Professional Documents

Culture Documents

CS-WELD-1002 - Pressure Welding Procedure and Recording System (02 98) - CS Energy Registered

Uploaded by

relateOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CS-WELD-1002 - Pressure Welding Procedure and Recording System (02 98) - CS Energy Registered

Uploaded by

relateCopyright:

Available Formats

Form S1745

(Amd 7/97)

CORPORATE PROCEDURE FOR

PRESSURE WELDING PROCEDURES AND RECORDING

SYSTEM

CS-WELD-1002

Responsible Officer: CS Welding Officer Approved : General Manager Production

Contents

1. Purpose

2. Scope

3. Actions

3.1 Welding System

3.2 Welding Procedures

3.3 Welder Qualification and Performance

3.4 Renewal of Welder Qualification (Ref AS 3992 Clause 9.8)

3.5 Weld Instructions

3.6 Non-Destructive Testing

3.7 Division of Workplace Health and Safety

3.8 Contractors

3.9 Reviews

4. Definitions

5. Reference Documentation

6. Attachments

7. Document History

1. Purpose

1.1 To establish and maintain a uniform pressure welding procedure and recording

system and set minimum technical standards.

1.2 To comply with the requirements of the Workplace Health and Safety Act and

Regulations, and Australian Standards.

1.3 To provide assurance to CS Energy that plant integrity will not be adversely

affected by welding operations carried out on the plant.

2. Scope

This procedure shall apply to pressure welding at all CS Energy power stations.

C:\Users\Mtulloch\Desktop\HS HANDBOOK\B D 08 3091 Procedure - PLANT WELDING - CS-WELD-1002 - Pressure Welding Page 1 of 5

Procedure and Recording System (02 98) - CS Energy Registered.DOC CS-WELD-1002

THIS DOCUMENT IS UNCONTROLLED IN HARD COPY FORMAT

3. Actions

3.1 Welding System

The welding system shall consist of, as a minimum, the following four elements:

1. Welding Procedures Manual.

2. Welder qualification and performance records which are maintained at the Power

Stations.

3. Welding Instructions/Non Destructive Testing Request issued at the Power Stations.

4. Technical Reports - stress relief records, NDT, hydrostatic tests issued at the Power

Stations.

3.2 Welding Procedures

Welding procedures generated by CS Energy shall be produced on CS Energy document

S1585.

A welding procedure shall:

Contain all technical information relevant to the class of weld.

The welder who qualified the procedure shall be identified.

Be witnessed by the Welding Supervisor.

Be approved by the CS Energy Welding Officer and General Manager Production.

All welding procedures shall be stored in the “Welding Procedures Manual” which shall be

issued and updated by the Welding Officer.

The primary responsibility for having additional welding procedures approved shall be

placed with the location identifying the need for such procedures.

For the qualification of a welding procedure the welding supervisor or the Welding

Officer’s representative at that location shall:

Check with Welding Officer to ensure a similar procedure is not being developed at

another location.

Obtain a procedure number from the Welding Officer.

Prepare the documentation for the procedure.

Send a copy of the procedure to the Welding Officer for comment (if considered

necessary).

Have procedure test piece identified with the Welding Procedure Number CS-WELD-

XXX and the welder’s name/number).

Have radiography and mechanical tests performed on weld.

Send procedure and test result (if satisfactory) to CS Energy Welding Officer for

approval.

The CS Energy Welding Officer shall forward the procedure to General Manager

Production for signature approval, who shall return the procedure, if approved, to CS

Energy Welding Officer for issue.

C:\Users\Mtulloch\Desktop\HS HANDBOOK\B D 08 3091 Procedure - PLANT WELDING - CS-WELD-1002 - Pressure Welding Page 2 of 5

Procedure and Recording System (02 98) - CS Energy Registered.DOC CS-WELD-1002

THIS DOCUMENT IS UNCONTROLLED IN HARD COPY FORMAT

The CS Energy Welding Officer shall issue the procedure to all holders of the Welding

Procedures Manual.

3.3 Welder Qualification and Performance

CS Energy shall keep a record of welder qualifications.

The records shall be kept in a manner that will enable an audit to be carried out by the

Division of WH & S, or the local Quality Co-ordinator.

The welder’s performance records shall be kept by the organisation employing the welder

and accessible upon request to CS Energy.

3.4 Renewal of Welder Qualification (Ref. AS 3992 Clause 9.8)

A welder’s qualification to weld a specified welding procedure shall remain valid, provided

that it can be shown from records maintained by the organisation employing the welder

that the welder has been employed with reasonable continuity using the relevant welding

processes, and has continued to produce satisfactory welds as verified by the non-

destructive examination, workmanship and pressure testing requirements of the relevant

pressure equipment standard unless:

(a) Six (6) months or more have elapsed since the welder was employed on the

relevant welding processes.

(b) There is some specific reason to question the welder’s ability.

A welder shall become qualified for an approved welding procedure by carrying out a test

weld and receiving a satisfactory report to a radiograph or ultrasonic examination [refer

AS3992 Clause 9.2(e)]. Provided the Welding Supervisor or Welding Officer is satisfied, a

welder whose qualification has lapsed may become re-qualified to the original welding

procedure by a successful radiograph examination of the first production weld to that

procedure or a test weld.

The maintenance of the qualification and performance records shall be the responsibility

of the Welding Officer for each Power Station.

Each welder shall have a unique identifier based on that welder’s initials. This will include

all sub-contract welders used at each power station.

3.5 Weld Instructions

Where pressure welding is required by Statutory regulation or specified codes, the Weld

Instruction/Non Destructive Test Request (Form S1588) shall be prepared by the Welder,

Welding Supervisor or the Welding Officer and approved by the Welding Supervisor or

Welding Officer. The purpose of the Weld Instruction is to ensure that specific details are

given to the Qualified Welder to carry out that work.

The instruction shall be prepared in duplicate, a copy shall be issued to the Welder, a

copy shall be filed in Callide ‘B’ File 370/80/1003 (Unit 1), 370/80/1005 (Unit 2)

370/80/1006 (Station) or Swanbank SW375/50/43. When required, an additional copy

may be issued to the NDT contractor to provide details for testing purposes.

In certain circumstances, the Welding Supervisor or Welding Officer may decide it is

impractical to have an individual weld instruction for each weld. In this case, an

alternative system may be used, provided it meets the following objectives.

C:\Users\Mtulloch\Desktop\HS HANDBOOK\B D 08 3091 Procedure - PLANT WELDING - CS-WELD-1002 - Pressure Welding Page 3 of 5

Procedure and Recording System (02 98) - CS Energy Registered.DOC CS-WELD-1002

THIS DOCUMENT IS UNCONTROLLED IN HARD COPY FORMAT

1. The persons carrying out the welding, heat treatment and NDT are fully aware of the

details of the work.

2. There is existing documentation which will tie together the welder, work performed

and all records pertaining to the work, including electronic based records.

All Weld Instruction/Non Destructive Test requests shall be produced on CS Energy Form

S1588 either in hard copy or electronic format.

3.6 Non-Destructive Testing

All non-destructive testing shall be in accordance with AS 4037, and other Power Station

specific requirements as nominated by the CS Energy Welding Officer.

NDT requests shall be produced on CS Energy Form S1588.

Records of all NDT inspections shall be filed with either the Weld Instruction or Contract

specific reports i.e. overhauls.

Where required, additional copies shall be kept with the Welder Qualification and

performance records.

3.7 Division of Workplace Health and Safety

All dealings with the Division of WH & S shall be made through the Technical Resource

Manager which will enable a uniform and consistent approach to Corporate matters.

3.8 Contractors

Before commencing work, a contract welder shall produce certification and/or qualification

records and if required, carry out a qualification test to the satisfaction of the Power

Station Welding Supervisor or the CS Energy Welding Officer’s representative.

Welder qualification records shall be kept for all subcontract welders qualified to CS

Energy procedures.

If contractors wish to use their own welding procedures, they shall require approval of the

CS Energy Welding Officer. In addition, Welder qualifications shall also be required to

their proposed welding procedure.

Records of these procedures shall be kept in the appropriate files.

3.9 Reviews

The responsibility for periodic reviews of this procedure lies with the CS Energy Welding

Officer.

4. Definitions

Welding Supervisor is a person qualified as a “Welding Supervisor” within the meaning of

AS1796 and nominated by the Power Station Manager.

Welding Officer is a person qualified as a Welding Supervisor within the meaning of

AS1796 and nominated by the General Manager Production as Welding Officer.

C:\Users\Mtulloch\Desktop\HS HANDBOOK\B D 08 3091 Procedure - PLANT WELDING - CS-WELD-1002 - Pressure Welding Page 4 of 5

Procedure and Recording System (02 98) - CS Energy Registered.DOC CS-WELD-1002

THIS DOCUMENT IS UNCONTROLLED IN HARD COPY FORMAT

Where a CS Energy site does not have a permanent Welding Supervisor or Welding

Officer, the CS Energy Welding Officer and General Manager Production may nominate a

“Welding Officer’s representative”, who is considered to have sufficient skills and

experience to perform limited duties normally undertaken by the Welding Officer or

Welding Supervisor.

5. Reference Documentation

Callide ‘B’ File 370/80/1003 (Unit 1)

Callide ‘B’ File 370/80/1005 (Unit 2)

Callide ‘B’ File 370/80/1006 (Station)

Swanbank File SW375/50/43

Form S1583 - Welder Qualification

Form S1585 - Welding Procedure

Form S1588 - Weld Instruction/Non Destructive Testing Request

AS1210 - SAA Unfired Pressure Vessel Code

AS1228 - Boilers - Water Tube

AS1796 - Certification of Welding and Welding Supervisors

AS3992 - Boilers and Pressure Vessels Welding and Brazing Qualification

AS4037 - Boiler and Pressure Vessels Examination and Testing

AS4041 - Pressure Piping

Workplace Health and Safety Act and Regulations

CS-WELD - Corporate Welding Manual

6. Attachments

None

7. Document History

Issue Date Nature of Changes

5/2/98 Original Issue

14/8/98 Reference to Plant Responsible Officer changed to Welding Officer. Rewording of last paragraph in 3.3.

Rev. 1 Callide File numbers changed in 3.5. Rewording of Paragraphs 3.6 and 3.8. Paragraph added to 4.

Definitions.

C:\Users\Mtulloch\Desktop\HS HANDBOOK\B D 08 3091 Procedure - PLANT WELDING - CS-WELD-1002 - Pressure Welding Page 5 of 5

Procedure and Recording System (02 98) - CS Energy Registered.DOC CS-WELD-1002

THIS DOCUMENT IS UNCONTROLLED IN HARD COPY FORMAT

You might also like

- Shortcut To A WPSDocument18 pagesShortcut To A WPSCepi Sindang Kamulan100% (1)

- Saep-1160 (NDT - Tracking and Reporting of Welding, NDT and Pressure Testing For Capital ProjectsDocument12 pagesSaep-1160 (NDT - Tracking and Reporting of Welding, NDT and Pressure Testing For Capital ProjectsShajin Mohammed Shamsudhin89% (9)

- Welding Manual R01 Nov 2006Document184 pagesWelding Manual R01 Nov 2006SHIVAJI CHOUDHURY100% (5)

- Mabruk Phase 4 Project: Procedure For Welded Joints of Process and Utility PipeworkDocument38 pagesMabruk Phase 4 Project: Procedure For Welded Joints of Process and Utility PipeworkJabel Oil Services Technical DPTNo ratings yet

- Manufacturing Standard FOR Handling and Manufacturing of Grade 91 MaterialDocument9 pagesManufacturing Standard FOR Handling and Manufacturing of Grade 91 Materialramaus100% (1)

- Saes A 004Document17 pagesSaes A 004Arvind ShakyaNo ratings yet

- PSP1Document171 pagesPSP1Klich77No ratings yet

- Ms For Demin Water Tank Modification Rev 1 Feb. 28 2011lastDocument9 pagesMs For Demin Water Tank Modification Rev 1 Feb. 28 2011lastsharif339100% (1)

- Welding InspectionDocument7 pagesWelding Inspectionzahid_497100% (1)

- Welding Inspection ProcedureDocument5 pagesWelding Inspection ProcedurePugalNo ratings yet

- Saep 1146Document8 pagesSaep 1146Ronanki RaviNo ratings yet

- Method Statement For Installation of Overhead CraneDocument88 pagesMethod Statement For Installation of Overhead CraneJohn100% (3)

- General Welding Fabrication and TestingDocument24 pagesGeneral Welding Fabrication and TestingAhmed FathyNo ratings yet

- Method of Statment For Welding of Carbon Steel Pipes Dks-mst-c11-001 Rev 1Document17 pagesMethod of Statment For Welding of Carbon Steel Pipes Dks-mst-c11-001 Rev 1Sherief Abd El Baky83% (12)

- Saep 323Document8 pagesSaep 323brecht1980100% (1)

- Welding Manual of Power SectorDocument184 pagesWelding Manual of Power SectorSiva GanaNo ratings yet

- General Specification For Welding and Weld Inspection (EIL)Document19 pagesGeneral Specification For Welding and Weld Inspection (EIL)Mitchel Fernandes100% (6)

- ASME BPVC Section VIII Division 2: Responsibilities and Duties ParagraphDocument3 pagesASME BPVC Section VIII Division 2: Responsibilities and Duties ParagraphSubrata PatraNo ratings yet

- Saep 311Document31 pagesSaep 311brecht1980No ratings yet

- 5.00.records - Weld RecordsPROCESSPIPING PDFDocument8 pages5.00.records - Weld RecordsPROCESSPIPING PDFcarlosNo ratings yet

- AICIP ExamDocument8 pagesAICIP Examcybercreed2002_11486100% (1)

- 45 Samss 013Document23 pages45 Samss 013Waleed MedhatNo ratings yet

- GFDS, Mnbfdlkyfdsdfgbn NgregnDocument13 pagesGFDS, Mnbfdlkyfdsdfgbn NgregnAnonymous 7YilBuIuQm100% (1)

- 015-IH-1008 (Pipeline Field Welding Non-Sour Service)Document17 pages015-IH-1008 (Pipeline Field Welding Non-Sour Service)npwalNo ratings yet

- Safety Instruction SheetDocument32 pagesSafety Instruction SheetAdamuNo ratings yet

- ARAMCO Material SpecificationDocument21 pagesARAMCO Material Specificationkhorzoo83% (6)

- Weld Manual 4 PowerDocument77 pagesWeld Manual 4 PowerGyanendra Narayan NayakNo ratings yet

- Asme Ix SlidesDocument35 pagesAsme Ix Slidesdhasdj100% (1)

- Welding Machine Calibration ProcedureDocument12 pagesWelding Machine Calibration ProcedureNDTInstructor88% (8)

- Custody Metering of Hydrocarbon GasesDocument39 pagesCustody Metering of Hydrocarbon GasesUmar Adamu100% (4)

- CG4352 GM1927 03a Gas MIG Braze Weld Quality Verification ProcedureDocument9 pagesCG4352 GM1927 03a Gas MIG Braze Weld Quality Verification ProcedureTeo de los SantosNo ratings yet

- MS For Welding Consumable ControlDocument10 pagesMS For Welding Consumable Controlmansih457100% (1)

- Engineering Standards Manual ISD 341-2: Chapter 13, Welding & Joining Volume 3, Welding Procedure SpecificationDocument5 pagesEngineering Standards Manual ISD 341-2: Chapter 13, Welding & Joining Volume 3, Welding Procedure SpecificationHadi BarakNo ratings yet

- MOS For Metallic Conduit InstallationDocument23 pagesMOS For Metallic Conduit InstallationAhmed MhnaNo ratings yet

- Saes A 004Document18 pagesSaes A 004emmanuilmoulos6339100% (1)

- Saes N 120Document13 pagesSaes N 120aamirapi100% (1)

- MNT-INTG-2007OP - Maintenance Welding InspectionDocument43 pagesMNT-INTG-2007OP - Maintenance Welding InspectionNatarajan MurugesanNo ratings yet

- Saes A 004Document22 pagesSaes A 004Branko_62100% (1)

- Saudi Aramco Inspection Checklist: Review of WPS & Process Control Procedure (Pipelines) SAIC-W-2038 WeldDocument4 pagesSaudi Aramco Inspection Checklist: Review of WPS & Process Control Procedure (Pipelines) SAIC-W-2038 Weldhamidjoyia100% (1)

- Safety Information Bulletin: Sb05-02 Subject: Putting Public Safety FirstDocument3 pagesSafety Information Bulletin: Sb05-02 Subject: Putting Public Safety FirstMSNo ratings yet

- Welding Procedure SpecificationsDocument14 pagesWelding Procedure SpecificationsBasavaraj KaraningNo ratings yet

- 34 Samss 118Document9 pages34 Samss 118naruto256No ratings yet

- General Requirements For ValvesDocument16 pagesGeneral Requirements For ValvesKrishna Prasad R100% (1)

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- Applied Process Design for Chemical and Petrochemical Plants: Volume 1From EverandApplied Process Design for Chemical and Petrochemical Plants: Volume 1Rating: 3.5 out of 5 stars3.5/5 (3)

- The Safety Relief Valve Handbook: Design and Use of Process Safety Valves to ASME and International Codes and StandardsFrom EverandThe Safety Relief Valve Handbook: Design and Use of Process Safety Valves to ASME and International Codes and StandardsRating: 3.5 out of 5 stars3.5/5 (14)

- Post Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&AFrom EverandPost Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&ANo ratings yet

- Guidelines for Auditing Process Safety Management SystemsFrom EverandGuidelines for Auditing Process Safety Management SystemsNo ratings yet

- Chemical and Process Plant Commissioning Handbook: A Practical Guide to Plant System and Equipment Installation and CommissioningFrom EverandChemical and Process Plant Commissioning Handbook: A Practical Guide to Plant System and Equipment Installation and CommissioningNo ratings yet

- Process Control for Sheet-Metal Stamping: Process Modeling, Controller Design and Shop-Floor ImplementationFrom EverandProcess Control for Sheet-Metal Stamping: Process Modeling, Controller Design and Shop-Floor ImplementationNo ratings yet

- Aviation Maintenance Technician Handbook—Powerplant (2024): FAA-H-8083-32BFrom EverandAviation Maintenance Technician Handbook—Powerplant (2024): FAA-H-8083-32BNo ratings yet

- The Safety Critical Systems Handbook: A Straightforward Guide to Functional Safety: IEC 61508 (2010 Edition), IEC 61511 (2015 Edition) and Related GuidanceFrom EverandThe Safety Critical Systems Handbook: A Straightforward Guide to Functional Safety: IEC 61508 (2010 Edition), IEC 61511 (2015 Edition) and Related GuidanceRating: 5 out of 5 stars5/5 (1)

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsFrom EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsRating: 3.5 out of 5 stars3.5/5 (3)

- Engineering Critical Assessment (ECA) for Offshore Pipeline SystemsFrom EverandEngineering Critical Assessment (ECA) for Offshore Pipeline SystemsNo ratings yet

- Aircraft Dispatcher Oral Exam Guide: Prepare for the FAA oral and practical exam to earn your Aircraft Dispatcher certificateFrom EverandAircraft Dispatcher Oral Exam Guide: Prepare for the FAA oral and practical exam to earn your Aircraft Dispatcher certificateNo ratings yet

- SSP700ADocument4 pagesSSP700AKanwar Bir SinghNo ratings yet

- Part 6 CapacitorWorksheetDocument2 pagesPart 6 CapacitorWorksheetMARIANNE ALEXIE DIAZNo ratings yet

- T2 Homework 2Document3 pagesT2 Homework 2Aziz Alusta OmarNo ratings yet

- MontecarloDocument44 pagesMontecarloAnand Krishna GhattyNo ratings yet

- Automobile Engineering NotesDocument120 pagesAutomobile Engineering Notesakshay2992No ratings yet

- DSNHP00197140000690828 2022Document2 pagesDSNHP00197140000690828 2022Vidya SagarNo ratings yet

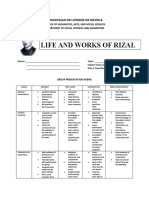

- Rubrics - Reporting - RizalDocument2 pagesRubrics - Reporting - RizaljakeNo ratings yet

- A Level Biology A Core Practical 10 - Ecology InvestigationDocument6 pagesA Level Biology A Core Practical 10 - Ecology InvestigationAlfred SangNo ratings yet

- Module 5 Lesson 5.1 - For ResearchDocument16 pagesModule 5 Lesson 5.1 - For ResearchJohn Clieford AdarayanNo ratings yet

- Group 1 ResearchDocument16 pagesGroup 1 ResearchSaedamenNo ratings yet

- The Awakening Study Guide AnswersDocument24 pagesThe Awakening Study Guide AnswersAli RidhaNo ratings yet

- ANSYS SimplorerDocument2 pagesANSYS Simplorerahcene2010No ratings yet

- Electrostatics DPPDocument10 pagesElectrostatics DPPhimesh2006hNo ratings yet

- Prediction of Pile Performance in Permafrost Under Lateral LoadDocument14 pagesPrediction of Pile Performance in Permafrost Under Lateral LoadFelipe PereiraNo ratings yet

- Topic 1: Introduction To Telecommunication: SPM1012: Telecommunication and NetworkingDocument22 pagesTopic 1: Introduction To Telecommunication: SPM1012: Telecommunication and Networkingkhalfan athmanNo ratings yet

- IMPRSDocument11 pagesIMPRSridho kusumaNo ratings yet

- Ii Week 12 (Seminar)Document30 pagesIi Week 12 (Seminar)ccNo ratings yet

- Ericsson - Cell PlanningDocument5 pagesEricsson - Cell PlanningBassem AbouamerNo ratings yet

- Citizen ManualDocument18 pagesCitizen ManualWalter MeinneNo ratings yet

- History of Sport PsychologyDocument13 pagesHistory of Sport PsychologyObii DenisNo ratings yet

- HFAss 6Document1 pageHFAss 6Taieb Ben ThabetNo ratings yet

- Numerical Study of Depressurization Rate During Blowdown Based On Lumped Model AnalysisDocument11 pagesNumerical Study of Depressurization Rate During Blowdown Based On Lumped Model AnalysisamitNo ratings yet

- Curs FinalDocument8 pagesCurs FinalandraNo ratings yet

- High Temperature Materials An Introduction PDFDocument110 pagesHigh Temperature Materials An Introduction PDFZeeshan HameedNo ratings yet

- Organizational Changes and Stress Management - OBDocument52 pagesOrganizational Changes and Stress Management - OBBenny WeeNo ratings yet

- Format of Actual BatchDocument16 pagesFormat of Actual Batchaljhon dela cruzNo ratings yet

- SAES-L-610 PDF Download - Nonmetallic Piping in Oily Water Services - PDFYARDocument6 pagesSAES-L-610 PDF Download - Nonmetallic Piping in Oily Water Services - PDFYARZahidRafiqueNo ratings yet

- Cree J Series™ 2835 Leds: Product Description FeaturesDocument28 pagesCree J Series™ 2835 Leds: Product Description FeaturesLoengrin MontillaNo ratings yet

- CMMI DAR Effectively Apply The Decision Analysis and Resolution (DAR) ProcessDocument26 pagesCMMI DAR Effectively Apply The Decision Analysis and Resolution (DAR) Processjgonzalezsanz8914100% (1)

- Project of Telephone DirectoryDocument15 pagesProject of Telephone DirectoryShree CyberiaNo ratings yet