areas that require a sophisticated finish. These natural stones come in a range of colors and sizes,

Primary ground floor beams are connected to the column via fin plates. the plates including smaller slabs or rounded stones for a more rustic look for the exterior walls.

are welded with the column and bolted to the web of the beams. Natural stone cladding can be installed on the wall either by using a -

· Wet method · Dry method

SHIMS

DRILLED

ANCHOR

STAINLESS

ANCHORAGE TYPES- STEEL BENT

PLATE

COLUMN AND BEAM JOINT DETAILS

THE CONSTRUCTION COMPONENTS-

corrugated steel sheet profile- the indentations of which allows it to provide

support to the concrete.

Anti- fracture mesh- which is positioned in a similar manner to when employed for Bent Stainless Shelf Angle With FILLED WITH

Installed Strap Welded Stainless

solid slabs and the objective of which is the prevention of fractures provoked by Plate Rebated Stone SEALANT

Anchor Steel 'T'

reflection and temperature..

STONE

Negative framework- which installed in the upper section of the slab and centered

in the indentations, it serve function to absorb the tensile stresses generated in the

adjacent slabs support. Strap anchors Plug anchors

Fire- resistance framework- installed to ensure that the slabs fire resistance

complies with the projects specifications.

concrete- which is poured directly onto the composite slab. SECTION OF STONE CLADDING

COLUMN AND BEAM JOINTS AT FOUNDATION COLUMN AND COLUMN JOINTS

SIGN BVDU COLLEGE OF ARCHITECTURE, PUNE

ADITI PADIYAR, JASMITA MARELLA, BHAVYA TRIPATHI, EVISHA GUPTA, SAMPADA KULKARNI

MATERIALS AND TECHNIQUES SHRUTI PANGARE, SWARNIM JAISWAL, VAIJAYANTI MUNDADA

2020-2021

BUILDING CONSTRUCTION AND MATERIALS

SEM - 6

DATE SHEET NO.

PRODUCED BY AN AUTODESK STUDENT VERSION

PRODUCED BY AN AUTODESK STUDENT VERSION

PRE ENGINEERED BUILDING/STRUCTURE PORTAL STEEL FRAME

THE COMPOSITION OF PORTAL STEEL FRAME BUILDINGS

1. Primary framing: transverse rigid frames (including middle

and end rigid framing), floor beams, crane beams, support

Pre-Engineered Buildings (PEBs) are the building components which are manufactured at a factory and assembled on site. Usually PEBs are systems, etc.

steel structures and can be an alternative to conventional structural steel buildings. PEB structural components are fabricated at the factory to 2. Secondary framing: roof purlin and wall girt, etc.

3. Envelope structure: roof and wall panels;

exact size, transported to site and assembled at site, usually with bolted connections. This type of Structural Concept is generally used to build: 4. Auxiliary structures: stairs, platforms, handrails, etc .;

5. Foundation.

· Industrial and Small Manufacturing Buildings

· Small Retail and Commercial Office Buildings

· Warehouses and Storage Units

R.F. RAFTER

FLANGE BRACE

(50X50X3 ) • Portal Steel Frame Buildings is the most common PRINCIPAL COMPONENTS OF A PORTAL FRAMED BUILDING

STIFFENER PLT structure system. • The primary steelwork consists of columns and rafters, which form portal frames,

• It widely used in light steel buildings such as and bracing.

ROOFING SHEET

warehouses, workshops, sheds, garages. • The light gauge secondary steelwork consists of side rails for walls and purlins for the

• A portal frame building comprises a series of roof.

R.F. COLUMN

transverse frames braced longitudinally. • The secondary steelwork supports the building envelope, but also plays an important

7300

role in restraining the primary steelwork.

• The roof and wall cladding separate the enclosed space from the external

1500

4000

environment as well as providing thermal and acoustic insulation.

3M BRICKWALL • The structural role of the cladding is to transfer loads to secondary steelwork and also

to restrain the flange of the purlin or rail to which it is attached.

RIGID FRAME ELEVATION

24790

CASTELLATED BEAM

• A castellated beam is a beam style where an I-beam is

subjected to a longitudinal cut along its web following a Roof structure

specific pattern.

ADVANTAGES OF PEB DISADVANTAGES OF PEB CROSS-SECTION SHOWING A PORTAL FRAME AND ITS • The purpose is to divide and reassemble the beam with

RESTRAINTS a deeper web by taking advantage of the cutting

· Reduced construction time. · This type of structure can be attractive when it is

pattern.

· Flexibility of Expansion. left exposed.

PRODUCED BY AN AUTODESK STUDENT VERSION

PRODUCED BY AN AUTODESK STUDENT VERSION

· Large Clear Spans · The parts of the pre-engineered buildings are

· Low maintenance susceptible to corrosion. • A castellated beam is a beam that has a regular

· Energy Efficient Roofing and Wall systems · The insulating of the building will furthermore and repeating pattern of hexagonal holes.

· Architectural Versatility • It is created by cutting the pattern lengthwise

increase the construction cost across two different halves, offsetting, and then

· Single source Responsibility welding them together to create a single

expanded beam.

FILLET WELD BOLTED CONNECTIONS RIVETED CONNECTIONS • The facade systems that are used in multi story buildings depend

on the function and scale of the building.

• In medium to high rise city center buildings, either fully glazed

Fillet welding refers to the process Rivets are used for strengthening

of joining two pieces of metal A connection between structural façades or lightweight curtain walling systems are generally used.

different types of steel structures • Modern curtain walling systems are ‘unitized’ and are installed in

together when they are members made with plates and and to provide stability in complex widths of 1.2 to 2 m and height of 3.6 to 4.2 m. An example of the

perpendicular or at an angle. bolts, as opposed to a riveted structures created using more use of curtain walling units in a steel framed building is shown

or welded construction than 10 pieces of steel. (above right).

• Brickwork may be supported at each floor by the edge

• beams in steel frames.

In other more conventional building types, brickwork and • These attachments are in the form of stainless steel

lightweight cladding may be connected back to light steel infill brackets that are connected to steel plates welded to the

walls. Glazing systems edge beams.

• A typical light steel infill wall is shown (left). In this case, the • The brackets are placed at 400 or 600mm spacing along

brickwork is ground supported for heights of up to 12m and is •Posts or beams that are usually in the form of the edge beam, depending on the wall height of 2.8 to 4m

TRUSS JOINTS : ANGLE TO THE GUSSET TYPES OF FILLET WELD CONCENTRIC CONNECTIONS (and hence its weight), and allow for adjustments on site

laterally supported by the infill walls. circular hollow sections (CHS), or in some cases,

fillet weld at heel & toe . MITRE FILLET WELD

CONCAVE FILLET WELD

rectangular hollow sections (RHS). to align with the brick coursing.

and symmetrical. about c.g •Vertical or horizontal trusses using smaller CHS • The projecting stainless steel angle fits into the mortar

Cladding interfaces with the structure sections. joint. The detail shows the typical build-up of materials at

RIVET •Inclined arms from the internal structure, where an edge beam to achieve a high level of thermal

PLATES TO BE JOINED PLATES TO BE JOINED • The connection of unitized curtain walling systems to the the glazing system is used to create a large atrium insulation.

DEEP PENETRATION WELD

CONVEX FILLET WELD

or featured entrance area

P edge of a steel framed building is often made by specific •Combined post and tension tie systems using

connection systems that attach to the top of the slab (and are •Single tie systems which are efficient for roofs or

contained within the raised access floor), and also to the when positive wind pressure exceeds negative

fillet weld at heel toe ADVANTAGES OF WELDED JOINTS BOLTED CONNECTION

pressure as the ties only act in tension. Double tie

and width of angle

USING T SECTION CHORD bottom flange of the edge beams.

This joint is much more effective systems, which are often used when the ties on

than the bolted joints with no

• An example of this type of system is shown. These one side are outside of the building, and both sets

ADVANATAGES OF BOLTING

threat of being loose with time attachments allow for adjustment on site to allow for of ties act in tension. The vertical member can be

as it is in case of bolted joints. Use of unskilled labour and simple tools variations in the deflection of the beams and site tolerances. very small.

There is no need of of drawing Noiseless and quick fabrication

No special equipment/process

P holes in the metal pieces and

Fast progress of work LAP JOINT

increase the stress concentration

The connection supports loads as BUTT JOINT

at that point as the two metal soon as the bolts are tightened

parts are thoroughly joined. Due to the smaller number of bolts,

the gusset plate sizes are reduced. ADVANATAGES OF RIVETING DISADVANATAGES OF RIVETING

fillet weld provided at the DISADVANTAGES OF WELDED JOINTS Deformation is minimized.

Cost Effectiveness More Work Force

heel and toe of angle Toxic fumes are generated by Increases Production Output Higher Structural Weight

the joint is being made which Flexibility in Design Lack of Aesthetic Finish

can be breathed in by the DISADVANTAGES OF BOLTING

Easy Inspection and Maintenance The riveting process is noisier

the person welding it. Durability

lesser strength in the axial tension than welding

Unlike the bolted joint they

P cannot be easily assemble to BOLTED CONNECTION Under the vibratory loads,

the strength is reduced

Ability to make joint regardless

The riveted joints are bulkier

of the location Attachment of a unitized curtain walling system to an edge beam

dismantled whenever there USING ANGLE CHORDS if the connections are get very loosened.

High shear strength than welding in a steel framed building

is a requirement.

SIGN BVDU COLLEGE OF ARCHITECTURE, PUNE

MORE DETAILS:- STEEL TRUSS T.Y.B.ARCH

BUILDING CONSTRUCTION AND MATERIALS

DATE

SEM - 6

SHEET NO.

2020-2021

ROLL NO.

PRODUCED BY AN AUTODESK STUDENT VERSION

PRODUCED BY AN AUTODESK STUDENT VERSION

RAFTER 150x75x10mm. ANGLE BRACKET GLASS &

100x75x10mm GLASS FRAME

ANGLE RAIL ANGLE 2-

ANGLE PURLIN 90x65x10mm. ANGLE CLEAT 65x65x6mm. 125x75x10mm 150x75x10mm GLASS JOINT

ANGLE RAIL RIDGE CAPING LEAD

10mm THK GUSSET PLATE 10mm THK GUSSET PLATE ANGLE CLEAT FLASHING

80x60x10mm FLASHING 100x100x10mm

1mmTHK GI SHEET BOTTOM CLEAT GLASS JOINT ANGLE CLEAT

ANGLE CLEAT 125x75x10

125x75x12 CLEAT ANGLES 2-65x50x8mm

150x75x10 12mm THK PLATE

J BOLTS(6.5mm)

RUNNER 150x100x10mm.

EAVES ANGLE CLEAT 300x150x8mmTHK

ANGLE CLEAT 100x75x10mm.

BRACE PLATE 350mm@C/C.

GUTTER 100x100x10mm ISMC 100. 25mm WIDTH 1mmTHK

GANTRY GANTRY GANTRY

300x150x8mmTHK CORRUGATED GI SHEET.

BRACE PLATE 350mm@C/C.

DETAIL AT END COLOUMN

600x150x8mmTHK BRACE PLATE 350mm@C/C.

14mm THK BASE PLATE (750x450mm).

G.L

SECTION AA' 150mm THK PCC BED(1200x900mm).

150mm THK RCC SLAB. BUILT UP STEEL

STANCHION MADE UP

0.6000 10.0000 10.0000 10.0000 BY JOINING TWO

CHANNELS

ADVANTAGES OF INDUSTRIAL SHADE:

STIFFENER PLATE

1.NO WELDING AT SITE IS REQUIRED. IT IS VERY EASY AND SAFE FOR INDUSTRIES WERE

WELDING INSIDE PLANT IS REQUIRED. BASE

2.LESS WASTE IS GENERATED. PLATE

7.5000

3.CONSTRUCTION TIME IS REDUCED AND BUILDINGS ARE COMPLETED SOONER, ALLOWING

A A'

AN EARLIER RETURN OF THE CAPITAL INVESTED. ANCHOR BOLT/

FOUNDATION BOLT

4.ON SITE CONSTRUCTION IS MINIMIZED.

5.THE CONSTRUCTION TIME IS VERY LESS IN COMPARISON TO CIVIL WORK.

PRODUCED BY AN AUTODESK STUDENT VERSION

PRODUCED BY AN AUTODESK STUDENT VERSION

STUB RCC COLUMN

0.6000

30.0000

HOLDING DOWN BOLT

PLAN RIDGE CAPING

100 X 15 X 10

ANGLE

BRACKET

PATENT

GLAZING

ANGLE BRACKET

100x75x10mm

ANGLE RAIL RIDGE CAPING

125x75x10mm 150 X 75 X 10

ANGLE AS A RAFTER 10 MM GUSSET PLATE

ANGLE RAIL BACK TO NORTH

80x60x10mm FLASHING LIGHT TRUSS

RAFTER 2-150x75x10mm. GLASS JOINT 100 X 75 10 MM

ISA 50 MM

GLASS & TOP ANGLE AS

6 MM THICK RECTANGULAR RCC FOUNDATION

25mm WIDTH 1mmTHK CORRUGATED GI SHEET.

D GLASS FRAME

10mm THK

LATTICE GIRDER

STRUT 2-65x50x8mm.

GUSSET PLATE 10 MM THICK GUSSET PLATE

ANGLE PURLIN 90x65x10mm. CLEAT (SCALE

150x75x10 1:10)

ANGLE CLEAT 65x65x6mm. BOTTOM CLEAT

125x75x12

J BOLTS(6.5mm)

ANGLE 2-

DETAIL AT 'D' TYPICAL VIEW OF STUB COLUMN

10mm THK GUSSET PLATE 150x75x10mm

DETAIL AT 'A' LEAD

FLASHING

AND STANCHION FIXING

A GUTTER

380x150mm

(40x10)

GUTTER

EAVES GUTTER ANGLE CLEAT STRAPS

100x100x10mm @450C/C.

(80x10)GUTTER STRAPS RCC

@900C/C. ANGLE CLEAT MEMBER/FOUNFATION

18

60x60x10mm

ANGLE CLEAT

C 1300 X 900

BASE PLATE

150 150

16 M THICK

J BOLTS(6.5mm) B ANGLES 2-65x50x8mm 12mm THK PLATE

10mm THK J BOLT 1100 MM X 750 MM

RUNNER 150x100x10mm. GUSSET PLATE 150

ANGLE CLEAT 125x75x10 PURLIN 800

ANGLE CLEAT 100x75x10mm. ISMC 100. 200X100X10

STIFNER PLATE

ROOFING 6 MM THICK

300x150x8mmTHK

BRACE PLATE 350mm@C/C.

DETAIL AT 'C' SHEET

TRUSS DETAIL 50 X 50 MM

ISMC 350 @ 53.66 SQ.CM

350 X 100 X 13.5 THICK FLANGE

6 MM THICK 8.1 M M THICK WEB

ANCHOR BOLT

16 MM DIA

CLEAT

75X75X8

DETAIL AT BASE

DETAIL AT J-HOOK

DETAIL AT 'B'

TITLE SHEET SCALE BVDU COLLEGE OF ARCHITECTURE STAMP

VAIJAYANTI MUNDADA

TY B- ARCH 2021-22 SEM- VI

NORTH LIGHT TRUSS 2 1:20 BUILDING CONSTRUCTION AND MATERIALS

ROLL NO.: 36

PRODUCED BY AN AUTODESK STUDENT VERSION

You might also like

- Top Skid Elevation View: W W AADocument1 pageTop Skid Elevation View: W W AAchaitanya rosNo ratings yet

- Proposed Three Storey Residential With Basement Unionmax Corp./Fu ZiqiangDocument1 pageProposed Three Storey Residential With Basement Unionmax Corp./Fu ZiqiangNeil ArmstrongNo ratings yet

- Plaster Chipping Location Plan at SCP Building, Cosmos Films. (SH9) (23-08-2022)Document1 pagePlaster Chipping Location Plan at SCP Building, Cosmos Films. (SH9) (23-08-2022)sri projectssNo ratings yet

- Obra'C' 2X660 MW Thermal Power Extension ProjectDocument1 pageObra'C' 2X660 MW Thermal Power Extension ProjectCaspian DattaNo ratings yet

- 28449789-Glin153-72-C-D-A0-011 Rev 0 Structural Layout of Pipe Rack G A Train 1-SHT 1Document1 page28449789-Glin153-72-C-D-A0-011 Rev 0 Structural Layout of Pipe Rack G A Train 1-SHT 1Hks InfrastructureNo ratings yet

- Balok Baja New KitchenDocument1 pageBalok Baja New KitchenArif SumiantoNo ratings yet

- Obra'C' 2X660 MW Thermal Power Extension ProjectDocument1 pageObra'C' 2X660 MW Thermal Power Extension ProjectCaspian DattaNo ratings yet

- Workshop G..f.slab Detail 1Document1 pageWorkshop G..f.slab Detail 1manoj_structureNo ratings yet

- R O A D: Slab DetailsDocument1 pageR O A D: Slab Detailskasardarshan7No ratings yet

- Bearing-Sht 1Document2 pagesBearing-Sht 1Mrinal KayalNo ratings yet

- FRAME RCC BUILDING STRUCTURE PUNE-ModelDocument1 pageFRAME RCC BUILDING STRUCTURE PUNE-ModelStructform ConsultantNo ratings yet

- 2Nd Flr. Beam Plan 3Rd Flr. Beam Plan 4Th Flr. Beam Plan: Foundation Plan Column Pedestal Plan Tie Beam PlanDocument1 page2Nd Flr. Beam Plan 3Rd Flr. Beam Plan 4Th Flr. Beam Plan: Foundation Plan Column Pedestal Plan Tie Beam PlanReymond IgayaNo ratings yet

- Reign of Winter - 04 - The Frozen Stars - Interactive MapsDocument5 pagesReign of Winter - 04 - The Frozen Stars - Interactive MapsRichard Bernard100% (1)

- C-02-A R0 11.05.22 Shri Anilbhai Ground Beam PlanDocument1 pageC-02-A R0 11.05.22 Shri Anilbhai Ground Beam PlanGyayak BhutaNo ratings yet

- KSA Floor PlanDocument1 pageKSA Floor PlanJunaid ShahNo ratings yet

- Beam Centreline Footing-Cottage BEAM SLABDocument1 pageBeam Centreline Footing-Cottage BEAM SLABridsalz1111No ratings yet

- 10-D-Urubah 10-3 (LANDSCAPE FURNITURE DRAWING) - (Detail 3)Document1 page10-D-Urubah 10-3 (LANDSCAPE FURNITURE DRAWING) - (Detail 3)Hashim AlfraidiNo ratings yet

- Sample G+3 Building PlanDocument1 pageSample G+3 Building Plan31 Ajay KaleNo ratings yet

- Tower Crane Foundation Setting Layout-ModelDocument1 pageTower Crane Foundation Setting Layout-ModelProject Planning teamNo ratings yet

- Arch 5Document1 pageArch 5Fred GervacioNo ratings yet

- General Arrangement Drawing of RCC Beam & ColumnDocument1 pageGeneral Arrangement Drawing of RCC Beam & ColumnProjects CortexNo ratings yet

- BB-016229-002 RevDocument1 pageBB-016229-002 RevManikandan SubburajNo ratings yet

- Denah Pembalokan LT 2Document1 pageDenah Pembalokan LT 2Kenzo RyoichiNo ratings yet

- Office s3 s8Document6 pagesOffice s3 s8Jestoni AlaurinNo ratings yet

- Primarosa S1Document1 pagePrimarosa S1escuderoconstructionsNo ratings yet

- Https WWW - Dmc.com Media DMC Com Alice PDF PAT1575Document5 pagesHttps WWW - Dmc.com Media DMC Com Alice PDF PAT1575Carmen Arce EdmNo ratings yet

- Screenshot 2023-03-21 at 12.05.03 PMDocument1 pageScreenshot 2023-03-21 at 12.05.03 PMRitesh WNo ratings yet

- BB 016229 002Document1 pageBB 016229 002Manikandan SubburajNo ratings yet

- Bearing Forces For POT PTFE R1Document6 pagesBearing Forces For POT PTFE R1Thrk TwrNo ratings yet

- PS12 - 21 of 21Document1 pagePS12 - 21 of 21hasan.mohamed2305No ratings yet

- Drawing1 NITA PLAN DRCS-ModelDocument1 pageDrawing1 NITA PLAN DRCS-ModelSatish KhadseNo ratings yet

- Catrina She0lDocument3 pagesCatrina She0lAustrevert Fion FionNo ratings yet

- Structural Drawings NewDocument7 pagesStructural Drawings NewMarzuqi A. HalimNo ratings yet

- BEAM SCHEDULE (C28:Fy414) (LEVEL: 0m) : A B C A B CDocument1 pageBEAM SCHEDULE (C28:Fy414) (LEVEL: 0m) : A B C A B CCarl Justin AzucenaNo ratings yet

- 14800120116-Shubham Maity - Co Lab Assignment 4Document3 pages14800120116-Shubham Maity - Co Lab Assignment 4DEBOJYOTI SAHANo ratings yet

- Block F Edited-ModelDocument1 pageBlock F Edited-ModelPratikNo ratings yet

- Foundation Plan Second Floor Framing Plan Roof Beam Plan: FC1 FC2 FC3 FC4 FC5Document1 pageFoundation Plan Second Floor Framing Plan Roof Beam Plan: FC1 FC2 FC3 FC4 FC5VWSSI Technical TeamNo ratings yet

- Ba2 Ba2 Ba2Document1 pageBa2 Ba2 Ba2nizardmaulanaNo ratings yet

- Beam Double LineDocument1 pageBeam Double LineVed PatwaNo ratings yet

- Generator Gantry Elevation A, B & C (Without Kop)Document1 pageGenerator Gantry Elevation A, B & C (Without Kop)Ucok DedyNo ratings yet

- Wazzup Mga Paa - 2 PDFDocument1 pageWazzup Mga Paa - 2 PDFChocoSparklesNo ratings yet

- Wazzup Mga Paa - PDFDocument1 pageWazzup Mga Paa - PDFChocoSparklesNo ratings yet

- Brownstone Draft Floor Plans Elevation Site PlanDocument29 pagesBrownstone Draft Floor Plans Elevation Site PlanRonnie TanNo ratings yet

- Cross Section Area Gi Oke2Document14 pagesCross Section Area Gi Oke2maherdanaNo ratings yet

- H Anchor Bolt Plan: C B B B B A ADocument1 pageH Anchor Bolt Plan: C B B B B A AArsene LupinNo ratings yet

- Ground Level - MonochromeDocument1 pageGround Level - MonochromeSunil HgNo ratings yet

- F.F Floor Slab DetailDocument1 pageF.F Floor Slab DetailHardik PatelNo ratings yet

- As Built Drawing: NotesDocument1 pageAs Built Drawing: Notesmohamed fawzanNo ratings yet

- As Built Drawing: Equipment RoomDocument1 pageAs Built Drawing: Equipment Roommohamed fawzanNo ratings yet

- 21-27 Durham Street, Mount Druit (111 & 144) - MRT111-30m & MRT152-32m Jib Plan ViewDocument1 page21-27 Durham Street, Mount Druit (111 & 144) - MRT111-30m & MRT152-32m Jib Plan ViewEmon RayNo ratings yet

- 2 PDFDocument1 page2 PDFChocoSparklesNo ratings yet

- 2 2 PDFDocument1 page2 2 PDFChocoSparklesNo ratings yet

- Denah BalokDocument1 pageDenah BalokSapruddin BatubaraNo ratings yet

- ST36-01 SC03Document1 pageST36-01 SC03Naresh KumarNo ratings yet

- ST36-01 - Lift Room SC03Document1 pageST36-01 - Lift Room SC03u.jothipandiyan anaikkaraiNo ratings yet

- Beam Detailed DiagramDocument1 pageBeam Detailed DiagramVed PatwaNo ratings yet

- Https WWW - Dmc.com Media DMC Com Alice PDF PAT1557Document5 pagesHttps WWW - Dmc.com Media DMC Com Alice PDF PAT1557Carmen Arce EdmNo ratings yet

- A2 PHC PIU COL FOOTING PLINTH Revised - 15.07.2020-ModelDocument1 pageA2 PHC PIU COL FOOTING PLINTH Revised - 15.07.2020-ModelPratikNo ratings yet

- A2-PHC PIU COL FOOTING PLINTH Revised - 15.07.2020-ModelDocument1 pageA2-PHC PIU COL FOOTING PLINTH Revised - 15.07.2020-ModelPratikNo ratings yet

- Vasant Udyan, New DelhiDocument5 pagesVasant Udyan, New DelhikhushiNo ratings yet

- QuestionnaireDocument1 pageQuestionnairekhushiNo ratings yet

- Bihar UrbanizationDocument43 pagesBihar UrbanizationkhushiNo ratings yet

- Patna Urbanisation, Up IiDocument5 pagesPatna Urbanisation, Up IikhushiNo ratings yet

- 9 M Wide Road: Parking Area For Inhouse GuestDocument1 page9 M Wide Road: Parking Area For Inhouse GuestkhushiNo ratings yet

- Spiritual Experience: A That Transcends BoundariesDocument1 pageSpiritual Experience: A That Transcends BoundarieskhushiNo ratings yet

- WD Setting Out PlanDocument1 pageWD Setting Out PlankhushiNo ratings yet

- When Does PCY Work Better Than A-Priori in Terms O...Document3 pagesWhen Does PCY Work Better Than A-Priori in Terms O...khushiNo ratings yet

- Nameplate EeeDocument1 pageNameplate EeekhushiNo ratings yet

- Site AnalysisDocument1 pageSite AnalysiskhushiNo ratings yet

- Literature Case Study Ad ViDocument5 pagesLiterature Case Study Ad VikhushiNo ratings yet

- Elective Case StudyDocument11 pagesElective Case StudykhushiNo ratings yet

- Dog Legged Staircase BCMDocument1 pageDog Legged Staircase BCMkhushiNo ratings yet

- Khushi, Div-B - Sheet1Document1 pageKhushi, Div-B - Sheet1khushiNo ratings yet

- Comparative Chart For Material Online Market StudyDocument3 pagesComparative Chart For Material Online Market StudykhushiNo ratings yet

- Elective-Iv Case Study: By: Tarangi Joshi T.Y.B.Arch, Div-BDocument11 pagesElective-Iv Case Study: By: Tarangi Joshi T.Y.B.Arch, Div-BkhushiNo ratings yet

- Presentation 13Document3 pagesPresentation 13khushiNo ratings yet

- Case Study Indias First Net Zero Energy Building Indira Paryavaran BhavanDocument5 pagesCase Study Indias First Net Zero Energy Building Indira Paryavaran Bhavan64LABDHI SHAHNo ratings yet

- Barrier Free Design Mohit - 14Document1 pageBarrier Free Design Mohit - 14khushiNo ratings yet

- Saleslist 2Document29 pagesSaleslist 2scribd495No ratings yet

- White Box Unearthed TroveDocument34 pagesWhite Box Unearthed TroveJustin BechenNo ratings yet

- Windows 10 ActivationDocument2 pagesWindows 10 ActivationAgunk panduNo ratings yet

- ICTSI 2014 PGT Qualifying School Day 2 ResultDocument4 pagesICTSI 2014 PGT Qualifying School Day 2 ResultPhilGolfTourNo ratings yet

- Educational Escape Room Game Project-1Document3 pagesEducational Escape Room Game Project-1Goldenwealth App techNo ratings yet

- HARRISON Important Alogrithms Compiled by Medicinosis MagnusDocument61 pagesHARRISON Important Alogrithms Compiled by Medicinosis MagnusBhuma DesaiNo ratings yet

- Detailed Lesson Plan in Physical EducationDocument6 pagesDetailed Lesson Plan in Physical EducationRosalinda Tabing JraNo ratings yet

- Winning The Blackmar-Diemer Gambit: 62 Traps White Can Use.Document17 pagesWinning The Blackmar-Diemer Gambit: 62 Traps White Can Use.Bill Harvey67% (3)

- Fire Ted ThompsonDocument91 pagesFire Ted ThompsonDanny DichNo ratings yet

- Storytelling With The Sorte DeckDocument14 pagesStorytelling With The Sorte DeckSendral OrokNo ratings yet

- WTC 2021 Faq Document: Want More Information About The WTC ?Document21 pagesWTC 2021 Faq Document: Want More Information About The WTC ?arnaudgoetzmannNo ratings yet

- Heart The City Beneath - Core BookDocument226 pagesHeart The City Beneath - Core Bookhellno100% (2)

- Dragons of Dragon Issue 146Document43 pagesDragons of Dragon Issue 146LauraHenson100% (3)

- Bowling Service Parts - 28 201739 000 Rev 01 2019Document320 pagesBowling Service Parts - 28 201739 000 Rev 01 2019teletecloisir maintenanceNo ratings yet

- Andrea Pirlo Pro LicenseDocument30 pagesAndrea Pirlo Pro LicenseCarlos Victoria100% (2)

- Space Cadets: Away MissionsDocument36 pagesSpace Cadets: Away MissionsODRNo ratings yet

- P eDocument9 pagesP eMARIANo ratings yet

- The Planes of ExistenceDocument12 pagesThe Planes of ExistenceJohanna SparkNo ratings yet

- Software Tips & Tricks Anti Virus Learning System Operation GamesDocument14 pagesSoftware Tips & Tricks Anti Virus Learning System Operation GamesAudrian Jr BunnavvieNo ratings yet

- A Brief History KarfballDocument1 pageA Brief History KarfballAlexandra TarshilovaNo ratings yet

- Cambridge IGCSE: First Language English 0500/21Document4 pagesCambridge IGCSE: First Language English 0500/21구름No ratings yet

- UntitledDocument20 pagesUntitledErica FieldNo ratings yet

- 1534708188562Document34 pages1534708188562Onur SüerNo ratings yet

- Twisted Bayonet v1Document31 pagesTwisted Bayonet v1radzombie100% (1)

- Druid Subclass - Circle of BloodDocument2 pagesDruid Subclass - Circle of BloodAz ComicsNo ratings yet

- Free 1 Month Xbox Live CodeDocument19 pagesFree 1 Month Xbox Live Codexboxlivecode2011No ratings yet

- Alternate Rogue - GM BinderDocument16 pagesAlternate Rogue - GM BinderCaio mantovani AlvesNo ratings yet

- Lamia (PF2)Document4 pagesLamia (PF2)Ryan FearNo ratings yet

- Scoop As Many As 88 Multi - Win Prizes On The UK LottoDocument7 pagesScoop As Many As 88 Multi - Win Prizes On The UK LottofahiyanNo ratings yet