Professional Documents

Culture Documents

Brochure CCM - SH

Uploaded by

Bambang AmingOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Brochure CCM - SH

Uploaded by

Bambang AmingCopyright:

Available Formats

HOW DOES IT WORK?

The CCMs calculate the concentration

of a solution by using the different

measuring methods, and sometimes

by combining them.

DIFFERENT MODELS

INTRODUCTION There are different models of CCMs

The Rhosonics CCM stands for Chemical that can be used for different

Concentration Meter and this category of applications and in different

instruments allows measuring the industries:

concentration of chemicals and solutions in

real-time. The CCMs are designed to CCM 8500

withstand many different chemicals and to Measures the concentration of one

match harsh process conditions. chemical in a solution. It uses the

speed of sound and temperature for

that. It can be used to measure the

FEATURES AND BENEFITS concentration of H2SO4 in an acid

The major features and benefits of the plant, for example.

CCMs are:

CCM 9500

• Real-time measurement Measures the concentration of two

• Chemical resistant sensors chemicals in a solution. It uses the

• Easy operation and installation speed of sound, temperature and

conductivity for that. This technology

is used in the Copper foil plants to

measure H2SO4 & Cu++.

MEASURING METHODS

• Speed of sound CCM B30

Measures the concentration of two or

The speed of sound is determined by three chemicals in a solution. This

measuring the time that the ultrasonic meter was specially developed to

wave takes to travel over a known distance measure TMAH+PR+(CO3) in Flat

in the liquid, known as the time of flight. Panel Display manufacturing sites.

• Temperature CCM COD

Measures the COD concentration of

The temperature is measured by a Pt100, sugar-based wastewaters. This meter

used to obtain an accurate speed of sound. was specially developed to be used in

the inlet of breweries WWTP, and it

• Conductivity can also be used for the same

application in soft-drinks WWTP.

The conductivity is measured by applying

electrical current to a sensor immersed in a

solution and measuring the resulting

voltage.

INSTALLATION

The CCMs can be installed inline with

the use of a pipe integration system,

and they can also be mounted to

tanks with the use of sensors

designed for that purpose. The CCM

B30 comes with small tubes, so this

meter is installed in a by-pass.

APPLICATIONS

The CCMs can be used in a variety of

applications whenever there’s the

need for measuring chemical

concentrations. Some of the

industries where this technology can

be used are:

• Copper foil (H2SO4 & Cu++) CONTACT

• Zinc refineries (H2SO4 & Zn) Phone: +31 341 370 073

• Breweries WWTP Email: info@rhosonics.com

• Flat Panel Display manufacturing Website: www.rhosonics.com

plants

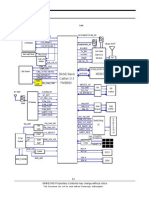

DATASHEET

CCM COD CCM 9500 CCM 8500 CCM B30

Method Speed of sound, Speed of sound, Speed of sound and Speed of sound,

General attenuation, attenuation, temperature Conductivity and

Conductivity and Conductivity and temperature

temperature temperature

Readings COD in g/l, TSS in Conductivity in Concentration in Concentration in

wt% or g/l, TDS in mS/cm, TSS in wt% WT% or g/l; WT% and

wt% or g/l, or g/l, TDS in wt% or Temperature in Temperature in

Temperature in g/l, Temperature in °Celsius °Celsius

°Celsius °Celsius

Accuracy 0.1 g/l COD, 0.1 Up to 0.02 wt%. Up to 0.02 wt%. Up to 0.001 wt% (1

mS/cm conductivity. ppm)

In the inlet of a

breweries WWTP in

a range of 0-50 g/l

at 18-50 in °Celsius

Power supply 18-32 VDC 18-32 VDC 18-32 VDC 18-32 VDC

Transmitter

Output 4-20mA outputs 4-20mA outputs 4-20mA outputs Modbus RTU over

(2x), Alarm output (2x), Alarm output (2x), Alarm output RS-232

(2x), RS485/RS422 (2x), RS485/RS422 (2x), RS485/RS422

using Modbus using Modbus using Modbus

Optional: 4-20 mA Optional: 4-20 mA Optional: 4-20 mA

input, Ethernet, input, Ethernet, input, Ethernet,

HART, Profibus HART, Profibus HART, Profibus

Data logging USB data logging & USB data logging & USB data logging & Continuous;

fault reporting fault reporting fault reporting retrievable via USB

stick

Cable glands 5x M20x1.5 for Ø4-9 5x M20x1.5 for Ø4-9 5x M20x1.5 for Ø4-9 2x M16X1.5 for Ø 2-

mm cable mm cable mm cable 6 mm cable

Ambient -20 °C to +65 °C -20 °C to +65 °C -20 °C to +65 °C 5 °C to +60 °C

(-4 °F to 149 °F) (-4 °F to 149 °F) (-4 °F to 149 °F) (41 °F to 140 °F)

temperature

Humidity < 95% at 40 °C < 95% at 40 °C < 95% at 40 °C < 95% at 40 °C

(noncondensing) (noncondensing) (noncondensing) (noncondensing)

Protection IP65, NEMA 4X IP65, NEMA 4X IP65, NEMA 4X IP65, NEMA 4X

rating

Materials Epoxy coated steel Epoxy coated steel Epoxy coated steel POM / Stainless

Optional: SS304 or Optional: SS304 or Optional: SS304 or Steel

SS316 SS316 SS316 Wetted parts in

Ceramics and PVDF

Display 5,7” Color Touch 5,7” Color Touch 5,7” Color Touch 240x128 dots

Screen Screen Screen (WxH), 5 colors

Installation Inline via a spool- Inline via a spool- Inline or side- Via a by-pass (PVDF

piece; and in-tank piece or cell (3/4”); mounted to tanks BSPT 3/8" female

via tank sensor and in-tank via tank connector)

sensor

©2022 RHOSONICS ∙ SPECIFICATIONS ARE SUBJECT TO CHANGE WITHOUT NOTICE –03/2022

You might also like

- CO2 Duct Transmitter Detects Temperature, RH & CO2Document4 pagesCO2 Duct Transmitter Detects Temperature, RH & CO2Edward Quispe CervantesNo ratings yet

- Elster EnCal 3000 H2S Rev 05Document2 pagesElster EnCal 3000 H2S Rev 05Tania NoorNo ratings yet

- Flexible. Intuitive. Tailored For You.: Water Analysis SystemDocument8 pagesFlexible. Intuitive. Tailored For You.: Water Analysis SystemFranco ArellanoNo ratings yet

- Hobre GatekeeperDocument4 pagesHobre GatekeeperTeymur AzizovNo ratings yet

- ApN EnCal 3000 H2S 20100427Document2 pagesApN EnCal 3000 H2S 20100427mohamedwalyNo ratings yet

- Carel Temperature and Humiditify Sensors PDFDocument1 pageCarel Temperature and Humiditify Sensors PDFElşən Yusifoğlu ƏsgərovNo ratings yet

- Powerful Portable Flue Gas AnalyserDocument2 pagesPowerful Portable Flue Gas Analyserzane truesdaleNo ratings yet

- Density Measurement For Quality Monitoring and Process ControlDocument20 pagesDensity Measurement For Quality Monitoring and Process ControlBrijesh GajjarNo ratings yet

- AAS 920 600C Telaire T3000 121218 WebDocument4 pagesAAS 920 600C Telaire T3000 121218 WebBang NagaNo ratings yet

- Mediciones CEMS - ZZ-025-0802EDocument4 pagesMediciones CEMS - ZZ-025-0802EdcarunchioNo ratings yet

- Sensor de Temperatura e Umidade CarelDocument1 pageSensor de Temperatura e Umidade CarelMayconLimaNo ratings yet

- Low Cost - High Performance Devices For HVAC ProfessionalsDocument4 pagesLow Cost - High Performance Devices For HVAC ProfessionalscarlosNo ratings yet

- Euro Trade Price List 2023 - VCP SwedenDocument32 pagesEuro Trade Price List 2023 - VCP Swedennathan.trabajo1No ratings yet

- Carbo 510 Smart Sensor Carbo 2100 MVE: CO Analyzers For BeveragesDocument6 pagesCarbo 510 Smart Sensor Carbo 2100 MVE: CO Analyzers For BeveragesQuang TrầnNo ratings yet

- Nitoring Methane Slip: Why em ?Document2 pagesNitoring Methane Slip: Why em ?Arunkumar MuthukrishnanNo ratings yet

- Isweek F2000TSM-CO2 Series Carbon Dioxide DetectorDocument3 pagesIsweek F2000TSM-CO2 Series Carbon Dioxide DetectorindustrialNo ratings yet

- FMGCEM40xx Series: Flue Gas AnalyserDocument6 pagesFMGCEM40xx Series: Flue Gas AnalyserMeindert gerssenNo ratings yet

- Single Point Gas DetectorDocument4 pagesSingle Point Gas Detectorahmsa.morsyNo ratings yet

- GasguideDocument2 pagesGasguideJulio Cesar VazquezNo ratings yet

- Dco-S4Document3 pagesDco-S4vinodharan mahalingamNo ratings yet

- 920 Multi-Gas Analyzer: Product Data SheetDocument2 pages920 Multi-Gas Analyzer: Product Data Sheetlaoying qdNo ratings yet

- TCS ManualDocument19 pagesTCS Manualtanya.wuNo ratings yet

- FDO2 Optical Oxygen Sensor Data SheetDocument14 pagesFDO2 Optical Oxygen Sensor Data SheetZoran ConstantinescuNo ratings yet

- Product ComparisonDocument2 pagesProduct Comparisonm mNo ratings yet

- Chlorine Gas DetectorDocument3 pagesChlorine Gas Detectormohamad chaudhariNo ratings yet

- GasAlert XT Datasheet (5558 10 En)Document2 pagesGasAlert XT Datasheet (5558 10 En)nkouhiNo ratings yet

- Haffmans C-DGM: CO / O GehaltemeterDocument2 pagesHaffmans C-DGM: CO / O GehaltemeterXANPHOXYL KIBETNo ratings yet

- Rotronic Pharma Broschuere 3Document8 pagesRotronic Pharma Broschuere 3CarlosNo ratings yet

- ManualDocument7 pagesManualAsri GaniNo ratings yet

- CRL-DS-01550-En - Coriolis RCT1000 With RCS005 and RCS008 Sensors Product Data SheetDocument8 pagesCRL-DS-01550-En - Coriolis RCT1000 With RCS005 and RCS008 Sensors Product Data SheetSankarNo ratings yet

- 4 Brimstone Specifications 943TGX April 2022 - R1Document1 page4 Brimstone Specifications 943TGX April 2022 - R1Francisco Rodriguez G.No ratings yet

- Process GCs/Process Analyzers (Total VOCs)Document4 pagesProcess GCs/Process Analyzers (Total VOCs)Jennifer MaclachlanNo ratings yet

- Intelligent Gas Sensor Monitors Toxic GasesDocument2 pagesIntelligent Gas Sensor Monitors Toxic GasesVincent GabrielNo ratings yet

- D3230 Leaflet NSB Tech ENGDocument4 pagesD3230 Leaflet NSB Tech ENGEng-sadeq HesseinNo ratings yet

- room-co2-transmitter-cdr-100vaDocument3 pagesroom-co2-transmitter-cdr-100vanfasimoes.trmNo ratings yet

- Gasalertextreme Datasheet 5558-10-EnDocument2 pagesGasalertextreme Datasheet 5558-10-Enapi-433779908No ratings yet

- Sps Siot SCT Series Humidity Temperature Wall Mount Transducers Datasheet 32302444 A en Ciid 155859Document7 pagesSps Siot SCT Series Humidity Temperature Wall Mount Transducers Datasheet 32302444 A en Ciid 155859DoniNo ratings yet

- Gas Alert Extreme Data Sheet 555812 enDocument2 pagesGas Alert Extreme Data Sheet 555812 enAlvaro Muñoz BaezaNo ratings yet

- CODEL CEMS and Process ProductsDocument10 pagesCODEL CEMS and Process ProductsnguyenanhtuanbNo ratings yet

- Portable Co2 O2 Tpo Meter C DGM Haffmans Leaflet v2048 enDocument2 pagesPortable Co2 O2 Tpo Meter C DGM Haffmans Leaflet v2048 entayachewendayehuNo ratings yet

- Flygt ENM-10 Floating SwitchDocument4 pagesFlygt ENM-10 Floating SwitchWharfedale100% (2)

- B-Atmos-14-EDocument2 pagesB-Atmos-14-Ejoel abrahamNo ratings yet

- Field Thermal Mass Flowmeter FMT400-VTS, FMT400-VTCS (Sensyflow VT-S/VT-CS)Document16 pagesField Thermal Mass Flowmeter FMT400-VTS, FMT400-VTCS (Sensyflow VT-S/VT-CS)Ali JawadNo ratings yet

- CO2 Salida Analogax3Document4 pagesCO2 Salida Analogax3Tomas VelasquezNo ratings yet

- Endress-Hauser Dosimag 5BH ENDocument4 pagesEndress-Hauser Dosimag 5BH ENDiki DikiNo ratings yet

- 330 2LLdatasheetDocument2 pages330 2LLdatasheetanibalqNo ratings yet

- Analyser For Measurement of Toxic Gases AMS 6420: The ApplicationDocument2 pagesAnalyser For Measurement of Toxic Gases AMS 6420: The ApplicationSayak BoseNo ratings yet

- CEMS SpecificationDocument10 pagesCEMS SpecificationPriyabrat KumarNo ratings yet

- New Dew Point sensor S220 (Suto-itec) 메뉴얼Document6 pagesNew Dew Point sensor S220 (Suto-itec) 메뉴얼빠끄No ratings yet

- CO2 RoomDocument2 pagesCO2 RoomAlan TanNo ratings yet

- Brochure CDM SHDocument4 pagesBrochure CDM SHBambang AmingNo ratings yet

- Chlorine Measurement Probes GuideDocument1 pageChlorine Measurement Probes GuideAmir NooriNo ratings yet

- Product Data Sheet 700xa Process Gas Chromatograph en 70652Document20 pagesProduct Data Sheet 700xa Process Gas Chromatograph en 70652Jamshed AhmedNo ratings yet

- Smart Titrator PAT940Document9 pagesSmart Titrator PAT940Vasily IgnatovNo ratings yet

- 1 Product Category SpecialDocument16 pages1 Product Category SpecialOmar SaeedNo ratings yet

- Lo Flo 020513Document2 pagesLo Flo 020513Eng - Mohamed MakramNo ratings yet

- MGA 12 EX Multi Gas Analyser for Explosive AtmospheresDocument2 pagesMGA 12 EX Multi Gas Analyser for Explosive AtmospheresTrung TrinhNo ratings yet

- Millimeter-Wave Receiver Concepts for 77 GHz Automotive Radar in Silicon-Germanium TechnologyFrom EverandMillimeter-Wave Receiver Concepts for 77 GHz Automotive Radar in Silicon-Germanium TechnologyNo ratings yet

- Newnes Radio and Electronics Engineer's Pocket Book: Revised by the Editorial Staff of Electronics Today InternationalFrom EverandNewnes Radio and Electronics Engineer's Pocket Book: Revised by the Editorial Staff of Electronics Today InternationalNo ratings yet

- Industrial Hub SwitchDocument2 pagesIndustrial Hub SwitchBambang AmingNo ratings yet

- Phoenix Contact 3044076 enDocument56 pagesPhoenix Contact 3044076 enBambang AmingNo ratings yet

- Kuka PB Palettierer enDocument13 pagesKuka PB Palettierer ensoniaNo ratings yet

- Buenergyv2 2en PDFDocument6 pagesBuenergyv2 2en PDFBambang AmingNo ratings yet

- Mass Flow Measurement Without Media ContactDocument6 pagesMass Flow Measurement Without Media ContactBambang AmingNo ratings yet

- Phoenix Contact 0310020 en PDFDocument4 pagesPhoenix Contact 0310020 en PDFBambang AmingNo ratings yet

- Brochure CDM SHDocument4 pagesBrochure CDM SHBambang AmingNo ratings yet

- Brochure Rhosonics Clamp-InDocument2 pagesBrochure Rhosonics Clamp-InBambang AmingNo ratings yet

- Control Technology, IO Systems and Automation Infrastructure-2Document1 pageControl Technology, IO Systems and Automation Infrastructure-2Bambang AmingNo ratings yet

- Brochure CDM SHDocument4 pagesBrochure CDM SHBambang AmingNo ratings yet

- En HQ Proficloud LoresDocument12 pagesEn HQ Proficloud LoresBambang AmingNo ratings yet

- Industrial Hub Switch-1Document1 pageIndustrial Hub Switch-1Bambang AmingNo ratings yet

- Process Indikator 96x48Document45 pagesProcess Indikator 96x48Bambang AmingNo ratings yet

- Tsfluxus S831v1-0en LeuDocument8 pagesTsfluxus S831v1-0en LeuBambang AmingNo ratings yet

- PLC relay modules for industrial automationDocument14 pagesPLC relay modules for industrial automationBambang AmingNo ratings yet

- Power Supply 5 AmpereDocument16 pagesPower Supply 5 AmpereBambang AmingNo ratings yet

- NameDocument1 pageNameMiin MiinNo ratings yet

- Digital Display - FA MCR-D-TUI-UI-2REL-UP - 2907064: Key Commercial DataDocument7 pagesDigital Display - FA MCR-D-TUI-UI-2REL-UP - 2907064: Key Commercial DataBambang AmingNo ratings yet

- Solid-State Relays - PLC-HPT-24DC/230AC/10 - 2905215: Key Commercial DataDocument13 pagesSolid-State Relays - PLC-HPT-24DC/230AC/10 - 2905215: Key Commercial DataBambang AmingNo ratings yet

- Wireless Module - FL WLAN 5110 - 1043193: Key Commercial DataDocument9 pagesWireless Module - FL WLAN 5110 - 1043193: Key Commercial DataBambang AmingNo ratings yet

- Power Supply Unit - QUINT4-PS/3AC/24DC/40/IOL - 1151047: Key Commercial DataDocument16 pagesPower Supply Unit - QUINT4-PS/3AC/24DC/40/IOL - 1151047: Key Commercial DataBambang AmingNo ratings yet

- Resume for Marketing CoordinatorDocument1 pageResume for Marketing CoordinatorArbi Yuda PamungkasNo ratings yet

- Installation and Commissioning FL WLAN 101x/201x Product FamilyDocument46 pagesInstallation and Commissioning FL WLAN 101x/201x Product FamilyBambang AmingNo ratings yet

- August 2020Document2 pagesAugust 2020Charry RoblesNo ratings yet

- CH 2 - Op-Amp ApplicationDocument52 pagesCH 2 - Op-Amp Applicationknighthood4all100% (2)

- Caterpillar 988 Wheel Loader Operators Manual SN 87aDocument6 pagesCaterpillar 988 Wheel Loader Operators Manual SN 87aCarlos Cetina100% (1)

- NVRAM Troubleshooting GuideDocument8 pagesNVRAM Troubleshooting GuideGerardo SantiagoNo ratings yet

- How Do I Fix The Error - Failed To Initialize The Aspen Properties Enterprise DatabaseDocument7 pagesHow Do I Fix The Error - Failed To Initialize The Aspen Properties Enterprise DatabaseSaidFerdjallahNo ratings yet

- Are Harmonics Still A Problem in Data CentersDocument11 pagesAre Harmonics Still A Problem in Data CentersAnonymous dM4QtbCJ0No ratings yet

- Introduction To RoboticsDocument17 pagesIntroduction To RoboticsBharath ThatipamulaNo ratings yet

- Empowerment Technology Quarter 1 Week 2Document12 pagesEmpowerment Technology Quarter 1 Week 2BananaNo ratings yet

- Plugs Modulares AmpDocument14 pagesPlugs Modulares AmpAstrid Marin PalaciosNo ratings yet

- Sensor - EC-5 para Umidade Do SoloDocument24 pagesSensor - EC-5 para Umidade Do SoloDanilo AndradeNo ratings yet

- Surpass Hit 7025Document2 pagesSurpass Hit 7025Đỗ TháiNo ratings yet

- OperManual SB ST310U Rev112 09 12 2017 PDFDocument67 pagesOperManual SB ST310U Rev112 09 12 2017 PDFrichardNo ratings yet

- Intel® Compute Stick Stk1Aw32Sc STK1A32SC: Technical Product SpecificationDocument27 pagesIntel® Compute Stick Stk1Aw32Sc STK1A32SC: Technical Product SpecificationjohnyredblueNo ratings yet

- Keppel LeTourneauDocument16 pagesKeppel LeTourneauArun Santhakumaran100% (1)

- Seeding To A Plan: by ShivanaDocument31 pagesSeeding To A Plan: by ShivanaShivanagowda SannagowdarNo ratings yet

- Level 3 Troubleshooting GuideDocument44 pagesLevel 3 Troubleshooting GuideFabiomarferreira100% (1)

- Digital B2B Marketing Strategies of Kuehne + NagelDocument5 pagesDigital B2B Marketing Strategies of Kuehne + NagelRahul GuptaNo ratings yet

- Cs101 Midterm Solved Paper With ReferenceDocument5 pagesCs101 Midterm Solved Paper With ReferenceAqsa AhsanNo ratings yet

- Validation Criteria ChecklistDocument3 pagesValidation Criteria Checklistbacharnaja0% (1)

- Contemporary Issues and The Impact of Technology On MADocument30 pagesContemporary Issues and The Impact of Technology On MALHNo ratings yet

- Ebook Business Continuity PlanningDocument14 pagesEbook Business Continuity Planningapi-464002100No ratings yet

- Viewsat Ultra Manual V01Document21 pagesViewsat Ultra Manual V01Frank BarrettoNo ratings yet

- Siemens JD 400ADocument4 pagesSiemens JD 400Amc1256No ratings yet

- Mobile App Development Proposal For EcommerceDocument8 pagesMobile App Development Proposal For EcommerceRiya Chawla100% (1)

- Job Egress-A Gateway To Experience The Work: Vivek Kumar Sehgal Akshay Jagtiani, Meha ShahDocument8 pagesJob Egress-A Gateway To Experience The Work: Vivek Kumar Sehgal Akshay Jagtiani, Meha ShahBoga SandhyaNo ratings yet

- MIS EndTerm MBA07032 DakshMalhotraDocument6 pagesMIS EndTerm MBA07032 DakshMalhotraDakshNo ratings yet

- High Reliability Hall Effect SensorDocument2 pagesHigh Reliability Hall Effect SensorHari KiranNo ratings yet

- White Paper c11 733618Document32 pagesWhite Paper c11 733618Luca OrabonaNo ratings yet

- User Manual ADM PDFDocument464 pagesUser Manual ADM PDFLuis100% (1)

- Best Android 4Document17 pagesBest Android 4Ishan LakhwaniNo ratings yet

- Injector Sleeve Installation On 2008-2017 Detroit Diesel DD15 & 16 Diesel EnginesDocument2 pagesInjector Sleeve Installation On 2008-2017 Detroit Diesel DD15 & 16 Diesel EnginesIonut-alexandru IordacheNo ratings yet