Professional Documents

Culture Documents

Consolidated Undrained Triaxial Compression Test For Undisturbed Soils

Consolidated Undrained Triaxial Compression Test For Undisturbed Soils

Uploaded by

Faten Abou ShakraOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Consolidated Undrained Triaxial Compression Test For Undisturbed Soils

Consolidated Undrained Triaxial Compression Test For Undisturbed Soils

Uploaded by

Faten Abou ShakraCopyright:

Available Formats

CONSOLIDATED UNDRAINED TRIAXIAL COMPRESSION TEST FOR

TXDOT DESIGNATION: TEX-131-E

UNDISTURBED SOILS

Test Procedure for

CONSOLIDATED UNDRAINED TRIAXIAL

COMPRESSION TEST FOR UNDISTURBED SOILS

TxDOT Designation: Tex-131-E

Effective Date: August 1999

1. SCOPE

1.1 This method determines the angle of internal friction (φ) and cohesion (c) strength

parameters of soils by triaxial compression testing.

1.2 When pore pressures are measured, the effective values of internal friction and cohesion,

(φ') and (c') respectively, can be calculated.

1.3 The values given in parentheses (if provided) are not standard and may not be exact

mathematical conversions. Use each system of units separately. Combining values from

the two systems may result in nonconformance with the standard.

2. APPARATUS

2.1 Loading device, a variable-speed, motor-driven, screw, or other compression system that

is strain-controlled, having sufficient capacity and sensitivity. (See Figure 1.)

2.2 Load measuring device, such as a proving ring, normally mounted on the outside of the

test chamber, capable of measuring axial loads to within 1.0% of the anticipated load at

failure. An electronic load cell may also be used to measure the axial loads applied to the

test specimen, mounted inside the test chamber. When a load cell is used, the following

accessory electronic equipment may be needed to indicate the loads:

2.2.1 Amplifier, to increase the electrical signals from the load cell so they are sufficiently large

to be detected by a digital voltmeter or strip chart recorder.

2.2.2 Power source, constant voltage, to excite the load cell or pressure transducer.

2.2.3 DC bridge balance, to balance the electrical circuits of the measuring system.

2.2.4 Data recording device, to indicate the load or pressure.

2.3 Deformation indicator, a dial extensiometer graduated to 0.03 mm (0.001 in.), with a

travel of about 10% of the length of the test specimen, or other comparable device.

CONSTRUCTION DIVISION 1 – 10 LAST REVIEWED: SEPTEMBER 2014

CONSOLIDATED UNDRAINED TRIAXIAL COMPRESSION TEST FOR

TXDOT DESIGNATION: TEX-131-E

UNDISTURBED SOILS

2.4 Trimming equipment, including a frame, equipment capable of measuring the dimensions

of the specimen to the nearest 0.3 mm (0.01 in.), sample cutter, end-trimming device,

trimming and carving tools.

2.5 Pore pressure device, a closed manometer, a null indicator, or a pressure transducer.

When a pressure transducer is used, the same data acquisition system used to monitor

loads may be used.

2.6 Drying oven, thermostatically controlled, capable of maintaining a temperature of

110 ± 5°C (230 ± 9°F).

2.7 Balance, Class G2 in accordance with Tex-901-K, minimum capacity of 4000 g.

2.8 Pressure chamber, including sample base plate, porous stone, two lubricated end plates

(optional), O-rings or other seals, stopcock valve, sample header, tubing for drainage, top

cap, load piston, rubber membrane, and filter paper.

2.9 Miscellaneous apparatus, including vacuum pump and pressure device with associated

regulators and gages, membrane expander, moisture content cans, and data sheets.

Figure 1—Schematic Diagram of a Typical Consolidated Undrained Triaxial Apparatus

CONSTRUCTION DIVISION 2 – 10 LAST REVIEWED: SEPTEMBER 2014

CONSOLIDATED UNDRAINED TRIAXIAL COMPRESSION TEST FOR

TXDOT DESIGNATION: TEX-131-E

UNDISTURBED SOILS

3. PREPARING SPECIMEN

3.1 Specimens should have a minimum diameter of 33.0 mm (1.3 in.)

The largest particle in the test specimen should be smaller than one-tenth of the

specimen diameter.

For specimens that have a diameter of 71.1 mm (2.8 in.) or larger, the largest

particle size should be smaller than one-sixth of the specimen.

If larger particles are present after the completion of a test of an undisturbed

specimen, make appropriate notations in the report of the test data.

3.1.1 The height to diameter (H/D) ratio must be between 2.0 and 3.0 with a recommended

value of 2.0, except that:

When lubricated end plates are used, the (H/D) ratio may be lowered to 1.25.

The height and diameter of the specimen will be measured to the nearest 0.3 mm

(0.01 in.) using a vernier caliper or other suitable device.

Note 1—This method requires testing a minimum of three specimens.

3.2 Undisturbed specimens may be prepared from large undisturbed samples or from samples

secured in accordance with AASHTO T 207 or the Bridge Division's Geotechnical

Manual.

3.3 When tubes are received in the laboratory, extrude the samples using a jack or other

methods that will not disturb the sample.

3.4 When samples are not tested immediately, place in plastic bags to preserve moisture

content.

3.5 Any method of trimming is acceptable which, for the material being tested, produces

minimum disturbance.

3.5.1 Place the specimen in the end-trimming device and trim so the ends are perpendicular to

the longitudinal axis of the uniform circular specimen.

3.5.2 Obtain diameter and height of the specimen and determine the initial mass.

3.5.3 If the entire test specimen is not to be used for determination of moisture content, secure

and immediately place a representative sample of cuttings for this purpose in a covered

container, in accordance with Tex-103-E.

4. PROCEDURE

4.1 Prepare pedestal by placing a saturated porous stone on the pedestal, with a filter paper

disk on top. Place the specimen on the porous stone and a filter paper strip cage alongside

the specimen to provide the desired drainage path, as shown in Figure 2.

CONSTRUCTION DIVISION 3 – 10 LAST REVIEWED: SEPTEMBER 2014

CONSOLIDATED UNDRAINED TRIAXIAL COMPRESSION TEST FOR

TXDOT DESIGNATION: TEX-131-E

UNDISTURBED SOILS

4.2 Using a vacuum membrane expander, place a thin, leak-proof membrane over the

specimen. Place O-rings or other pressure seals around the membrane at the baseplate or

cap of the pedestal to provide a positive seal. Place an additional filter paper disk, porous

stone, and header or top cap, on top of the specimen. Place O-rings or other pressure seals

around the membrane at the cap to provide a positive seal. Place the hollow cylinder on

the base and secure. Place the loading piston into the chamber through the bushings and

lower until it enters, but does not touch, the recess in the top cap. Secure the loading

piston with the locking device.

4.3 Place the test chamber containing the specimen in the loading frame and fill with fluid.

Saturate the drainage line, header caps, and filter paper surrounding the specimen, to

remove air from between the sample and membrane.

4.4 Apply a small back pressure and chamber pressure with chamber pressure approximately

1 to 13.8 kPa (2 psi) greater than back pressure, to cause water to flow slowly from the

pore pressure line. Connect pore pressure line to pore pressure-measuring device.

Increase back pressure and chamber pressure increments whenever pore pressure readout

indicates pressure equalization has been achieved throughout the sample. Maintain

chamber pressure approximately 34.4 kPa (5 psi) greater than back pressure, to prevent

flow between the sample and membrane.

4.5 Check the degree of saturation by closing the drainage valve and increasing the confining

pressure 34.4 kPa (5 psi) or more. The ratio of pore pressure change to the change in

confining pressure for a saturated sample is:

ΔU / Δσ3 = 1.0 = B, Pore Pressure Coefficient.

4.6 Continue to increase back pressure and confining pressure until pore pressure response

indicates a B value of at least 0.95.

Note 2—If pore pressure measurements are not required, eliminate this step.

4.7 The consolidation phase of the test allows the specimen to reach equilibrium in a drained

state under the effective consolidation stress for which a strength determination is

required. During consolidation, data is obtained for use in determining when

consolidation is complete, and for computing a rate of strain to be used for the shear

portion of the test. The consolidation procedure is as follows:

4.7.1 When the saturation phase of the test is completed, bring the axial load piston into contact

with specimen cap and record the reading on deformation indicator.

4.7.2 Take care not to apply an axial load to the specimen exceeding 0.5% of the estimated

axial load at failure.

4.7.3 After recording the reading, raise the piston a small distance above specimen cap and

lock in place.

4.8 With the specimen drainage valves closed, hold the back pressure constant and increase

the chamber pressure until the difference between the chamber pressure and the back

pressure equals the desired effective consolidation pressure.

CONSTRUCTION DIVISION 4 – 10 LAST REVIEWED: SEPTEMBER 2014

CONSOLIDATED UNDRAINED TRIAXIAL COMPRESSION TEST FOR

TXDOT DESIGNATION: TEX-131-E

UNDISTURBED SOILS

4.9 Obtain an initial buret reading and then open appropriate drainage valves so specimen

may drain from both ends into the buret.

4.9.1 At increasing intervals of elapsed time (0.1, 0.2, 0.5, 1, 2, 4, 8, 15, and 30 min. and at

1, 2, 4, and 8 hr., etc.) observe and record buret readings.

4.9.2 After the 15 min. reading, record the accompanying deformation indicator readings

obtained by carefully coupling the piston with the specimen cap.

4.9.3 Depending on soil type, intervals may be changed to convenient intervals that allow for

adequate definition of volume change versus time.

4.10 Plot buret and deformation indicator readings versus the logarithm of elapsed time.

4.10.1 Allow consolidation to continue for at least one log cycle or one overnight period, after

100% primary consolidation has been achieved.

4.10.2 A marked deviation between the slopes of the buret and deformation indicator curves

toward the end of consolidation, based on deformation indicator readings, indicates fluid

leakage from the chamber into the specimen. Test should be terminated.

4.11 Determine the time for 50% primary consolidation, t50:

4.11.1 Plot the buret readings versus the log of time in minutes.

4.11.2 Find the buret reading representing 100% primary consolidation.

4.11.3 First, draw a straight line through the points representing the final readings and that

exhibit a straight line trend and a flat slope.

4.11.4 Draw a second straight line tangent to the steepest part of the buret-log time curve.

4.11.5 The intersection represents the buret corresponding to 100% primary consolidation.

4.11.6 Compression that occurs subsequent to 100% primary consolidation is secondary

compression.

4.11.7 Time required for 50% consolidation, t50, may be found graphically from buret-log time

curve by observing the time that corresponds to 50% of primary consolidation of the

curve.

4.12 Before axial load is applied, close the valve between the chamber and the buret so that

the specimen is sheared in an undrained condition. Measure any volume change that

occurs during consolidation.

4.13 Start loading device and slow it to run a few minutes at desired testing speed to

compensate for piston friction or upward thrust on the piston due to chamber pressure or

both. Record zero reading of load and deformation measuring devices when piston makes

contact with top header.

CONSTRUCTION DIVISION 5 – 10 LAST REVIEWED: SEPTEMBER 2014

CONSOLIDATED UNDRAINED TRIAXIAL COMPRESSION TEST FOR

TXDOT DESIGNATION: TEX-131-E

UNDISTURBED SOILS

Note 3—Remove the piston lock before starting the loading device. If the chamber

pressure is insufficient to restrain the loading piston from falling onto the top cap, then

the additional load applied to the sample by the loading piston will have to be added to

the deviator load.

4.14 In the triaxial test:

4.14.1 The rate of strain should allow for equalization of pore pressures (if measured) in the test

specimen.

4.14.2 Assuming failure will occur after 4%, a suitable rate strain may be obtained by dividing

4% by ten times the value of t50.

4.14.3 This rate of strain will allow determination of accurate stress paths in the range necessary

to define effective strength envelopes.

4.14.4 If however, it is estimated that failure will occur at a strain value lower than 4%, obtain a

suitable strain rate by dividing the estimated failure strain by ten times the value of t50.

4.14.5 Record load and deformation readings at sufficiently small intervals to accurately define

the stress-strain curve.

4.15 The criterion of failure shall be the maximum value of the deviator stress, provided a

maximum does occur.

4.15.1 If no definite maximum occurs and the deviator stress continued to increase with strain,

failure will be taken as the deviator stress at 15% strain.

4.15.2 If pore pressures are measured, the maximum effective principal stress ratio may be used

as the failure criterion.

4.16 After failure, release all pressures and drain the confining fluid from the test chamber.

4.16.1 Disassemble the testing apparatus, examine the specimen, and sketch the mode of failure.

4.16.2 Obtain the specimen weight, height, and diameter for density and determine final

moisture content.

CONSTRUCTION DIVISION 6 – 10 LAST REVIEWED: SEPTEMBER 2014

CONSOLIDATED UNDRAINED TRIAXIAL COMPRESSION TEST FOR

TXDOT DESIGNATION: TEX-131-E

UNDISTURBED SOILS

Figure 2—Filter Strip Cage

5. CALCULATIONS

5.1 Calculate the volume strain (∈V):

∈V = Δ V / V

V = π Ld 2 / 4

Δ V = π Δ Ld 2 / 4

Where:

V = original volume of specimen

ΔV = volume change as measured by buret

L = length of specimen as determined by physical measurements, mm (in.)

ΔL = change in length of specimen during consolidation, mm (in.)

d = average of a minimum of three physical diameter measurements, mm (in.)

CONSTRUCTION DIVISION 7 – 10 LAST REVIEWED: SEPTEMBER 2014

CONSOLIDATED UNDRAINED TRIAXIAL COMPRESSION TEST FOR

TXDOT DESIGNATION: TEX-131-E

UNDISTURBED SOILS

5.2 Assuming that the specimen strains equally in all directions during consolidation, the

length of the specimen after consolidation may be determined by ∈1 = ∈v / 3. Alternately,

measure the change in length of the specimen directly.

5.3 Calculate the axial strain for a given applied load:

∈ V = Δ l / ls

Where:

Δ l = change in length of the specimen as determined from the deformation indicator, mm

(in.)

ls = length of specimen after consolidation, mm (in.)

5.4 Calculate the average cross-sectional area for a given applied load (A) or from

dimensions obtained by direct measurement:

A = A0 / ( 1− ∈ )

5.5 Calculate the deviator load per unit area for a given applied load:

σ d = P / A = σ 1− σ 3

Where:

P = applied deviator load, kg (lbs.)

A = corresponding average cross-sectional area, mm2 (in.2)

σd = deviator load per unit area

A0 = initial average cross-sectional area of the specimen, m2 (in.2)

6. GRAPHS

6.1 The maximum value of the deviator stress (σd = σ1 - σ3), or the maximum effective

principal stress ratio σ1/ σ3, is selected and used to construct the Mohr's circles.

6.1.1 If pore pressure, U, was measured, subtract U from principal stresses.

6.1.2 When all Mohr's circles have been plotted, draw a line that is most nearly tangent to all

the circles.

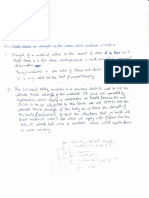

6.1.3 The construction of a Mohr Stress Circle is shown in Figure 3.

6.1.4 The intersection of this line with the ordinate axis is the cohesion (effective U is

measured) value, c (c') and the angle between this line and the horizontal is the angle of

internal friction, (effective is U is measured) φ (φ').

CONSTRUCTION DIVISION 8 – 10 LAST REVIEWED: SEPTEMBER 2014

CONSOLIDATED UNDRAINED TRIAXIAL COMPRESSION TEST FOR

TXDOT DESIGNATION: TEX-131-E

UNDISTURBED SOILS

Figure 3—Construction of Mohr Stress Circle

CONSTRUCTION DIVISION 9 – 10 LAST REVIEWED: SEPTEMBER 2014

CONSOLIDATED UNDRAINED TRIAXIAL COMPRESSION TEST FOR

TXDOT DESIGNATION: TEX-131-E

UNDISTURBED SOILS

7. REPORTING

7.1 Project information and location of sample

7.2 Type of test performed, i.e., consolidated undrained triaxial test with pore pressure

measurements or consolidated undrained triaxial test without pore pressure measurements

7.3 Type and shape of specimen, i.e., undisturbed, remolded, cylindrical, or prismatic

7.4 Initial density and moisture content

7.5 Remarks – note any unusual conditions or other data that would be considered necessary

to properly interpret the results obtained

7.6 Plot of Mohr circles and envelope with cohesion and angle of internal friction.

CONSTRUCTION DIVISION 10 – 10 LAST REVIEWED: SEPTEMBER 2014

You might also like

- Soil Tests-Brief Method StatementDocument7 pagesSoil Tests-Brief Method StatementDr Wong Kim YuenNo ratings yet

- Stormwater Drainage and GeotechnicalDocument394 pagesStormwater Drainage and GeotechnicalreluNo ratings yet

- Triaxial Test SystemsDocument9 pagesTriaxial Test SystemsAfifah FauziNo ratings yet

- TMH-6 - ST10Document10 pagesTMH-6 - ST10ATHOLSCHWARZNo ratings yet

- D1560Document7 pagesD1560Aleksei AvilaNo ratings yet

- C680Document22 pagesC680Antonio Julián Sánchez NuñoNo ratings yet

- 1 Introduction To VibrationDocument4 pages1 Introduction To VibrationMohamed AslamNo ratings yet

- MB PT Floors Dec17Document24 pagesMB PT Floors Dec17Alparslan GureNo ratings yet

- Astm E283Document5 pagesAstm E283Lupita Ramirez50% (2)

- Triaxial TestingDocument5 pagesTriaxial TestingAakash Budhiraja100% (2)

- Calculation of Critical Temperatures by Empirical FormulaeDocument6 pagesCalculation of Critical Temperatures by Empirical FormulaeAndress SsalomonnNo ratings yet

- Tex-416-A, Air Content of Freshly-Mixed Concrete by The Pressure MethodDocument13 pagesTex-416-A, Air Content of Freshly-Mixed Concrete by The Pressure MethodegemetsatisNo ratings yet

- Steer by Wire Error Codes enDocument31 pagesSteer by Wire Error Codes enKadoche SantoNo ratings yet

- Gases and Vacua: Handbook of Vacuum PhysicsFrom EverandGases and Vacua: Handbook of Vacuum PhysicsA. H. BeckNo ratings yet

- Norma Tension Superficial D1331Document4 pagesNorma Tension Superficial D1331cristiangggNo ratings yet

- Standard Test Method For Pneumatic Leak Testing of TubingDocument5 pagesStandard Test Method For Pneumatic Leak Testing of TubingWilliam Chang50% (2)

- ASTM D 6706-Pullout PDFDocument7 pagesASTM D 6706-Pullout PDFSasankamouli Sravanam100% (1)

- Triaxial Compression TestDocument53 pagesTriaxial Compression TestAndyra Jaiz BadduNo ratings yet

- Aggregate 10% Fines Value BS 812-111 - BS en 1097 - 2Document4 pagesAggregate 10% Fines Value BS 812-111 - BS en 1097 - 2rajeshji_000100% (1)

- D4123Document4 pagesD4123FranklinNo ratings yet

- Triaxial Test: Consolidated UndrainedDocument9 pagesTriaxial Test: Consolidated UndrainedNguyễn Hòa100% (1)

- Lightolier Lytecaster Downlights Catalog 1988Document68 pagesLightolier Lytecaster Downlights Catalog 1988Alan Masters100% (1)

- Retention Support Stability CDDocument53 pagesRetention Support Stability CDAshraf GebreelNo ratings yet

- ASTM D 2325-68 (R00) Standard Test Method For Capillary-Moisture Relationships For Coarse - and Medium - Textured Soils by Porous-Plate ApparatusDocument6 pagesASTM D 2325-68 (R00) Standard Test Method For Capillary-Moisture Relationships For Coarse - and Medium - Textured Soils by Porous-Plate ApparatusPablo Antonio Valcárcel Vargas100% (1)

- Triaxial TestDocument14 pagesTriaxial TestSi Rerumpai LautNo ratings yet

- Astm D 4767Document11 pagesAstm D 4767Darren KamNo ratings yet

- MethodStatement CUTriaxial SaturationDocument2 pagesMethodStatement CUTriaxial SaturationDr Wong Kim YuenNo ratings yet

- ASTM D 2290Document5 pagesASTM D 2290Pablo AlcázarNo ratings yet

- D 2938 - 95 R02 PDFDocument3 pagesD 2938 - 95 R02 PDFJosephNo ratings yet

- Pressure Transient Formation and Well Testing: Convolution, Deconvolution and Nonlinear EstimationFrom EverandPressure Transient Formation and Well Testing: Convolution, Deconvolution and Nonlinear EstimationRating: 2 out of 5 stars2/5 (1)

- UU Triaxial TestDocument11 pagesUU Triaxial Testprinces_anaNo ratings yet

- Laboratory Soil Tests MethodDocument6 pagesLaboratory Soil Tests MethodDr Wong Kim YuenNo ratings yet

- Triaxial Test ProcedureDocument7 pagesTriaxial Test ProcedureMuazNo ratings yet

- MTC 131Document17 pagesMTC 131borisov2009No ratings yet

- E 128 - 99 - RteyoaDocument3 pagesE 128 - 99 - RteyoaSaurabh ChoudhariNo ratings yet

- OedometerDocument7 pagesOedometerDaniel ShinnickNo ratings yet

- Test 09Document6 pagesTest 09Ateafac Anastasia NjuafacNo ratings yet

- Density of Soil In-Place by The Rubber-Balloon Method: NDR Standard Method T 205Document8 pagesDensity of Soil In-Place by The Rubber-Balloon Method: NDR Standard Method T 205Leo FernandezNo ratings yet

- Triaxial Test: Xzdetermination of Shear Parameters by Triaxail TestDocument8 pagesTriaxial Test: Xzdetermination of Shear Parameters by Triaxail TestTenzinKesangNo ratings yet

- Triaxial Compression TestDocument17 pagesTriaxial Compression Testsajjad.ghazai2001No ratings yet

- Part 1 Introduction To Triaxial TestingDocument4 pagesPart 1 Introduction To Triaxial TestingFernando CachúNo ratings yet

- Fatigue Life of Compacted Bituminous Mixes Subject To Repeated Flexural BendingDocument14 pagesFatigue Life of Compacted Bituminous Mixes Subject To Repeated Flexural Bendingतिप्लोकाची तिरुनचिपल्ली केरकेट्टाNo ratings yet

- D6723.1203165 1 DirectTensionTesterDocument13 pagesD6723.1203165 1 DirectTensionTesterAnantNo ratings yet

- T807 OM-94 Bursting Strength of Paperboard and LinerboardDocument4 pagesT807 OM-94 Bursting Strength of Paperboard and LinerboardEdmund KohSSNo ratings yet

- Astm D 1558-99 - AtençãoDocument3 pagesAstm D 1558-99 - Atençãomarco.valentimNo ratings yet

- Multispeed Universal Electromechanical Test Device CU-CD IMDocument31 pagesMultispeed Universal Electromechanical Test Device CU-CD IMkutalmış doğanNo ratings yet

- Method 2E - Determination of Landfill Gas Production Flow RateDocument15 pagesMethod 2E - Determination of Landfill Gas Production Flow RateOrwah malkawiNo ratings yet

- Report On Cyclic Triaxial Test: GE-502 Foundation Engg-IDocument12 pagesReport On Cyclic Triaxial Test: GE-502 Foundation Engg-IAjmal AfzalNo ratings yet

- ASTM Vol.4.10Document3 pagesASTM Vol.4.10Prastika Wahid SantosoNo ratings yet

- D 1599 PDFDocument3 pagesD 1599 PDFrickatmanNo ratings yet

- Air Permeability ASTM D737 96 Standard TDocument2 pagesAir Permeability ASTM D737 96 Standard TDeidra CadeNo ratings yet

- Pressuremeter Test: Experiment No. 05Document24 pagesPressuremeter Test: Experiment No. 05rishav baishyaNo ratings yet

- Undrained Triaxial TestDocument7 pagesUndrained Triaxial TestadityatheaaaNo ratings yet

- E 283 Â " 04 RTI4MWDocument6 pagesE 283 Â " 04 RTI4MWdorbarelNo ratings yet

- Triaxial Test 2850Document2 pagesTriaxial Test 2850Mostafa MagdyNo ratings yet

- D 6918 - 03Document4 pagesD 6918 - 03luis-12No ratings yet

- Method 2E - Determination of Landfill Gas Production Flow RateDocument26 pagesMethod 2E - Determination of Landfill Gas Production Flow Ratemagafi448No ratings yet

- Lab 2 ReportDocument29 pagesLab 2 ReportBobby Golas100% (2)

- Triaxial Test (UC)Document3 pagesTriaxial Test (UC)Aisha MalikNo ratings yet

- Modern Sensors HandbookFrom EverandModern Sensors HandbookPavel RipkaRating: 5 out of 5 stars5/5 (1)

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Perhitungan Koefisien Drag Dan Kooefisie Ae10d5d8Document6 pagesPerhitungan Koefisien Drag Dan Kooefisie Ae10d5d8RiskiNo ratings yet

- Controlled-Volume Metering Pumps: For Nomenclature, Definitions, Application, and OperationDocument8 pagesControlled-Volume Metering Pumps: For Nomenclature, Definitions, Application, and Operationsjk_akolNo ratings yet

- 2010 TJC SolDocument12 pages2010 TJC SolPooja KapurNo ratings yet

- USS Physics - 1Document75 pagesUSS Physics - 1Aryan singhNo ratings yet

- M19 Knig9404 Ism C19 PDFDocument31 pagesM19 Knig9404 Ism C19 PDFnorma_jeannNo ratings yet

- Math 117calculus I (2015 1) SyllabusDocument3 pagesMath 117calculus I (2015 1) SyllabusMunira Binte MostafaNo ratings yet

- Daewoo dwf-1094 8094 7094 PDFDocument25 pagesDaewoo dwf-1094 8094 7094 PDFFLASH_2401No ratings yet

- Brenta Oxia EdgerDocument3 pagesBrenta Oxia EdgerBetulaPendulaNo ratings yet

- Lead, Zinc and Strontium Distribution in The Oxidation ZoneDocument11 pagesLead, Zinc and Strontium Distribution in The Oxidation ZoneAnonymous Lrw61wNo ratings yet

- Fomadux Roll Film enDocument1 pageFomadux Roll Film enALP69No ratings yet

- S&T - at-3BE17N6-024-CMEA (Span 200 M - Sag 1% - Nesc Medium)Document1 pageS&T - at-3BE17N6-024-CMEA (Span 200 M - Sag 1% - Nesc Medium)Kevin Chavez RodriguezNo ratings yet

- Fundamentals of Matrices: Scalar, Vectors and MatricesDocument15 pagesFundamentals of Matrices: Scalar, Vectors and MatricesTania Farzana KeyaNo ratings yet

- IRT Stitch enDocument2 pagesIRT Stitch enJaime BerryNo ratings yet

- Ramanujan PDFDocument3 pagesRamanujan PDFQazq WsxwNo ratings yet

- High-Precision Chilled Mirror HygrometerDocument4 pagesHigh-Precision Chilled Mirror HygrometerAldrin HernandezNo ratings yet

- Post-Buckling Optimisation of Composite Stiffened Panels Using Neural NetworksDocument11 pagesPost-Buckling Optimisation of Composite Stiffened Panels Using Neural NetworksBosco RajuNo ratings yet

- F4 Mid-Year '09 P3Document9 pagesF4 Mid-Year '09 P3Marz ZamzuriNo ratings yet

- So Fab Creative ProductionsDocument4 pagesSo Fab Creative ProductionsJunel MabasaNo ratings yet

- NCP 24 25Document15 pagesNCP 24 25Arunashish MazumdarNo ratings yet

- 15 Apil 2021: Stsenth A 7eks The of OnDocument4 pages15 Apil 2021: Stsenth A 7eks The of OnMarisha BhattiNo ratings yet

- Iso Astm 51275-13Document6 pagesIso Astm 51275-13Dmitry_ucpNo ratings yet

- Presentation On Dynamic Load Application in Etabs3Document24 pagesPresentation On Dynamic Load Application in Etabs3Jabbar JabbarNo ratings yet