Professional Documents

Culture Documents

FlowBiz Forged Lift Check Valve 1500 Class

Uploaded by

FlowBiz Exports Pvt. Ltd.Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

FlowBiz Forged Lift Check Valve 1500 Class

Uploaded by

FlowBiz Exports Pvt. Ltd.Copyright:

Available Formats

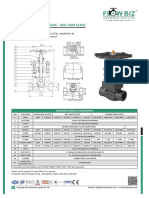

FORGED STEEL CHECK VALVE SCREWED END, SOCKET & BUTT WELD END - ASA 1500 CLASS

SPECIFICATIONS

Design Standard : API 602 / BSEN ISO 15761

Type : Lift / Piston Check Valve Bolted / Weld Cover

6

7

5

4

H~

Øb

NPT THREADS As per ASME B1.20.1

L

ØSW

Øb

D

L1

L2

BUTT WELD (BWE) SOCKET WELD (SW)

STANDARD MATERIAL COMBINATION

P.No. Description Carbon Steel to ASTM Alloy Steel to ASTM Stainless Steel to ASTM

1 BODY A105 A350 LF2 A182 F5 A182 F11 A182 F22 A182 F9 A182 F304 A182 F316 A182 F304L A182 F316L

2 SEAT RING As per Trim Material Combination

3 WEDGE As per Trim Material Combination

4 GASKET Stainless steel + Graphoil

5 COVER A105 A350 LF2 A182 F5 A182 F11 A182 F22 A182 F9 A182 F304 A182 F316 A182 F304L A182 F316L

6 STUDS A193 B7 A320 L7 A193 B7 A193 B16 A193 B16 A193 B16 A193 B8 A193 B8 A193 B8 A193 B8

7 NUTS A194 2H A194 Gr.4 A194 2H A194 Gr.4 A194 Gr.4 A194 Gr.8 A194 Gr.8 A194 Gr.8 A194 Gr.8 A194 Gr.8

Body Material Combination with ASTM F304H, F316H, F321, F347 also provided on request

06 Copyright-2021 @FlowBiz Exports Pvt. Ltd. Email ID : info@flowbizexports.com | www.flowbizexports.com

TRIM MATERIAL COMBINATION (ON REQUEST)

Trim No. Seat Ring Face Wedge Seat Face Stem Backseat Bush Lantern Ring

1 F6a/13% Cr. F6a/13% Cr. F6a/AISI 410 F6a/AISI 410 F6a/AISI 410

2 F304 F304 F304/AISI 304 F304/AISI 304 F304/AISI 304

5 STELLITE STELLITE F6a/AISI 410 F6a/AISI 410 F6a/AISI 410

8 STELLITE F6a/13% Cr. F6a/AISI 410 F6a/AISI 410 F6a/AISI 410

9 MONEL MONEL MONEL MONEL MONEL

10 F316 F316 F316/AISI 316 F316/AISI 316 F316/AISI 316

12 316+STELLITE 316 F316/AISI 316 F316/AISI 316 F316/AISI 316

13 ALLOY 20 ALLOY 20 ALLOY 20 ALLOY 20 ALLOY 20

NOTE: Other Trim Combination can be provided as Trim Material Combination on request

• All Dimensions in mm

DIMENSIONAL DATA CLASS - 1500 (Full Bore)

ø SWE

DN NPS øb L1(BWE) L2(SWE) H D Aprox. Wt. (Kgs)

BS 3799 ASME B16.11

1 +0.3 22.2

15 /2 12 100 100 78

21.8 -0.0 21.8

11 1.450

3 +0.3 27.6

20 /4 16 124 124 90

27.4 -0.0 27.2

14 2.200

+0.3 34.3

25 1 19 145 104 97 14 3.915

34.1 -0.0 33.9

+0.3 43.1

32 1 1/4 31 170 170 120 14 5.400

42.9 -0.0 42.7

+0.3 49.2

40 1 1/2 31 170 170 120 14 7

49 -0.0 48.8

Note : The above data is subject to change without notice due to our continuing product improvement program. (WEIGHT GIVEN IN KGS)

TEST PRESSURES

SHELL TEST SEAT TEST

CLASS

(HYDROSTATIC) HYDROSTATIC PNEUMATIC

1500 384 Bar 5568 Psi g 282 Bar 4075 Psi g N.A. N.A.

Valves can be supplied in other MOC’s on request

SS (ASTM A 182 Gr.F304H/ F321) , DSS (ASTM A 182 Gr.F50 /F51/ F53/F55)

07 Copyright-2021 @FlowBiz Exports Pvt. Ltd. Email ID : info@flowbizexports.com | www.flowbizexports.com

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5796)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Experiment 2 - Aldehyde and KetonesDocument3 pagesExperiment 2 - Aldehyde and KetonesFaris Syahmi100% (2)

- FlowBiz Cast Steel Swing Check ValveDocument3 pagesFlowBiz Cast Steel Swing Check ValveFlowBiz Exports Pvt. Ltd.No ratings yet

- Forged Steel Check Valve Flange End - Asa 150 Class: Standards & SpecificationsDocument9 pagesForged Steel Check Valve Flange End - Asa 150 Class: Standards & SpecificationsFlowBiz Exports Pvt. Ltd.No ratings yet

- FlowBiz High Pressure Universal Design Non Return ValveDocument1 pageFlowBiz High Pressure Universal Design Non Return ValveFlowBiz Exports Pvt. Ltd.No ratings yet

- Flowbiz Cast Steel Nd40 Globe ValvesDocument2 pagesFlowbiz Cast Steel Nd40 Globe ValvesFlowBiz Exports Pvt. Ltd.No ratings yet

- FlowBiz Forged Steel Globe Valve Reduced BoreDocument2 pagesFlowBiz Forged Steel Globe Valve Reduced BoreFlowBiz Exports Pvt. Ltd.No ratings yet

- FlowBiz Forged Steel Globe Valve 1500 ClassDocument2 pagesFlowBiz Forged Steel Globe Valve 1500 ClassFlowBiz Exports Pvt. Ltd.No ratings yet

- FlowBiz Forged Steel Globe ValveDocument14 pagesFlowBiz Forged Steel Globe ValveFlowBiz Exports Pvt. Ltd.No ratings yet

- FlowBiz Forged Steel Globe Valve Full BoreDocument2 pagesFlowBiz Forged Steel Globe Valve Full BoreFlowBiz Exports Pvt. Ltd.No ratings yet

- Phase Diagram of The Fe-C-V SystemDocument6 pagesPhase Diagram of The Fe-C-V SystemUlises Quintana CarhuanchoNo ratings yet

- Properties and Characteristics of MaterialsDocument17 pagesProperties and Characteristics of MaterialsBensoy YambaNo ratings yet

- Calcium Chewable TabletDocument1 pageCalcium Chewable TabletmulyanaNo ratings yet

- Baby RabbitDocument25 pagesBaby RabbitStephine Bochu100% (1)

- 3Document8 pages3sriram bharathNo ratings yet

- Piping QC Chart-1Document1 pagePiping QC Chart-1Muthu SubramanianNo ratings yet

- Catalog-Speciality Chemical - NOF - America PDFDocument76 pagesCatalog-Speciality Chemical - NOF - America PDFLim Chee SiangNo ratings yet

- Construction and Building Materials: Reza Bani Ardalan, Alireza Joshaghani, R. Douglas HootonDocument7 pagesConstruction and Building Materials: Reza Bani Ardalan, Alireza Joshaghani, R. Douglas HootonCarlos CameroNo ratings yet

- MNL 67-2009 PDFDocument128 pagesMNL 67-2009 PDFlolo100% (2)

- Adsorbents: Zeo-Tec Zeolite Molecular Sieve 4ADocument1 pageAdsorbents: Zeo-Tec Zeolite Molecular Sieve 4AmayankNo ratings yet

- Heavier Elements (Metallurgy)Document34 pagesHeavier Elements (Metallurgy)Natish JaglanNo ratings yet

- Design of Water Storage Tanks, and Down Take Pipes - Lecture 1Document46 pagesDesign of Water Storage Tanks, and Down Take Pipes - Lecture 1sakshi meherNo ratings yet

- GD KT Pro-0276-0407 #Sus #Abs #v1Document92 pagesGD KT Pro-0276-0407 #Sus #Abs #v1vikasindiaNo ratings yet

- PMCCDocument100 pagesPMCCSarangNo ratings yet

- A - PG - 029 - Anlage - 12: General Rework Regulations For Welding SeamsDocument9 pagesA - PG - 029 - Anlage - 12: General Rework Regulations For Welding SeamspranayNo ratings yet

- Aluminum-Bronze Sand Castings: Standard Specification ForDocument5 pagesAluminum-Bronze Sand Castings: Standard Specification ForIsma RioNo ratings yet

- Electric Welding 003709 MBPDocument429 pagesElectric Welding 003709 MBPAulia Haq AqobyNo ratings yet

- Notice: Environmental Statements Availability, Etc.: New Chemicals, Receipt and Status InformationDocument4 pagesNotice: Environmental Statements Availability, Etc.: New Chemicals, Receipt and Status InformationJustia.comNo ratings yet

- Materials Today: Proceedings: Inti Jagan, Pongunuru Naga Sowjanya, Kanta Naga RajeshDocument6 pagesMaterials Today: Proceedings: Inti Jagan, Pongunuru Naga Sowjanya, Kanta Naga Rajeshjohn davidNo ratings yet

- Cetco Volclay Water StopDocument4 pagesCetco Volclay Water Stopdedikartiwa_dkNo ratings yet

- Current Eng CI NO-HUB List Price SheetDocument36 pagesCurrent Eng CI NO-HUB List Price SheetGenevieve GayosoNo ratings yet

- 2.superfinishing ProcessDocument9 pages2.superfinishing ProcessVikrant Sharma100% (1)

- Vertical Retort Pit FurnaceDocument2 pagesVertical Retort Pit FurnaceskluxNo ratings yet

- Unit 2 - Matter and Energy Fuels: Learning ObjectivesDocument6 pagesUnit 2 - Matter and Energy Fuels: Learning ObjectivesNiña Viaña BinayNo ratings yet

- Comparison of BHEL Vs DOOSANDocument12 pagesComparison of BHEL Vs DOOSANParveen NakwalNo ratings yet

- IACS Rec - 79Document10 pagesIACS Rec - 79tyuNo ratings yet

- Windows-1256 Mechanical Seals For ABS Pumps en PDFDocument4 pagesWindows-1256 Mechanical Seals For ABS Pumps en PDFaminjolesNo ratings yet

- Venus Gifting Cataloge Part-A - Price ListDocument48 pagesVenus Gifting Cataloge Part-A - Price ListNAVKAR PUNENo ratings yet

- Biswas Cold StorageDocument264 pagesBiswas Cold Storageesaif447No ratings yet