Professional Documents

Culture Documents

Flowbiz Cast Steel Nd40 Globe Valves

Uploaded by

FlowBiz Exports Pvt. Ltd.Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Flowbiz Cast Steel Nd40 Globe Valves

Uploaded by

FlowBiz Exports Pvt. Ltd.Copyright:

Available Formats

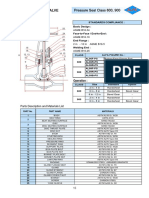

CAST STEEL ND40 GLOBE VALVES BS: 5160/DIN: 2401 (PN40)

SPECIFICATIONS :

FlowBiz have designed Bolted bonnet with an integral yoke, outside screw rising stem suitable for repacking under

pressure when fully open. Flanged ends drilled to DIN 2545 with raised face and comes with the renewable seat.

BOLTED BONNET, RISING STEM, S.S. TRIM, FLANGES AS PER DIN STD 2545 : PN 40 (R.F.)

ØHW~

18

17

16

15

14

13

12

H~

11

10

9

8

7

6

5

K (P.C.D)

4

Ødk

ØD

Øb

3

2

1

f nxØd

T n=No. off holes f

d=Dia. off holes

T

L±2

STANDARD MATERIAL COMBINATION

Part NO. DESCRIPTION MATERIALS SPECIFICATIONS

1 BODY C.C.S. ASTM A216 Gr.WCB

2 BODY SEAT RING 13% Cr. STEEL ASTM 1 182:01 Gr. F6a

3 DISC C.C.S. ASTM A216 Gr.WCB 13% Cr. WELD DEPOSIT

4 THRUST PLATE HARDENED STEEL -------------

5 LOCKING WASHER S.S ANY GRADE

6 DISC NUT 13% Cr. STEEL ASTM A276 TYPE410/ASTM A 182 Gr. F6a

7 STEM 13% Cr. STEEL ASTM A276 TYPE410/ASTM A 182 Gr. F6a

8 BACK SEAT BUSH 13% Cr. STEEL ASTM A276 TYPE410/ASTM A 182 Gr. F6a

9 GASKET SPRIAL WOUND S.S.304 WITH GRAPHITE FILLER

10 BONNET C.C.S ASTM A216 Gr.WCB

11 STUDS & NUTS ALLOY STEEL/H.T.STEEL ASTM A 193 GR. B7/ ASTM A 194 Gr.2H

12 PACKING FLEXIBLE GRAPHITE

13 GLAND C.C.S. ASTM A216 Gr.WCB

14 STUDS & NUTS ALLOY STEEL/High Tensile Steel ASTM A 193 Gr.B7/ ASTM A 194 Gr.2H

15 YOKE BUSH AL. BRONZE BSEN 1982 Gr. CC333G

16 HAND WHEEL D.I. ASTM A536 Gr. 80-55-06

17 WASHER CARBON STEEL IS 2062 Gr.A

18 NUT FOR HANDWHEEL CARBON STEEL BS 916-53

NOTE : The above data is subject to change without notice due to our continuing product improvement program.

Valves can be supplied in other MOC’s on request :

SS (ASTM A 351 Gr.CF3MN / CF8C / CN7M), DSS (ASTM A 995 Gr.4A / 5A/ 3A/ 6A)

01 Copyright-2021 @FlowBiz Exports Pvt. Ltd. Email ID : info@flowbizexports.com | www.flowbizexports.com

ØHW~

18

17

16

15

14

13

12

H~

11

10

9

8

7

6

5

4

K (P.C.D)

Ødk

ØD

Øb

3

2

1

f nxØd

T n=No. off holes f

d=Dia. off holes

T

L±2

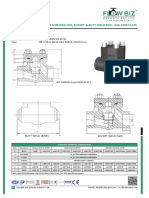

All Dimensions are in mm

PRESSURE / TEMPERATURE RATINGS TO BS 5160 / DIN 2401

NOMINAL MAX. PERMISSIBLE GAUGE WORKING PRESSURE ˚C

PRESSURE 10 TO 120 ˚C 200 ˚C 250 ˚C 300 ˚C 350 ˚C 400 ˚C 425 ˚C

PN 40 40bar 40bar 38bar 33bar 28bar 23bar 20bar

DIMENSIONAL DATA

DN 15 20 25 32 40 50 65 80 100 125 150 200 250 300

NPS 1

/2” 3

/4” 1” 1 1/4” 1 1/2” 2” 2 1/2” 3” 4” 5” 6” 8” 8” 12”

ØHW~ 125 125 160 160 200 200 250 250 300 300 300 350 400 400

L 130 150 160 180 200 230 290 310 350 400 480 600 730 850

Øb 15 20 25 32 40 50 65 80 100 125 150 200 250 300

ØD 95 105 115 140 150 165 185 200 235 270 300 375 450 515

~H(Close) 190 196 225 236 291 314 325 380 435 468 555 645 - -

~H(Open) 194 201 231 244 301 327 341 400 460 499 593 695 - -

dk 45 58 68 78 88 102 122 138 162 188 218 285 345 410

k 65 75 85 100 110 125 145 160 190 220 250 320 385 450

n 4 4 4 4 4 4 8 8 8 8 8 12 12 16

Ød 14 14 14 18 18 18 18 18 22 26 26 30 33 33

Aprox.Wt

3.23 4.85 6.35 11.7 14 20.3 32.8 42.5 66.5 105.7 169.3 268 419 660

Kgs.

TEST PRESSURES

NOMINAL PRESSURE RATING SHELL TEST (HYDROSTATIC) SEAT TEST (HYDROSTATIC & 6.9 BAR (AIR)

PN 40 60 BAR 60 BAR

NOTE : The above data is subject to change without notice due to our continuing product improvement program.

Valves can be supplied in other MOC’s on request :

SS (ASTM A 351 Gr.CF3MN / CF8C / CN7M), DSS (ASTM A 995 Gr.4A / 5A/ 3A/ 6A)

02 Copyright-2021 @FlowBiz Exports Pvt. Ltd. Email ID : info@flowbizexports.com | www.flowbizexports.com

You might also like

- Steel and Its Heat Treatment: Bofors HandbookFrom EverandSteel and Its Heat Treatment: Bofors HandbookRating: 2.5 out of 5 stars2.5/5 (3)

- FlowBiz Cast Steel Angle Type Globe ValvesDocument2 pagesFlowBiz Cast Steel Angle Type Globe ValvesShakir AnsariNo ratings yet

- 316L Stainless Steel Fittings and Galvanized Pipe Bill of MaterialsDocument4 pages316L Stainless Steel Fittings and Galvanized Pipe Bill of MaterialsNikhil RajuNo ratings yet

- HidraulicaDocument4 pagesHidraulicaAntonio Anatoly Viamont PintoNo ratings yet

- Diaphragm ValveDocument2 pagesDiaphragm ValveHardik ShahNo ratings yet

- EN232400202-02Document1 pageEN232400202-02bevara santhoshkumarNo ratings yet

- Data Sheet UbsvDocument6 pagesData Sheet UbsvMeet JaniNo ratings yet

- Cast Steel Globe Valve Class: Figure No. Gl1Rcb8 Gl1Bcb8 Gl1Jcb8Document4 pagesCast Steel Globe Valve Class: Figure No. Gl1Rcb8 Gl1Bcb8 Gl1Jcb8Sushil ChauhanNo ratings yet

- GL 125 150Document1 pageGL 125 150FABIONo ratings yet

- Top Guide Control ValveDocument1 pageTop Guide Control ValveArman MominNo ratings yet

- Valvula Warren-2155-5nDocument2 pagesValvula Warren-2155-5nFernando castellano castroNo ratings yet

- Valvulas TCIDocument15 pagesValvulas TCIGuillermo de la Fuente SantiagoNo ratings yet

- Ball Check ValveDocument2 pagesBall Check ValveHardik ShahNo ratings yet

- Datasheet CHK VLV (14in #150)Document1 pageDatasheet CHK VLV (14in #150)chintanNo ratings yet

- 3Document1 page3Dinesh KumarNo ratings yet

- Globe Valves - ASME Class 900 & 1500: Flanged EndDocument1 pageGlobe Valves - ASME Class 900 & 1500: Flanged EndMunishTrichyNo ratings yet

- Channelsleeper SetDocument1 pageChannelsleeper SetShafiul AzamNo ratings yet

- Requirement: 261 Sets. List of Fittings For Steel Channel Sleeper (One Set) List of FittingsDocument1 pageRequirement: 261 Sets. List of Fittings For Steel Channel Sleeper (One Set) List of FittingsBWS JALANDHARNo ratings yet

- RTJ PDFDocument5 pagesRTJ PDFEmiliano ZappaterraNo ratings yet

- Cast Steel Gate Valve Class 150 & 300 SpecificationsDocument4 pagesCast Steel Gate Valve Class 150 & 300 Specificationsarmin heidariNo ratings yet

- 03b Check Valves Preesure SealDocument2 pages03b Check Valves Preesure SealAndri AjaNo ratings yet

- 13 - Check ValvesDocument14 pages13 - Check ValvesSiles LimberdsNo ratings yet

- Gate Valve Materials ListDocument2 pagesGate Valve Materials ListJavier FernandezNo ratings yet

- Tdi 50000 Tpy, GNFCDocument6 pagesTdi 50000 Tpy, GNFCkrunal panchalNo ratings yet

- Warren 1155 8 Valvulas Compuert Api600 Trim 8Document4 pagesWarren 1155 8 Valvulas Compuert Api600 Trim 8Luis ArenasNo ratings yet

- KITZ - Cast Iron - 125FCL&125FCYDocument2 pagesKITZ - Cast Iron - 125FCL&125FCYdanang hadi saputroNo ratings yet

- Forged Steel Check Valves - Bs 5352, Ansi B16.34 CLASS-600,800,1500 & 2500Document2 pagesForged Steel Check Valves - Bs 5352, Ansi B16.34 CLASS-600,800,1500 & 2500ThomasFrenchNo ratings yet

- FlowBiz Forged Steel Gate Valve Flanged End 150 ClassDocument2 pagesFlowBiz Forged Steel Gate Valve Flanged End 150 ClassSHAKIR ANSARINo ratings yet

- Cast Iron Swing Check Valve Spec SheetDocument2 pagesCast Iron Swing Check Valve Spec SheetevelingonNo ratings yet

- Estimasi Piping Accessories and Bulk Material For First Firing Unit #1Document4 pagesEstimasi Piping Accessories and Bulk Material For First Firing Unit #1Arif BinorikaNo ratings yet

- Plummech Check ValvesDocument1 pagePlummech Check ValvesNguyễn Đăng PhúcNo ratings yet

- Swing Check Valve 900 Class SpecDocument1 pageSwing Check Valve 900 Class SpecMunishTrichyNo ratings yet

- Cast Steel Globe Valve Pressure Seal Class 1500, 2500Document3 pagesCast Steel Globe Valve Pressure Seal Class 1500, 2500Andri AjaNo ratings yet

- Class 150 Cast Carbon Steel Gate ValveDocument1 pageClass 150 Cast Carbon Steel Gate Valvearief sugiartoNo ratings yet

- Delta Pacific Valve Mfg. Co.: New York, U.S.ADocument1 pageDelta Pacific Valve Mfg. Co.: New York, U.S.ALê Tuấn AnhNo ratings yet

- Butterfly Valve Wafer TypeDocument2 pagesButterfly Valve Wafer TypeHardik ShahNo ratings yet

- Ring joint gaskets and profiles for oil and gas pipelinesDocument5 pagesRing joint gaskets and profiles for oil and gas pipelinesmohamedNo ratings yet

- Material AsmDocument6 pagesMaterial Asmrawalepushkar123No ratings yet

- 600scjs#cy 2-12 - 15Document2 pages600scjs#cy 2-12 - 15MohamadIbnuHassanNo ratings yet

- REL OSY 399F - FM UL OS&Y Multi LingualDocument2 pagesREL OSY 399F - FM UL OS&Y Multi LingualAhmed Salah Abd EL-WahedNo ratings yet

- Jl. Perak Timur 102 Surabaya: Weight SummaryDocument74 pagesJl. Perak Timur 102 Surabaya: Weight SummaryhajarNo ratings yet

- Comp PN16Document1 pageComp PN16Martin Augusto Torrau CayoNo ratings yet

- 11d Pms Rev00a Ongc 27jul15Document3 pages11d Pms Rev00a Ongc 27jul15abhiNo ratings yet

- Astm A 403 Gr. WP304L-S Astm A 403 Gr. WP304L-WX Astm A 182 GR.F304LDocument2 pagesAstm A 403 Gr. WP304L-S Astm A 403 Gr. WP304L-WX Astm A 182 GR.F304LEILA545 QAQCNo ratings yet

- 4C-01-02 Rev 2Document5 pages4C-01-02 Rev 2Christian Martínez G.No ratings yet

- TS - 19series SafetyDocument4 pagesTS - 19series SafetykicsnerNo ratings yet

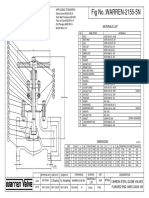

- Fig No.:WARREN-1155-5N: Materials ListDocument2 pagesFig No.:WARREN-1155-5N: Materials ListDiego OrtegaNo ratings yet

- V1-2 Severe Service Metal Seated Ball ValvesDocument2 pagesV1-2 Severe Service Metal Seated Ball ValvesSergio Gana GonzalezNo ratings yet

- Fox ™ Triple Effect Air Vent + Anti Water Hammer: FeaturesDocument5 pagesFox ™ Triple Effect Air Vent + Anti Water Hammer: FeaturesNicolás Polito MuñozNo ratings yet

- Diaphragm Valve Parts ListDocument1 pageDiaphragm Valve Parts ListS AMNo ratings yet

- Non Return Valves Cast Steel APIDocument4 pagesNon Return Valves Cast Steel APILinson GeorgeNo ratings yet

- Po SR No-112 (170159) 6X150 2150 MM ExtDocument1 pagePo SR No-112 (170159) 6X150 2150 MM ExtDebasis Pattnaik DebaNo ratings yet

- Centralized Foam System Pipe Data SheetDocument2 pagesCentralized Foam System Pipe Data SheetIsrael Raja AbhilashNo ratings yet

- 4 - Check Valves MuellerDocument14 pages4 - Check Valves MuellerFIRSON ANDRES SerranoNo ratings yet

- Relief ValveDocument2 pagesRelief ValveRobertoNo ratings yet

- Piping Class Detail: ENI Database PROJ: JA0051 REV: 2 DOC: CAFC-00-SP-P-00OO30Document1 pagePiping Class Detail: ENI Database PROJ: JA0051 REV: 2 DOC: CAFC-00-SP-P-00OO30Asma GouasmiaNo ratings yet

- Beric Forged Steel ValvesDocument32 pagesBeric Forged Steel ValvesKit AnnoncerNo ratings yet

- CMPC Pulp: G.Navarrete P.StrodthoffDocument5 pagesCMPC Pulp: G.Navarrete P.StrodthoffCesar Eugenio Sanhueza ValdebenitoNo ratings yet

- Fig 4923 GDocument1 pageFig 4923 GAsmaaNo ratings yet

- FlowBiz Forged Lift Check Valve 1500 ClassDocument2 pagesFlowBiz Forged Lift Check Valve 1500 ClassFlowBiz Exports Pvt. Ltd.No ratings yet

- FlowBiz Non Slam Disc Check ValveDocument3 pagesFlowBiz Non Slam Disc Check ValveFlowBiz Exports Pvt. Ltd.No ratings yet

- FlowBiz Cast Steel Swing Check ValveDocument3 pagesFlowBiz Cast Steel Swing Check ValveFlowBiz Exports Pvt. Ltd.No ratings yet

- Forged Steel Check Valve Flange End - Asa 150 Class: Standards & SpecificationsDocument9 pagesForged Steel Check Valve Flange End - Asa 150 Class: Standards & SpecificationsFlowBiz Exports Pvt. Ltd.No ratings yet

- FlowBiz High Pressure Universal Design Non Return ValveDocument1 pageFlowBiz High Pressure Universal Design Non Return ValveFlowBiz Exports Pvt. Ltd.No ratings yet

- FlowBiz Forged Steel Globe ValveDocument14 pagesFlowBiz Forged Steel Globe ValveFlowBiz Exports Pvt. Ltd.No ratings yet

- FlowBiz Forged Steel Globe Valve Full BoreDocument2 pagesFlowBiz Forged Steel Globe Valve Full BoreFlowBiz Exports Pvt. Ltd.No ratings yet

- FlowBiz Forged Steel Globe Valve 1500 ClassDocument2 pagesFlowBiz Forged Steel Globe Valve 1500 ClassFlowBiz Exports Pvt. Ltd.No ratings yet

- FlowBiz Forged Steel Globe Valve Reduced BoreDocument2 pagesFlowBiz Forged Steel Globe Valve Reduced BoreFlowBiz Exports Pvt. Ltd.No ratings yet

- Exposure: Poisoned Water, Corporate Greed, and One Lawyer's Twenty-Year Battle Against DuPontFrom EverandExposure: Poisoned Water, Corporate Greed, and One Lawyer's Twenty-Year Battle Against DuPontRating: 4.5 out of 5 stars4.5/5 (18)

- Desperate: An Epic Battle for Clean Water and Justice in AppalachiaFrom EverandDesperate: An Epic Battle for Clean Water and Justice in AppalachiaRating: 4 out of 5 stars4/5 (1)

- The Rights of Nature: A Legal Revolution That Could Save the WorldFrom EverandThe Rights of Nature: A Legal Revolution That Could Save the WorldRating: 5 out of 5 stars5/5 (1)

- Waste: One Woman’s Fight Against America’s Dirty SecretFrom EverandWaste: One Woman’s Fight Against America’s Dirty SecretRating: 5 out of 5 stars5/5 (1)

- Slow Violence and the Environmentalism of the PoorFrom EverandSlow Violence and the Environmentalism of the PoorRating: 4 out of 5 stars4/5 (5)

- 3rd Grade Science: Life Sciences in Eco Systems | Textbook EditionFrom Everand3rd Grade Science: Life Sciences in Eco Systems | Textbook EditionNo ratings yet

- Art of Commenting: How to Influence Environmental Decisionmaking With Effective Comments, The, 2d EditionFrom EverandArt of Commenting: How to Influence Environmental Decisionmaking With Effective Comments, The, 2d EditionRating: 3 out of 5 stars3/5 (1)

- Busted!: Drug War Survival Skills and True Dope DFrom EverandBusted!: Drug War Survival Skills and True Dope DRating: 3.5 out of 5 stars3.5/5 (7)

- The Cyanide Canary: A True Story of InjusticeFrom EverandThe Cyanide Canary: A True Story of InjusticeRating: 4 out of 5 stars4/5 (51)

- Reduce, Reuse and Recycle : The Secret to Environmental Sustainability : Environment Textbooks | Children's Environment BooksFrom EverandReduce, Reuse and Recycle : The Secret to Environmental Sustainability : Environment Textbooks | Children's Environment BooksNo ratings yet

- Ecosystem Facts That You Should Know - The Forests Edition - Nature Picture Books | Children's Nature BooksFrom EverandEcosystem Facts That You Should Know - The Forests Edition - Nature Picture Books | Children's Nature BooksNo ratings yet

- Principles of direct and superior responsibility in international humanitarian lawFrom EverandPrinciples of direct and superior responsibility in international humanitarian lawNo ratings yet

- Environmental Education in Practice: Concepts and ApplicationsFrom EverandEnvironmental Education in Practice: Concepts and ApplicationsNo ratings yet

- New Paradigms in Environmental Biomonitoring Using PlantsFrom EverandNew Paradigms in Environmental Biomonitoring Using PlantsSupriya TiwariNo ratings yet

- Land Divided by Law: The Yakama Indian Nation as Environmental History, 1840-1933From EverandLand Divided by Law: The Yakama Indian Nation as Environmental History, 1840-1933No ratings yet

- Down to the Wire: Confronting Climate CollapseFrom EverandDown to the Wire: Confronting Climate CollapseRating: 4.5 out of 5 stars4.5/5 (8)

- Exposure: Poisoned Water, Corporate Greed, and One Lawyer's Twenty-Year Battle against DuPontFrom EverandExposure: Poisoned Water, Corporate Greed, and One Lawyer's Twenty-Year Battle against DuPontRating: 4.5 out of 5 stars4.5/5 (9)

- Stand Up That Mountain: The Battle to Save One Small Community in the Wilderness Along the Appalachian TrailFrom EverandStand Up That Mountain: The Battle to Save One Small Community in the Wilderness Along the Appalachian TrailRating: 3 out of 5 stars3/5 (3)