Professional Documents

Culture Documents

ENEN Metal Primer PDS

Uploaded by

Novica ĐorđevićOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ENEN Metal Primer PDS

Uploaded by

Novica ĐorđevićCopyright:

Available Formats

Product Data Sheet

Edition 11.2011

Identification no.

020945074100000024

Version no. 01

Two-component, anti-corrosive primer for exposed metal

substrates prior to the application of Sika Liquid Plastics’

Roofing and Balcony Waterproofing Systems

Product Sika Liquid Plastics’ Metal Primer is an anti-corrosive, two-component, epoxy

primer. It consists of a grey base (Part A) and an activator (Part B).

Description

Uses Anti-corrosive primer for exposed metal substrates, used prior to the application

of Decothane Base Coat and Decothane Balcons waterproofing system.

Characteristics / Touch dry in 3 hours (at 20°C)

Advantages Low temperature curing down to 5°C

Can be recoated after 6 hours depending on temperature

Exceptional corrosion protection in industrial and marine environments

Roofing

Can be used as Barrier Primer over bituminous substrates (in conjunction

with fully reinforced systems)

Compatible with many well adhered existing coatings and roofing systems

– adhesion testing should always be carried out

Can be overcoated with a wide range of Liquid Plastic’s membranes

Good levelling and curing at lower temperatures.

Product Data

Form

Appearance Pearl Grey liquid (Part A); brown liquid (Part B)

Packaging 5 litre

Storage

Storage Conditions / Store in original, unopened and undamaged sealed packaging in dry conditions

Shelf Life away from direct sunlight in a well ventilated area at temperatures >0°C and <

25°C. Protect from frost.

A shelf-life of 12 months is expected, from the date of production, when stored

in accordance with the above recommendations at a temperature of 20°C.

Exposure to higher temperatures will reduce the shelf-life.

Reference should also be made to the storage recommendations of the material

safety datasheet.

This Metal Primer 1/4

Product Data Sheet

Edition 11.2011

Identification no.

020945074100000024

Version no. 01

Technical Data

Chemical Base Solvent borne epoxide resin (part A) and amide curative (Part B)

Density 1.2 – 1.4 kg/L (mixed product)

Flash Point Part A = 43°C; Part B = 26°C

System Information

Substrate Quality Substrate must be in a sound condition and free from grease.

Substrate Preparation

Metals:

Steelwork is ideally prepared to Sa2½ (Swedish Standard SIS 05 : 5900 = 2nd quality BS4232 = S.S.P.C.

grade SP10) OR as indicated by the blasting specification which may be of a higher standard. Where blasting

Roofing

is not permitted, then clean metal preparation by pin hammer etc is acceptable. Circumstances may dictate

other methods of preparation may be used eg wire brush, grinding, etc. but it must be appreciated these may

be less successful in returning to a bright clean metal. Completed surface should be free from all

contamination and laminations.

Dull exposed galvanised surfaces may be treated direct after satisfactory adhesion test. New bright

galvanised surfaces may require mordant solution.

Non-ferrous metals are prepared as follows. Remove any deposits of dust and oxidation and abrade to bright

metal. Wire brushing can be used for soft metal such as lead. All necessary health and safety guidelines

must be followed. The surface must be clean and free from grease which, if present, must be removed with a

proprietary solution. Wash with detergent, rinse and dry.

General:

Coatings, bitumen, etc should be cleaned dry, sound and free from grease. Adhesion and compatibility tests

should be carried out on all non-metal substrates.

Application Conditions and Limitations

Adhesion Testing Prior to the commencement of works, adhesion / substrate compatibility trials

should be carried out onto the substrate to confirm substrate suitability and

adhesion of the proposed system.

Substrate and Ambient +5 °C min. / +40 °C max.

Temperature

The substrate and ambient air temperature must be a minimum of 5°C during

application and initial curing.

Dew Point Beware of condensation. Surface temperature during application must be at

least +5°C above dew point.

This Metal Primer 2/4

Product Data Sheet

Edition 11.2011

Identification no.

020945074100000024

Version no. 01

Coverage Rates Apply one coat, at a rate of 0.15 L/m² per coat (equivalent to a maximum of 6.5

2

m /L) to achieve a minimum dry film thickness of 130 microns. Demanding

locations where high levels of protection of bare metal is necessary, sharp/cut

edges or angles or areas that have been subject to heavy preparation may

require two coats, coverage depends on substrate surface and profile. Always

allow for application losses, surface irregularities, etc.

Application onto surfaces other than metal – e.g. on mineral felt in conjunction

with the Decothane Solar 25 System – may need individual assessment –

please consult each individual Sika Liquid Plastics’ project specification.

Application Instructions

Application Method Ensure surface is prepared as detailed above is dry and free from dust and any

by-products of preparation. Prime steel within 4 hours of blasting (before re-

oxidation). Previously primed areas must be free from contamination before re-

priming or top coating.

Prepare primer by mixing the base until uniform. Add the activator and re-mix

until homogeneous. Ensure that material at sides and base of container are

thoroughly mixed.

Apply by spray, brush or roller.

Roofing

When applied by brush or roller additional coats may be required to reach

specified coverage rates.

Application Tools Use brushes for small areas only. For other applications, a roller or airless

spray equipment with a 0.45mm (18 thou) tip should be used. Please see

Section on Health and Safety for further information.

Potlife 1 hour at 20°C

Note: Pot life will decrease at higher temperatures and increase at lower

temperatures.

Waiting Time / At 20 °C: Dry to touch 3 hours

Overcoating Dry through 5 hours

Overcoat after a minimum of 6 hours

Notes on Application

Limitations Do not apply in wet weather or to wet surfaces.

Improved curing is achieved at temperatures between 10°C and 30°C. If cooler,

then curing times will be extended.

Any surfaces left uncoated for a period of more than 7 days should be abraded

and re-primed with this product.

Health and Safety For information and advice on the safe handling, storage and disposal of

Information chemical products, users shall refer to the most recent Material Safety Data

Sheet containing physical, ecological, toxicological and other safety-related

data.

When spraying use appropriate PPE – see MSDS for information. Operatives

must be trained in the use of high pressure spray equipment.

This Metal Primer 3/4

Product Data Sheet

Edition 11.2011

Identification no.

020945074100000024

Version no. 01

General Information

Specification NBS is the industry standard specification system, which allows architects,

Assistance specifiers and engineers to insert clauses into specifications by manufacturer

and product, making the process quicker and more efficient. We are members

of NBS Plus and therefore detailed up-to-date product information is readily

available to create accurate specifications.

Disclaimer The information, and, in particular, the recommendations relating to the

application and end- use of Sika products, are given in good faith based on

Sika' s current knowledge and experience of the products when properly stored,

handled and applied under normal conditions in accordance with Sika' s

recommendations. In practice, the differences in materials, substrates and

actual site conditions are such that no warranty in respect of merchantability or

of fitness for a particular purpose, nor any liability arising out of any legal

relationship whatsoever, can be inferred either from this information, or from

any written recommendations, or from any other advice offered. The user of the

product must test the product’s suitability for the intended application and

purpose. Sika reserves the right to change the properties of its products. The

proprietary rights of third parties must be observed. All orders are accepted

subject to our current terms of sale and delivery. Users must always refer to the

most recent issue of the local Product Data Sheet for the product concerned,

copies of which will be supplied on request.

Roofing

Contact Details For further information please contact:

Sika Liquid Plastics

Sika House

Miller Street

Preston

PR1 1EA

Enquiry Line: 01772 259781

Fax: +44 (0)1772 255670

e-mail: liquidplastics@uk.sika.com

Registered office: Sika Ltd, Watchmead, Welwyn Garden City, Hertfordshire, AL7 1BQ

Registered in England: 226822

This Metal Primer 4/4

You might also like

- Thermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesFrom EverandThermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesRating: 3.5 out of 5 stars3.5/5 (3)

- Atmospheric Pressure Plasma Treatment of Polymers: Relevance to AdhesionFrom EverandAtmospheric Pressure Plasma Treatment of Polymers: Relevance to AdhesionNo ratings yet

- Barrier 90 - English (Uk) - Issued.06.12.2007Document3 pagesBarrier 90 - English (Uk) - Issued.06.12.2007Mohamed FaragNo ratings yet

- Ceram Kote 54 SF - ARAMCO ApprovedDocument1 pageCeram Kote 54 SF - ARAMCO ApprovedSherif AbdelhameedNo ratings yet

- iKOTE AC 40 (DEC-2023) V1.3Document2 pagesiKOTE AC 40 (DEC-2023) V1.3nguyen hoang AnhNo ratings yet

- Penguard Stayer - English (Uk) - Issued.06.12.2007Document3 pagesPenguard Stayer - English (Uk) - Issued.06.12.2007Mohamed FaragNo ratings yet

- Polycoat Rbe FR: Rubberized Bitumen EmulsionDocument2 pagesPolycoat Rbe FR: Rubberized Bitumen EmulsionAbidNo ratings yet

- Naviguard ME - English (Uk) - Issued.06.12.2007Document3 pagesNaviguard ME - English (Uk) - Issued.06.12.2007Mohamed FaragNo ratings yet

- Carboguard 703 GFDocument2 pagesCarboguard 703 GFlhanx2100% (2)

- Penguard FC - English (Uk) - Issued.06.12.2007Document4 pagesPenguard FC - English (Uk) - Issued.06.12.2007Mohamed FaragNo ratings yet

- TDS - Penguard Express ZP - English (Uk) - Issued.26.11.2010Document4 pagesTDS - Penguard Express ZP - English (Uk) - Issued.26.11.2010Anindya Aulia PratiwiNo ratings yet

- G4258 Silver - Pds-EnDocument3 pagesG4258 Silver - Pds-EnuraliNo ratings yet

- Interline 1012+ds+engDocument4 pagesInterline 1012+ds+engSUBHOMOYNo ratings yet

- High Build Epoxy Coating Technical DataDocument3 pagesHigh Build Epoxy Coating Technical Databehrooz rajabshehniNo ratings yet

- TDS - Barrier 90 - English (Uk) - Issued.05.10.2011Document4 pagesTDS - Barrier 90 - English (Uk) - Issued.05.10.2011ansarALLAAHNo ratings yet

- BASF MasterSeal M 790 TdsDocument9 pagesBASF MasterSeal M 790 TdsAmar WadoodNo ratings yet

- Coal Tar Epoxy 83 - English (Uk) - Issued.06.12.2007Document3 pagesCoal Tar Epoxy 83 - English (Uk) - Issued.06.12.2007Mohamed FaragNo ratings yet

- Eh6280 (HS)Document2 pagesEh6280 (HS)anminsungNo ratings yet

- Thermaline 450 PDFDocument2 pagesThermaline 450 PDFNageswara Rao BavisettyNo ratings yet

- 6640 SIP-SPLASH 640 June-12Document2 pages6640 SIP-SPLASH 640 June-12ShaikhRizwanNo ratings yet

- TERRAFLEXDocument1 pageTERRAFLEXChitko KoNo ratings yet

- Flexoplast®: Product Data SheetDocument2 pagesFlexoplast®: Product Data SheetRoyete M Silfani PattyNo ratings yet

- 3 - PC 7049 - Apcodur MioDocument3 pages3 - PC 7049 - Apcodur Miosujay AvatiNo ratings yet

- Penguard FC: Technical DataDocument4 pagesPenguard FC: Technical DataMohamed FarhanNo ratings yet

- Safeguard Universal AGDocument7 pagesSafeguard Universal AGMar PardalesNo ratings yet

- PDS Simacover Tar Epoxy 3404-00Document4 pagesPDS Simacover Tar Epoxy 3404-00Aulia RahmahNo ratings yet

- Steelmaster 60WB: Technical Data Sheet Application GuideDocument10 pagesSteelmaster 60WB: Technical Data Sheet Application GuideyugandharNo ratings yet

- ShaliProtek PuR 40Document3 pagesShaliProtek PuR 40Rana MahatoNo ratings yet

- TDS - Muki Z 2008 - English (Uk) - Issued.26.11.2010Document4 pagesTDS - Muki Z 2008 - English (Uk) - Issued.26.11.2010Keith ChooNo ratings yet

- Barrier ZepDocument3 pagesBarrier ZepJairo Gómez SánchezNo ratings yet

- Jotun Resist 5WFDocument4 pagesJotun Resist 5WFSergio SmithNo ratings yet

- Penguard ZP AO - English (Uk) - Issued.06.12.2007Document3 pagesPenguard ZP AO - English (Uk) - Issued.06.12.2007Mohamed FaragNo ratings yet

- Proguard CN 100 Iso TDSDocument3 pagesProguard CN 100 Iso TDSm_f_deathNo ratings yet

- Zinc Epoxy Primer Technical Data SheetDocument3 pagesZinc Epoxy Primer Technical Data SheetMohamed FaragNo ratings yet

- Intertherm 50: Silicone AluminiumDocument4 pagesIntertherm 50: Silicone Aluminiumnoto.sugiartoNo ratings yet

- Sika Boom FR Gun Foam PdsDocument3 pagesSika Boom FR Gun Foam PdsReno MaulanaNo ratings yet

- Decothane Root Resistant Top Coat: Product Data SheetDocument4 pagesDecothane Root Resistant Top Coat: Product Data SheetKRISHNA PRASATH SNo ratings yet

- Penguard Express ZPDocument5 pagesPenguard Express ZPMustafa Al-YasseriNo ratings yet

- Intergard 251 Tech Data SheetDocument0 pagesIntergard 251 Tech Data SheetL Mahender ReddyNo ratings yet

- Epilux 155 SFDocument2 pagesEpilux 155 SFMohamed NasifNo ratings yet

- Masterflow 400 TdsDocument3 pagesMasterflow 400 TdsverNo ratings yet

- Radiant Barrier Coating: For Energy Conservation and Light ReflectionDocument2 pagesRadiant Barrier Coating: For Energy Conservation and Light ReflectionEsaNo ratings yet

- Interzone 101Document0 pagesInterzone 101hennawijayaNo ratings yet

- Marathon XHBDocument5 pagesMarathon XHBakbarNo ratings yet

- Penguard Clear Sealer: Technical Data Sheet Application GuideDocument7 pagesPenguard Clear Sealer: Technical Data Sheet Application GuideAnonymous 4SFfEmcHmDNo ratings yet

- Marathon IQ GF - English (Uk) - Issued.06.12.2007Document3 pagesMarathon IQ GF - English (Uk) - Issued.06.12.2007Mohamed FaragNo ratings yet

- Jotatemp 650 (ENG)Document3 pagesJotatemp 650 (ENG)Dedi KartiwaNo ratings yet

- Protective Coating-3Document0 pagesProtective Coating-3Sivaratnam NavatharanNo ratings yet

- PC 7048 - Asian Epoxy Dual CoatDocument3 pagesPC 7048 - Asian Epoxy Dual CoatGunjan GaganNo ratings yet

- Xylan 80-018-g6706 Black - BeDocument2 pagesXylan 80-018-g6706 Black - BeSYED MAZHARNo ratings yet

- Jotun Resist 86 Data SheetDocument7 pagesJotun Resist 86 Data SheetKunal AjgaonkarNo ratings yet

- Interseal 547 PaintDocument4 pagesInterseal 547 PaintSUBHOMOYNo ratings yet

- TDS Epoxy Zinc Phosphate Primer HB 50 GreyDocument3 pagesTDS Epoxy Zinc Phosphate Primer HB 50 GreySAlman Khan50% (2)

- Marathon XHB Epoxy Coating Technical DataDocument3 pagesMarathon XHB Epoxy Coating Technical DataMohamed FaragNo ratings yet

- Marathon: Technical Data SheetDocument5 pagesMarathon: Technical Data SheetOkinawa TeakNo ratings yet

- Interbond 600 PDFDocument4 pagesInterbond 600 PDFTrịnh Minh KhoaNo ratings yet

- Primer SC PDFDocument3 pagesPrimer SC PDFFrancois-No ratings yet

- AG 494 Jotafloor Sealer Euk GBDocument6 pagesAG 494 Jotafloor Sealer Euk GBAhmed SalahNo ratings yet

- Residential Asphalt Roofing Manual Design and Application Methods 2014 EditionFrom EverandResidential Asphalt Roofing Manual Design and Application Methods 2014 EditionNo ratings yet

- Water-Based Paint Formulations, Vol. 3From EverandWater-Based Paint Formulations, Vol. 3Rating: 4.5 out of 5 stars4.5/5 (6)

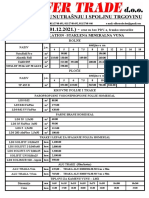

- Offer Trade Cenovnik Staklena I FolijeDocument1 pageOffer Trade Cenovnik Staklena I FolijeNovica ĐorđevićNo ratings yet

- Stone Wool Boards: Technical Specification BenefitsDocument1 pageStone Wool Boards: Technical Specification BenefitsNovica ĐorđevićNo ratings yet

- Offer Trade FolijeDocument1 pageOffer Trade FolijeNovica ĐorđevićNo ratings yet

- Hromos TrstenikDocument1 pageHromos TrstenikNovica ĐorđevićNo ratings yet

- RUS, M 3 UDocument7 pagesRUS, M 3 UNovica ĐorđevićNo ratings yet

- Muscat International Airport plaster specificationDocument23 pagesMuscat International Airport plaster specificationDiana Alexandra Comaromi0% (1)

- CBT Questions on Welding Codes, Processes, and DefectsDocument5 pagesCBT Questions on Welding Codes, Processes, and DefectsAris Bulaong100% (1)

- Saes L 109Document16 pagesSaes L 109Abdullah RiazNo ratings yet

- Fabrication Methods of Metal Matrix Composites (MMCS)Document7 pagesFabrication Methods of Metal Matrix Composites (MMCS)Mohamed KhalifaNo ratings yet

- Prevention From Inter-Granual CorrosionDocument7 pagesPrevention From Inter-Granual CorrosionDevashish JoshiNo ratings yet

- PIPING SYSTEMS ARRANGEMENTDocument19 pagesPIPING SYSTEMS ARRANGEMENTNur SalimNo ratings yet

- CUPALDocument3 pagesCUPALMitica BdNo ratings yet

- Truss Solutions For Curved RoofsDocument3 pagesTruss Solutions For Curved RoofszamaxxNo ratings yet

- Durability of Concrete Exposed To Marine Environment-A Fresh LookDocument30 pagesDurability of Concrete Exposed To Marine Environment-A Fresh LookElizabeth CruzNo ratings yet

- Concrete Mix Design m75Document2 pagesConcrete Mix Design m75nil sutar100% (1)

- Anti-Corrosion en 110117 LowDocument12 pagesAnti-Corrosion en 110117 Lowinfo9316No ratings yet

- ETH - 7000013952 - Civil BOQDocument39 pagesETH - 7000013952 - Civil BOQBijaya RaulaNo ratings yet

- BoilerDocument23 pagesBoileronspsnons123100% (1)

- SCI P292 SecureDocument222 pagesSCI P292 Secureg1g1ng100% (1)

- 20SQGD070 Spec SheetDocument5 pages20SQGD070 Spec Sheetsametb_1No ratings yet

- ClimalifeDocument5 pagesClimalifeVicente AlarconNo ratings yet

- Astm C 704 PDFDocument11 pagesAstm C 704 PDFJeganeswaranNo ratings yet

- Design Primer For Hot ClimateDocument16 pagesDesign Primer For Hot ClimateHiren SavaliyaNo ratings yet

- Engineering polymers annealing guideDocument3 pagesEngineering polymers annealing guidejuan k RestrepoNo ratings yet

- Metric Design Guide: (PBS-PQ260)Document53 pagesMetric Design Guide: (PBS-PQ260)Sunil IistNo ratings yet

- CP Abalaba 201704Document13 pagesCP Abalaba 201704Larasanto Cipta AgungNo ratings yet

- Dynaflow Vs Stay Silv 15Document2 pagesDynaflow Vs Stay Silv 15Zeljko RisticNo ratings yet

- CRANE - Flow of Fluids - Through Valve, Fittings and PipesDocument133 pagesCRANE - Flow of Fluids - Through Valve, Fittings and PipesPherx JhossNo ratings yet

- Electrical Code Requirements for Lighting and Convenience OutletsDocument11 pagesElectrical Code Requirements for Lighting and Convenience OutletsJocel SangalangNo ratings yet

- 2024 - MTRL 494 - Assignment 4Document3 pages2024 - MTRL 494 - Assignment 4vjscricNo ratings yet

- A Review On Hydrogen Embrittlement Risk Based Inspection 1688970506Document31 pagesA Review On Hydrogen Embrittlement Risk Based Inspection 1688970506Pranav PramodNo ratings yet

- Liangchew CatalogueDocument48 pagesLiangchew CatalogueKyaw Naing AungNo ratings yet

- Merazzo Flooring: Affordable Terrazzo-Style Flooring For Any SpaceDocument8 pagesMerazzo Flooring: Affordable Terrazzo-Style Flooring For Any Space서영규No ratings yet

- Umri Road Work Done-1Document162 pagesUmri Road Work Done-1DPRE PIU ADILABADNo ratings yet

- Seminar S.G IronDocument32 pagesSeminar S.G Ironravikataria02No ratings yet