Professional Documents

Culture Documents

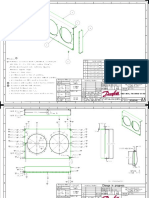

Rev. 0 - Welding Details10 To 4

Uploaded by

Hiệp Phạm VănOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Rev. 0 - Welding Details10 To 4

Uploaded by

Hiệp Phạm VănCopyright:

Available Formats

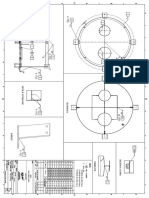

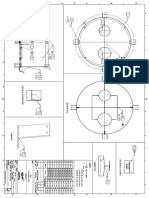

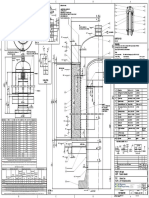

12 11 10 9 8 7 6 5 4 3 2 1

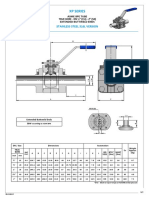

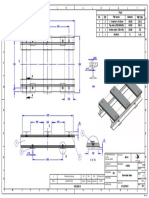

1 3 4" ASME B16.5 - WN FLANGED RF - #150 SA350M Gr.LF2 Cl. 1 7,4 kg

1 2 10" ASME B16.5 - WN FLANGED RF - #150 SA350M Gr.LF2 Cl. 1 25,3 kg

H 1 1 ASME B16.9 Reducer 273 / 114,3 x 9,27. SA420M Gr. WPL6 8,8 kg H

Qty. Pos. Description/Dimension Drawing/Material Unit wt.

G G

F F

1

W1

356

2

E E

D EXAMINATION GENERAL NOTES: D

General requirement Dimensions:

In accordance with ASME B31.3 para. 341.4.1 - All flange bolt holes to straddle horizontal and vertical axis u.o.n.

Additional examination as required by Class/NOV inspector - All dimensions are given without deductions for beveling gap or allowance for

machining unless otherwise noted (u.o.n.).

Visual - All sharp edges shall be rounded by grinding to a radius of minimum 2mm.

100% on all welds Remove all burrs, weldslag and spatters

According to ASME/BPVC Section V, article 9

Materials:

MPE - Materials shall conform to requirements in NACE MR0175 Clause A.2.1.4

20% on all welds

C RE/UE Heat treatment C

Minimum 5% of circumferential butt welds are to be examined fully - In accordance with ASME B31.3 Table 331.1.1

TESTING

Hydrostatic Leak Test

In accordance with ASME B31.3 para 345.4

To be tested independently or with main assembly

Tolerances except as noted Welding except as noted Total weight

Impact testing ISO 13920-AE EN 287-1/2

In accordance with ASME B31.3 para. 323.3 ISO 2768-mK-E ASME IX 41,5 kg

Additional testing as required by Class/NOV inspector ASME B31.3

B B

Hardness testing

- In accordance with NACE MR0175 part 2, 7.3.3 0 02-Oct-2014 Issued for Construction ROJO TONO DOLE

Rev. Date Description Made Checked Appr.

This document contains proprietary and confidential information which

W1 belongs to National Oilwell Norway AS. It is loaned for limited purposes

only and remains the property of National Oilwell Norway AS.

Design data Reproduction, in whole or in part, or use of this design or distribution of

this information to others is not permitted without the express written

consent of National Oilwell Norway AS. This document is to be returned

National Oilwell Varco Norway AS

Column 1 Column 2 to National Oilwell Norway AS upon request and in any event upon P.O. Box 168, Drengsrudhagen 4

Inside completion of the use for which it was loaned. N-1371 Asker, Norway

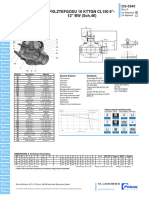

Design code ASME B31.3 2012 ed. Title:

Welding Details

Design pressure 16 barg 10" to 4" 150# ASME B16.9 REDUCER 16BAR,

Design temperature -46/+121 deg. C -46 C to 121 C

Outside Design medium density 2200 kg/m^3

Impact testing in accordance with ASME B31.3 para.323.3 Required

A Hydrostatic test in accordance with B31.3 para. 345.4 Required Scale: Projection: Size: Main Part: A

1:5 A1

Test pressure 24 bar 15min Drawing Number: Sheet: Revision:

Note; See ASME B31.3 Fig. 328.4.2 & 328.4.3 Corrosion allowance process piping 3,0 mm DP84-S5704 1/1 0

12 11 10 9 8 7 6 5 4 3 2 1

You might also like

- Welding Details 10" 150# ASME B16.9 TEE 16BAR, - 46 C To 121 C DP84-S5403Document1 pageWelding Details 10" 150# ASME B16.9 TEE 16BAR, - 46 C To 121 C DP84-S5403Hiệp Phạm VănNo ratings yet

- Parts list for lifting slings and insertsDocument1 pageParts list for lifting slings and insertsAdrian CantaragiuNo ratings yet

- Cus3pr16 M 20ft Rev.0Document1 pageCus3pr16 M 20ft Rev.0DouglasAtiasNo ratings yet

- ASME BPE XP SERIES TUBEDocument2 pagesASME BPE XP SERIES TUBEThomas C. LaneNo ratings yet

- GD Frac ValvesSeats Spec-SheetDocument2 pagesGD Frac ValvesSeats Spec-SheetbayuNo ratings yet

- Cus10c16-M-20ft Rev.0Document1 pageCus10c16-M-20ft Rev.0DouglasAtiasNo ratings yet

- Advantedge 600mmDocument1 pageAdvantedge 600mmJavier TorresNo ratings yet

- R Series Ex D: Stainless SteelDocument6 pagesR Series Ex D: Stainless SteelTran DucNo ratings yet

- 1GG0081614 Tomas Test Assy ADocument1 page1GG0081614 Tomas Test Assy APuneeth RajanasiriyuruNo ratings yet

- Info Tecnica PekosDocument1 pageInfo Tecnica PekosRobertoNo ratings yet

- 50 10xaa1 He40 21RDCH 1016Document1 page50 10xaa1 He40 21RDCH 1016uma raneNo ratings yet

- Rak ConsumableDocument1 pageRak ConsumableWawan SaputraNo ratings yet

- CATDrawing1 ModelDocument1 pageCATDrawing1 Modelawarade276No ratings yet

- 8790-85-0021 - 01 Field Wiring (Control)Document1 page8790-85-0021 - 01 Field Wiring (Control)pstechnical_43312697No ratings yet

- EBRO Butterfly ValveDocument8 pagesEBRO Butterfly ValveNirav ShahNo ratings yet

- 61-Lel-Axp-Pip-Is-0406 SHT 4 of 7Document1 page61-Lel-Axp-Pip-Is-0406 SHT 4 of 7Aravind BabuNo ratings yet

- Acpm GN CDRDocument1 pageAcpm GN CDRalusiusNo ratings yet

- Fig FM276 Strainers CraneFS DS 1702 P208Document1 pageFig FM276 Strainers CraneFS DS 1702 P208ธนาธิป 002No ratings yet

- Mach 10465657 A PDFDocument1 pageMach 10465657 A PDFshahanarab934No ratings yet

- Signal Mast Beaver 1200 With Awning: Ihc Holland Beaver Dredgers B.VDocument1 pageSignal Mast Beaver 1200 With Awning: Ihc Holland Beaver Dredgers B.VMD shawonNo ratings yet

- 61-LEL-WHP-PIP-IS-0232 SHT 2Document1 page61-LEL-WHP-PIP-IS-0232 SHT 2Aravind BabuNo ratings yet

- TUBERIAS PVCDocument1 pageTUBERIAS PVCTaty TatitaNo ratings yet

- Eternis Aroma ConsoleDocument6 pagesEternis Aroma ConsolePawan PatilNo ratings yet

- Lifting Plan DrawingDocument1 pageLifting Plan DrawingPintu kumarNo ratings yet

- Basket Fan 130cm - Exploded ViewDocument1 pageBasket Fan 130cm - Exploded ViewEric SimardNo ratings yet

- Vms Approval: Section A-A Detail EDocument1 pageVms Approval: Section A-A Detail ELuong LeNo ratings yet

- Diffuser (DF) With Al-Obss (375X520)Document1 pageDiffuser (DF) With Al-Obss (375X520)Akshay KadiaNo ratings yet

- Dimensi Pompa DESMIDocument8 pagesDimensi Pompa DESMIDeddyNo ratings yet

- Technical Specification and Materials of ConstructionDocument1 pageTechnical Specification and Materials of ConstructionAhmadNo ratings yet

- Generator Base DrawingDocument1 pageGenerator Base Drawingpasan rajasingheNo ratings yet

- DM5 004 02 MoldDocument1 pageDM5 004 02 MoldLuong LeNo ratings yet

- Example Drawing GD&TDocument3 pagesExample Drawing GD&TEngineerNo ratings yet

- Ductile Iron Fully-Lugged PN16: Features & BenefitsDocument1 pageDuctile Iron Fully-Lugged PN16: Features & BenefitsRonaldNo ratings yet

- 1050mm VEE PLOUGHDocument1 page1050mm VEE PLOUGHstuart2333maleNo ratings yet

- Pertashop UpdateDocument60 pagesPertashop UpdateFX. Gatot SuryantoNo ratings yet

- Installation example for FASERFIX SUPER channel system in concrete up to load class F 900Document1 pageInstallation example for FASERFIX SUPER channel system in concrete up to load class F 900Mihail KoprivchinNo ratings yet

- Acople Hidraulico Tipo MariposaDocument2 pagesAcople Hidraulico Tipo MariposaYosed Leonardo Santos GomezNo ratings yet

- Foundation, pedestal layout and detailsDocument1 pageFoundation, pedestal layout and detailsJustin ArulvalanNo ratings yet

- 4Document3 pages4MostafaElrakhawyNo ratings yet

- Item No. Material QTY Req'D Brass Bar Alloy 380: TolerancesDocument2 pagesItem No. Material QTY Req'D Brass Bar Alloy 380: Tolerancescarlosar1477No ratings yet

- GT outlet transition duct assembly detailsDocument1 pageGT outlet transition duct assembly detailsprasongNo ratings yet

- Fan shroud assembly drawingDocument5 pagesFan shroud assembly drawingviniciusschwabNo ratings yet

- Lg6300e (fb9)Document3 pagesLg6300e (fb9)tarek.elhassen.transportNo ratings yet

- Aluminium 2Document1 pageAluminium 2Istvan DedeNo ratings yet

- RF Cabinet - 443529109671 - REV SDocument5 pagesRF Cabinet - 443529109671 - REV Sanphat.hanoi.computerNo ratings yet

- Pioneer DJM-S3 QRT1016Document38 pagesPioneer DJM-S3 QRT1016Wenderson FeltrinNo ratings yet

- Advantedge 900mmDocument1 pageAdvantedge 900mmJavier TorresNo ratings yet

- The 4310 Series Is Designed To Provide Quick Access For Product Gauging, Temperature Measure Ment or SamplingDocument2 pagesThe 4310 Series Is Designed To Provide Quick Access For Product Gauging, Temperature Measure Ment or SamplingVinicio VillarruelNo ratings yet

- NZ - Valvula de BolaDocument2 pagesNZ - Valvula de Bolajorge manuelNo ratings yet

- FIG. 2010CR: 2000 Psi Forged Steel Hex-Bar RP Ball ValveDocument1 pageFIG. 2010CR: 2000 Psi Forged Steel Hex-Bar RP Ball ValveVictor LopezNo ratings yet

- Misc RW 001Document1 pageMisc RW 001Tanveer IqbalNo ratings yet

- Advantedge 450mmDocument1 pageAdvantedge 450mmJavier TorresNo ratings yet

- 8790-85-0005 - 01 PLC Integral IODocument1 page8790-85-0005 - 01 PLC Integral IOpstechnical_43312697No ratings yet

- 50 10xaa1 He40 22RDCH 1016Document1 page50 10xaa1 He40 22RDCH 1016uma raneNo ratings yet

- 80-100 Micron Galvanized Structure DetailsDocument9 pages80-100 Micron Galvanized Structure Detailsisan.structural TjsvgalavanNo ratings yet

- PLOT PLAN FOR GGS TEGAL PACINGDocument7 pagesPLOT PLAN FOR GGS TEGAL PACINGNur Arif Trisandi SapariNo ratings yet

- Feeder Trolley Mbs 500 Ur40e 81s-Asm General ArrangementDocument2 pagesFeeder Trolley Mbs 500 Ur40e 81s-Asm General ArrangementGeorgios PourtsidisNo ratings yet

- Toyota Tacoma Electrical Wiring DiagramDocument39 pagesToyota Tacoma Electrical Wiring DiagramEnrique Lopez100% (2)

- HWU 340K EHR-03: Issued For ConstructionDocument1 pageHWU 340K EHR-03: Issued For ConstructionRedy K PutraNo ratings yet

- The Rough Guide to Beijing (Travel Guide eBook)From EverandThe Rough Guide to Beijing (Travel Guide eBook)Rating: 2 out of 5 stars2/5 (1)

- Rev. 0 - Welding Details10 To 4Document1 pageRev. 0 - Welding Details10 To 4Hiệp Phạm VănNo ratings yet

- 2030 01 WMDocument1 page2030 01 WMHiệp Phạm VănNo ratings yet

- 2020 02 WMDocument1 page2020 02 WMHiệp Phạm VănNo ratings yet

- 2020 01 WMDocument1 page2020 01 WMHiệp Phạm VănNo ratings yet

- P2186336-65-9010-r2-Drawing ListDocument1 pageP2186336-65-9010-r2-Drawing ListHiệp Phạm VănNo ratings yet

- R3 0.12" (Typ) : Weld No. WPS PQR VT MPI PT RT Impact Test W1 W2 W3 W4 W5 W6 W7 W8 W9 W10 W11 W12 W13 W14 W15 W16 W17Document1 pageR3 0.12" (Typ) : Weld No. WPS PQR VT MPI PT RT Impact Test W1 W2 W3 W4 W5 W6 W7 W8 W9 W10 W11 W12 W13 W14 W15 W16 W17Hiệp Phạm VănNo ratings yet

- 1 1 Name Plate Plate 1, 160 X 100 A240 TP316 (L) Qty Description Dimensions Material CommentsDocument1 page1 1 Name Plate Plate 1, 160 X 100 A240 TP316 (L) Qty Description Dimensions Material CommentsHiệp Phạm VănNo ratings yet

- Birdscreen Stiffener-Long Birdscreen Stiffener-Long: 14 0.55 " 4 X Per Seg Men T (Typ)Document1 pageBirdscreen Stiffener-Long Birdscreen Stiffener-Long: 14 0.55 " 4 X Per Seg Men T (Typ)Hiệp Phạm VănNo ratings yet

- (Ajusted at Shop) : 45° Side SupportDocument1 page(Ajusted at Shop) : 45° Side SupportHiệp Phạm VănNo ratings yet

- Description: The RJH-601 Series Are General Purpose HCR For Molding, Extruding and Calendering CompressionDocument1 pageDescription: The RJH-601 Series Are General Purpose HCR For Molding, Extruding and Calendering CompressionSamNo ratings yet

- Decoprime Primer WTDocument2 pagesDecoprime Primer WTMonal ShindeNo ratings yet

- Topic2 Casting Spring08-09Document85 pagesTopic2 Casting Spring08-09Ayush KishoreNo ratings yet

- Door Welding Inspection ReportDocument9 pagesDoor Welding Inspection ReportAnilkumarNo ratings yet

- Steel Bars, Carbon, Hot-Wrought, Special Quality: Standard Specification ForDocument6 pagesSteel Bars, Carbon, Hot-Wrought, Special Quality: Standard Specification ForAnıl ZiylanNo ratings yet

- Nitoproof 600PF: Hydrocarbon Free, Liquid Applied Elastomeric One Coat Waterproofing Membrane UsesDocument2 pagesNitoproof 600PF: Hydrocarbon Free, Liquid Applied Elastomeric One Coat Waterproofing Membrane UsesKishore Nayak kNo ratings yet

- Magnesium Contents in Ductile IronDocument2 pagesMagnesium Contents in Ductile Ironarnaldorcr8646No ratings yet

- Soldering and Brazing Principles and PracticeDocument7 pagesSoldering and Brazing Principles and PracticeWilly UioNo ratings yet

- 2.excellent Top Kraft - MM KartonDocument2 pages2.excellent Top Kraft - MM KartonMark Sebastian MitranNo ratings yet

- FT Power Tool FlyerDocument5 pagesFT Power Tool Flyer莫明No ratings yet

- MCQ in Machine Design and Shop Practice Part 13 ME Board ExamDocument19 pagesMCQ in Machine Design and Shop Practice Part 13 ME Board ExamKenn Earl Bringino VillanuevaNo ratings yet

- Dial Indicators: FeaturesDocument1 pageDial Indicators: FeaturesAkmalNo ratings yet

- Standard for Protective Coating SystemsDocument55 pagesStandard for Protective Coating SystemsArun KumarNo ratings yet

- 3.4 Golden Joint ProcedureDocument9 pages3.4 Golden Joint ProcedureArieNo ratings yet

- Extruded Alloy 6063Document0 pagesExtruded Alloy 6063Lasantha DadallageNo ratings yet

- 成达水处理科技产品画册(2022 06 04)Document37 pages成达水处理科技产品画册(2022 06 04)chao shenNo ratings yet

- Sheet Metal Welding-Tips PDFDocument5 pagesSheet Metal Welding-Tips PDFMphilipTNo ratings yet

- Appendix T - Weld Metal - Welding Procedure Specification Notch Toughness Verification Test - BNBC 2020 CommentaryDocument2 pagesAppendix T - Weld Metal - Welding Procedure Specification Notch Toughness Verification Test - BNBC 2020 CommentaryTarif Aziz MarufNo ratings yet

- Vessel Sample External Inspection ReportDocument3 pagesVessel Sample External Inspection ReportabdellahNo ratings yet

- As - NZS Iso 14171 - 2013Document8 pagesAs - NZS Iso 14171 - 2013airul6No ratings yet

- MTM Lab ReportDocument68 pagesMTM Lab ReportAbu Bakar KhanNo ratings yet

- Coldformed SectionsDocument56 pagesColdformed SectionsSwapnil ToraskarNo ratings yet

- Pa PLT Lay Clover x01Document1 pagePa PLT Lay Clover x01Nathan ChenNo ratings yet

- TimberDocument55 pagesTimberAra Abdullah100% (1)

- Mapei Sports Flooring SystemsDocument38 pagesMapei Sports Flooring SystemsWolves CreataNo ratings yet

- ZL 440 Product Data SheetDocument3 pagesZL 440 Product Data SheetVishal ChudasamaNo ratings yet

- Filtration and Separation in RefineriesDocument30 pagesFiltration and Separation in RefineriesprogerNo ratings yet

- Sample PQRDocument2 pagesSample PQRudaysrp33% (3)

- MEM R2 Companion Volume Implementation Guide 2019Document192 pagesMEM R2 Companion Volume Implementation Guide 2019Stanley AlexNo ratings yet

- Norton Abrasive Solutions-Gear IndustryDocument36 pagesNorton Abrasive Solutions-Gear IndustryJItesh PAtilNo ratings yet