Professional Documents

Culture Documents

Military Fuel Hydrant

Uploaded by

Jorge MuñizCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Military Fuel Hydrant

Uploaded by

Jorge MuñizCopyright:

Available Formats

Military Fuel Hydrant Pit Assembly

Application

To provide on/off or pressure/flow control while dispensing

fuel to a military aircraft.

General Benefits

• Less costly, easy operational and maintenance access to

adapter and valves by use of aircraft load-rated/one-hand

lift, fail-safe Cover and stepdown platform.

• Safer operation due to automatic cover latches which

eliminate jet blast or vehicle-bounce cover openings.

• Easier, less costly operations because deadman control Typical Pit Assembly Typical Pit Internals

with hose and rewind control are integral part of pit

assembly.

• Easier Pit location and identification with abrasion/

corrosion/chemical resistant color coded cover service

lettering.

• Safer operation assured by the use of safety orange cover

mounted panels alerting personnel to the open cover.

• Easier, less costly field installation, operations and

maintenance since the Cover, Pit and all internal Waterproof Cover Latch/Delatch Mechanism Non-Waterproof Counterweight Cover

components are provided with guaranteed optimum

placement and support by Dabico as a completely Waterproof or Non-Waterproof Cover Options

prefabricated, factory assembled package, ready for A waterproof cover and frame helps prevent fluids and dirt/

installation by others. debris from entering the Pit when the cover is closed.

Factory Assembly Benefits DABICO patented waterproof covers greatly reduce costly

operations and maintenance by reducing the need for a

• Easier, less costly field installation since Pit assembly is

drainage system and/or the frequency of manual Pit

shipped ready for installation.

sumping.

• Less costly operation and maintenance due to guaranteed

optimum placement of internal components. Optionally non-waterproof covers are available on request.

• Guaranteed competitive internal component pricing. Counterweight or Torsion Spring Cover Actuation

• Factory warranty and support of complete Pit assembly. Dabico’s patented torsion spring actuated covers provide

maximum available working space within the Pit assembly.

Customisation

The Pit size and components shown are only a typical Alternatively, countertweight covers can be supplied.

representation. See page 2 (over) for Specification Checklist. Other Fuel System Pit Assemblies Available from

If your project has different requirements or a special DABICO:

application, please contact us for a custom Pit assembly • Isolation Valve Pit Assemblies

design.

• High Point Vent Pit Assemblies

Ease of Maintenance

• Low Point Drain Pit Assemblies

The use of white pigmented GRP with internal gel-coat fin-

ish ensures maximum reflected light for ease of maintenance • Leak Detection Pit Assemblies

and cleaning when working inside the Pit. • Surge Suppressor Pit Assemblies

Quality and Value You Can Depend On

DABICO (Europe) NORTH AMERICA

Units 5A & 5B St. Annes Ind. Estate 2995 Airway Ave.

Stockton on Tees Costa Mesa,

TS18 2HF England CA 92626 USA

Tel. (+44) 1642-608245 Tel. (+1) 714-545-7900

Fax (+44) 1642-608224 Fax. (+1) 714-545-7676

email: genmail@dabico.co.uk email: genmail@dabico.com

Web: www.dabico.co.uk Web: www.dabico.com

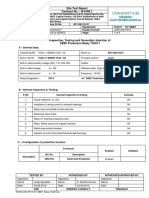

MILITARY FUEL HYDRANT PIT ASSEMBLY Military Fuel Hydrant Pit Assembly

Specifications

PIT COVER ASSEMBLY SHALL HAVE:

• All primary metal cast aluminum, alloy No. A356.2, per Fed.

Spec. QQ-A-601F, with T-6 heat treat per Mil. Spec. H-6088F,

with no exceptions.

• Service lettering that is of abrasion/corrosion/chemical-resistant

color coded, polyester powder coated.

• Hand-holes at a minimum 44mm depth and 48 cu. cm. volume,

and integral, automatic latches.

• Latches with no above-grade protrusions whether in use or

not, and interconnected so activating one unlatches both.

• One-piece and opens to 90 degrees with a maximum11.34 kg.

( 25 lb.) lift, and closes with a minimum 22.68 kg. (50 lb.) push,

using torsion-actuated mechanisms.

• A cover that does not “pop” open when a latch is released, and

is designed to fail-safe open once lifted beyond the 80-degree

point in the opening arc. Once in the 90 degree position, cover

to remain fully open.

• A hold-open bar is provided that automatically locks the cover

in the full-open position, and releases with one-hand operation.

• Highest Pit internal component accessible from a maximum of

140mm from Pit top.

• High visibility orange panels on top & under sides for safety.

• A prototype test report submitted and the test conducted by an

independent testing company in the following manner: cover

loading over each of two, spaced at a maximum of 915 mm [36"

] on centers for Pit with inside length greater than 1,524 mm [60"

], 1,291 sq. cm.( 200 sq. in. ) footprints shall result in a minimum

70 kg/sq. cm (1,000 Psi) rating with a maximum 3.81 mm (0.150")

full load deflection at center indicators and deflection “rebound”

within 0.254 mm (0.010") after load release.

• D.O.T. AC 150/5320-6C compliance.

• No: visual shrink porosity cavity areas, fillers, weldments and

paint to hide.

• Load bearing mating flange surfaces of the Pit and cover that

are flat to within 1.27 mm(0.050") total indicator reading.

Military Fuel Hydrant Pit Assembly

• Been provided by a company with over 30 years experience in

Specification Checklist the supply of cast aluminum covers for airfield applications.

Complete and fax to DABICO (Europe) at: PIT COVER SEAL SHALL HAVE (Where Appropriate):

(+44) 1642 608224 for customised drawing(s) and budgetary • The capability to automatically engage Pit flange when cover

quotation.

is seated in the closed position without any secondary latching

COVER TYPE motions. Seal (if fitted) shall be affixed without mechanical

T Waterproof T Non-Waterproof fasteners, have a minimum field life of 1 year, and be ozone/

T Torsion Spring Actuated T Counterweight Actuated UV resistant.

Pit Size • A sealing surface that is separate from load-bearing surface.

T DAB-725/41 – 1905mm x 635mm x 1041mm • A prototype environmental test report that is submitted and the

Fuel/Defuel Hydrant Valve(s) ____ test conducted by an independent testing company in the

Hydrant Valve Type: following categories and standards: Totally submerged cover

T On/Off T Pressure Control T Other: ________ shall pass less than 100 grams of water per hour following:

Size: T 4"x 4" T 6"x 4" T 6"x 6" T 4"x 2-1/2" T ______ a) hot (70°C) and cold (4°C) cycling conforming to Mil Std-810.

Maintenance Valve Type: b) seal contamination (door seal & mating frame sealing surface

T Butterfly T Ball T ______ coated with sand and soil mixture).

Maintenance Valve Size: • Passed submersion and hose down tests equal to NEMA 250

T 4" T 6" T ______ standards for Type 6 exterior enclosures except that the cover

Pipe Entry: T Side T Bottom T Single Boot T Double Boot is tested in 150 mm (6”) deep standing water.

Piping System Type: PIT INTERNAL COMPONENTS

T Single Pipe T Double Containment • All the Pit internal components shown and described in the

Filler Vessels: plans and specifications shall be provided by the pit

T Yes T No Size(s): ________ manufacturer as a completely factory assembled package.

Hose Reel(s):

T Yes T No Size(s): ________

Person requesting:______________________________________

Company name:_________________________________________

Telephone:_______________________________________________

Fax:_____________________________________________________

e-mail:__________________________________________________

Quality and Value You Can Depend On

You might also like

- Leak Free Stuffing BoxesDocument2 pagesLeak Free Stuffing BoxesjorgeNo ratings yet

- Captura de Tela 2023-11-29 À(s) 20.19.42Document44 pagesCaptura de Tela 2023-11-29 À(s) 20.19.42Julio SantosNo ratings yet

- Aeroquip - A-HOOV-MC001-E1 - Overview - LRDocument6 pagesAeroquip - A-HOOV-MC001-E1 - Overview - LRMarcelo MalagoNo ratings yet

- Special Promo Auto Glass & Workshop EssentialsDocument20 pagesSpecial Promo Auto Glass & Workshop EssentialskenywkNo ratings yet

- Pivot MasterDocument2 pagesPivot MasterAleck VieyraNo ratings yet

- 576047-191 Bomba Red Yacket 3 PDFDocument2 pages576047-191 Bomba Red Yacket 3 PDFEstacion AvenidaNo ratings yet

- Gauge - Pole - Cover - For - Floating - Roof - Tanks LR PDFDocument2 pagesGauge - Pole - Cover - For - Floating - Roof - Tanks LR PDFArlen NurlanNo ratings yet

- PDS-PITTWRAP CW Plus Jacketing-US-enDocument3 pagesPDS-PITTWRAP CW Plus Jacketing-US-enJorge Manuel MezaNo ratings yet

- Series A: Product GuideDocument8 pagesSeries A: Product GuideFrank Felipe Cruz ChavezNo ratings yet

- A HOOV MC001 E1 - OverviewDocument6 pagesA HOOV MC001 E1 - OverviewjernejzajecNo ratings yet

- Acoplamento Wrapflex FalkDocument16 pagesAcoplamento Wrapflex FalkArthur Magalhães SanduvettiNo ratings yet

- Anderson Greenwood Liquid Storage Internal Tank ValvesDocument10 pagesAnderson Greenwood Liquid Storage Internal Tank ValvesMichael J. BaneNo ratings yet

- Series E: Product GuideDocument8 pagesSeries E: Product GuideFrank Felipe Cruz ChavezNo ratings yet

- RaiDocument2 pagesRaiuptc1985No ratings yet

- Brochure - Century SmallDocument8 pagesBrochure - Century SmallBalqis BaslemanNo ratings yet

- May Nen IntermechDocument2 pagesMay Nen IntermechUchiha SaitamaNo ratings yet

- Oil SkimersDocument139 pagesOil SkimerszirimiaNo ratings yet

- XX-CLONE Through-Flow CleanerDocument4 pagesXX-CLONE Through-Flow CleanerEdson CastelliNo ratings yet

- Air MGMT Brochure 2013Document8 pagesAir MGMT Brochure 2013manuelsaurioNo ratings yet

- HCVValve DSDocument4 pagesHCVValve DSPriyam KmNo ratings yet

- Master Catalog-AeroquipDocument388 pagesMaster Catalog-AeroquipCOM GRAVENo ratings yet

- Cissell SpecificationsDocument4 pagesCissell Specificationsmairimsp2003No ratings yet

- Cissell Specifications HD 75 100 125 170 190Document4 pagesCissell Specifications HD 75 100 125 170 190mairimsp2003No ratings yet

- New Packer - 001 PDFDocument76 pagesNew Packer - 001 PDFNagarjunSHNo ratings yet

- EVAPCO AXS Cooling Tower Catalogue Bulletin 333A REV 1Document7 pagesEVAPCO AXS Cooling Tower Catalogue Bulletin 333A REV 1David Bryant100% (1)

- Evo-Trieve® EB0 Retrievable Straddle - HalliburtonDocument2 pagesEvo-Trieve® EB0 Retrievable Straddle - HalliburtonYovaraj KarunakaranNo ratings yet

- National Boom Trucks Spec Ef6a51Document8 pagesNational Boom Trucks Spec Ef6a51Juan Carlos Torres MartinezNo ratings yet

- Pivot MasterDocument2 pagesPivot MasterNithin GNo ratings yet

- Datasheet PRT - 1100 TonDocument2 pagesDatasheet PRT - 1100 TonVictor Uyoque GiraldoNo ratings yet

- Catalogo AeroquipDocument387 pagesCatalogo AeroquipMarcelo Godinho BatistaNo ratings yet

- Centrifuge Digtor22CDocument9 pagesCentrifuge Digtor22Cbilal khan0% (1)

- Premier Butyl Tape System IFU DENSODocument4 pagesPremier Butyl Tape System IFU DENSOChuck AnsphilNo ratings yet

- OASC TDDocument8 pagesOASC TDFati ZoraNo ratings yet

- Tankjet 360 Tank Cleaner Tankjet 360 Tank CleanerDocument2 pagesTankjet 360 Tank Cleaner Tankjet 360 Tank CleanerAlejandro VescovoNo ratings yet

- Coiled Tubing Workover ApplicationsDocument60 pagesCoiled Tubing Workover Applicationsak_adamNo ratings yet

- Tech PDFDocument3 pagesTech PDFAwais JalaliNo ratings yet

- Series D: Product GuideDocument8 pagesSeries D: Product GuideFrank Felipe Cruz ChavezNo ratings yet

- High Deviation Tool StringsDocument11 pagesHigh Deviation Tool Stringskyle warrenNo ratings yet

- Catalogo Detallado QH441Document39 pagesCatalogo Detallado QH441JesusFloresRodriguezNo ratings yet

- Delta Blower Generation 5: Rotary Lobe BlowersDocument16 pagesDelta Blower Generation 5: Rotary Lobe Blowersteguh priyo utomoNo ratings yet

- 576 1 80 cct-1Document110 pages576 1 80 cct-1Danny Cacuango100% (1)

- Carrier - 39 XT Air HandlingDocument24 pagesCarrier - 39 XT Air HandlingorganicspolybondNo ratings yet

- Grand Raid XXL roof top tent provides comfortable camping in all conditionsDocument2 pagesGrand Raid XXL roof top tent provides comfortable camping in all conditionsDian WisesaNo ratings yet

- CableBolt TDSDocument2 pagesCableBolt TDSMarkusMakuAldoNo ratings yet

- PackerDocument76 pagesPackerRafael100% (1)

- Wire Line ch-1Document20 pagesWire Line ch-1Ammar HrzNo ratings yet

- ERKE Group, Soilmec SM-8G AnchoringDocument12 pagesERKE Group, Soilmec SM-8G Anchoringerkegroup100% (1)

- Made in Europe: Advanced Flexitank ManufacturingDocument8 pagesMade in Europe: Advanced Flexitank ManufacturingPaulo DiasNo ratings yet

- Articol PPDP PDFDocument2 pagesArticol PPDP PDFCodruta DîrjanNo ratings yet

- Goulds - ICO I-Frame SeriesDocument16 pagesGoulds - ICO I-Frame SeriesAlexNo ratings yet

- 187 DMR BearingIsolators 01Document7 pages187 DMR BearingIsolators 01Teguh SetionoNo ratings yet

- Tetra Pak Aseptic Tank VC: Aseptic, Vertical Storage Tank For Viscous Food ProductsDocument2 pagesTetra Pak Aseptic Tank VC: Aseptic, Vertical Storage Tank For Viscous Food ProductsYacineNo ratings yet

- Floating Suction Lines and Skimmer Units: Tank Drain SystemsDocument6 pagesFloating Suction Lines and Skimmer Units: Tank Drain SystemsLassadNo ratings yet

- Subsea Gate Valve: Suzhou Douson Drilling & Production Equipment Co., LTDDocument2 pagesSubsea Gate Valve: Suzhou Douson Drilling & Production Equipment Co., LTDindraNo ratings yet

- Aero Indoor and Weathertight Outdoor Air Handlers: Product DataDocument172 pagesAero Indoor and Weathertight Outdoor Air Handlers: Product DataANGEL MURILLONo ratings yet

- Pt. Magdatama - Brosur Wabo Jeene JointDocument4 pagesPt. Magdatama - Brosur Wabo Jeene JointRismansyah Rizqian SundawaNo ratings yet

- AWH Brochure CleaningTechnology PDFDocument8 pagesAWH Brochure CleaningTechnology PDFtpichileNo ratings yet

- Itema WeavingMachines Instructions After ShutdownDocument4 pagesItema WeavingMachines Instructions After ShutdownSounak SasmalNo ratings yet

- Completion Equipment 1709291573Document8 pagesCompletion Equipment 1709291573Reza heidari orojlooNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- CF-OPT-02: Olympic Bar HolderDocument2 pagesCF-OPT-02: Olympic Bar HolderJorge MuñizNo ratings yet

- CF-3264 Manual PG 00-29 (0507-000)Document30 pagesCF-3264 Manual PG 00-29 (0507-000)Jorge MuñizNo ratings yet

- CF-3264 Manual PG 00-29 (0507-000)Document30 pagesCF-3264 Manual PG 00-29 (0507-000)Jorge MuñizNo ratings yet

- Roc-It Weight Cage (0406-016)Document39 pagesRoc-It Weight Cage (0406-016)Dago GrannobleNo ratings yet

- Seated Mid-Row: Record Serial Number Here Catalog Number Customer ServiceDocument31 pagesSeated Mid-Row: Record Serial Number Here Catalog Number Customer ServiceJorge MuñizNo ratings yet

- IT - Lesson 8 - Methods of PaymentDocument16 pagesIT - Lesson 8 - Methods of PaymentFrancisco J. Salinas B.100% (1)

- IT - Lesson 8 - Methods of PaymentDocument16 pagesIT - Lesson 8 - Methods of PaymentFrancisco J. Salinas B.100% (1)

- Competitive Initiative Aviation Fuel Reclamation System Technical SpecificationDocument24 pagesCompetitive Initiative Aviation Fuel Reclamation System Technical SpecificationJorge MuñizNo ratings yet

- Aviation Jet Fuel Testing Instruments PDFDocument16 pagesAviation Jet Fuel Testing Instruments PDFAltif Abood0% (1)

- Viking Pump EngineeringDocument7 pagesViking Pump EngineeringJorge MuñizNo ratings yet

- 19722-0 SSAFLAB FiltrationDocument1 page19722-0 SSAFLAB FiltrationJorge MuñizNo ratings yet

- IP 565 Water Effect On Particle CountingDocument5 pagesIP 565 Water Effect On Particle CountingJorge Muñiz100% (1)

- Flow Through Hose and Pressure Loss Due To Friction Are Indicated in The Diagram BelowDocument1 pageFlow Through Hose and Pressure Loss Due To Friction Are Indicated in The Diagram BelowJorge MuñizNo ratings yet

- Scan 2Document10 pagesScan 2Jorge MuñizNo ratings yet

- Gorman Rupp Pumps Engineering DataDocument25 pagesGorman Rupp Pumps Engineering DataJorge MuñizNo ratings yet

- Viscosity 1Document6 pagesViscosity 1Jorge MuñizNo ratings yet

- E 343GFDocument2 pagesE 343GFJorge MuñizNo ratings yet

- 155 17-O2 PDFDocument152 pages155 17-O2 PDFArshad MahmoodNo ratings yet

- Honeywell Cs071ae Evaporative Cooler Owner's Manual PDFDocument22 pagesHoneywell Cs071ae Evaporative Cooler Owner's Manual PDFAlbert TaczNo ratings yet

- Pembuatan Control Fuel ArduinoDocument6 pagesPembuatan Control Fuel ArduinoAgoeng NoegrossNo ratings yet

- DIY Heated Seats RetrofitDocument27 pagesDIY Heated Seats RetrofitvalymadNo ratings yet

- Coa - Lecture 3 - BNCDocument5 pagesCoa - Lecture 3 - BNCShizz denariNo ratings yet

- Olflex Connector - Servo AssemblyDocument12 pagesOlflex Connector - Servo AssemblyKien Nguyen TrungNo ratings yet

- PIC18F24 25Q10 Data Sheet DS40001945B 1365742 PDFDocument770 pagesPIC18F24 25Q10 Data Sheet DS40001945B 1365742 PDFNikhil DeshmukhNo ratings yet

- MIO Soul Catalog PartsDocument54 pagesMIO Soul Catalog Partsnchez86% (79)

- Lec# 8 The Addressing Modes of 8085 MicroprocessorDocument20 pagesLec# 8 The Addressing Modes of 8085 MicroprocessorSalva KhanNo ratings yet

- CST 2022 3 PCR Catalogue PDFDocument56 pagesCST 2022 3 PCR Catalogue PDFPencari CuanNo ratings yet

- Susol RMU - E - 180702Document28 pagesSusol RMU - E - 180702Sandeep Kr Arya0% (1)

- FocusDocument65 pagesFocusRoberto Sanchez67% (3)

- Chapter: - 1: Manually and Power Operated Reaper MachineDocument44 pagesChapter: - 1: Manually and Power Operated Reaper MachinevenuNo ratings yet

- 16 Dornier Seastar BrochureDocument20 pages16 Dornier Seastar BrochurefebriansyahNo ratings yet

- Motores Panasonic PDFDocument293 pagesMotores Panasonic PDFMarlon MorelNo ratings yet

- CD1000A - User Manual V1.0Document88 pagesCD1000A - User Manual V1.0Engr ShoaibNo ratings yet

- Otn, Otr, Otf TransformersDocument6 pagesOtn, Otr, Otf TransformersDott PalmitoNo ratings yet

- Hci 05 / Hci 08 / Hci 10 Touch Panel Operator Interface SpecificationDocument6 pagesHci 05 / Hci 08 / Hci 10 Touch Panel Operator Interface SpecificationdirgayasaNo ratings yet

- VM SssssssDocument18 pagesVM Ssssssskalin3169899No ratings yet

- RISC-V Core RISC-V CoreDocument3 pagesRISC-V Core RISC-V CoreRajini KasalaNo ratings yet

- Ahts 130tn BP, Dp2 Spec SheetDocument2 pagesAhts 130tn BP, Dp2 Spec SheetKhaled MohamedNo ratings yet

- MX-600 Mammography X-ray System SpecsDocument77 pagesMX-600 Mammography X-ray System SpecsАлександр Благов86% (7)

- IRF Inductors: Epoxy Conformal Coated Uniform Roll CoatedDocument3 pagesIRF Inductors: Epoxy Conformal Coated Uniform Roll CoatedΠΑΝΑΓΙΩΤΗΣΠΑΝΑΓΟΣNo ratings yet

- 1483 E IMS 8 StorageDocument10 pages1483 E IMS 8 StorageJuan Manuel Pescador ReyesNo ratings yet

- Case 788-988 Service ManualDocument1,146 pagesCase 788-988 Service ManualVinnichuk OlesNo ratings yet

- rc38 Recs For Frost Protection Measures For Sprinklers PDFDocument12 pagesrc38 Recs For Frost Protection Measures For Sprinklers PDFNahado DMNo ratings yet

- Diagnostic Tests - Two-Filter SystemDocument42 pagesDiagnostic Tests - Two-Filter Systemcells-crosser0xNo ratings yet

- Official Banking SBI CLERK Computer KnowledgeDocument5 pagesOfficial Banking SBI CLERK Computer KnowledgevijayNo ratings yet

- IRFP250: 33A, 200V, 0.085 Ohm, N-Channel Power MOSFET FeaturesDocument8 pagesIRFP250: 33A, 200V, 0.085 Ohm, N-Channel Power MOSFET FeaturesLevu ObiWan VasiljevicNo ratings yet

- N6166 - E05 - F513 - HV - SBEF - Relay - 7SJ61 Site Test ReportDocument9 pagesN6166 - E05 - F513 - HV - SBEF - Relay - 7SJ61 Site Test Reportমোঃ মহসিনNo ratings yet