Professional Documents

Culture Documents

Deaerator: Deaerating Water or Beverage

Uploaded by

GeorgiosKirkimtzis0 ratings0% found this document useful (0 votes)

61 views2 pagesOriginal Title

Deaerator_PDLeaflet

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

61 views2 pagesDeaerator: Deaerating Water or Beverage

Uploaded by

GeorgiosKirkimtzisCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

Deaerator

Deaerating water or beverage

APPLICATION WORKING PRINCIPLE

Deaerators are used to reduce excessive gas content in A deaerator consists of a vacuum vessel equipped with

liquids. Reducing oxygen in water is crucial to prevent spray pipes, circulating pipes, pumps and a vacuum

downstream product fouling, colour changes or vessel equipped with a continuous level sensor.

oxidation-induced degradation. The incoming liquid (usually water) is sprayed into the

Acceptable oxygen content typically varies from 0.2 vacuum vessel. The level inside is monitored by the

to 1 ppm, dependent on application. continuous level sensor and regulated by a modulating

inlet valve.

A typical application can be: The pressure inside the deaerator is usually around 30

ظDeaerating water or beverage mbar (abs). The vacuum is created by an independent

vacuum unit located on the frame base.

HIGHLIGHTS For optimal deaeration effect, the liquid circulates

ظCompact design requires minimal floor space through multiple chambers.

ظNo wastewater as vacuum pump has independent

cooling ring

ظFully cleanable system

ظDual deaeration chamber design increases deaeration

efficiency and keeps the capacity more flexible

ظAdditional oxygen reduction through small injection

of CO2

© Tetra Pak International S.A., Tetra Pak Processing Equipment AG, 2021-03

MAIN COMPONENTS TECHNICAL DATA

ظ Main frame All parts in contact with the product are made of AISI

ظ Deaeration tank 316L.

ظ Recirculation pump The frame is made of AISI 304L.

ظ Vacuum unit Standard sizes enable the following capacities:

ظ Discharge pump ظ50,000 l/h

ظ Main water supply ظ100,000 l/h

ظ CIP supply ظ150,000 l/h

Other capacities on request

CONTROL PANEL (OPTIONAL)

The deaerator is controlled by an Allen Bradley Control- Residual oxygen content is 0.6 ppm without CO2 addition.

Logix or Siemens PLC. This is fitted in a cabinet located Residual oxygen content with CO2 addition is 0.3 ppm (at

on the frame, when requested. a reference temperature of 15°C).

Electrical power

400 V, 50 Hz

Compressed air

600 kPa (6 bar)

LAYOUT EXAMPLE

Measurements on request

Tetra Pak, and PROTECTS WHAT’S GOOD are trademarks

belonging to the Tetra Pak Group. www.tetrapak.com

You might also like

- Contemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsFrom EverandContemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsNo ratings yet

- How Industrial Businesses Can Reduce Production Costs With Reverse Osmosis: Industrial Reverse OsmosisFrom EverandHow Industrial Businesses Can Reduce Production Costs With Reverse Osmosis: Industrial Reverse OsmosisRating: 5 out of 5 stars5/5 (1)

- CIP Unit: Cleaning in Place With Full FlexibilityDocument2 pagesCIP Unit: Cleaning in Place With Full FlexibilityHanh TranNo ratings yet

- Technical Report Azud Helix Automatic FT200 Aa DLP-1Document5 pagesTechnical Report Azud Helix Automatic FT200 Aa DLP-1bedhief ahmedNo ratings yet

- PumpsDocument33 pagesPumpsSamson HaykonNo ratings yet

- Hot Water SpecDocument2 pagesHot Water SpecsafinditNo ratings yet

- Ficha Técnica d200Document2 pagesFicha Técnica d200ventas3No ratings yet

- TB 59 10 - 07 Centec Paulaner1Document3 pagesTB 59 10 - 07 Centec Paulaner1dagNo ratings yet

- Azanechiller Series 2010 (3) Final VersionDocument12 pagesAzanechiller Series 2010 (3) Final VersionRajkumar GulatiNo ratings yet

- Deaerators BrochureDocument4 pagesDeaerators BrochurefahimshkNo ratings yet

- Oxycom IntrCool Brochure (2019) Short VersionDocument15 pagesOxycom IntrCool Brochure (2019) Short VersionRajeshNo ratings yet

- DeaeratorDocument6 pagesDeaerator9kkn7rsdm8No ratings yet

- Informacion Valvula DesaireadoraDocument4 pagesInformacion Valvula DesaireadoraCesar GraterolNo ratings yet

- TA17049Document10 pagesTA17049cek.lagukuNo ratings yet

- Give Your Family 100% Safe & Tasty WaterDocument2 pagesGive Your Family 100% Safe & Tasty WaterAnupam JadhavNo ratings yet

- Water Presure Reducing ValveDocument16 pagesWater Presure Reducing ValvekicsnerNo ratings yet

- On Line Self Cleaning Filter Operating Manual: Prepared: PM Verified: TM Controlled: QM Approved: MD IssuedDocument13 pagesOn Line Self Cleaning Filter Operating Manual: Prepared: PM Verified: TM Controlled: QM Approved: MD IssuedDaniel Touzet MalagaNo ratings yet

- Pumps: Select The Optimum Model Between Two Different Types of PumpDocument2 pagesPumps: Select The Optimum Model Between Two Different Types of PumpLinh LeeNo ratings yet

- Capital Controls Series 600 Gas ChlorinatorDocument4 pagesCapital Controls Series 600 Gas ChlorinatorFranco ArellanoNo ratings yet

- FD TCR Industrial 1Document8 pagesFD TCR Industrial 1HemonNo ratings yet

- Operator Installation & Instruction Manual: Auto-Purger Plus, App Non-Condensible Gas (Air) & Water Purger For AmmoniaDocument20 pagesOperator Installation & Instruction Manual: Auto-Purger Plus, App Non-Condensible Gas (Air) & Water Purger For AmmoniaRASHEED YUSUFNo ratings yet

- Removal of Water From Industrial Ammonia SystemsDocument10 pagesRemoval of Water From Industrial Ammonia SystemsMTOLNo ratings yet

- Horizontal, Single-Stage, Composite Centrifugal Pump 50 HZ: Grundfos Data BookletDocument16 pagesHorizontal, Single-Stage, Composite Centrifugal Pump 50 HZ: Grundfos Data BookletSaber ElkassasNo ratings yet

- Condensate - Recovery - Solutions SB S71 02 ENDocument16 pagesCondensate - Recovery - Solutions SB S71 02 ENpxpingenieriaNo ratings yet

- Alfa Laval AldoxDocument2 pagesAlfa Laval AldoxDmytroNo ratings yet

- Rotary Evaporators EYELA JapanDocument12 pagesRotary Evaporators EYELA Japanard_caballeroNo ratings yet

- SB DatasheetDocument4 pagesSB DatasheetMohammad AnwarNo ratings yet

- GT Tank Series: GT-D With Double DiaphragmDocument2 pagesGT Tank Series: GT-D With Double Diaphragmqsa000No ratings yet

- Espec - Tec.bombas Lowara DL A 60HzDocument39 pagesEspec - Tec.bombas Lowara DL A 60HzpapashoNo ratings yet

- EZ-Stream DataSheet MRK WebDocument4 pagesEZ-Stream DataSheet MRK WebIan AdjaNo ratings yet

- GasniZagrevaci 3 MASTERDocument25 pagesGasniZagrevaci 3 MASTERZoran JurakNo ratings yet

- Cooling Tower SOPDocument8 pagesCooling Tower SOPBoiler Scrubber50% (2)

- Tetra Pak Aseptic Tank VC: Aseptic, Vertical Storage Tank For Viscous Food ProductsDocument2 pagesTetra Pak Aseptic Tank VC: Aseptic, Vertical Storage Tank For Viscous Food ProductsYacineNo ratings yet

- Condensate Recovery Solutions SB S71 02 enDocument16 pagesCondensate Recovery Solutions SB S71 02 ensenthil031277No ratings yet

- On-Site Electrolytic Chlorination Skid-Mounted OSEC B-Pak SystemDocument4 pagesOn-Site Electrolytic Chlorination Skid-Mounted OSEC B-Pak SystemgohviccNo ratings yet

- Sentinel: Portable Purification SystemDocument8 pagesSentinel: Portable Purification SystemJuan Carlos CastroNo ratings yet

- UC2 - Water Treatment System (Group3)Document166 pagesUC2 - Water Treatment System (Group3)Banjo MirandillaNo ratings yet

- New: UR610 Series: Athalon Return Line FiltersDocument3 pagesNew: UR610 Series: Athalon Return Line FiltersMelyssa Motta da SilvaNo ratings yet

- TDS - BWD736 240523Document6 pagesTDS - BWD736 240523MaferNo ratings yet

- Tetra-Pak-7000-Litres-Aseptic-Tank-Vd-Buffering-Processing-Equipment 2Document2 pagesTetra-Pak-7000-Litres-Aseptic-Tank-Vd-Buffering-Processing-Equipment 2Frank valdezNo ratings yet

- Flyer VACUSOG EnglishDocument1 pageFlyer VACUSOG Englishafiffathin_akramNo ratings yet

- SIEMENS - Chlorination-Skid PDFDocument4 pagesSIEMENS - Chlorination-Skid PDFgkdora574No ratings yet

- Vacuum Pumps and Compressors For The Electric Power IndustryDocument6 pagesVacuum Pumps and Compressors For The Electric Power IndustryPinky BasuNo ratings yet

- Air Release Valve Cla-ValDocument4 pagesAir Release Valve Cla-Valventas2.fireproofcolNo ratings yet

- At - Cooling TowersDocument12 pagesAt - Cooling TowersDragos PopescuNo ratings yet

- Cat-O-Ex On-Ex: Efficient Deaeration For The Brewing IndustryDocument4 pagesCat-O-Ex On-Ex: Efficient Deaeration For The Brewing IndustryJoshua JohnsonNo ratings yet

- Electrolysers Brochure Rev C PDFDocument16 pagesElectrolysers Brochure Rev C PDFVăn Tuấn NguyễnNo ratings yet

- OMVE CF121 Bench-Top Carbo-FillDocument2 pagesOMVE CF121 Bench-Top Carbo-FillsambhavjoshiNo ratings yet

- Gasmizer Gas Recovery SystemDocument2 pagesGasmizer Gas Recovery SystemАлексей ИващенкоNo ratings yet

- TCA BrochureDocument16 pagesTCA BrochurejdbNo ratings yet

- Gasmizer Gas Recovery SystemDocument2 pagesGasmizer Gas Recovery SystemАлексей ИващенкоNo ratings yet

- Purgador Aire HansenDocument12 pagesPurgador Aire Hansenyoye1968No ratings yet

- Water Treatment - EngineerTraining2021fffDocument49 pagesWater Treatment - EngineerTraining2021fffRakeshKrishnanNo ratings yet

- Hemas HosptalDocument4 pagesHemas HosptalansudasinghaNo ratings yet

- Chiller Cooling Tower AHUDocument9 pagesChiller Cooling Tower AHUAli Hassan RazaNo ratings yet

- Brew-250Document4 pagesBrew-250Eray YILMAZNo ratings yet

- Donaldson Visokotlačni FilteriDocument86 pagesDonaldson Visokotlačni FilteriViktor -stNo ratings yet

- Feed Water TanksDocument4 pagesFeed Water TanksvirtualmecanicaNo ratings yet

- Prevention of Actuator Emissions in the Oil and Gas IndustryFrom EverandPrevention of Actuator Emissions in the Oil and Gas IndustryNo ratings yet

- Part Numbers Guide For Bardiani Valves.: Canada and North America EditionDocument26 pagesPart Numbers Guide For Bardiani Valves.: Canada and North America EditionGeorgiosKirkimtzisNo ratings yet

- Manual For The Design of Pipe Systems and Pumps - GEADocument56 pagesManual For The Design of Pipe Systems and Pumps - GEABeomHee LeeNo ratings yet

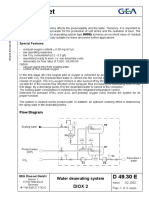

- Water Deaerating System DIOX 2 - GEA DiesselDocument2 pagesWater Deaerating System DIOX 2 - GEA DiesselGeorgiosKirkimtzisNo ratings yet

- Tetra Alcarb: in - Line Carbonation UnitDocument2 pagesTetra Alcarb: in - Line Carbonation UnitGeorgiosKirkimtzisNo ratings yet

- Ardiani: We Need The Geometry of This PartDocument1 pageArdiani: We Need The Geometry of This PartGeorgiosKirkimtzisNo ratings yet

- Water Deaeration System DIOX 1 - GEA DiesselDocument2 pagesWater Deaeration System DIOX 1 - GEA DiesselGeorgiosKirkimtzisNo ratings yet

- 2015 - Pmo Final - 7 1 2016Document447 pages2015 - Pmo Final - 7 1 2016GeorgiosKirkimtzisNo ratings yet

- Buffer Tank Drawing 150LtDocument1 pageBuffer Tank Drawing 150LtGeorgiosKirkimtzisNo ratings yet

- Industrial Screens Brochure JOHNSON SCREENS WFDDocument16 pagesIndustrial Screens Brochure JOHNSON SCREENS WFDMark JohnsonNo ratings yet

- Origin of BulletsDocument1 pageOrigin of BulletsOnecimo Zapata IIINo ratings yet

- Glass CompaniesDocument10 pagesGlass CompaniesJatin AgarwalNo ratings yet

- b115mp3 P0aea QSG Ww456rtasDocument17 pagesb115mp3 P0aea QSG Ww456rtasRichard Medina100% (1)

- MECH5 GETTING STARTEDv3Document6 pagesMECH5 GETTING STARTEDv3Justin JacksonNo ratings yet

- How Thought Leadership Drives Demand Generation: 2019 Edelman-Linkedin B2B Thought Leadership Impact StudyDocument27 pagesHow Thought Leadership Drives Demand Generation: 2019 Edelman-Linkedin B2B Thought Leadership Impact StudyDiego TellezNo ratings yet

- RF Backhual Engineer ResumeDocument5 pagesRF Backhual Engineer ResumemadhubaddapuriNo ratings yet

- 00 LSPU Stage 2 Audit Report 2018 PDFDocument21 pages00 LSPU Stage 2 Audit Report 2018 PDFRolando Cruzada Jr.No ratings yet

- AS ING Rev0 PDFDocument38 pagesAS ING Rev0 PDFNguyen Quyet ThangNo ratings yet

- Thumb Rule DesignDocument77 pagesThumb Rule Designarjun kumar100% (1)

- Cisco1300APBridge Spec WebDocument14 pagesCisco1300APBridge Spec Webahfuoahrf0384No ratings yet

- Ec Council Certified Security Analyst Ecsa v8Document5 pagesEc Council Certified Security Analyst Ecsa v8fazli3036No ratings yet

- Gn001 Application Guide: Design With Gan Enhancement Mode HemtDocument44 pagesGn001 Application Guide: Design With Gan Enhancement Mode HemtTuan TranNo ratings yet

- Softening Point of Bitumen (Ring-and-Ball Apparatus) : Standard Test Method ForDocument5 pagesSoftening Point of Bitumen (Ring-and-Ball Apparatus) : Standard Test Method ForPyone Ei ZinNo ratings yet

- SSPC Hand/Power Tool Cleaning RequirementsDocument33 pagesSSPC Hand/Power Tool Cleaning RequirementsJake Sparrow88% (8)

- Terex RCI 510 Calibration and Troubleshooting ManualDocument34 pagesTerex RCI 510 Calibration and Troubleshooting ManualBenjamin Gir PolNo ratings yet

- Short-Term Scheduling of Battery in A Grid-Connected PV-Battery SystemDocument9 pagesShort-Term Scheduling of Battery in A Grid-Connected PV-Battery SystemEric GalvánNo ratings yet

- ACC 5 Supported 3rd Party Cameras & Encoders PDFDocument8 pagesACC 5 Supported 3rd Party Cameras & Encoders PDFDanilo Moreira CisternaNo ratings yet

- KithausDocument4 pagesKithausZulaikah MontecinosNo ratings yet

- Director VP Supply Chain Management in Washington DC Resume Michael MorrisDocument1 pageDirector VP Supply Chain Management in Washington DC Resume Michael MorrisMichaelMorris2No ratings yet

- Siemens ET200M Systems ManualDocument240 pagesSiemens ET200M Systems ManualAndrey ZimnitskiyNo ratings yet

- Manning's N ValuesDocument4 pagesManning's N ValuesWong Kuan SengNo ratings yet

- AAC-004 Technical LogDocument12 pagesAAC-004 Technical LogMohammed HamidNo ratings yet

- Lecture 6 - Special Purpose Diodes - 2Document26 pagesLecture 6 - Special Purpose Diodes - 2Willian CarlosNo ratings yet

- MSEDCL - End User Training Manual - Consolidation of CGRF Cases - Zone-JEDocument17 pagesMSEDCL - End User Training Manual - Consolidation of CGRF Cases - Zone-JEanandNo ratings yet

- 5R55N / 5R55S / 5R55W: Ganzeboom Transmission Parts & Torque ConvertersDocument2 pages5R55N / 5R55S / 5R55W: Ganzeboom Transmission Parts & Torque ConvertersDejan Lenarcic100% (1)

- Registration Form - Atls - India: ATLS® Provider Course, SIHS PuneDocument2 pagesRegistration Form - Atls - India: ATLS® Provider Course, SIHS PuneTushar DeshmukhNo ratings yet

- Welding FundamentalsDocument44 pagesWelding FundamentalsDhinasuga DhinakaranNo ratings yet

- Ams Iii GDocument4 pagesAms Iii Ghemang_nsNo ratings yet

- Science Form 1 Chapter 1 - 7Document12 pagesScience Form 1 Chapter 1 - 7Nur Atiah Daud100% (1)

- West Bengal Pollution Control Board ContactDocument18 pagesWest Bengal Pollution Control Board ContactAvik PattanayakNo ratings yet