Professional Documents

Culture Documents

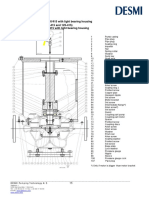

Screw Dimension Moment in NM

Uploaded by

arnoldbusaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Screw Dimension Moment in NM

Uploaded by

arnoldbusaCopyright:

Available Formats

Tighten Allen screws in the coupling according to below table.

Screw dimension Moment in Nm

M8 8

M10 15

M12 27

M16 65

M20 127

6.8 SHAFT

When the pump has been assembled, check that the shaft rotates freely and without noise.

7. FROST PROTECTION

Pumps which are not in operation during frost periods are to be drained to avoid frost damage. Remove

the plug (3) at the bottom to empty the pump. Alternatively, it is possible to use anti-freeze liquids in

normal constructions.

8. DISMANTLING

Before dismantling the pump make sure that it has stopped. Empty the pump of liquid before it is

dismantled from the piping system. If the pump has been pumping dangerous liquids you are to be

aware of this and take the necessary safety measures.

If the pump has been pumping hot liquids, take great care that it is drained before it is

removed from the piping system.

9. START-UP

A centrifugal pump will not function until it has been filled with liquid between the foot valve and

somewhat above the impeller of the pump.

____________________________________________________________________________________

DESMI Pumping Technology A/S 8

Tagholm 1

9400 Nørresundby – Denmark

Tel: +45 96 32 81 11 Fax: +45 98 17 54 99

E-mail: desmi@desmi.com

www.desmi.com

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Seacor Maya: Main Particulars Electronics & ControlsDocument2 pagesSeacor Maya: Main Particulars Electronics & ControlsarnoldbusaNo ratings yet

- ATLAS COPCO Air Compressors GA30-90 GA37 110VSDDocument9 pagesATLAS COPCO Air Compressors GA30-90 GA37 110VSDCardoso MalacaoNo ratings yet

- HM Series Brochure Eng 2011 PDFDocument12 pagesHM Series Brochure Eng 2011 PDFulaogtNo ratings yet

- GC Compressor Brochure 10-02-20Document6 pagesGC Compressor Brochure 10-02-20arnoldbusaNo ratings yet

- SEACOR Pride: Main Particulars Rescue CapabilitiesDocument1 pageSEACOR Pride: Main Particulars Rescue CapabilitiesarnoldbusaNo ratings yet

- L Series Compresoras GARDNER DENVERDocument12 pagesL Series Compresoras GARDNER DENVERjulio0% (1)

- Westfalia Separator Mineraloil Systems GMBH: Instruction Manual and Parts ListDocument182 pagesWestfalia Separator Mineraloil Systems GMBH: Instruction Manual and Parts ListarnoldbusaNo ratings yet

- TMV2 Quick Reference GeneralDocument31 pagesTMV2 Quick Reference GeneralarnoldbusaNo ratings yet

- Technical BTHDocument1 pageTechnical BTHarnoldbusaNo ratings yet

- IOGP LSR IntroductionDocument28 pagesIOGP LSR IntroductionharyosetyoNo ratings yet

- User Manual: TM Master v2Document142 pagesUser Manual: TM Master v2Creatza ElenaNo ratings yet

- Watertight Sliding DoorDocument21 pagesWatertight Sliding DoorarnoldbusaNo ratings yet

- TM MasterDocument39 pagesTM MasterKomang DeliNo ratings yet

- Bombas Desmi2Document1 pageBombas Desmi2arnoldbusaNo ratings yet

- Safty, S and P Flex Separation - 584610 - v1 PDFDocument20 pagesSafty, S and P Flex Separation - 584610 - v1 PDFSan ZawNo ratings yet

- User Manual 384141Document20 pagesUser Manual 384141arnoldbusaNo ratings yet

- Traconed 141012 Regulation Poster - Emergency Muster ListDocument1 pageTraconed 141012 Regulation Poster - Emergency Muster ListarnoldbusaNo ratings yet

- v5 Instrcution BookDocument181 pagesv5 Instrcution BookarnoldbusaNo ratings yet

- Alfa Laval Separartor p615 Alarms & Fault FindingsDocument17 pagesAlfa Laval Separartor p615 Alarms & Fault FindingsIgors Vrublevskis100% (1)

- Specification No. 881201-07-01/1 Book No. 592604 02 Rev. 8Document60 pagesSpecification No. 881201-07-01/1 Book No. 592604 02 Rev. 8arnoldbusaNo ratings yet

- Instruction Manual HL2-90Document28 pagesInstruction Manual HL2-90SimonaMauna67% (6)

- MTU ControlPanels PDFDocument4 pagesMTU ControlPanels PDFShoaib IqbalNo ratings yet

- v4 Parameter ListDocument16 pagesv4 Parameter ListarnoldbusaNo ratings yet

- v3 IS BOOKDocument215 pagesv3 IS BOOKarnoldbusaNo ratings yet

- Anchor Handling Manual MSFDocument45 pagesAnchor Handling Manual MSFfeghuolhakim100% (4)

- Part 3 Truster ControlDocument56 pagesPart 3 Truster ControlarnoldbusaNo ratings yet

- Temperature Sensors Data SheetDocument4 pagesTemperature Sensors Data Sheetgordanz13No ratings yet

- 16V92A Marine Pleasure CraftDocument2 pages16V92A Marine Pleasure CraftarnoldbusaNo ratings yet

- HAB Workboat GuideDocument92 pagesHAB Workboat GuidearnoldbusaNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)