Professional Documents

Culture Documents

2instruction Manual

2instruction Manual

Uploaded by

Nimesh Silva0 ratings0% found this document useful (0 votes)

18 views76 pagesOriginal Title

2Instruction Manual

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

18 views76 pages2instruction Manual

2instruction Manual

Uploaded by

Nimesh SilvaCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 76

LITHOSTAR LP82

2

Instruction Manual

AGFA

Oo

LITHOSTAR LP82

Instruction Manual 2

Jan.

Summary

4. Introduction

2. Consumables

3. Operation of the processor

34. Prescriptions and precautions

3.2. Configuration

3.3. Basic operation

3.4, User interface

35. Preparing the processor for operation

3.6. Operating the processor

37. Treatment of the AGFA LITHOSTAR printing plates after

processing

3.8. Replacement of the containers

3.9. Chemicals and water consumption

4. Manipulation of the consumables

4a. Manipulation of the AGFA LITHOSTAR chemicals

42, Manipulation of the unexposed AGFA LITHOSTAR printing plates

5. Programming the processor

5.1. Programming the printing plate sizes

5.2, Programming the time

5.3. Programming the active and inactive periods

5.4. ‘The system control feature

6 Maintenance

6.1. General safety measures

6.2 Software-maintenance function

6.3. Cleaning the processor

7. Waste treatment

mM AGFA's environmental guidelines

72. Collecting the chemical waste

72: Treatment of the different types of waste

‘7

10

13

17

19

23

24

26

28

28

28

29

29

30

31

34

at

at

at

45

53

53

53

55

AGFA

LITHOSTAR LP82

2 Instruction Manual

8.

84

8.2.

8.3.

8.4.

8.5.

8.6.

87.

Nov. ‘98,

‘Trouble-shooting

‘A warning is indicated on the display

‘An overtemperature is detected in one of the trays of the

processor

Other messages

Power problems

Problems when inserting a printing plate

Other problems

Trouble-shooting matrix

56

56

65

66

68

68

69

69

AGFA &

LITHOSTAR LP82

Instruction Manual 2

4. Introduction

AGFA LITHOSTAR is a high-speed platemaking

system for both analogue and digital plate

exposure. It combines the ease of handling and

the stability of aluminium printing plates with the

speed and quality of the silver halide technology.

LITHOSTAR plates are based on Agfa's DTR

(Diffusion Transfer Reversal) process, used in

high-quality products for many years.

‘The AGFA LP82 is a plate processor elaborated

for AGFA LITHOSTAR offset printing plates. It has

been designed 1o obtain the highest quality,

productivity, reliability and facility of use.

If properly used and maintained, the processor

will prove to be an efficient plate production tool

for many years.

Jan. '97

AGFA &

LITHOSTAR LP82

2 Instruction Manual

Nov. ‘98

Consumables

+ Lithostar aluminium printing plates :

° LAP-B

© LAP-O

Agia offers a wide variety of printing plate sizes

please ask for more information.

Thickness 0.15 / 0.20 / 0.30 mm

(6/8/12 MIL)

Sizes on demand

0.35 & 0.40 mm on request

* Printing plate correctors +

* Negative corrections (wiping the image) :

= Corrector pen : FNBYV

= Corrector fluid (100 cc): FX8BU

* Positive corrections (adding image) :

"+" corrector pen (3 pieces): FRETK

© Developer + L5000b

Capacity of a developer container : 20 |

* Finisher: —L5300b

Capacity of a finisher container : 20 |

* Waste container labels: 3ZNWW.

(60 pieces)

LITHOSTAR

its oes wast sale san p> 7

UtesaVeateungscistide- aac Ling pH et>7

‘ites care Lita son akainomsp spi 87

Uitostarvemerngsae-Akaische opassg p »7

Fen celpeowso tes Soin aia p> 7

Fes tatareo tes -Sosne aia congt> 7

For more information about the waste

container labels, refer to ‘7.2. Collecting the

chemical waste’

* Plate cleaner: G642b

AGFA

LITHOSTAR LP82

Instruction Manual 2

3. Operation of the processor

3.1. Prescriptions and precautions

3.1.1. Prescriptions

‘The following prescriptions should be read attentively before using the processor

* Follow the instructions given by Agfa

When working with the processor AGFA LITHOSTAR LP82, take into account all the instuctions and safely

‘measures given in this manual and other Agfa publications in order to avoid problems with quality, heath,

safety and/or environment.

Do not forget to read attentively the directives given in “6.1. General safety measures’.

* Only use AGFA LITHOSTAR consumables

Jn order to ensure a permanent high quality when processing printing plates, only AGFA LITHOSTAR chemicals

and products should be used.

* Handle the chemicals with care

Consult the appropriate M.S.D.S. (Meterial Safety Data Sheets) before handling chemicals and always follow

the safely instructions given on the labels of the chemicals.

* Collect the waste for treatment

The addresses of authorised waste collecting and treatment companies can be obtained from the local Agfa

representative.

© If the processor has been provided with the optional on-line bridge AGFA

LITHOSTAR OLB&2 and/or with the optional stacker AGFA LITHOSTAR LS82, read

attentively the corresponding prescriptions, precautions and safety information

In case of the User Manual, refer to chapter 5 ‘Notes’, In case of the Service Manual, refer to chapter 9

“Adgitional Information’.

AGFA

LITHOSTAR LP82

2 Instruction Manual

2.6.00 Nov. '98

3.1.2. Precautions

This paragraph gives an overview of the different points which should be taken Into account

when using the processor or when carrying out an Intervention on it

* Before the processor enters an active state, ensure that :

- the lower (L) and upper (U) rollers are placed at their correct location (ensure that the numbers

on their right side correspond to the ones on the right side of the frame of the processor) :

ta & SSoTOOT Sen8- So8- o-8-

—Q

®

©:© :@: @

4] A AMARA A

+L ORRRRAR A

= all the lower rollers have been installed

Poter has ben dled

correctly and pushed as far as possible

towards the left side.

If a lower roller has been provided with a

gear, ensure that:this gear engages

correctly when installing the corresponding

upper roller.

~ all the upper rollers have been installed

correctly and pushed as far as possible

towards the left side.

Also ensure that the ring at the right side of

the rollers fits correctly into its holder (refer

to the diagram) and that their gear(s)

engage(s) correctly.

AGFA &

LITHOSTAR LP82

Instruction Manual. 2

= the two white bushings (one for the rollers

system and one for the rear roller) at the

right side of the diffusion section fit correctly

into their holder.

= the three white bushings at the right side of

the wash section conveyor rollers fit

correctly into their holder.

= the gutter system and the separate gutters

of the rinsing and finishing sections fit

correctly into position.

= the two-piece suction unit is correctly:

installed on the bottom of the wash tray.

= the two partition plates of the wash section

fit correctly into position.

= the printing plate guide at the rear side of

the diflusion section fits correctly into

position

= the printing plate guide on the bottom of the

developer tray has not been positioned

upside down and that it fits correctly into

the grooves of the tray.

= the anti-oxidation cover of the developer

section has been installed correctly.

Before starting the operation of the processor,

especially when one or more trays have been

drained, ensure that the four manual drain

valves behind the right cover as well as the

four manual drain valves underneath the

processor are closed.

After having carried out a maintenance or a

servicing operation, ensure that :

= no tools or foreign matters remain in the

processor.

Jan. ‘97 2.7.00

= the spray nozzles assembly of the wash

section has been re-installed.

Do not forget to check if the seal has been

provided when re-installing the spray nozzles

assembly.

Before turning off the main switch, ensure that

the processor Is in the OFF-mode.

The rollers should always be in the open

condition when turning off the power supply

towards the processor.

Before closing the front upper cover, ensure

that the rewash flap is closed correctly

Never (re-Jinsert damaged printing plates into

the processor.

Never remove the inside protection plate

which can be found behind the right cover

and the four manual drain valves : this may

only be done by an Agfa service technician.

Never interchange the developer, finisher and

waste containers.

It the containers have been interchanged

accitlentally, the corresponding circulation

circuits should be cleaned by using the

circulation feature of the software-maintenance

function (refer to °6.3.3, Circulating water in

order to clean the circulation circuits).

In order to avoid mixing of the different

solutions inside the processor, never open all

the manual drain valves together but drain the

trays separately.

If the trays are not filled directly after they

have been emptied, it is recommended to

clean them,

AGFA

LITHOSTAR LP82

2 Instruction Manual

2.8.00 Jan. ‘97

+ If a ‘waste container full’ condition is detected

during the operation of the processor (the

waste container is then filled by means of the

overflows of the different trays), the operation

of the processor will be halted after 1 m2 has

been processed in order to avoid an overtiow

of the waste container.

If a ‘waste container full" condition is detected

when emptying the trays (this is done by using

the manual drain valves), THE VALVES

SHOULD BE CLOSED MANUALLY.

It the manuel drain valves are not closed in time,

the waste container will overfiow.

Therefore, before emptying a tray, always ensure

that there is enough room in the waste container

and avoid leaving the processor alone when

emptying the trays.

‘* The diffusion tray has not been provided with

@ manual drain valve.

Winen using the diffusion tray to clean the

‘components of the processor, take into account

that the cleaning water will directly be drained

towards the waste container : ensure thet there is

‘enough room in the waste container to accept

the cleaning water (also refer to the previous

remark).

* When the rollers have been taken out of the

processor, be careful not to damage them :

- Never place the rollers so that their rubber

surface rests onto the edge of a sink, a

tray, a

- When placing the rollers upon each other,

ensure that there is no contact between the

gears and the rubber surfaces.

Never lubricate a roller cams shaft or the main

Grive shaft : if one or more of the solutions of

the processor have been soiled with oil or

Grease, the corresponding trays and

circulation circuits should be cleaned

thoroughly (refer to § 6.3.3.).

The feed-in rollers should never come into

contact with developer or any other liquid in

order to avoid that the printing plate sticks

‘onto the rollers instead of being conveyed

towards the developing section.

For this reason, and if @ printing plate jam has

‘occurred in the developing section, open the

rollers and then remove the plate by pushing or

pulling it towards the rear side.

NEVER pull back a printing plate once it has

been taken up by the feed-in rollers,

{i the processor will not be used for @ long

time (holidays, ...), "Holiday filling’

(refer to § 6.3.4.) should be carried out in

order to avoid smell problems.

When replacing a fuse, ensure that the new

fuse is of the same type and has the same rate

as the old one :

‘CAUTION

For continued protection

‘against fre, replace only with

‘Same type and rating oF fuse,

Ensure that the processor is no longer under

tension before touching areas marked by the

following symbol :

AGFA @

LITHOSTAR LP82

Instruction Manual 2

van. '97 2.9.00

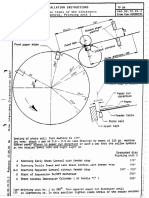

3.2. Configuration

1 Emergency stop knob 7 Waste container

2 Control panet 8 Developer container

3 ‘Rewash start/stop" switch 9 Wash water drain valve

4 Rinsing solution drain valve 10 Developer drain valve

5 Finisher drain valve 11 Main switch

6 Finisher container

AGFA}

LITHOSTAR LP82

2 Instruction Manual

2:10.00 Jan. ‘97

3.3. Basic operation

‘The basic operation of the processor AGFA LITHOSTAR LP82 is illustrated in the following cross-

sectional view :

1 Feed:in section

2 Developing section

3 Diffusion section

4 Rewash section

5 Wash section

Water supply

Developer container

oe

6 Rinsing section

7 Finishing section

8 Drier section

9 Exit section

© Waste container

d Finisher container

AGFA @

LITHOSTAR LP82

Instruction Manual 2

3.3.1. Feed-in section

‘The feed-in section is used to insert a printing

plate into the processor.

‘The presence of a plate on the feed-in table is

detected by means of an optical sensor.

3.3.2. Developing section

In the developing section, the (exposed) printing

plate is developed.

The plate is first submerged in the developer tray

and the excess of developer on the plate is then

pressed off by means of a pair of squeegee

rollers.

3.3.3. Diffusion section

The developed printing plate is conveyed on a

rollers system in order to allow the diffusion of the

silver.

3.

Rewash section

Can be used to re-insert a printing plate into the

processor.

‘This can be necessary to :

* clean the corrector off the printing plate if

manual corrections have been made

* clean off the gum-layer and re-hydrophobise

printing plates which have been stored after a

process operation

Jan. ‘97 2.41.00

3.3.5, Wash section

The printing plate is washed by means of tepid

water under high pressure in order to remove the

gelatine layer and the barrier layer.

Before leaving the wash section, the excess of

water is pressed off the plate by means of a pair

of squeegee rollers.

3.3.6. Rinsing section

‘The washed printing plate is rinsed with finisher

coming from the finishing section.

The rinsing section avoids that the finishing

section is excessively soiled by gelatine in order to

ensure that the hydrophobising effect of the

finisher lasts longer.

Before leaving the rinsing section, the excess of

rinsing solution is pressed off the plate by means

of a pair of squeegee rollers.

3.3.7. Finishing section

The finishing section ensures the hydrophobising

of the silver image on the printing plate and

applies a gum-layer to avoid oxidation of the

printing plate.

Before leaving the finishing section, the excess of

finisher is pressed off the plate by means of a pair

of squeegee rollers.

AGFA

LITHOSTAR LP82

2 Instruction Manual

2.12.00 Jan. ‘97

3.3.8, Drier section

Both sides of the printing plate are dried by means

of hot air,

The air stream is generated by means of a

centrifugal ventilator. Two electrical heaters

ensure that the air is heated.

3.3.9. Exit section

‘The processed printing plate is fed out of the

processor.

AGFA @

LITHOSTAR LPs2

Instruction Manual 2

3.4, User interface

Jan. '97 2.13.00

‘As shown in the following diagram, the contro! panel of the processor AGFA LITHOSTAR LPE2 consists

of a display and seven keys :

If the display contrast is too low or if the display is

unreadable, hold down the »-key and then

depress the A-key several times.

1, alter more than 16 depressions of the A-key, the

display is still unreadable, there might be a problem

with the display.

Ifthe display contrast is too high, use the »-key in

‘combination with the V -key.

This procedure to change the display contrast can

‘only be used when the basic screen (the screen on

Which “wenu" can be selected) is indicated,

The key located at the right side of the display can

be used to illuminate the display : the display then

remains illuminated until the key is depressed

again or until the processor is turned off.

In most cases, the selection of an item on the

display occurs by a b-cursor (which can be

moved by using the A- and V-keys) and then

depressing the OK-key.

‘The upper left comer of the display shows the

following items :

= The mode into which the processor is

presently

- The selected function and/or

subfunction(s) of the menu

‘The upper right comer of the display shows the

‘cursor keys which can be used on the screen

which Is presently indicated,

AGFA &

LITHOSTAR LP82

2 Instruction Manual

2.14.00 Nov. '98

3.4.1, Modes of the processor

‘The processor AGFA LITHOSTAR LP82 can be in.

‘one of the following four modes :

© The READY-mode

The processor is ready to accept a printing

plate.

During the READY-mode, the levels as well as

the temperatures in the different trays are

constantly checked and, if necessary,

corrected.

‘The READY-mode is set in one of the following

cases :

= When the processor is warmied up and

ready after it has been made active by

using the ‘on/off"-key

= When the processor is warmed up and

ready after it has entered an pre-

Programmed active period

The WAIT-mode

The processor is not ready to operate or

cannot accept a printing plete.

‘The reason is always indicated by means of a

message.

The different possible messages are :

“WAIT + Starting vp"

“WAIT : Rewash open - Rewash busy"

“WAIT 1 Processor ie stil busy"

“WAIT + Roller cams are moving”

"WAIT : Temp. developer too high*

“WAIT : Temp. developer too low”

“WAIT : Level developer too low”

“WAIT : Replenishing developer"

“WAIT : Temp. wash water too high"

CWAIT : Temp. wash vater too low’

‘WAIT : Level wash water too Low"

‘WAIT : Replenishing wash vater*

‘WAIT : Temp. rinse too high’

“WAIT : Temp. rinse too lov"

“WAIT + Level rinse too low

“WAIT : Tomp. finisher too high’

‘WAIT : Temp. finisher too los"

‘WAIT : Level finisher too low’

“WAIT + Replenishing finisher"

‘waIT : Temp. drier section too nigh"

‘WAIT : Temp. drier section too low"

‘WAIT + Imager requests processing’ (")

"WAIT : Plate coming from imager" (*)

“WAIT : Starting up stacker" (**)

(Can only be indicated if the processor is on-line

with an imager (with or without the optional on-

line bridge OLBB2).

(") Can only be indicated it the optional stacker LS82

has been installed,

For more information, refer to the appropriate

operating instructions.

AGFA

LITHOSTAR LP82

Instruction Manual 2

* The OFF-mode

‘The processor enters an inoperational state

where the power consumption is reduced to

an absolute minimum (only the electronics are

in stand-by).

When the processor enters the OFF-mode,

the rollers are opened.

In order to avoid damage (sticking together or

deformation) of the rollers, they should always be

open before turing off the main switch of the

processor.

Witis necessary to turn off the main switch, frst

enter the OF F-mode, walt approx. § sec in order

10 allow the rollers 10 open and only then tum off

the switch.

If one tries to insert a printing plate by way of

the feedin table during the OFF-mode, a beep

signal is generated and the warning "Plate

Anput not accepted’ is indicated in order to

warm that the rollers are not closed.

This is done because, in this case, the printing

plate could reach the developer through the

‘opened feed:in rolers : pulling back the plate

would then result in moistening the feed-in rollers

and this should always be avoided.

The processor enters the OFF-mode in one of

the following cases :

= When the processor is turned on by

using-the main switch

- When the processor is made inactive by

using the “on/off'-key

- When the processor enters a pre-

programmed inactive period

~ When selecting "Maintenance" on the

basic screen

van. '97 2.15.00

* The NOT READY-mode

‘The processor cannot operate : an action is

expected from the operator (for instance the

replacement of a container).

In most cases, the NOT READY-mode will be

preceded by a warning on the display and the

processor will only enter the NOT READY-

mode if the action required by the warning is

not carried out.

In order to avoid that the processor enters the

NOT READY-mode, do not wait too long before

carrying out the action required by a warning.

In case of a more serious problem, the NOT

READY-mode will be entered immediately.

‘The warnings can be indicated in the four

modes.

For a list of the different possible warnings,

refer to "8.1. A warning is indicated on the

display’.

AGFA &

LITHOSTAR LP82

2 Instruction Manual

2.16.00 van, ‘97

3.4.2, Menu of the processor

‘The menu of the processor can be entered by

depressing the OK-key when ‘Menu’ is selected.

‘enw’ is almost alvrays indicated when the menu of

the processor has not been entered.

W ten" should be selected, use the A- and ¥ keys.

The following screen is then indicated :

tine soe

(ote maintenance ser

Systen control

Exit

‘The following seven functions are available

Maintenance"

Used to proceed to the maintenance screen

(the OFF-mode will automatically be entered).

For more information, refer to § 6.2.

* ‘Single program"

Allows re-programming the processor in case

of days off, overwork or special use without

having to change the week program.

For more information, refer to § 5.3.2

* ‘Week progrant

Used to program the active and inactive

periods for each day of the week.

For more information, refer to § 5.3.1.

© Plate sizes’

Used to program the printing plate sizes,

For more information, refer to § 6.1.

* "Time set*

Used to set the date and/or the time.

For more information, refer to § 52.

* "system control”

Used to set the language, the display contrast,

the beep duration, the measurement setup,

the acceptance delay and the maintenance

info screen. Also used to read the

temperatures of the solutions in the trays as

well as the production data.

For more information, refer to § 6:4

"exit"

Used to leave the menu and to return to the

basic screen,

Each screen representing a (sub)funetion of the

menu offers the possibility (normally “sxxie* or

“pone’) to return to the preceding screen.

When returning to a preceding screen, the

cursor will almost always be positioned before

the ‘gxit" line of that screen. As a result, itis in

most cases possible to go back to the basic

‘screen by successive depressions of the OK-key

and without having to select “sxte" on each

intermediate screen.

Important !

ferently, the menu and its

different functions and subfunctions can be

entered in each mode of the processor:

Depending on the mode, the corresponding

‘screens might be slightly different (especially the

top line of the screen),

In order to avoid too complex illustrations when

explaining the (sub)functions of the different

‘modes, only the screens for the READY-mode will

be represented.

AGFA &

LITHOSTAR LP82

Instruction Manual 2

3.5. Preparing the processor for operation

3

Turning the processor on and off

The processor is turned on and off by using the

main switch which can be found at the right side

of the front legs assembly.

It is recommended that the main switch remains on

at all tines : management of the power

consumotion can be regulated by programming

active and inactive periods (refer to § 3.6.2.) which

also allow an efficient use of the processor.

Important !

Ifit is necessary to turn off the main switch,

ensure that the rollers are open.

For opening the rollers, first enter the OF F-made

by depressing the ‘onvoff-key and then wait

approx. § sec in order to allow the rollers to open.

If the rollers remain closed, they may be damaged

by the pressure (sticking together or deformation),

When the main switch is turned on, the processor

enters the OFF-mode :

‘The processor enters the OFF-mode, even if the

ain switch is turned on during a pre-programmed

active period.

During the OFF-mode, messages can already be

indicated on the display.

If the maintenance info screen has been set, the

‘wenu" screen also shows the maintenance

information (also refer to § 5.4).

Jan. ‘97 2.47.00

3.5.2. Emergency stop

The screen described in this paragraph also applies

when the upper covers are not closed (correctly).

‘An emergency stop knob has been provided on

the front right side of the feed-in table.

Push on the knob if, for any reason, it is necessary

to interrupt the operation of the processor.

It an emergency stop is required on a processor

installed as a two-room configuration (lightroom +

darkroom), the emergency stop knob on the feecin

table can be used in tho darkroom while the main

switch can be used in the lightroom.

If the ‘rewash not allowed" indicator incorporated in

the ‘rewash startéstop" switch (located at the right

side of the rewash feed-in table) lights up, the

‘operation of the processor can also be interrupted

by pushing on the switch (refer to §.3.6.4).

When the emergency stop knob is pushed, the

knob locks itself and the following screen is,

indicated

Open the rollers

Chose the roiiers

[Soneinue > unlock oneraone:

Using the A- and Y-keys, make the appropriate

selection and then depress the OK-key.

Do not forget to unlock the emergency stop knob

by turning it slightly in the clockwise direction

(direction of the arrows),

AGFA >

LITHOSTAR LP82

2 Instruction Manual

2.18.00 Jan. ‘97

3.5.3. Emptying all the trays of the processor

This paragraph should only be carried out if the

trays of the processor contain solutions which

should be replaced.

If the trays are already empty or ifthe solutions in

the trays should not be replaced, directly proceed to

"2.6. Operating the processor’,

‘* Ensure that the waste container is (almost)

empty and that it is placed correctly.

Important !

Take into account that the total contents of all the

trays of the processor slightly exceeds 20 |. It will

therefore be necessary to replace the waste

container while emptying all the trays, especially

when the container is not empty when starting the

operation.

Emptying the trays is carried out by manual drain

valves : if the waste container is full, this will be

detected and a warning will be indicated, BUT

THE VALVES SHOULD BE CLOSED MANUALLY.

Also note that, if the main switch is not tured on

when emptying the trays, a warning will not even

be indicated when the waste container is full,

In order to avoid mixing of the different solutions

inside the processor, never open all the manual

drain valves together but open them one by one

(wait until a specific section is empty and close the

corresponding valve before opening a next one).

* Open the right cover of the processor and,

using the developer drain valve, drain the

developer from the developer tray and the

corresponding circulation circuit.

1 Finisher drain valve

2 Rinsing solution drain valve

3 Wash water drain valve

4 Developer drain valve

‘* When all the developer has been drained,

close the developer drain valve and then

repeat this operation successively in order to

drain the wash water, the rinsing solution as

well as the finisher.

* Close the right cover of the processor.

Important !

If the trays will not be filled directly after they have

been emptied, it is recommended to clean them.

If the processor will not be used for a long time

(holidays, ...), a "Holiday £i11ing’ (refer to

§ 6.3.4.) should be carried out in order to avoid

smell problems,

AGFA

LITHOSTAR LP82

Instruction Manual 2

3.6. Operating the processor

3.6.1. Activation of the processor

When the “on/off'-key is depressed or when

reaching a pre-programmed active period, the

processor enters the WA\T-mode in order to

warm up and to carry out some preliminary

checks :

When the processor enters the WAIT-mode, a beep

is generated,

Ensure that the four manual drain valves behind the

right cover as well as the four manual drain valves

underneath the processor are closed.

W the rays are empty or if they do not contain

‘enough solution, the processor will start to fil them

automatically.

‘Normally, the processor needs 20 - 30 minutes to be

ready.

If the maintenance info screen has been set, the

‘Nenu" screen also shows the maintenance

information (also refer to § 5.4).

‘When the processor is ready to accept the first

printing plate, it changes to the READY-mode :

At the same time, a beep is generated.

Jan. ‘97 2.49.00

3.6.2. Active and inactive periods

In order to allow power consumption control as

well as efficient use, the processor can be in one

of the two following states :

= The active state

Normal operation of the processor with

checking and, if necessary, also correcting

the levels as well as the temperatures in the

different trays.

When the processor becomes active, it wil first

enter the WAIT-mode in order to warm up and

to cay out some preliminary checks,

- The inactive state

Inoperational state during which the power

consumption is reduced to an absolute

minimum.

The inactive state corresponds to the OFF

‘mode (the rollers of the processor are open).

‘The state of the processor can be determined by :

- simply depressing the ‘on/off'-key on the

control panel of the processor

= programming the functions "Week progran’

andjor ‘Single program of the menu

Ten minutes before entering a pre-programmed

inactive period, the message ‘OFF AT : Day hi

in the bottom line of the screen starts blinking.

If there is stil a printing plate inside the processor

when an inactive period should be entered, “OFF

AFTER PLATE" is indicated in the right part of the

bottom line of the screen,

Wore aster piars*is indicated, itis sill possible to

insert a following printing plate as long as the trailing

‘edge of the previous plate has not left the processor

AGFA}

LITHOSTAR LP82

2 Instruction Manual

Jan. ‘97

3.6.3. Processing printing plates

Ensure that the processor is in the READY-mode.

Position the printing plate centered against the

feed-in rollers.

After the pre-programmed acceptance delay, the

printing plate is automatically fed into the

processor.

The acceptance delay can be programmed by using

‘accept deiay" of the system control feature (refer

10§ 5.4).

Important !

Never pull back a printing plate once it has been

taken up by the feed-in rollers,

Pulling back a printing plate could result in

damage to the plate and in the moistening of the

feed-in rollers.

Never (re-Jinsert a damaged printing plate into the

Processor.

When operating the processor, take into account

the following points :

* If the processor changes to the NOT READY-

mode when trying to insert a printing plate,

carefully pull out the plate : the processor will

indicate the reason why the printing plate has

not been accepted,

* Ifa printing plate jam occurs, always open the

rollers before removing the jammed printing

plate.

* Ifa printing plate has jammed in the

developing section, and in order to avoid

moistening of the feed-in rollers, always

remove the plate by pulling it towards the rear

side.

It the feed-in rollers are soiled or moistened,

ALWAYS clean them,

* When continuously inserting printing plates,

ensure that they never overlap each other :

wait until the processor is again in the READY-

mode (a beep is generated !) before inserting

new printing plate.

It the plates overlap, the processor will operate

but an unknown format or a too long printing

late will be detected,

* In order to ensure an even processing, the

center of the feed-in table should be used as

reference when a plate is fed into the

processor.

* In order to avoid scratches on a previous

printing plate, remove that plate from the exit

guide before the arrival of a following one.

AGFA

LITHOSTAR LP82

Instruction Manual 2

3.6.4. Rewash system

The rewash system has been incorporated in the

‘font upper cover of the processor.

1 the optional ‘kit LP82 plates 0.4 mm’ has been

provided, a new front upper cover has been installed

(on the processor: this cover does not have an

incorporated rewash system.

The rewash section offers the possibility to re-

insert printing plates into the processor (without

passing through the developing section and the

diffusion section) in order to * a

= clean the corrector off the printing plate If

manual corrections have been made

- clean off the gum-layer and re-hydrophobise

printing plates which have been stored after

a process operation

The possibility of carrying out a rewash operation

is indicated by the red *rewash not allowed” LED

which has been incorporated in the ‘rewash

starl/stop* switch located at the right side of the

rewash feed-in table :

- If the LED lights up, this indicates that the

rewash flap may not be opened (a printing

plete is passing through the diffusion section

or the processor is not ready for operation).

The LED also lights up during the whole

rewash operation.

= If the LED doas not light up, a rewash

operation may be carried out:

Nov. 2.21.00

‘+ Ensure that the processor is in the READY-

mode and that the “rewash not allowed"

indicator does not light up.

Important 1

Never pull back a printing plate once it has been

taken up by the wash section entrance rollers.

Pulling back a printing plate could result in

damage to the plate.

* Open the rewash flap.

AGFA

LITHOSTAR LP82

2 Instruction Manual

2.22.00 Jan. ‘97

* Position the printing plate centered against the

stationary wash section entrance rollers.

If the printing plate is not positioned against the

wash section entrance rollers, it wil not be taken

up during the following step.

In order to ensure an even rewash operation, the

center of the revash feed-in table should be

used as reference.

‘* Push on the “ewash start/stop" switch in

order to initiate the rewash operation.

Itit is necessary to interrupt the rewash

operation, push on the ‘rewash start/stop” ewiteh

once again.

It the printing plate jams, always open the rollers

before removing the plate.

Interrupting the operation of the

Processor by means of the “rewash

start/stop" switch

‘The “rewash start/stop" switch can be used to

interrupt the operation of the processor

whenever the “rewash not allowed" indicator

lights up.

When the operation of the processor has

been interrupted by pushing on the switch, the

following screen will be indicated :

ARE) STOP" SWITCH PRESSED

Clore the rollers

Using the 4- and Y-keys, make the appropriate

selection and then depress the OK-key.

AGFA &

LITHOSTAR LP82

Instruction Manual 2

3.7. Treatment of the AGFA LITHOSTAR

printing plates after processing

For more information about the manipulation of the

unexposed printing plates, refer to “4.2. Manipulation

of the unexposed AGFA LITHOSTAR printing plates”.

3.7.1. Corrections on the printing plates

'* Negative corrections (wiping the image)

If necessary, images can-be wiped-off the

processed printing plates by using a corrector

en or corrector fluid (also refer to “2.

Consumables’).

Immediately after the correction, the corrector

should be cleaned off by rewashing the plate

or by using a cotton swab moistened with

finisher L5300b.

The corrector should never dry on the printing

plate !

© Positive corrections (adding image)

Hf necessary, a "+" corrector pen can be used

to add image on the processed printing plate

{also refer to "2. Consumables’).

The corrector should be totaly dry before using

the printing plate for a printing operation !

van. ‘97 2.23.00

3.7.2. Storage of the processed printing plates

before the printing operation

Before the printing operation, the processed

Printing plates should preferably be stored in a dry

and heated place :

- Temperature between 18°C and 24°C

- Relative humidity between 40 % and 70 %

= Image side against image side

If the printing plates have been stored for more

than one month or in case of doubt about the

storage temperature and humidity, itis

recommended to rewash the plates before

printing.

3.7.3. Treatment of the printing plates after

printing

After a printing operation, remove the ink by using

plate cleaner G642b, carefully clean the plate by

using finisher and then wipe it dry by using a

cotton pad.

If itis necessary to keep the printing plates for

later use, store them under the same conditions

as the ones given in the previous paragraph.

AGFA &

LITHOSTAR LP&82

2 Instruction Manual

2.24.00 Nov. "98,

3.8. Replacement of the containers

3.8.1. Replacement of the developer and finisher

containers

‘The necessity to replace a developer or a finisher

container is indicated by a warning (refer to

"8.1. A warning is indicated on the display’).

When the warning is indicated, it wil stil be possible

to process 1 mé. If, after that, the container has not

been replaced, the processor enters the NOT

READY-mode.

‘The finisher container (with label LS300b) is the

one located at the rear side while the developer

container (with label L5000p) is the one located at

the front side.

The middle container is the waste container (refer to

the next subparagraph).

In order to ensure a correct installation of the

containers, the developer immersion system has

been provided with a red label and the indication

L5000b while a blue label and the indication L5300b

can be found on the finisher immersion system,

Important !

Never interchange the developer, finisher and

waste containers,

Wf the containers have been interchanged

accidentally, the corresponding circulation circuits

should be cleaned by using the circulation feature

of the software-maintenance function (refer to

"6.3.3. Circulating water in order to clean the

circulation circuits")

* Taking care not to damage the iubes

connecting the immersion system of the

container, take the container out of the drip

tray underneath the processor.

* Unscrew the cap of the container and then

carefully take the immersion system (for

an entity with the cap) out of the empty

container.

* Take a new container, remove its cap by

using the special tool supplied with the -

processor and then insert the immersion

system into It

oo

* Screw the cap of the

onto the container.

\mersion system firmly

* Ensure that the immersion system touches the

bottom of the container.

I not, carefully push down on the immersion

‘system until it touches the bottom of the

container.

If the immersion system does not touch the

‘bottom of the container, an empty condition will

be detected before the container is really empty.

* Carefully place the container back into the drip

tray underneath the processor.

AGFA &

LITHOSTAR LP82

Instruction Manual

2

3.8.2. Replacement of the waste container

The necessity to replace the waste container is

Indicated by a warning (refer to 8.1. A waming is

indicated on the display’).

The waste container can be filled in two ways :

- By way of the overflow pipes in the different

trays

When a ‘waste container full condition is

dotected, a warning ia incioatod. Aho same

time, the processor stops all the replenishing

eperations so that no mare solution wil flow

into the overflow pipes. It will however still be

ppossiblo to process 1 m?. afer that, the

waste container has not been replaced, the

processor enters the NOT READY:mode.

- By opening the manual drain valves in order

to empty the trays

When a ‘waste container ful" condition is

detected, a warning is indicated (if the main

‘switch is turned on) but THE VALVES

‘SHOULD BE CLOSED MANUALLY in order to

avoid overflow.

* Taking care not to damage the tubes

connecting the immersion system of the waste

container, take the container out of the drip

tray underneath the processor.

* Unscrew the cap of the container and then

carefully take the immersion system (which

forms an entity with the cap) out of the full

container.

Nov. "98 2.25.00

+ Empty the container or take an empty one

Ensure that a full waste container is correctly

closed before putting it away.

Empty developer or finisher containers can be

used as waste container : ensure that the waste

container has the appropriate label (refer to “7.2.

Coltecting the chemical waste’).

© Insert the immersion system into the empty

container,

* Screw the cap of the immersion system firmly

onto the container.

+ Carefully place the waste container back into

the drip tray underneath the processor.

* If the waste container has been replaced in

response to @ warning indicated on the

display, do not forget to confirm its

replacement by depressing the OK-key.

AGFA &

LITHOSTAR LP82

2 Instruction Manual

2.26.00 Jan. ‘97

3.9. Chemicals and water consumption

The values given under ‘Chemicals and wator

consumption" in “Specifications* (part 1) apply to a

processor which is used regularly and processes

approx. 10 wPiday,

{In case of low production or long periods of

inactivity, some additional replenishing operations

are cartied out.

3.9.1. The developer tray

‘The developer tray is only replenished with

developer.

‘The developer is replenished in function of the

processed plate surface (200 mim?) and, in order

to avoid oxidation, also in function of the time

(100 mifhour).

When canying out a rewash operation, no developer

wil be replenished into the developer tray.

A very small amount of developer is also replenished

into the wash tray (refer to the next subparagraph).

‘The developer replenishing algorithm assumes

that dally at least 10 m? (= 2 | of developer) are

processed.

Mt, during a working dlay, less than 10 m® have been

processed, an additional replenishment A

compensating the m® which have not been

processed will take place when warming up for the

(rst) active period of the next working day.

It the processor has not left the active state, this

operation will take place at § am of the next

‘morning.

Further, 2.4 | (= 24 hours x 100 minour) of

developer are daily replenished for antt-oxidation

Purposes.

While the processor is active, 100 mi of developer

are replenished every hour.

It the processor has left the active state, an

additional replenishment 8 compensating the

inactive hours will take place when warming up for

the (fist) active period of the next working day.

The total amount of developer replenished during

the additional replenishments A and 8 will never

exceed 5! which is the capacity of the developer

tray.

It the processor has not been used for more than 72

hours, 4 message will ask to drain the developer tray

‘80 that fresh developer can be supplied to the tray.

Wnecessary, remove the sludge trom the developer

tray by using a soft brush and then rinse the tray

after draining.

In order 0 avoid processing problems due to aged

developer, an opened developer container should

be replaced after a week.

Considering the information given above, the

minimal daily developer consumption of a normally

operating processor is 4.4 |.

The following diagram illustrates how the daily

developer consumption depends on the

processed plate surface :

4 day

“4

2

10

8

6

4

g wiiday

Sp

5 10 15 20 25 30 35 40 45 60

AGFA}

3.9.2. The wash tray

The wash tray is replenished with water and a

‘small amount of developer.

A very small amount of developer is supplied to the

wash tray in order to avoid the formation of bacteria

and/or the deterioration of the wash water.

Replenishing of the wash tray will also take place

during a rewash operation.

The water is replenished in function of the

processed plate surface (200 mlm2).

‘The following diagram illustrates how the daily

water consumption depends on the processed

plate surface :

aay

5 10 15 20 25 30 35 40 45 50

LITHOSTAR LP82

Instruction Manual 2

Jan. '97 2.27.00

3.9.3. The

isher tray

The finisher tray is only replenished with finisher.

The finisher is replenished in function of the

processed plate surface (100 mim).

When carrying out a rewash operation, finisher will

be replenished into the finisher tray.

The finisher replenishing algorithm assumes that

daily at least 10 m2 (= 11 of finisher) are

processed.

1, during a working day, less than 10 m? have been

processed, an additional replenishment

compensating the m? which have not been

processed will ake place when warming up for the

(rst) active period of the next working day.

I the processor has not left the active state, this

‘operation will ake place at § am of the next

‘morning.

In order to avoid processing problems due to aged

finisher, an opened finisher container should be

replaced within 30 days.

The following diagram illustrates how the daily

finisher consumption depends on the processed

plate surface :

t Niday

8

8

: ae

= miiday

5 10 15 20 25 30 35 40 45 60

AGFA

LITHOSTAR LP82

2 Instruction Manual

2.28.00 Jan. ‘97

4. Manipulation of the

consumables

4.1. Manipulation of the AGFA

LITHOSTAR chemicals

For the manipulation of the chemicals, always

follow the instructions on the labels on the

containers,

‘Once a container has been opened, it should be

used until it is empty (never store a container

which has already been opened).

In order to avoid processing problems due to aged

developer, an opened developer container should

be replaced after a week. It is recommended to

replace an opened finisher container within 30 days.

{tthe processor has not been used for more than 72

hours, a message will ask 1 drain the developer tay

0 that fresh developer can be supplied tothe tray.

necessary, remove the sludge fiom the developer

tray by using @ soft brush and thon rine the tray

after draining.

If the period of inactivity exceeds a month, itis

recommended to replace all the solutions.

4.2. Manipulation of the unexposed AGFA

LITHOSTAR printing plates

The printing plates should be stored in a dry

location at a temperature laying between 20°C

and 32°C.

‘Never expose the printing plates to temperatures

‘exceeding 32°C for more than 24 hours,

If the plates have been stored at low

temperatures, and in order to avoid condensation,

it is recommended to leave them at least one hour

in the darkroom before using them.

The printing plates should not be processed at

temperatures exceeding 35°C.

‘Always put the unexposed printing plates back

into their light-proof bags (ensure that the bags

are correctly closed) or into the Agfa plate safe.

AGFA >

LITHOSTAR LP82

Instruction Manual 2

5. Programming the processor

|. Programming the printing plate sizes

Start from the basic screen :

Say Shae Fe AT) bay Shim

Depress the OK-key in order to enter "Menu" and

then use the a- and v-keys in order to select

"plate sizes"

Single program

Wook program

} Place sires

Time eet

sete eh

Bae

system control

xis,

Enter ‘plate sizes" by depressing the OK-key :

aaa or eait a piate size

Delete a plate size

Exit,

kdaor edie printing plate sim

For a detailed description of the different

Possibilities, refer to the following subparagraphs.

Nov. ‘98.

'* Adding a printing plate size to the programi or

changing an existing one

Ensure that the cursor selects "Add or edit

a plate size’ and then depress the OK-key :

A slightly different screen will be indicated if

‘anglo" has been selected for the measurement

setup.

Enter or change the printing plate size :

~ If necessary, use the 4- and ¥-keys to

select the desired printing plate size number

- Use the »- and <-keys to select the values

determining the length and the width (or to

eave them)

= Use the 4- and ¥-keys to increase or

decrease the value selected in the previous

‘step (autorepeat : faster increase or

decrease when the key remains depressed)

The length may be set between 0.310 m and

1.130 m while the width may be set between

0.225 m and 0.820 m.

1, during autorepeat, a maximal (minimal) value

is reached, the autorepeat operation continues

starting from the minimal (maximal) value.

AGFA

LITHOSTAR LP82

2 Instruction Manual

2.30.00 Jan. ‘97,

* Deleting a printing plate size from the program

Using the A- and V-keys, select ‘Delete a

plate size":

Add or edit a platé’size

Delete

plate size

Bete

Beteta a printing plate sive

Depress the OK-key :

SARS

Tenge x maaen

8-0 2008

a: Blea0

slese = 8888

cam

[Select sive to delete ana press “Ox™

A slightly different screen will be inaicated it

‘angio" has been selected for the measurement

setup.

*.. empty" will bo indicated if there are no

programmed printing plate sizes.

Using the A- and Y-keys, select a printing

plate size ('02" for the following diagram) and

then depress the OK-key :

x taeh

e.600

2:68

1600

Cam

REALLY DELETE 7 Tf

Depress the OK-key once again to confirm

that the printing plate size may be deleted.

Otherwise, use the A-key or the V-key to return

‘othe "piace sizes" soreen

After having deleted a printing plate size, the

aumbering of the sizes will be adapted.

5.2, Programming the time

Start from the basic screen :

Depress the OK-Key in order to enter ‘Menu’ and

then use the 4- and V-keys in order to select

“Time set":

Waintenance

Single program

week progean

Plate sizes

tine set

syst

Beit

control.

Enter ‘time set" by depressing the OK-key :

REE

Do/MH/YYTY

Dar, 4a/an/yyvy hhimm

A slightly different screen will be indicated if

“angio” has been selected for the measurement

setup.

If necessary, change the time and/or the date :

= Use the »- and ~-keys to select the items

forming the date and the time (autorepeat)

The selection occurs as follows :

day => month -> year -> hour -> minutes -> » -> day

The name of the day is set automatically.

- Use the 4- and ¥-keys to increase or

decrease an item (autorepeat)

- The Ok-key can be used instead of "exit"

AGFA

LITHOSTAR LPs82

Instruction Manual 2

5.3. Programming the active and inactive

periods

5.3.1. Week program

‘The week program allow’s programming the active

and inactive periods of the processor for each

day of the week.

As long as a day has not been programmed as

“spoctal' or “ors” by using ‘single progran (refer

to the following subparagraph), the processor will be

active and inactive as programmed in the week

program. 3

In order to reduce the total consumption of power

‘and chemicals, itis recommended to use the

‘single progran' feature in case of a foreseeable

period of inactivity.

Start from the basic screen :

Depress the OK-key in order to enter "Menu and

then use the A- and V-keys in order to select

‘Week program:

Maintenance

Single program

pweck progran

Plate sizes

Time 2st

[rogram the active and inactive

system control

aaie

Enter ‘week program" by depressing the OK-key

(the following diagram shows an example) :

van. '97 2.31.00

PRN

If it is necessary to change the active and

inactive periods for a day of the week, select the

day (‘Mon" for the following diagram) by using the

4- and Y-koys and then depress the Ox-key :

‘The time of the day can be selected by using the

new A-cursor which can be moved, in steps of

1/2 hour, towards the left and the right by means.

of the »- and <-keys.

In order to program an active period, move the

cursor towards the desired starting time and then

depress the A-key. As a result, the 1/2 hour

following the starting time will be activated (shown

in black). Each depression of the - or --key will

now activate a following or preceding 1/2 hour.

If it is necessary to program an inactive period,

carry out the same procedure by using the V-key.

If the day has been programmed correctly,

confirm by depressing the OK-key : returning to

the ‘week program" screen can now occur by

using "Exit" which is selected automatically.

AGFA &

LITHOSTAR LP82

2 Instruction Manual

2.32.00 Jan. ‘97

5.3.2. Single program

‘The week program determines the active and

inactive periods for each day of the week.

In order to avoid that the week program should

be re-programmed in case of days off, overwork

(oF special use of the processor, the single

program has been provided.

Taking into account that the changes in the single

program will only be carried out once (afterwards

the week program is set again), the single

program offers the following possibilities (which

are explained in the following subparagraphs) :

= Prolongation of the active period into which

the processor is at present

- Reprogramming one or more days of the

‘coming week

* Prolongation of the active period into which

the processor is at present

Start from the basic screen :

CE CREMEFVEETET

Depress the OK-key in order to enter “Menu”

and then use the &- and ¥-keys in order to

select ‘Single program":

Maintenance

Single program

Wook program

Plate sizes

ime set

System control

Bxie

Enter ‘single program’ by depressing the

OK-key (the following diagram shows an

example) and then select the line ‘ada 30

min to present active period’ by using

the A- and V-keys :

Padd 30 min to present active period

Mon WoekPE. iii1s) Seis

Toe Off

ed WeekDr. (iiii11; mE Ls

Thu Weekpr: C1) —__——-LC000

Fei Spectal 7

Sat special Gavia Mm

Sun Weekpes Se

Bete

Each depression of the OK-key will now result

in the prolongation of the present active

period by one 1/2 hour.

‘The new time at which the active period will

be terminated is given in the lower right

comer of the screen.

If the processor is not in an active period when

selecting the line mentioned above, the

message ‘Adding 30 min only possible if

active" will be indicated on the display.

AGFA

LITHOSTAR LP82

Instruction Manual 2

* Reprogramming one or more days of the

coming week

Start from the basic screen :

GE a} Day Bnew

Depress the OK-key.in.order-to enter ‘Menu

and then use the A- and ¥-keys in order to

select ‘Single program’:

J Singie program

Wook program

Ht

[rogram special days of saa i/? hour

system control

Bale

Enter “Single program by depressing the

Ok-key (the following diagram shows an

example) :

READYsHENUsSTNGLE PROGRAW

‘Add 30 min to precont active period

|-Non w;

T T

Togram special days of coming week

Wed WeekPes (iitt 1) TL

The Weer) CCC —_/0CC00

Fei Spactal Ss

Sat special Be

Ban Woekpe.

Bide

Jan. '97 2.33.00

If it is necessary to temporarily change the

active and inactive periods for a day of the

coming week, select the day (‘Mon’ for the

following diagram) by using the A- and Y-keys

and then depress the OK-key :

The following subparagraphs explain the

different possibilities offered by the above

screen :

- Making the selected day inactive (for

instance in case of a day off) :

Ensure that ‘of£" is selected and then

depress the OK-key.

The overview screen will again be indicated

with the selected day programmed as

inactive.

- Setting the selected day back to the week

program :

Select "weekpr." by using the 4- and ¥-

keys and then depress the OK-key.

The overview screen will again be indicated

with the selected day as programmed in the

week program.

AGFA &

LITHOSTAR LP82

2 Instruction Manual

2.34.00 Jan. ‘97

= Making a special program for the solected

day :

Select "special" by using the A- and ¥-

keys and then depress the OK-key.

The following screen is indicated :

The active and inactive periods of the

selected day can now be programmed as

described for the week program.

If the present day is programmed as ‘ors" or

"special", the single program will be carried

out immediately and the processor will change

back to the week program at the end of the

day.

Using the “on/off'-key to set the processor

from inactive to active or vice versa will not

affect the week program or the single

Program,

{Ifthe processor is made active (inactive) by

using the ‘on/off-key in an inactive (active)

period, it will return to the inactive (active) state

when reaching the next programmed inactive

(active) period.

5.4, The system control feature

The system control feature allows carrying out

one of the following operations :

~ Changing the language

= Changing the display contrast

= Changing the beep duration

= Changing the measurement setup

= Changing the acceptance delay

- Setting or cancelling the maintenance info

screen

- Reading the temperatures of the solutions

in the different trays

= Reading the different production data

- Enabling or disabling the optional stacker

- Entering the service mode (only for the

Agfa service technician)

Start from the basic screen :

|

[bay hin OEE AT? bay hl

Depress the OK-key in order to enter "Menu" and

then use the A- and Y-keys in order to select

"system control":

Week program

Plate sizes

Times.

b system controt

(So to the epsten contror

bing screen

Single program

AGFA}

Another depres:

following screen =

of the OK-key shows the

Pranguase

Display contrast

Beep duration

Dnies

Recest delay

[ress “on™ for settin

Vasntenance info screen ow

Tenperatures

Production data

Stack

Servic:

Bie

: Enabled

‘The function "stacker" is only indicated if the

optional stacker AGFA LITHOSTAR LS82 has

been provided and it allows enabling or

disabling the stacker.

For more information, refer to the appropriate

operating instructions.

The function will not be indicated any more in the

screens represented in the following

subparagraphs.

‘The function "Service" can only be accessed

by the Agfa service technician in order to

enter the service mode (a special code is

needed).

When the function is selected, ‘service only for

Agfa service techaictan’is indicated in the

bottom line of the screen.

wing subparagraphs explain the other

ies offered by the system control setting

screen,

LITHOSTAR LP82

Instruction Manual 2

Jan. '97 2.35.00

‘© Changing the language

This feature allows changing the language used

on the display of the processor.

Besides ‘tagiish’ the processor offers the

possibility to use two additional languages.

For more information, ask the Agfa service

technician,

Using the a- and v-keys, select ‘Language"

and then depress the OK-key :

Eangusge

PEnglish

Sona Language"

w3re languages

Exit

“end Language’ and "3rd Language’ stand for the

‘wo additional languages mentioned above.

Use the A- and Y-keys to select the desired

language and then depress the OK-key.

AGFA

LITHOSTAR LP82

2 Instruction Manual

Jan. ‘97

© Changing the display contrast

4H, and only it, the basic screen is indicated, the

display contrast can also be changed by

holding down the »-key and then depressing

the A- or V-ey one or more times.

Using the A- and Y-keys, select ‘Display

contrast’

Tangvage

}Sisplay contrast,

Beap duration

Unies

Aecept delay

English

60.

Moerie

2.9 sec

[press “ox= for setting display contrare

Maintenance info screen : ow

Temperatures

Production data

Exit

Depress the OK-key

Language

Display contrast

Beep duration

Onite

Accept delay

E

Sa “OK for setting display contrast

Maintenance info.screen : oN

Temperatures

Production data

Service

Exit

Using the a- and ¥-keys, increase or

decrease the display contrast and then

depress the OK-key.

The display contrast can be set in 16 steps.

* Changing the beep duration

Using the

duration’

- and V-keys, select ‘Beep

Bispial

splay contrast,

Beep duration

omits

R2cept delay

Maintenance info screen: oN

Temperatures

Production data

Service

Bait

Depress the OK-key

Tangu:

men

Dispay

Beep duration

Onite Metric

Accept delay 2:3 0c

tenance info screen ow

Temperatures

Production data

Service

Beat

Using the 4- and ¥-keys, increase or

decrease the beep duration and then depress

the OK-key (a beep with the last determined

duration will be generated).

The beep duration can be set between 0 and 2 sec.

Beeps are generated in the folowing eases :

- tbeep : The processor enters the WAIT-mode

or the READY-mode

+ 2beeps : Waring, jam, rewash operation or

emergency stop

= Sbeeps : Error condition

A continuous beep is generated when inserting @

printing plate in the OFF-mode or when the

processor is stil processing a previous plate.

A repeated beep indicates that the waste container

should be replaced.

AGFA &

LITHOSTAR LP82

Instruction Manual 2

* Changing the measurement setup

Using the A- and Y-keys, select "units" :

nguage

Display contrast

Beep duration

-onits

Accept delay

Tat

Fie or Angio

Jan. ‘97 2.37.00

© Changing the acceptance delay

Using the 4- and V-keys, select ‘Accept

delay":

Tanguage A

13y contract ? 62

Beep duration Bo sec

baits Metric

fxccepe deter Bro sec

Maintenan:

Temperatures

Production data

Service

Beit

info sereen + OW

Depress the OK-key :

‘Unies MeEriC,

Metric (in md

Anglo” (in fen

Brie

(er-unite 1 wetrie or Angie 4

[Press “Oke for sereim

Maintenance info screen : ON

Fomperacures

Production data

Exit

Depress the OK-key :

Tanguage

Display contrast :

Beep duration

Onits

Accept delay

Use the A- and ¥-keys to select the desired

measurement setup and then depress the OK-

key.

Maintenance info screen + ON

Tonporatares

Production date

Baie

Using the A- and ¥-keys, increase or

decrease the acceptance delay and then

depress the OK-key.

The acceptance delay can be set between 0 and §

sec.

AGFA

LITHOSTAR LP82

2 Instruction Manual

2.38.00 Jan. '97

© Setting or cancelling the maintenance info

screen

This feature allows to determine it maintenance

information is indicated on the “wenu* screen.

Using the A- and Y-keys, select

“Maintenance info screen":

Boop duration

Unies

Accept delay

pHatntenance info seri

Temperature

0-5 see

Motrie

Oro tec

Production data

Service

Exit

Language : English

Display contrast : 9B

Depress the OK-key :

Maintenance info screen t ON

ON

Beit

ean RENEE]

‘The maintenance info screen can be set /

cancelled by selecting ‘on* /‘oFe* and then

depressing the OK-key.

If the maintenance info screen has been set, the

‘wenu* screen looks as follows

Maintenance rate

Processed plates

The soreen now represents the number of printing

plates processed since the last plate counter reset

(refer to § 6.2). The screen also gives and visualises

the necessity for the maintenance by means of a so-

called ‘maintenance rate" (100% = 800 plates).

‘* Reading the temperatures of the solutions in

the different trays

This feature has been provided in order to be

able to check if the temperatures of the different

solutions of the processor do not differ too much

from their target value (the screen does not

allow any setting or calibration).

Using the A- and Y-keys, select

“Temperatures’:

Accept delay :

Maintenance info se

pTenperatures

Production data

Service

Bie

Language

Display contrast,

Beep duration

Depress the OK-key :

The first column shows the temperature which

is presently measured for the corresponding

section.

‘The second column shows the target

temperature for the different sections.

Leave the screen by depressing the OK-key.

AGFA @

LITHOSTAR LP82

* Reading the different production data

This feature has been provided in order to be

able to ask for the aiferent production data of

the processor (the screen does not allow any

resetting).

Using the A- and V-keys, select "Production

data"

vaies

Aecept delay

Maintenance info ser

peratures

|- Production data

Service

Exit

Language

Display contrast

Beep duration

Depress the OK-key :

PSST

Devel. /day i/day|— éd/mnm/yyyy

waver i Sayman/¥999

Rater/day ivday| Gayman yyyy

Fintshes i Sa/mam/Yyty

Fintes/aay Tyaay| daymmn/yyoy

Exe.

For'a1i plates’, ‘All rewash’, Developer’,

‘water’ and ‘Finisher’, the five last reset values

are kept in memory.

For ‘piates/day’, “Rewash/day’, Dovel./éay,

‘water/day’ and “Finis. /day’, the five last daily

values are kept in memory.

Instruction Manual 2

Jan. ‘97 2.39.00

The five values which are kept in memory for each

item can be obtained as follows

Ensure that the item is selected (“erates/aay" for

the following diagram) and then depress the »-key

in order to select the date :

Places/aay

All rewash

aaznmn/y¥y3)

davmmn/ 7993

8d /mmn/ 9993]

See

iiday|dd/mam/yyyy

i Sa/mnn/}339

Water/day Isday| — daymam/¥999

Finisher i Sayan /y39¥

Finis. / aa: Lvaay| aaymnn/y 999

Exit

A number (from 1 to 5) representing the memory

willbe indicated before the date and the A- and

Y-keys can be used to scroll through the

momories.

* ‘ALL plates"

Indicates the total surface of processed

printing plates since the value has been reset.

© "Plates/day"

Indicates the production of printing plates for

the present day.

© "ALL rewash*

Indicates the total surface of rewashed

printing plates since the value has been reset.

AGFA

LITHOSTAR LP82

2 Instruction Manual

2.40.00 Jan. ‘97

* "Rewash/day"

Indicates the surface of rewashed printing

plates for the present day.

Developer"

Indicates the total consumption of developer

since the value has been reset.

© "Devel. /day"

Indicates the amount of developer which has

been consumed on the present day.

* tWater*

Indicates the total consumption of water since

the value has been reset.

* CWater/day"

Indicates the amount of water which has been

consumed on the present day.

© "Finisher"

Indicates the total consumption of finisher

since the value has been reset.

© "Finis. /day’

Indicates the amount of finisher which has

been consumed on the present day.

AGFA @

LITHOSTAR LP82

Instruction Manual 2

6. Maintenance

6.1. General safety measures

Read the following safety measures attentively

before carrying out the maintenance instructions

given In this chapter :

* Consult the appropriate M.S.D.S. (Material

Safety Data Sheets) before handling chemicals

and always follow the safety instructions given

on the label of the chemicals.

© Itis recommended to wear glasses’or'safety

goggles to protect the eyes against the

splashing of chemicals.

1 the eyes have come into contact with

chemicals, rinse them thoroughly with clean and

cold running water. In case of iritation of the

eyes, immediately consult an eye specialist

* People who are sensitive to irritations or

allergies should wear safety gloves when

handling chemicals.

Ifthe skin has come into contact with

chemicals, wash thoroughly with clean

running water.

* Avoid the inhalation of chemical vapours and

ensure that the room is well-ventilated.

* Never by-pass or turn off the incorporated

safety and security devices.

© When carrying out a software-maintenance

procedure, the processor automatically enters

the OFF-mode (do not cut off the power), For

all the other interventions, ensure that the

power is cut off.

* Trouble-shooting and repairs should only be

carried out by an Agfa service technician.

dan. ‘97 2.41.00

6.2. Software-maintenance function

‘The software-maintenance function has been

provided to assist the operator when carrying out

the cleaning operations described further in this,

chapter. It offers the following possibilities :

- Reading and resetting the plate counter

(only if the maintenance info screen has

been set (refer to § 5.4)

= Circulating water in one or more trays

- Filling one or more trays

When selecting ‘kaintenance’, the processor will

automatically enter the OFF-mode (the rollers are

pened).

Start from the basic screen :

It the maintenance info screen has been set, the

‘wenu" screen also shows the maintenance

information (also refer to § 5.4).

Depress the OK-key in order to enter "Menu" and

then use the 4- and Y-keys in order to select

“Maintenance® :

Pusintenance

Single program

heck progeam

Diste”sizes

[Soto -paintenance seresm

System contrel

AGFA

LITHOSTAR LP82

2 Instruction Manual

2.42.00 Jen. ‘97

Another depression of the OK-key shows the

maintenance screen :

PLATE

Press "On" to reset the plate counter

‘Plate counter” is only indicated if tho

maintenance info screen has been set (also

refer to § 6.4).

The different possibilities offered by the above

screen are explained in the following

subparagraphs.

Contrary to the other screens described in this

instruction manual, the "ta intenaace” screen will

not be reset after § minutes.

‘+ Reading and resetting the plate counter

This feature is only available if the maintenance

info screen has been set (also refer to § 6.4).

If represented on the maintenance screen,

the item “Plate countex” gives the number