Professional Documents

Culture Documents

Shell Omala S2 GX 320: Performance, Features & Benefits

Uploaded by

pinjala sivasaiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Shell Omala S2 GX 320: Performance, Features & Benefits

Uploaded by

pinjala sivasaiCopyright:

Available Formats

Technical Data Sheet

• EXTRA PROTECTION

• Against contamination

Shell Omala S2 GX 320 •

•

Against oxidation

Against micropitting

Industrial Gear Oils

Shell Omala S2 GX oils are high quality extreme-pressure oils designed primarily for the lubrication of heavy duty

industrial gears. Their high load carrying capacity and anti-friction characteristics combine to offer superior

performance in gears.

Performance, Features & Benefits Shell Omala S2 GX oils offers:

Performance Benefits can be summarised in OMALA. C O · Excellent micropitting performance to help prolong

component life.

M (Protection against Contamination, Oxidation and

Micropitting) · Low sludge tendency, which reduces wear on rollers and

· Handling Contamination and hence maintaining system helps ensure bearing protection.

efficiency · Outstanding corrosion protection, protecting steel

components, even in the presence of contamination by water

Shell Omala S2 GX oils display a combination of excellent

water shedding capability and low foaming tendency. The and solids.

oils are designed to minimize the potential for foaming in Shell Omala S2 GX oils offers excellent shear stability by

the most testing of environments. maintaining its viscosity, thereby protecting the component

Shell Omala S2 GX oils have excellent water separation from friction and wear.

properties, such that excess water can be drained easily

Main Applications

from lubrication systems to help extend the life of the gears

and ensure efficient lubrication of the contact areas. · Enclosed industrial gear systems

Shell Omala S2 GX technology provides an extreme EP

Water can greatly accelerate surface fatigue of gears and

system which allows trouble-free application in most

bearings as well as promoting ferrous corrosion on internal

enclosed industrial gearboxes using steel spur and helical

surfaces. Water contamination should therefore be

gear drives with circulation or splash lubrication systems.

avoided or removed as quickly as possible after the

occurrence. · Highly loaded gears

· Long oil life through Oxidation stability – leading to

maintenance saving

Shell Omala S2 GX oils have an effective full extreme

pressure (EP) additive system allowing them to be used in

highly-loaded gear systems.

Shell Omala S2 GX oils are formulated to reduce the risk of

thermal and chemical breakdown throughout the

· Other applications

Shell Omala S2 GX oils are suitable for lubrication of

maintenance interval. They withstand high thermal loading

bearings and other components in circulating and splash-

and resist the formation of sludge to provide extended oil

lubricated systems. For loaded worm drives Shell Omala S4

life capability, even with bulk oil temperatures of up to

WE, Shell Morlina S4 B and Shell Omala S1 W are

1000C in certain applications.

·

recommended. For automotive hypoid gears, the appropriate

Excellent wear & corrosion protection incl. protection Shell Spirax Oil should be used.

against Micro-pitting

Shell do not recommend/support use in systems with fine

Shell Omala S2 GX oils have superb load carrying capacity filtration (<10 microns) because sustained foam control

that helps reduce gear tooth and bearing wear on steel performance is not assured. Please consult your Shell Local

components. Technical Advisor and Product Application Specialist.

Page 1 of 2 Omala S2 GX 320 (2015), v 1.4 06.06.2016.07.04

Specifications, Approvals & Recommendations · Siemens AG

Meets requirements of: Shell Omala S2 GX 150, 220, 320, 460 and 680 are

· ISO 12925-1 Type CKD (ISO 68 through 460) approved by Siemens AG for use in Flender gearboxes.

· ISO 12925-1 Type CKC (ISO 680, 1000) For a full listing of equipment approvals and

· DIN 51517- Part 3 CLP (ISO 68 through 1000) recommendations, please consult your local Shell Technical

· AGMA EP 9005- EO2 (ISO 68 through 1000)

Help Desk.

· AIST (US Steel) 224 (ISO 68 through 680) Compatibility & Miscibility

· Fives Cincinnati P-63 (ISO 68), P-76 (ISO 100), P-77 (ISO

150), P-74 (ISO 220), P-59 (ISO 320), P-35 (ISO 460), P-

Shell Omala S2 GX oils are compatible with various seal

materials to help prevent premature failure of seals and thus

34 (ISO 680), P-78 (ISO 1000) avoid leakage.

Typical Physical Characteristics

Properties Method Shell Omala S2 GX 320

Kinematic Viscosity @ 400C mm2/s ISO 3104 320

Kinematic Viscosity @ 1000C mm2/s ISO 3104 24.4

Viscosity Index ISO 2909 97

Flash Point COC 0

C ISO 2592 >250

Pour Point 0

C ISO 3016 -15

Density 0

@ 15 C Kg/m 3 ISO 12185 897

These characteristics are typical of current production. Whilst future production will conform to Shell's specification,

variations in these characteristics may occur.

Health, Safety & Environment

· Health and Safety

This product is unlikely to present any significant health or safety hazard when properly used in the recommended

application and good standards of personal hygiene are maintained.

Avoid contact with skin. Use impervious gloves with used oil. After skin contact, wash immediately with soap and water.

Guidance on health and safety is available on the appropriate Material Safety Data Sheet (MSDS), which can be obtained

from http://www.epc.shell.com/

· Protect the Environment

Take used oil to an authorised collection point. Do not discharge into drains, soil or water.

Additional Information

· Advice

Advice on applications not covered here may be obtained from your Shell Representative

Page 2 of 2 Omala S2 GX 320 (2015), v 1.4 06.06.2016.07.04

You might also like

- Plastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965From EverandPlastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965No ratings yet

- Industrial Gear Oil ProtectionDocument2 pagesIndustrial Gear Oil ProtectionAbdi UtamaNo ratings yet

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsFrom EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsRating: 5 out of 5 stars5/5 (1)

- Shell Omala S2 GX 150: Performance, Features & BenefitsDocument2 pagesShell Omala S2 GX 150: Performance, Features & BenefitsVijay HumidificationNo ratings yet

- Shell Omala S2 GX 320: Performance, Features & Benefits Main ApplicationsDocument2 pagesShell Omala S2 GX 320: Performance, Features & Benefits Main ApplicationsRaden ArdyNo ratings yet

- Shell Omala S2 GX 320 Technical Data SheetDocument2 pagesShell Omala S2 GX 320 Technical Data SheetOnie Hammamz OylNo ratings yet

- Omala S2 GX 320 newDocument2 pagesOmala S2 GX 320 newAhmed FathyNo ratings yet

- Shell Omala S2 GX 68: Performance, Features & Benefits Main ApplicationsDocument2 pagesShell Omala S2 GX 68: Performance, Features & Benefits Main Applicationshoussem houssemNo ratings yet

- Shell Omala S2 GX 680 TDSDocument2 pagesShell Omala S2 GX 680 TDSEdgar Leonel CortésNo ratings yet

- OmalaDocument2 pagesOmalaSunario YapNo ratings yet

- Shell Omala S2 GX 100: Performance, Features & Benefits Main ApplicationsDocument2 pagesShell Omala S2 GX 100: Performance, Features & Benefits Main ApplicationsAliNo ratings yet

- Shell Omala S2 GX 100: Performance, Features & Benefits Main ApplicationsDocument2 pagesShell Omala S2 GX 100: Performance, Features & Benefits Main ApplicationsRaden ArdyNo ratings yet

- Shell Omala S2 GX 150: Performance, Features & Benefits Main ApplicationsDocument2 pagesShell Omala S2 GX 150: Performance, Features & Benefits Main ApplicationsVelibor KaranovicNo ratings yet

- Industrial Gear Oil ProtectionDocument2 pagesIndustrial Gear Oil Protectionphucdc095041No ratings yet

- Omala S2 GX 460Document2 pagesOmala S2 GX 460Kieran MañalacNo ratings yet

- Omala S2 GX 150Document2 pagesOmala S2 GX 150Kieran MañalacNo ratings yet

- Shell Omala S2 GX 1000 - TDSDocument2 pagesShell Omala S2 GX 1000 - TDSbiron rumangunNo ratings yet

- Shell Omala S2 GX 100 Industrial Gear Oil ProtectionDocument2 pagesShell Omala S2 GX 100 Industrial Gear Oil ProtectionKieran MañalacNo ratings yet

- Shell Omala S2 GX 100 TDSDocument2 pagesShell Omala S2 GX 100 TDSEdgar Leonel CortésNo ratings yet

- Omala S2 GX 68Document2 pagesOmala S2 GX 68Kieran MañalacNo ratings yet

- Shell Omala S2 G 68: Performance, Features & BenefitsDocument3 pagesShell Omala S2 G 68: Performance, Features & BenefitsRaden ArdyNo ratings yet

- Shell Omala S2 G 320: Performance, Features & BenefitsDocument3 pagesShell Omala S2 G 320: Performance, Features & BenefitsMudabbir Shan AhmedNo ratings yet

- Shell Omala S2 G 1000: Performance, Features & BenefitsDocument3 pagesShell Omala S2 G 1000: Performance, Features & BenefitsRaden ArdyNo ratings yet

- Shell Omala S2 G 680 (Ar-BH) TDSDocument4 pagesShell Omala S2 G 680 (Ar-BH) TDSJavier GonzalezNo ratings yet

- GPCDOC Local TDS Bahrain Shell Omala S2 G 680 (Ar-BH) TDSDocument4 pagesGPCDOC Local TDS Bahrain Shell Omala S2 G 680 (Ar-BH) TDSAditomo PutrantoNo ratings yet

- Shell Omala S2 G 320: Performance, Features & BenefitsDocument3 pagesShell Omala S2 G 320: Performance, Features & BenefitsVelibor KaranovicNo ratings yet

- How To Use OilDocument3 pagesHow To Use OilMadhusudan SharmaNo ratings yet

- Omala S2 G 100Document3 pagesOmala S2 G 100AMITNo ratings yet

- Shell Omala S2 G 220 DatasheetDocument5 pagesShell Omala S2 G 220 DatasheetSergio OrdoviniNo ratings yet

- Omala 460Document4 pagesOmala 460Asad InaamNo ratings yet

- Shell Omala S2 G 100 Gear Oil TDSDocument3 pagesShell Omala S2 G 100 Gear Oil TDSWawanDarmawanNo ratings yet

- Gpcdoc Gtds Shell Omala s2 G 150 (En) TdsDocument3 pagesGpcdoc Gtds Shell Omala s2 G 150 (En) TdsMuhammad RipandiNo ratings yet

- Shell Omala S2 G 320: Performance, Features & BenefitsDocument3 pagesShell Omala S2 G 320: Performance, Features & BenefitsMohd FaidzalNo ratings yet

- 1481 Omala s2 G 68Document2 pages1481 Omala s2 G 68Sivarama KrishnanNo ratings yet

- Shell Omala S2 G 680: Performance, Features & BenefitsDocument3 pagesShell Omala S2 G 680: Performance, Features & BenefitsRaden ArdyNo ratings yet

- Shell Omala S2 G 100: Performance, Features & BenefitsDocument4 pagesShell Omala S2 G 100: Performance, Features & Benefitsرعد العكيليNo ratings yet

- S2 G 460 - TDS PDFDocument3 pagesS2 G 460 - TDS PDFWawanDarmawanNo ratings yet

- Shell Omala 320 Data SheetDocument4 pagesShell Omala 320 Data SheetAyus SyariffianaNo ratings yet

- Shell Omala S3 GP 320: Performance, Features & BenefitsDocument2 pagesShell Omala S3 GP 320: Performance, Features & BenefitsttchangcodonNo ratings yet

- Shell Omala S2 G 150: Performance, Features & BenefitsDocument3 pagesShell Omala S2 G 150: Performance, Features & BenefitsAzamuddin JasrelNo ratings yet

- Omala S2 G 220Document3 pagesOmala S2 G 220AMITNo ratings yet

- Shell Omala S2 G 220 Industrial Gear Oil TDSDocument3 pagesShell Omala S2 G 220 Industrial Gear Oil TDSTamara GarciaNo ratings yet

- Shell Omala S2 G 220 Industrial Gear Oil Technical Data SheetDocument2 pagesShell Omala S2 G 220 Industrial Gear Oil Technical Data SheetSholhan AzizNo ratings yet

- Shell Omala S4 GXV 320 - TDSDocument2 pagesShell Omala S4 GXV 320 - TDSDENNY BAYUAJINo ratings yet

- Shell Omala S2 G150 DatasheetDocument3 pagesShell Omala S2 G150 Datasheetphankhoa83-1No ratings yet

- Shell Omala S4 GXV 680 - TDSDocument2 pagesShell Omala S4 GXV 680 - TDSDENNY BAYUAJINo ratings yet

- 13 Omala S4 GX 220 PDFDocument2 pages13 Omala S4 GX 220 PDFthanhhuyenNo ratings yet

- Omala S4 GXV 220Document2 pagesOmala S4 GXV 220Aaron ChanNo ratings yet

- Omala s4 GXV 220Document2 pagesOmala s4 GXV 220Igreja CCMVNo ratings yet

- Shell Omala S1 W 460Document2 pagesShell Omala S1 W 460Muhammad SaputraNo ratings yet

- Omala S1 W 680Document2 pagesOmala S1 W 680Nigel RamkhalawanNo ratings yet

- Omala S1 W 460Document2 pagesOmala S1 W 460Adnan QayumNo ratings yet

- Long Life Synthetic Gear Oil for Severe ConditionsDocument2 pagesLong Life Synthetic Gear Oil for Severe ConditionsNokiabhre WijayaNo ratings yet

- Shell Omala S4 Wheel 680Document2 pagesShell Omala S4 Wheel 680Muhammad SaputraNo ratings yet

- Industrial Gear Oil Technical Data SheetDocument2 pagesIndustrial Gear Oil Technical Data SheetMuhammad SaputraNo ratings yet

- Shell Omala S4 GXV 220: Performance, Features & Benefits Main ApplicationsDocument2 pagesShell Omala S4 GXV 220: Performance, Features & Benefits Main ApplicationsAdham TunggalNo ratings yet

- UAE Shell Omala S4 GX 460Document3 pagesUAE Shell Omala S4 GX 460tylerdurdaneNo ratings yet

- 22638Document3 pages22638mhNo ratings yet

- Shell Omala S4 GXV 460 - TDSDocument2 pagesShell Omala S4 GXV 460 - TDSDENNY BAYUAJINo ratings yet

- Mahesh ResumeDocument3 pagesMahesh Resumepinjala sivasaiNo ratings yet

- Karthik ResumeDocument2 pagesKarthik Resumepinjala sivasaiNo ratings yet

- Format of Paper-1Document5 pagesFormat of Paper-1pinjala sivasaiNo ratings yet

- Seminar 18f05a0319 (SS)Document6 pagesSeminar 18f05a0319 (SS)pinjala sivasaiNo ratings yet

- Eesume For Phrma IndustryDocument1 pageEesume For Phrma Industrypinjala sivasaiNo ratings yet

- Advanced Materials Assignment - 1 - 3 QuestionsDocument1 pageAdvanced Materials Assignment - 1 - 3 Questionspinjala sivasaiNo ratings yet

- Literature reviews on thermal performance of radiators using nanofluidsDocument2 pagesLiterature reviews on thermal performance of radiators using nanofluidspinjala sivasaiNo ratings yet

- PrposalDocument3 pagesPrposalpinjala sivasaiNo ratings yet

- Pinjala Venkata Sivasai's ResumeDocument3 pagesPinjala Venkata Sivasai's Resumepinjala sivasaiNo ratings yet

- Solenoid Valve MFH-5-1/4: Data SheetDocument2 pagesSolenoid Valve MFH-5-1/4: Data Sheetpinjala sivasaiNo ratings yet

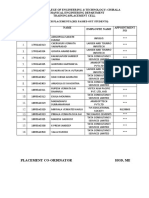

- 17-Batch Placements at St.Ann's College of Engineering & TechnologyDocument1 page17-Batch Placements at St.Ann's College of Engineering & Technologypinjala sivasaiNo ratings yet

- Seminar Schedule 2021Document1 pageSeminar Schedule 2021pinjala sivasaiNo ratings yet

- ST - Anns College of Engineering and Technology (II Shift Polytechnic)Document11 pagesST - Anns College of Engineering and Technology (II Shift Polytechnic)pinjala sivasaiNo ratings yet

- SignatureDocument1 pageSignaturepinjala sivasaiNo ratings yet

- Crusher FlowDocument1 pageCrusher Flowpinjala sivasaiNo ratings yet

- ST - Ann'S College of Engineering and TechnologyDocument18 pagesST - Ann'S College of Engineering and Technologypinjala sivasaiNo ratings yet

- HSMS DescriptionDocument2 pagesHSMS DescriptionVũ Văn Thành100% (1)

- John D. McKenna, ETS May 12, 2011Document14 pagesJohn D. McKenna, ETS May 12, 2011pinjala sivasaiNo ratings yet

- Digital Marketing - Scope Opportunities and Challenges - IntechOpen PDFDocument31 pagesDigital Marketing - Scope Opportunities and Challenges - IntechOpen PDFPratsNo ratings yet

- Upper-Room UVGI Leaflet G.L.A.Document4 pagesUpper-Room UVGI Leaflet G.L.A.MihaiAnastasiuNo ratings yet

- HUD Settlement Statement - 221-1993Document4 pagesHUD Settlement Statement - 221-1993Paul GombergNo ratings yet

- Being A Teacher: DR Dennis FrancisDocument14 pagesBeing A Teacher: DR Dennis FranciselsayidNo ratings yet

- Answer Sheet ToeicDocument2 pagesAnswer Sheet ToeicNgọc PhanNo ratings yet

- Resume Ked 2 1Document2 pagesResume Ked 2 1api-273985023No ratings yet

- Steel Cargoes GuidanceDocument64 pagesSteel Cargoes GuidanceAamir SirohiNo ratings yet

- PTET 2022 Admit Card for Baljinder KaurDocument2 pagesPTET 2022 Admit Card for Baljinder KaurSimranpreet SudanNo ratings yet

- xg01 Koso Kent Introl PDFDocument22 pagesxg01 Koso Kent Introl PDFhaidinuNo ratings yet

- Balco. Vicky. Project Optimation of Product MixDocument67 pagesBalco. Vicky. Project Optimation of Product Mixvicky_rock00007No ratings yet

- Update ResumeDocument3 pagesUpdate ResumeSubbareddy NvNo ratings yet

- GW - Energy Storage Solutions - Brochure-ENDocument24 pagesGW - Energy Storage Solutions - Brochure-ENjhtdtNo ratings yet

- 5 - BOSCH I - O ModuleDocument21 pages5 - BOSCH I - O ModuleFELIPE ANGELES CRUZ ROMONo ratings yet

- Electronic Skin PPT 2Document12 pagesElectronic Skin PPT 2Sunitha AteliNo ratings yet

- đề 3Document12 pagesđề 3Vi CầmNo ratings yet

- REST API For Oracle Fusion Cloud HCMDocument19 pagesREST API For Oracle Fusion Cloud HCMerick landaverdeNo ratings yet

- 08 BALDWINS 2016 Summer FIXED PRICE LIST - 06 - SCOTTISH COINS PDFDocument24 pages08 BALDWINS 2016 Summer FIXED PRICE LIST - 06 - SCOTTISH COINS PDFDer AdlerNo ratings yet

- CALCULATE TRADE AND CASH DISCOUNTSDocument13 pagesCALCULATE TRADE AND CASH DISCOUNTSrommel legaspi71% (7)

- BBVA OpenMind Book Change 19 Key Essays On How Internet Is Changing Our Lives Technology Internet InnovationDocument7 pagesBBVA OpenMind Book Change 19 Key Essays On How Internet Is Changing Our Lives Technology Internet InnovationSissiErricoNo ratings yet

- 6 1 Reducing Rational Expressions To Lowest TermsDocument21 pages6 1 Reducing Rational Expressions To Lowest Termsapi-233527181No ratings yet

- From The Caves and Jungles of Hindostan by Blavatsky, H. P. (Helena Petrovna), 1831-1891Document173 pagesFrom The Caves and Jungles of Hindostan by Blavatsky, H. P. (Helena Petrovna), 1831-1891Gutenberg.org100% (1)

- Questions - Financial AccountingDocument9 pagesQuestions - Financial AccountingMariamNo ratings yet

- ConnercasememoDocument12 pagesConnercasememoapi-339018690No ratings yet

- UEM Sol To Exerc Chap 097Document11 pagesUEM Sol To Exerc Chap 097sibieNo ratings yet

- Breaking Into Software Defined Radio: Presented by Kelly AlbrinkDocument40 pagesBreaking Into Software Defined Radio: Presented by Kelly AlbrinkChris Guarin100% (1)

- Showcase your talent and skills at Momentum 2021Document48 pagesShowcase your talent and skills at Momentum 2021Tanishq VermaNo ratings yet

- Logical Ability QuestionsDocument23 pagesLogical Ability Questionsjaya pavanNo ratings yet

- Issues in Microprocessor and Multimicroprocessor Systems - Veljko MilutinivicDocument240 pagesIssues in Microprocessor and Multimicroprocessor Systems - Veljko MilutinivicMirko MirkovicNo ratings yet

- DET-2 Service ManualDocument105 pagesDET-2 Service Manualkriotron50% (2)

- Incremental Analysis Decision MakingDocument4 pagesIncremental Analysis Decision MakingMa Teresa B. CerezoNo ratings yet

- Pocket Guide to Flanges, Fittings, and Piping DataFrom EverandPocket Guide to Flanges, Fittings, and Piping DataRating: 3.5 out of 5 stars3.5/5 (22)

- Machine Learning and Data Science in the Oil and Gas Industry: Best Practices, Tools, and Case StudiesFrom EverandMachine Learning and Data Science in the Oil and Gas Industry: Best Practices, Tools, and Case StudiesPatrick BangertRating: 3 out of 5 stars3/5 (2)

- Practical Reservoir Engineering and CharacterizationFrom EverandPractical Reservoir Engineering and CharacterizationRating: 4.5 out of 5 stars4.5/5 (3)

- Gas-Liquid And Liquid-Liquid SeparatorsFrom EverandGas-Liquid And Liquid-Liquid SeparatorsRating: 3.5 out of 5 stars3.5/5 (3)

- Hydraulic Fracturing in Unconventional Reservoirs: Theories, Operations, and Economic AnalysisFrom EverandHydraulic Fracturing in Unconventional Reservoirs: Theories, Operations, and Economic AnalysisNo ratings yet

- Machinery Lubrication Technician (MLT) I and II Certification Exam GuideFrom EverandMachinery Lubrication Technician (MLT) I and II Certification Exam GuideRating: 2 out of 5 stars2/5 (1)

- Asset Integrity Management for Offshore and Onshore StructuresFrom EverandAsset Integrity Management for Offshore and Onshore StructuresNo ratings yet

- Internal Combustion: How Corporations and Governments Addicted the World to Oil and Subverted the AlternativesFrom EverandInternal Combustion: How Corporations and Governments Addicted the World to Oil and Subverted the AlternativesRating: 4 out of 5 stars4/5 (2)

- Risk Management in the Oil and Gas Industry: Offshore and Onshore Concepts and Case StudiesFrom EverandRisk Management in the Oil and Gas Industry: Offshore and Onshore Concepts and Case StudiesNo ratings yet

- Industrial Piping and Equipment Estimating ManualFrom EverandIndustrial Piping and Equipment Estimating ManualRating: 5 out of 5 stars5/5 (7)

- Well Control for Completions and InterventionsFrom EverandWell Control for Completions and InterventionsRating: 4 out of 5 stars4/5 (10)

- Asphaltene Deposition Control by Chemical Inhibitors: Theoretical and Practical ProspectsFrom EverandAsphaltene Deposition Control by Chemical Inhibitors: Theoretical and Practical ProspectsNo ratings yet

- Biostratigraphic and Geological Significance of Planktonic ForaminiferaFrom EverandBiostratigraphic and Geological Significance of Planktonic ForaminiferaRating: 4 out of 5 stars4/5 (5)

- Pipeline Integrity: Management and Risk EvaluationFrom EverandPipeline Integrity: Management and Risk EvaluationRating: 4.5 out of 5 stars4.5/5 (6)

- A Practical Guide to Piping and Valves for the Oil and Gas IndustryFrom EverandA Practical Guide to Piping and Valves for the Oil and Gas IndustryRating: 5 out of 5 stars5/5 (3)

- Essentials of Coating, Painting, and Lining for the Oil, Gas and Petrochemical IndustriesFrom EverandEssentials of Coating, Painting, and Lining for the Oil, Gas and Petrochemical IndustriesRating: 5 out of 5 stars5/5 (5)

- Mooring System Engineering for Offshore StructuresFrom EverandMooring System Engineering for Offshore StructuresRating: 5 out of 5 stars5/5 (1)