Professional Documents

Culture Documents

S Setting Value, C Check Value) OT Outside Tolerance (X Is Set)

Uploaded by

LIONN TESTE2021Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

S Setting Value, C Check Value) OT Outside Tolerance (X Is Set)

Uploaded by

LIONN TESTE2021Copyright:

Available Formats

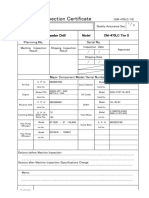

101405-9342 ZEXEL test values diesel fuel-injection equipment 03-05-22 02:30:36 Page 1

ZEXEL Ass'y No. 101405-9342

Bosch Ass'y No. 9 400 612 993

Bosch Typecode

Engine Type S4K-T

Manufacturer MITSUBISHI HEAV

Edition date 13-01-05 (8)

1 Adjustment conditions

CAT Designation Unit Set value min. max. Actual values OT

Test oil ISO4113 or {SAEJ96

7d}

1404 Test oil

P Test oil temperature degC 40 40 45

Nozzle and nozzle holder 105780-8140

Bosch type code EF8511/9A

Nozzle 105780-0000

Bosch type code DN12SD12T

Nozzle holder 105780-2080

Bosch type code EF8511/9

P Opening pressure MPa 17.2

P Opening pressure kgf/cm2 175

Injection pipe mm 6-2-600

Outer diameter - inner diameter - length (mm)

Overflow valve 131424-5720

P Overflow valve opening pressure kPa 255 221 289

P Overflow valve opening pressure kgf/cm2 2.6 2.25 2.95

P Tester oil delivery pressure kPa 255 255 255

P Tester oil delivery pressure kgf/cm2 2.6 2.6 2.6

Direction of rotation (viewed from drive side) R

Right

2 Adjustment specification

2.1 Injection timing adjustment

CAT Designation Unit Set value min. max. Actual values OT

P Direction of rotation (viewed from drive side) R

Right

P Injection order 1-3-4-2

S Pre-stroke mm 3.5 3.45 3.55

S Rack position R=A

After adjusting injection quantity.

P Beginning of injection position NO.1

Drive side

S Difference between angles 1 deg. 90 89.5 90.5

Cal 1-3

S Difference between angles 2 deg. 180 179.5 180.5

Cal 1-4

S Difference between angles 3 deg. 270 269.5 270.5

Cyl.1-2

2.2 Injection quantity adjustment

CAT Designation Unit Set value min. max. Actual values OT

P Adjusting point A

P Rack position 9.1

P Pump speed r/min 975 975 975

S Average injection quantity mm3/st. 93.5 92.5 94.5

S Max. variation between cylinders % 0 -2.5 2.5

P Basic *

P Fixing the lever *

CAT Designation Unit Set value min. max. Actual values OT

P Adjusting point D

P Rack position 6.8+-0.5

P Pump speed r/min 400 400 400

S Average injection quantity mm3/st. 12 10.7 13.3

S Max. variation between cylinders % 0 -10 10

P Fixing the rack *

CAT Designation Unit Set value min. max. Actual values OT

P Adjusting point E

P Rack position 9.3++

P Pump speed r/min 100 100 100

S Average injection quantity mm3/st. 80 80 85

P Fixing the lever *

P Rack limit *

S = Setting value, C = Check value)

OT = Outside Tolerance (X is set)

101405-9342 ZEXEL test values diesel fuel-injection equipment 03-05-22 02:30:36 Page 2

2.3 Governor adjustment

Name

K=10 N:Pump speed

N1=975r/min R:Rack position (mm)

N2=400r/min (1)Target notch: K

(2)Tolerance for racks not indicated: +-0.05mm.

(3)RACK LIMIT

(4)Set idle sub-spring

(5)Main spring setting

(6)Rack difference between N = N1 and N = N2

2.4 Speed control lever angle

Name

a=17deg+-5deg

b=0deg+-5deg

c=31deg+-3deg

F:Full speed

I:Idle

S:Stop

S = Setting value, C = Check value)

OT = Outside Tolerance (X is set)

101405-9342 ZEXEL test values diesel fuel-injection equipment 03-05-22 02:30:36 Page 3

2.5 Stop lever angle

Name

a=21deg+-5deg

b=(55deg)

aa=25mm N:Pump normal

bb=0r/min S:Stop the pump.

cc=1-0.5mm (1)Use the hole at R = aa

(2)Speed = bb, rack position = cc (sealed at delivery)

(3)Normal

2.6 Additional device adjustment

2.6.1 Additional device 1

Name I/P WITH LOAD PLUNGER ADJ

Load plunger-equipped pump adjustment

1. Adjust the variation between cylinders and the injection quantity.

2. At Full point A, adjust the pre-stroke to the specified value.

3. After pre-stroke adjustment, reconfirm that the fuel injection quantity and the variation between

cylinders is as specified.

2.7 Timing setting

Name

a=(110deg)

aa=6deg (1)Pump vertical direction

bb=9.1mm (2)Position of gear mark '3' at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)After adjusting the injection quantity, adjust at rack position bb.

S = Setting value, C = Check value)

OT = Outside Tolerance (X is set)

You might also like

- S Setting Value, C Check Value) OT Outside Tolerance (X Is Set)Document4 pagesS Setting Value, C Check Value) OT Outside Tolerance (X Is Set)Екатерина Калашникова100% (1)

- C Check Value) OT Outside Tolerance (X Is Set)Document4 pagesC Check Value) OT Outside Tolerance (X Is Set)Best Auto TechNo ratings yet

- 104740-0976 - Ford RangerDocument6 pages104740-0976 - Ford RangerBaytolgaNo ratings yet

- Data Kalibrasi Injection Pump Forklift MitsubishiDocument3 pagesData Kalibrasi Injection Pump Forklift Mitsubishinarama100% (1)

- 5471Document3 pages5471Mihai-Eugen Popa100% (2)

- 3031 PDFDocument4 pages3031 PDFMihai-Eugen Popa100% (1)

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- 3230F572T Parts CatalogDocument6 pages3230F572T Parts CatalogLIONN TESTE2021100% (1)

- Volvo 7900Document4 pagesVolvo 7900sffsdqNo ratings yet

- Problem Solving (Adrian Recamadas) : FindDocument9 pagesProblem Solving (Adrian Recamadas) : FindPJ PerezNo ratings yet

- Reeds Diesel Engine Troubleshooting HandbookDocument100 pagesReeds Diesel Engine Troubleshooting HandbooksirousNo ratings yet

- 321 L70me C8 - 2 GiDocument396 pages321 L70me C8 - 2 GiKarim Sowley DelgadoNo ratings yet

- 101609-3272 TD PDFDocument3 pages101609-3272 TD PDFadhit_90No ratings yet

- S Setting Value, C Check Value) OT Outside Tolerance (X Is Set)Document4 pagesS Setting Value, C Check Value) OT Outside Tolerance (X Is Set)Nikhil digheNo ratings yet

- S Setting Value, C Check Value) OT Outside Tolerance (X Is Set)Document3 pagesS Setting Value, C Check Value) OT Outside Tolerance (X Is Set)Pedro AbellanNo ratings yet

- 101402-9770 Test PlanDocument3 pages101402-9770 Test PlanMihai-Eugen Popa100% (1)

- Tabla 101481-0151Document7 pagesTabla 101481-0151LIONN ONESOLUTIONNo ratings yet

- 9412Document3 pages9412Mihai-Eugen Popa100% (1)

- S Setting Value, C Check Value) OT Outside Tolerance (X Is Set)Document3 pagesS Setting Value, C Check Value) OT Outside Tolerance (X Is Set)aimanNo ratings yet

- S Setting Value, C Check Value) OT Outside Tolerance (X Is Set)Document5 pagesS Setting Value, C Check Value) OT Outside Tolerance (X Is Set)carlos puertoNo ratings yet

- OT Outside Tolerance (X Is Set)Document4 pagesOT Outside Tolerance (X Is Set)Agus WijayadiNo ratings yet

- S Setting Value, C Check Value) OT Outside Tolerance (X Is Set)Document4 pagesS Setting Value, C Check Value) OT Outside Tolerance (X Is Set)OFFICE DANACNo ratings yet

- OT Outside Tolerance (X Is Set)Document4 pagesOT Outside Tolerance (X Is Set)carlos puertoNo ratings yet

- S Setting Value, C Check Value) OT Outside Tolerance (X Is Set)Document3 pagesS Setting Value, C Check Value) OT Outside Tolerance (X Is Set)Agus WijayadiNo ratings yet

- 101491-9530 Test DataDocument10 pages101491-9530 Test DataShoxNo ratings yet

- S Setting Value, C Check Value) OT Outside Tolerance (X Is Set)Document3 pagesS Setting Value, C Check Value) OT Outside Tolerance (X Is Set)Juan Gabriel OchoaNo ratings yet

- 101401-7321 - Isuzu Şampi̇yonDocument4 pages101401-7321 - Isuzu Şampi̇yonBaytolgaNo ratings yet

- S Setting Value, C Check Value) OT Outside Tolerance (X Is Set)Document6 pagesS Setting Value, C Check Value) OT Outside Tolerance (X Is Set)carlos puertoNo ratings yet

- OT Outside Tolerance (X Is Set)Document6 pagesOT Outside Tolerance (X Is Set)carlos puertoNo ratings yet

- S Setting Value, C Check Value) OT Outside Tolerance (X Is Set)Document3 pagesS Setting Value, C Check Value) OT Outside Tolerance (X Is Set)СТО Дизель Улан-УдэNo ratings yet

- S Setting Value, C Check Value) OT Outside Tolerance (X Is Set)Document5 pagesS Setting Value, C Check Value) OT Outside Tolerance (X Is Set)OFFICE DANACNo ratings yet

- S Setting Value, C Check Value) OT Outside Tolerance (X Is Set)Document6 pagesS Setting Value, C Check Value) OT Outside Tolerance (X Is Set)баха бахинскийNo ratings yet

- S Setting Value, C Check Value) OT Outside Tolerance (X Is Set)Document4 pagesS Setting Value, C Check Value) OT Outside Tolerance (X Is Set)Best Auto TechNo ratings yet

- Пожалуйста, Зарегистрируйте Свою Копию Pdffactory Pro: C = Check Value) Ot = Outside Tolerance (X Is Set)Document7 pagesПожалуйста, Зарегистрируйте Свою Копию Pdffactory Pro: C = Check Value) Ot = Outside Tolerance (X Is Set)баха бахинскийNo ratings yet

- S Setting Value, C Check Value) OT Outside Tolerance (X Is Set)Document6 pagesS Setting Value, C Check Value) OT Outside Tolerance (X Is Set)Praveen FernandoNo ratings yet

- 101603-9093 Test-DataDocument5 pages101603-9093 Test-DataShoxNo ratings yet

- S Setting Value, C Check Value) OT Outside Tolerance (X Is Set)Document6 pagesS Setting Value, C Check Value) OT Outside Tolerance (X Is Set)OFFICE DANACNo ratings yet

- S Setting Value, C Check Value) OT Outside Tolerance (X Is Set)Document5 pagesS Setting Value, C Check Value) OT Outside Tolerance (X Is Set)Muhammed Ali CangürNo ratings yet

- S Setting Value, C Check Value) OT Outside Tolerance (X Is Set)Document7 pagesS Setting Value, C Check Value) OT Outside Tolerance (X Is Set)carlos puertoNo ratings yet

- S Setting Value, C Check Value) OT Outside Tolerance (X Is Set)Document6 pagesS Setting Value, C Check Value) OT Outside Tolerance (X Is Set)LIONN TESTE2021No ratings yet

- 9322a050 - Erkunt Servet 80 TDocument6 pages9322a050 - Erkunt Servet 80 TBaytolgaNo ratings yet

- S Setting Value, C Check Value) OT Outside Tolerance (X Is Set)Document6 pagesS Setting Value, C Check Value) OT Outside Tolerance (X Is Set)BaytolgaNo ratings yet

- 104740-0976 - Ford RangerDocument6 pages104740-0976 - Ford RangerBaytolgaNo ratings yet

- C Check Value) OT Outside Tolerance (X Is Set)Document3 pagesC Check Value) OT Outside Tolerance (X Is Set)carlos puertoNo ratings yet

- 2005 PDFDocument5 pages2005 PDFMihai-Eugen PopaNo ratings yet

- S Setting Value, C Check Value) OT Outside Tolerance (X Is Set)Document5 pagesS Setting Value, C Check Value) OT Outside Tolerance (X Is Set)OFFICE DANACNo ratings yet

- S Setting Value, C Check Value) OT Outside Tolerance (X Is Set)Document3 pagesS Setting Value, C Check Value) OT Outside Tolerance (X Is Set)LIONN TESTE2021No ratings yet

- 104748-0230 - Mazda - Kia Ceres 2200 AyniDocument2 pages104748-0230 - Mazda - Kia Ceres 2200 AyniBaytolga100% (1)

- 104780-3031 Test PlanDocument4 pages104780-3031 Test PlanMihai-Eugen PopaNo ratings yet

- S Setting Value, C Check Value) OT Outside Tolerance (X Is Set)Document4 pagesS Setting Value, C Check Value) OT Outside Tolerance (X Is Set)Юрий ТрофимовNo ratings yet

- S Setting Value, C Check Value) OT Outside Tolerance (X Is Set)Document5 pagesS Setting Value, C Check Value) OT Outside Tolerance (X Is Set)BaytolgaNo ratings yet

- S Setting Value, C Check Value) OT Outside Tolerance (X Is Set)Document4 pagesS Setting Value, C Check Value) OT Outside Tolerance (X Is Set)Алексей ГавриловNo ratings yet

- S Setting Value, C Check Value) OT Outside Tolerance (X Is Set)Document4 pagesS Setting Value, C Check Value) OT Outside Tolerance (X Is Set)LIONN TESTE2021No ratings yet

- 9161Document5 pages9161BaytolgaNo ratings yet

- 104700-9191 Hyundai̇ Kia 2500Document5 pages104700-9191 Hyundai̇ Kia 2500BaytolgaNo ratings yet

- 104740-6142 9 460 620 023 Opel-Isuzu Test PlanDocument5 pages104740-6142 9 460 620 023 Opel-Isuzu Test PlanBaytolgaNo ratings yet

- Lionn Auto SoftwaresDocument3 pagesLionn Auto SoftwaresLIONN TESTE2021No ratings yet

- Zexel VRZ Pump PDFDocument12 pagesZexel VRZ Pump PDFalvarikokexNo ratings yet

- Test SheetDocument3 pagesTest SheetNemo NeoNo ratings yet

- 362Document2 pages362Ajay AsodariyaNo ratings yet

- Пожалуйста, Зарегистрируйте Свою Копию Pdffactory ProDocument4 pagesПожалуйста, Зарегистрируйте Свою Копию Pdffactory ProАлексей Гаврилов100% (1)

- CM 470Document4 pagesCM 470Chachou MohamedNo ratings yet

- C Check Value) OT Outside Tolerance (X Is Set)Document3 pagesC Check Value) OT Outside Tolerance (X Is Set)carlos puertoNo ratings yet

- 104648-0225 Lionn Auto SoftwaresDocument3 pages104648-0225 Lionn Auto SoftwaresLIONN ONESOLUTIONNo ratings yet

- 3230F563T Parts CatalogDocument6 pages3230F563T Parts CatalogLIONN TESTE2021No ratings yet

- 3230F563T Parts CatalogDocument6 pages3230F563T Parts CatalogLIONN TESTE2021No ratings yet

- 3230F350 PARTS CatalogDocument5 pages3230F350 PARTS CatalogLIONN TESTE2021No ratings yet

- 3230F563T Parts CatalogDocument6 pages3230F563T Parts CatalogLIONN TESTE2021No ratings yet

- S Setting Value, C Check Value) OT Outside Tolerance (X Is Set)Document6 pagesS Setting Value, C Check Value) OT Outside Tolerance (X Is Set)LIONN TESTE2021No ratings yet

- 3230F250 DATA CatalogDocument1 page3230F250 DATA CatalogLIONN TESTE2021No ratings yet

- Lionn Auto SoftwaresDocument3 pagesLionn Auto SoftwaresLIONN TESTE2021No ratings yet

- S Setting Value, C Check Value) OT Outside Tolerance (X Is Set)Document1 pageS Setting Value, C Check Value) OT Outside Tolerance (X Is Set)LIONN TESTE2021No ratings yet

- S Setting Value, C Check Value) OT Outside Tolerance (X Is Set)Document4 pagesS Setting Value, C Check Value) OT Outside Tolerance (X Is Set)LIONN TESTE2021No ratings yet

- S Setting Value, C Check Value) OT Outside Tolerance (X Is Set)Document3 pagesS Setting Value, C Check Value) OT Outside Tolerance (X Is Set)LIONN TESTE2021No ratings yet

- ADocument1 pageALIONN TESTE2021No ratings yet

- ADocument1 pageALIONN TESTE2021No ratings yet

- Datasheet BW212D-5 BW212DH-5 BW212PD-5 4f PRE58612010 SA03Document4 pagesDatasheet BW212D-5 BW212DH-5 BW212PD-5 4f PRE58612010 SA03EslamAldenAbdoNo ratings yet

- cm284 j843 Engine PDFDocument219 pagescm284 j843 Engine PDFкостя костяNo ratings yet

- 3306 Industrial Engine - Troubleshooting - Testing and AdjustingDocument93 pages3306 Industrial Engine - Troubleshooting - Testing and AdjustingJordy Zavaleta100% (7)

- Intern RepDocument24 pagesIntern RepsabihNo ratings yet

- 8R Final Tier 4 FT4 Series Tractors S N 090001 170000 8245R 8270R 8295R 8320R 8335R 8345R 8370R 8400R Replacement Parts GuideDocument3 pages8R Final Tier 4 FT4 Series Tractors S N 090001 170000 8245R 8270R 8295R 8320R 8335R 8345R 8370R 8400R Replacement Parts GuideVanderson FerreiraNo ratings yet

- Thermobile SB Range Used Oil Heaters With Automatic IgnitionDocument4 pagesThermobile SB Range Used Oil Heaters With Automatic IgnitionpatapieviciNo ratings yet

- 500 kVA EDG Innova Diesel PDFDocument5 pages500 kVA EDG Innova Diesel PDFRitaban222No ratings yet

- Extraccion de Codigos de Fallas Suzuki Vitara J20aDocument9 pagesExtraccion de Codigos de Fallas Suzuki Vitara J20aWilliam Moron100% (2)

- Installation and Operating ManualDocument60 pagesInstallation and Operating ManualBen AustriaNo ratings yet

- MCH 13 16 ManualDocument120 pagesMCH 13 16 ManualsmelloigorNo ratings yet

- Man BW LargeDocument20 pagesMan BW LargeVictor EugenNo ratings yet

- AGR 318 Lec 3 - Engine Cons & CompDocument42 pagesAGR 318 Lec 3 - Engine Cons & CompHaikal SapurataNo ratings yet

- Cae Engine PDFDocument4 pagesCae Engine PDFrajasekarNo ratings yet

- Diesel 1 - Hoja de Especificaciones - Kta50-G9Document4 pagesDiesel 1 - Hoja de Especificaciones - Kta50-G9Yonny TorradoNo ratings yet

- Technical English 4 WorkbookDocument48 pagesTechnical English 4 WorkbookqawsedrfNo ratings yet

- 17 - Datos Tecnicos PDFDocument4 pages17 - Datos Tecnicos PDFAnonymous iu95trpxNNo ratings yet

- Scangauge II ManualDocument36 pagesScangauge II ManualEric KabigtingNo ratings yet

- UNIT I Gas Power Cycles FinalDocument75 pagesUNIT I Gas Power Cycles FinalMAYUR BHOSALENo ratings yet

- Plant Shutdown For Overhaul To Do ListDocument10 pagesPlant Shutdown For Overhaul To Do ListsprotkarNo ratings yet

- Tad 941 VeDocument2 pagesTad 941 VePdroGsus Abregú TerronesNo ratings yet

- Critical Ship Equipment - Working On Critical SystemsDocument3 pagesCritical Ship Equipment - Working On Critical SystemsWisnu Kertaningnagoro100% (1)

- California t6 BrochureDocument21 pagesCalifornia t6 BrochuresreenathsNo ratings yet

- Economics of Power Generation Multiple Choice Questions and Answers Preparation For Competition Exams PDF - Preparation For Engineering PDFDocument14 pagesEconomics of Power Generation Multiple Choice Questions and Answers Preparation For Competition Exams PDF - Preparation For Engineering PDFER Mukesh ThakurNo ratings yet

- 01 Module 1-Introduction To Combustion EngineeringDocument26 pages01 Module 1-Introduction To Combustion Engineeringlei dennielleNo ratings yet

- GCC 28 enDocument6 pagesGCC 28 enEduardo VicoNo ratings yet

- Energetic Project Report - E2 - C2Document35 pagesEnergetic Project Report - E2 - C2hasnae malloukiNo ratings yet