Professional Documents

Culture Documents

Typical Properties of Britesorb® L10

Uploaded by

Dhil0 ratings0% found this document useful (0 votes)

109 views1 pageOriginal Title

BRITESORBL10

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

109 views1 pageTypical Properties of Britesorb® L10

Uploaded by

DhilCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

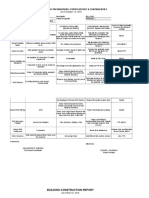

BRITESORB® L10

BRITESORB L10 is a silica xerogel powder

specifically produced for beer stabilization.

BRITESORB L10 combines good stabilization

performance with excellent filtration and minimal

dusting. BRITESORB L10 selectively removes

haze-forming proteins from beer without adversely

affecting flavor, foam, or filtration rate.

BRITESORB L10 Benefits:

• Food-grade product

• Extends non-biological beer stability by

removal of haze-forming proteins

• Does not affect beer-foam active components

• Insoluble in beer. Accepted by all brewing

traditions.

• Non-hazardous and environmentally friendly.

• Cost-effective.

BRITESORB L10 Dose Rates:

Beers up to 70% malt ratio are typically treated with

25-40 g/hL of BRITESORB L10 (5-10 #/100US

bbl). Beers greater than 70% malt ratio can require

Typical Properties of up to 60 g/hL (15#/100USbbl). Analysis of the beer

BRITESORB® L10 will give best dose rate. BRITESORB L10 is best

prepared as a 10% slurry in chilled de-areated

SiO2, ignited basis (%), FCC standard >94 water. Contact time should be minimum 20

pH (12% slurry) 8 minutes. Filtration temperature should be

Surface area (m2/g) 500 maximum 32oF.

Loss on drying @ 105oC (%) 3

BRITESORB L10 Storage & Handling:

Median particle diameter (µm) 10

Store the product in unopened bags in a dry place

Permeability (D’Arcy) 0.02 with temperatures between 35oF and 95oF. Product

is amorphous (no crystalline silica). Avoid dusting.

Please consult the MSDS available on request.

BRITESORB beer stabilizers are manufactured in

our state-of-the-art production facilities to meet all

regulatory requirements for food-grade silica.

Put BRITESORB L10 to your own test. Contact us

P.O. Box 840, Valley Forge, today to find out how this product can help you save

Pennsylvania 19482-0840 USA time and money brewing a beer that is clearly

Tel.: 01-800-944-7411 better.

www.pqcorp.com

You might also like

- Acusera Brochure May14 085007Document112 pagesAcusera Brochure May14 085007SeftiyantiNo ratings yet

- Cleaning and disinfection of food factories: a practical guideFrom EverandCleaning and disinfection of food factories: a practical guideNo ratings yet

- XYZ Laboratory: Iso/Iec 17025 Quality ManualDocument13 pagesXYZ Laboratory: Iso/Iec 17025 Quality ManualvictorNo ratings yet

- Analytical Methods for Drinking Water: Advances in Sampling and AnalysisFrom EverandAnalytical Methods for Drinking Water: Advances in Sampling and AnalysisNo ratings yet

- SOP of Gram StainDocument5 pagesSOP of Gram Stainzalam55100% (1)

- Laboratory Testing Turn-Around Times PolicyDocument5 pagesLaboratory Testing Turn-Around Times PolicyGHL AdaroNo ratings yet

- Quality ControlDocument15 pagesQuality Controlحسام الدين الحيفيNo ratings yet

- Sop For StaphDocument6 pagesSop For StaphLala SaadNo ratings yet

- Validation and Evaluation of Eight Commercially Available Point of Care CRP MethodsDocument7 pagesValidation and Evaluation of Eight Commercially Available Point of Care CRP MethodsAle AraujoNo ratings yet

- SOP for Good Laboratory PracticeDocument6 pagesSOP for Good Laboratory PracticeYousif50% (2)

- Laboratory SOPsDocument286 pagesLaboratory SOPsMohamed Annavi100% (1)

- ISO 17025 IntroDocument6 pagesISO 17025 Introakash batraNo ratings yet

- Manual For Procurement of Diagnostics-001-June2013Document34 pagesManual For Procurement of Diagnostics-001-June2013Jose MirandaNo ratings yet

- Laboratory ScopesDocument67 pagesLaboratory ScopesNash Si100% (1)

- ORA-LAB.4.13 Record and Data Management (v02)Document11 pagesORA-LAB.4.13 Record and Data Management (v02)Vedang BhagwatNo ratings yet

- Turbichem Ferritin 1Document2 pagesTurbichem Ferritin 1Dharmesh PatelNo ratings yet

- Autoclave SOPDocument7 pagesAutoclave SOPdeepanmb007No ratings yet

- Alcohol Determination Apparatus KitDocument2 pagesAlcohol Determination Apparatus KitMulayam Singh YadavNo ratings yet

- ORA-LAB.5.3 Facilities and Environmental Conditions (v02)Document9 pagesORA-LAB.5.3 Facilities and Environmental Conditions (v02)allysa almagroNo ratings yet

- Beloor Bayir Biotech Limited, Unit-Iii, Tumkur Certificate of AnalysisDocument1 pageBeloor Bayir Biotech Limited, Unit-Iii, Tumkur Certificate of Analysisad11010010No ratings yet

- Quality Control in Blood BankDocument46 pagesQuality Control in Blood BankTanyaNo ratings yet

- Refractive Index SOPDocument2 pagesRefractive Index SOPsuresh kumar100% (1)

- SOP For Operation and Calibration of PH Meter - Pharmaceutical GuidelinesDocument3 pagesSOP For Operation and Calibration of PH Meter - Pharmaceutical GuidelinesMushtaq KhanNo ratings yet

- Insert - CA 19-9 CalSet - Ms - 11776215122.v18.enDocument2 pagesInsert - CA 19-9 CalSet - Ms - 11776215122.v18.enYousra ZeidanNo ratings yet

- ISO 6888-1:1999 + A1: 2003 StaphDocument5 pagesISO 6888-1:1999 + A1: 2003 StaphsylvanaNo ratings yet

- MS-LM Laboratory Quality Manual - MasterDocument35 pagesMS-LM Laboratory Quality Manual - MasterFatt Vui HuangNo ratings yet

- ISO 63212002 (E) Slip Melting PointDocument11 pagesISO 63212002 (E) Slip Melting PointLam Lai YanNo ratings yet

- EuSalt AS008-2005 Potassium - Flame Atomic Absorption Spectrometric MethodDocument4 pagesEuSalt AS008-2005 Potassium - Flame Atomic Absorption Spectrometric MethodRuth Patinggi LPNo ratings yet

- Experiment (1) Volumetric Glassware and BalancesDocument8 pagesExperiment (1) Volumetric Glassware and BalancesMarah mazNo ratings yet

- BME-01 Equipment Iddentification TagDocument4 pagesBME-01 Equipment Iddentification TagPAPPU RANJITH KUMARNo ratings yet

- Analysis of Vitamins A and E by HPLCDocument9 pagesAnalysis of Vitamins A and E by HPLCamit545No ratings yet

- Chpt13 Quality Control AssuranceDocument7 pagesChpt13 Quality Control Assurancevisini100% (1)

- IQCPDocument1 pageIQCPPrabhu Selvaraj100% (1)

- Instructions For Use Trig: VITROS Chemistry Products TRIG SlidesDocument13 pagesInstructions For Use Trig: VITROS Chemistry Products TRIG SlidesSaravnan RajendranNo ratings yet

- McFarland StandardsDocument2 pagesMcFarland StandardsAlaa Noureldeen67% (3)

- Water System Reagents 072014Document3 pagesWater System Reagents 072014Mamang EstepeNo ratings yet

- Sample Procedure For Method Validation 1.: Document Control: SAP - Approved 20161221 Page 1 of 7Document7 pagesSample Procedure For Method Validation 1.: Document Control: SAP - Approved 20161221 Page 1 of 7YAMA ENGINEERSNo ratings yet

- Sop 2Document51 pagesSop 2ALCAZAR, RENZ JAZTINE R.100% (1)

- Leaning The Quality Control LaboratoryDocument7 pagesLeaning The Quality Control LaboratoryNarongchai PongpanNo ratings yet

- Randox ControlDocument103 pagesRandox ControlSunlifecare CardNo ratings yet

- Sop ASP HPLCDocument12 pagesSop ASP HPLCAngel PalominoNo ratings yet

- Sops IndexDocument3 pagesSops IndexIbrahim IssaNo ratings yet

- Quality Assurance in The Blood Transfusion LabDocument25 pagesQuality Assurance in The Blood Transfusion LabMichelle AnsahNo ratings yet

- Omnex Internal Auditor Training For ISO 17025 - 2017Document1 pageOmnex Internal Auditor Training For ISO 17025 - 2017allaboutfreeNo ratings yet

- Iso 15189 Manual DocumentsDocument10 pagesIso 15189 Manual DocumentsLisyaNo ratings yet

- STP of Ethifen SyrupDocument5 pagesSTP of Ethifen SyrupBejoy KarimNo ratings yet

- Stool SOPDocument8 pagesStool SOPchilsano47No ratings yet

- Chemistry and Tox InfoDocument129 pagesChemistry and Tox InfoGodstruthNo ratings yet

- Quality Standards for HIV Testing Labs ManualDocument137 pagesQuality Standards for HIV Testing Labs ManualMohandoss Murugesan0% (1)

- Aurora: Transform 680 Microwave Digestion SystemDocument1 pageAurora: Transform 680 Microwave Digestion SystemangelNo ratings yet

- SOP For Analysis of WaterDocument9 pagesSOP For Analysis of WaterGencay ErginNo ratings yet

- BSF Policy - RetentionDocument2 pagesBSF Policy - RetentionDarren CariñoNo ratings yet

- HIV 12 Stat Pak Dipstick Product Packet EnglishDocument6 pagesHIV 12 Stat Pak Dipstick Product Packet EnglishSagkyNo ratings yet

- Nystatin Oral Suspension AMVDocument33 pagesNystatin Oral Suspension AMVOm PandeyNo ratings yet

- ISO 17025 Laboratory Accreditation PresentationDocument19 pagesISO 17025 Laboratory Accreditation PresentationschwarthraulNo ratings yet

- Vitamin Analysis by HPLCDocument4 pagesVitamin Analysis by HPLCJuan PerezNo ratings yet

- NABL 142 Policy On Calibration & TreasebilityDocument5 pagesNABL 142 Policy On Calibration & Treasebilitysudhasesh2000100% (2)

- Biosystems ListadoDocument48 pagesBiosystems ListadoJorge PinedaNo ratings yet

- The New ISO 16140 Standards.: Paul in 'T Veld, Food and Consumer Product Safety Authority (NWVA), The NetherlandsDocument23 pagesThe New ISO 16140 Standards.: Paul in 'T Veld, Food and Consumer Product Safety Authority (NWVA), The Netherlandssajid waqasNo ratings yet

- Biofoam: Dosage Rate Application InformationDocument2 pagesBiofoam: Dosage Rate Application InformationDhilNo ratings yet

- TEC - Wi.04.01.31 Calcium Determination inDocument3 pagesTEC - Wi.04.01.31 Calcium Determination inDhilNo ratings yet

- Brewing Process Performance 1Document1 pageBrewing Process Performance 1DhilNo ratings yet

- KINGFISHER BREWING RECIPEDocument6 pagesKINGFISHER BREWING RECIPEDhilNo ratings yet

- DNA Affirmative - MSDI 2015Document146 pagesDNA Affirmative - MSDI 2015Michael TangNo ratings yet

- Inertial Reference Frames: Example 1Document2 pagesInertial Reference Frames: Example 1abhishek murarkaNo ratings yet

- Best Home Oxygen Concentrators-Lowest Prices & Fast Shipping (Oxygen Machines) - 2021 - YuwellDocument1 pageBest Home Oxygen Concentrators-Lowest Prices & Fast Shipping (Oxygen Machines) - 2021 - YuwellPelayanan ResusitasiNo ratings yet

- Stellar Structure and EvolutionDocument222 pagesStellar Structure and Evolutionjano71100% (2)

- Document-SAP EWM For Fashion 1.0: 1.general IntroductionDocument3 pagesDocument-SAP EWM For Fashion 1.0: 1.general IntroductionAnonymous u3PhTjWZRNo ratings yet

- SMEs, Trade Finance and New TechnologyDocument34 pagesSMEs, Trade Finance and New TechnologyADBI EventsNo ratings yet

- Chanel SWOT AnalysisDocument5 pagesChanel SWOT AnalysisJeish KimNo ratings yet

- Staining TechniquesDocument31 pagesStaining TechniquesKhadija JaraNo ratings yet

- Barelwiyah, Barelvi Chapter 1 (Part 2 of 5)Document31 pagesBarelwiyah, Barelvi Chapter 1 (Part 2 of 5)Dawah ChannelNo ratings yet

- Organic Facial Remedies Versus Inorganic Facial RemediesDocument13 pagesOrganic Facial Remedies Versus Inorganic Facial Remediesapi-271179911No ratings yet

- WEEK 8. - Gen Math-PortfolioDocument12 pagesWEEK 8. - Gen Math-PortfolioOreo ProductionsNo ratings yet

- Biamp Vocia Catalog Apr2020Document24 pagesBiamp Vocia Catalog Apr2020Mahavir Shantilal DhokaNo ratings yet

- Sample QuestionsDocument70 pagesSample QuestionsBushra MaryamNo ratings yet

- Structural IfpDocument4 pagesStructural IfpDanny NguyenNo ratings yet

- LNG Vaporizers Using Various Refrigerants As Intermediate FluidDocument15 pagesLNG Vaporizers Using Various Refrigerants As Intermediate FluidFrandhoni UtomoNo ratings yet

- PediculosisDocument14 pagesPediculosisREYMARK HACOSTA100% (1)

- Monster Visual Discrimination CardsDocument9 pagesMonster Visual Discrimination CardsLanaNo ratings yet

- Fehniger Steve-Pump VibrationDocument35 pagesFehniger Steve-Pump VibrationSheikh Shoaib100% (1)

- OPHTHALDocument8 pagesOPHTHALVarun ChandiramaniNo ratings yet

- Telecommunications TechnicianDocument4 pagesTelecommunications Technicianapi-78381064No ratings yet

- Clarinet Lecture Recital - Jude StefanikDocument35 pagesClarinet Lecture Recital - Jude Stefanikapi-584164068No ratings yet

- Delhi (The Capital of India) : Ebook by Ssac InstituteDocument27 pagesDelhi (The Capital of India) : Ebook by Ssac InstituteAnanjay ChawlaNo ratings yet

- Bhakti Trader Ram Pal JiDocument232 pagesBhakti Trader Ram Pal JiplancosterNo ratings yet

- Winkens Et Al 2009Document8 pagesWinkens Et Al 2009Marta SanchezNo ratings yet

- Class Opening Preparations Status ReportDocument3 pagesClass Opening Preparations Status ReportMaria Theresa Buscato86% (7)

- Quality Improvement Reading Material1Document10 pagesQuality Improvement Reading Material1Paul Christopher PinedaNo ratings yet

- Google Search StringsDocument12 pagesGoogle Search StringsPrashant Sawnani100% (1)

- Admission Procedure For International StudentsDocument8 pagesAdmission Procedure For International StudentsAndreea Anghel-DissanayakaNo ratings yet

- 10 Tips To Support ChildrenDocument20 pages10 Tips To Support ChildrenRhe jane AbucejoNo ratings yet

- Icelandic Spells and SigilsDocument16 pagesIcelandic Spells and SigilsSimonida Mona Vulić83% (6)