Professional Documents

Culture Documents

GN 5860 Load Rings Continued: Safety Instructions

Uploaded by

AlbertoOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

GN 5860 Load Rings Continued: Safety Instructions

Uploaded by

AlbertoCopyright:

Available Formats

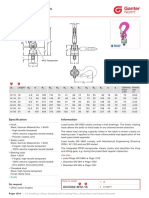

GN 5860 Load Rings continued

3.1

3.2

3.3

3.4

3.5

Method of

mounting

Number 1 1 2 2 2 2 2 3 and 4 3 and 4 3 and 4

Angles of

inclination 0° 90° 0° 90° 0 to 45° 45 to 60° asymm. 0 to 45° 45 to 60° asymm.

Factor 1 1 2 2 1,4 1 1 2,1 1,5 1

M 8 0,60 t 0,30 t 1,20 t 0,60 t 0,42 t 0,30 t 0,30 t 0,63 t 0,45 t 0,30 t

3.6

M 10 0,90 t 0,45 t 1,80 t 0,90 t 0,63 t 0,40 t 0,40 t 0,94 t 0,67 t 0,40 t

M 12 1,20 t 0,60 t 2,40 t 1,20 t 0,84 t 0,60 t 0,60 t 1,26 t 0,90 t 0,60 t

M 16 2,60 t 1,30 t 5,20 t 2,60 t 1,82 t 1,30 t 1,30 t 2,73 t 1,95 t 1,30 t

M 20 4,00 t 2,00 t 8,00 t 4,00 t 2,80 t 2,00 t 2,00 t 4,25 t 3,00 t 2,00 t

M 24 7,00 t 3,50 t 14,00 t 7,00 t 4,90 t 3,50 t 3,50 t 7,35 t 5,25 t 3,50 t

3.7

M 30 10,00 t 5,00 t 20,00 t 10,00 t 7,00 t 5,00 t 5,00 t 10,50 t 7,50 t 5,00 t

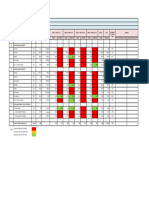

Safety instructions

The above load capacity table shows the maximum loads in metric tonnes as factor of the load

ring type and at an operating temperature range of –40 °C to +100 °C, with a safety coefficient of 4

3.8

taken into account for all values.

The load ring GN 5860 may be used only if it is bolted with the minimum screw-in depth which

depends on the material and if the bolt contact surface is plane and fixed at a right angle to the

tap hole.

If permanently mounted in place, the swivel eye bolt must rotate freely by 360° and must not rest

3.9

on edges or other fixture, e.g. crane hooks. The load rings are not suitable for permanent rotary

movement under load exposure.

The operating instruction contains further guidelines and is included with every load ring (see also at

www.ganternorm.com/en/service).

3.4 Installing, Lifting, Damping with Leveling Feet, Lifting Gear and Rubber Elements | Page 1513

You might also like

- Repair Stratergies of Structurer For Maintainance and Rehabiliation by K.r.thankiDocument64 pagesRepair Stratergies of Structurer For Maintainance and Rehabiliation by K.r.thankikrunalNo ratings yet

- Corrosion Resistance of Cupronickels - An Overview PDFDocument39 pagesCorrosion Resistance of Cupronickels - An Overview PDFrabnixNo ratings yet

- SKF Nut Sockets PDFDocument1 pageSKF Nut Sockets PDFslipsittinNo ratings yet

- Aircraft Structure Design PrinciplesDocument28 pagesAircraft Structure Design PrinciplesVenugopal Krishna0% (1)

- Food Processing - PPTDocument20 pagesFood Processing - PPTAngelie Rescallar100% (2)

- HealthOne Medical DD ProjectDocument4 pagesHealthOne Medical DD ProjectIrfan Darmawan0% (1)

- KilnDocument67 pagesKilnneerav saxena0% (1)

- Particle Size DistributionDocument10 pagesParticle Size DistributionSaraswati Noor100% (1)

- Succession Definition To Codicils (Follow The Outline)Document7 pagesSuccession Definition To Codicils (Follow The Outline)Thalia SalvadorNo ratings yet

- Determination of Specific Gravity: ReferencesDocument26 pagesDetermination of Specific Gravity: ReferencesSagheer AhmedNo ratings yet

- Chapter 10: Abdominal Disorders: Multiple ChoiceDocument5 pagesChapter 10: Abdominal Disorders: Multiple ChoiceJamieNo ratings yet

- HRC Coupling PDFDocument8 pagesHRC Coupling PDFJorge Calderon RojasNo ratings yet

- Laminate T60XXDocument1 pageLaminate T60XXPalomajimNo ratings yet

- Load Hooks: D LD e H H H H H K K K K C SDocument2 pagesLoad Hooks: D LD e H H H H H K K K K C SAlbertoNo ratings yet

- GN 589 Lifting Points Continued: Safety InstructionsDocument1 pageGN 589 Lifting Points Continued: Safety InstructionsAlbertoNo ratings yet

- GN 586 Safety Swivel Load Rings Continued: Mounting MethodDocument1 pageGN 586 Safety Swivel Load Rings Continued: Mounting MethodRaul G. MartinezNo ratings yet

- Name Height Elevation HsDocument12 pagesName Height Elevation HsTri huỳnhNo ratings yet

- Safety Notes: GN 581 Safety Swivel Lifting Eye Bolts ContinuedDocument1 pageSafety Notes: GN 581 Safety Swivel Lifting Eye Bolts ContinuedRaul G. MartinezNo ratings yet

- Reduced Load: M MA AR RY YL LA AN ND D M ME ET TR Riic CS SDocument1 pageReduced Load: M MA AR RY YL LA AN ND D M ME ET TR Riic CS SRenny DevassyNo ratings yet

- ST5513 6tDocument3 pagesST5513 6tEmpNavalNo ratings yet

- SPC Moisture %Document1 pageSPC Moisture %Dhananjay PatilNo ratings yet

- Burgman I - Especificões de ServiçosDocument10 pagesBurgman I - Especificões de ServiçosFellipe TofanelloNo ratings yet

- Momentos de Por. PrincipalesssssssDocument62 pagesMomentos de Por. PrincipalesssssssMarcos Luis Chuquilin VergaraNo ratings yet

- Tanko S30 SpecificationDocument1 pageTanko S30 SpecificationJuan IglesiasNo ratings yet

- Planilla de Metrados CorregDocument7 pagesPlanilla de Metrados CorregRiquelmer Ramos BautistaNo ratings yet

- Waterline BrochureDocument2 pagesWaterline BrochureHLYCNo ratings yet

- A Cero Princ in PalesDocument75 pagesA Cero Princ in PalesMarcos Luis Chuquilin VergaraNo ratings yet

- Hangcha Self Propelled Electric Scissor Lifts - Aerial Work PlatformDocument2 pagesHangcha Self Propelled Electric Scissor Lifts - Aerial Work PlatformTommy SmithNo ratings yet

- Steel Tubes: Welded and SeamlessDocument2 pagesSteel Tubes: Welded and Seamlessamit kumar sarkarNo ratings yet

- Tabla Se Carga Kato 10tnDocument3 pagesTabla Se Carga Kato 10tnRosa Gabriela Palacios ChavezNo ratings yet

- ★R90 5样本(总图2+2) 220718Document11 pages★R90 5样本(总图2+2) 220718Danyi ZhangNo ratings yet

- 1 .2 Ultrapure Fittings: Fittings With Either Tri-Weld® For Orbital Welding Connections. Line in Compliance CurrentDocument41 pages1 .2 Ultrapure Fittings: Fittings With Either Tri-Weld® For Orbital Welding Connections. Line in Compliance CurrentAtul SharmaNo ratings yet

- USTER Quality Report: Total (40) Time To Break S B-Force GF Elongation % Tenacity RKM B-Work CN - CMDocument1 pageUSTER Quality Report: Total (40) Time To Break S B-Force GF Elongation % Tenacity RKM B-Work CN - CMIlhom ZakirovNo ratings yet

- Cantidades de Obra Estructuras Warrutamana (Incluye M/O-Transporte)Document2 pagesCantidades de Obra Estructuras Warrutamana (Incluye M/O-Transporte)Katherin Cortes PerezNo ratings yet

- Fendtslicer 2001 TD enDocument2 pagesFendtslicer 2001 TD enMahmoudNo ratings yet

- Memorial para Calculo de Perda de Carga - 2018Document1 pageMemorial para Calculo de Perda de Carga - 2018MAURONo ratings yet

- TABLE: Story Data Name Height Elevation Master Story Similar To Splice StoryDocument27 pagesTABLE: Story Data Name Height Elevation Master Story Similar To Splice Storybui thanh tuanNo ratings yet

- BroDocument6 pagesBroAnonymous sjzDt9OONo ratings yet

- A6V10094175 - Flow Switch For Use in Hydraulic Systems QVE1900 - deDocument2 pagesA6V10094175 - Flow Switch For Use in Hydraulic Systems QVE1900 - deRadu HereaNo ratings yet

- SLT160 (L5523-12) Service ManualDocument74 pagesSLT160 (L5523-12) Service ManualAlbert FaragNo ratings yet

- HVAC DataDocument49 pagesHVAC DataআসিফহাসানখানNo ratings yet

- Calculo de Acero Viga: Verificar O.KDocument7 pagesCalculo de Acero Viga: Verificar O.KAlex ChavarriNo ratings yet

- Penggabungan AgregatDocument2 pagesPenggabungan AgregatIndira RamadhinaNo ratings yet

- Planilla de Metrados (Acero Corrugado Fy 4200kg/cm2)Document4 pagesPlanilla de Metrados (Acero Corrugado Fy 4200kg/cm2)John PalaciosNo ratings yet

- Chapter15 Reliability and Maintenance Assignment PLMARTINEZDocument11 pagesChapter15 Reliability and Maintenance Assignment PLMARTINEZjay-ar dimaculanganNo ratings yet

- LFSSL 30 0gr eDocument8 pagesLFSSL 30 0gr eArslan AhmedNo ratings yet

- Wall Load Cal For Plan Win Frame WinDocument2 pagesWall Load Cal For Plan Win Frame WinnileshNo ratings yet

- 722 4arDocument1 page722 4armarutheshNo ratings yet

- Taller Hidraulica. 4Document6 pagesTaller Hidraulica. 4sanchezlisardo98No ratings yet

- Pub47 h3 PDFDocument18 pagesPub47 h3 PDFROMULO CUBIDNo ratings yet

- DTH - Martillo Zandvik TodozDocument39 pagesDTH - Martillo Zandvik TodozedwinNo ratings yet

- Push Over Portico de 2 PisosDocument2 pagesPush Over Portico de 2 PisosAlexis MasamiNo ratings yet

- Proforma AaaDocument4 pagesProforma AaaFrnd MorenoNo ratings yet

- Capacidad de Carga (General)Document68 pagesCapacidad de Carga (General)leoNo ratings yet

- TorsionDocument4 pagesTorsionsaifulsabdinNo ratings yet

- RAB Serang SNI 07-11-2016 ErryDocument822 pagesRAB Serang SNI 07-11-2016 ErryMarquez LumiuNo ratings yet

- Ace Rode Secunda RiosDocument14 pagesAce Rode Secunda RiosMarcos Luis Chuquilin VergaraNo ratings yet

- Job/ Project: Taker Off: Element: Pekerjaan Dinding Date: Sheet No: 1 S/D Sket GambarDocument50 pagesJob/ Project: Taker Off: Element: Pekerjaan Dinding Date: Sheet No: 1 S/D Sket GambarAcilNo ratings yet

- WPR T7 Week 4 of September - 22Document1 pageWPR T7 Week 4 of September - 22satpuraNo ratings yet

- Terex A300 LoadsDocument22 pagesTerex A300 LoadssekharbrsNo ratings yet

- Chiyoda Welding Products: Combination Welding and Cutting TorchesDocument13 pagesChiyoda Welding Products: Combination Welding and Cutting Torchesandi permanaNo ratings yet

- Chips de 3/4 Tamiz No P.R. C/ TZ P.R. C/ TZ P.R.A. P.Q.P. % R.A. % Q.PDocument2 pagesChips de 3/4 Tamiz No P.R. C/ TZ P.R. C/ TZ P.R.A. P.Q.P. % R.A. % Q.PAlejandra FNo ratings yet

- eNodeB Alarm Handling ReferenceDocument528 pageseNodeB Alarm Handling ReferenceRahul SharmaNo ratings yet

- Talurit Splicing System Selection Table For TCU and TCUK FerrulesDocument1 pageTalurit Splicing System Selection Table For TCU and TCUK FerrulesmartjenningsNo ratings yet

- Cooling Tower (From Apparatus To Calculation Only) )Document13 pagesCooling Tower (From Apparatus To Calculation Only) )AlohaaSwezzNo ratings yet

- SMC AR2014 cd11Document78 pagesSMC AR2014 cd11Jerelleen RodriguezNo ratings yet

- V 23148Document3 pagesV 23148nelucurtaNo ratings yet

- Alkaloid Production in Cell Cultures of Catharanthus: Roseus Elicited With Cyclodextrins and JasmonateDocument1 pageAlkaloid Production in Cell Cultures of Catharanthus: Roseus Elicited With Cyclodextrins and JasmonateAdriana CristinaNo ratings yet

- Republic Act 8552 Domestic Adoption Act of 1998Document9 pagesRepublic Act 8552 Domestic Adoption Act of 1998AD100% (1)

- Hand Atlas of Human Anatomy Vol IIDocument253 pagesHand Atlas of Human Anatomy Vol IIizogggNo ratings yet

- A Study To Assess The Knowledge Regarding Emotional Exhaustion and Its Prevention Among Staff Nurses in Selected Hospital, Kanpur, U.P.Document3 pagesA Study To Assess The Knowledge Regarding Emotional Exhaustion and Its Prevention Among Staff Nurses in Selected Hospital, Kanpur, U.P.Editor IJTSRDNo ratings yet

- Abs Ex58f - AsiaDocument4 pagesAbs Ex58f - AsiaGiang CaoNo ratings yet

- Gastropod Saudi ArabiaDocument9 pagesGastropod Saudi Arabiajadoonreal1979No ratings yet

- Trucks DesigDocument116 pagesTrucks DesigEdgar Rojas EspejoNo ratings yet

- Harris Hotel and Convention Hall BekasiDocument14 pagesHarris Hotel and Convention Hall BekasiMonica VrettyciaNo ratings yet

- Hypothesis Test (Two Populations)Document22 pagesHypothesis Test (Two Populations)I Gusti Nyoman Yudi HartawanNo ratings yet

- Mte 4 ReportDocument8 pagesMte 4 ReportZeke KazamiNo ratings yet

- The Ultimate Michigan Car Accident HandbookDocument78 pagesThe Ultimate Michigan Car Accident HandbookBuckfire & Buckfire PCNo ratings yet

- Conversion Functional Shift Root Creation: English LinguisticsDocument11 pagesConversion Functional Shift Root Creation: English LinguisticsHải YếnNo ratings yet

- KinshipDocument28 pagesKinshipAngelica Marie BallonNo ratings yet

- Drug Calculation - IV Fluids CalculationDocument3 pagesDrug Calculation - IV Fluids Calculationchristy INo ratings yet

- Fike VentingDocument6 pagesFike Ventingjpdavila205No ratings yet

- 00 (Methanol Project)Document13 pages00 (Methanol Project)KhalidMadaniNo ratings yet

- Characterization of Kodi Adu Goats of Tamil Nadu, IndiaDocument14 pagesCharacterization of Kodi Adu Goats of Tamil Nadu, IndiaIndian Journal of Veterinary and Animal Sciences RNo ratings yet

- Sample NODDocument3 pagesSample NODSteve Mun GroupNo ratings yet

- Engineering Mechanics (ME 105) Tutorial Sheet-4Document4 pagesEngineering Mechanics (ME 105) Tutorial Sheet-4nsbaruaoleNo ratings yet

- Oversized Primary Pulley Regulator Valve Kit: Jatco/Nissan JF015E (RE0F11A)Document2 pagesOversized Primary Pulley Regulator Valve Kit: Jatco/Nissan JF015E (RE0F11A)marranNo ratings yet

- A Study On Sale and Distribution Management of Hindustan Unilever LimitedDocument35 pagesA Study On Sale and Distribution Management of Hindustan Unilever LimitedJakir HussainNo ratings yet