Professional Documents

Culture Documents

Helmboldt Angebot E Kran Und Katzfahren Von Hand

Uploaded by

Ahmad shayebOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Helmboldt Angebot E Kran Und Katzfahren Von Hand

Uploaded by

Ahmad shayebCopyright:

Available Formats

Kransysteme

Klaus Hemboldt quotation

001900-0000000-20210927-20

Mr. Klaus Hemboldt page: 1 of 4

Edewecht, 27/09/2021

customer

ABUS Werksvertretung

Gerd Nöding

phone: 04486/8430

fax: 04486/8806

gn@hochmuth.eu

your enquiry: Palästina

date of enquiry: 27/09/2021

Dear Mr. Hemboldt,

Thank you very much for your inquiry.

We are pleased to submit our preliminary offer which will only become effective after you have received our written

confirmation.

Our quotation is based on our currently valid general conditions of sales, maintenance, and repair which are

available to view on www.abus-kransysteme.de.

Please do not hesitate to contact us by phone, or request a visit, if you wish to discuss our offer.

Best regards,

Industrievertretung Hochmuth e. K.

Gerd Nöding

ABUS Kransysteme GmbH Bankverbindungen: BLZ Konto-Nr. Handelsregister: HRB Köln 39091

Sonnenweg 1 D-51647 Gummersbach Deutsche Bank AG, Gummersbach 384 700 91 0 100 800 USt.-ID.Nr.: DE 811 575 164

Tel. (0 22 61) 37-0 Fax (0 22 61) 37-247 HSBC Trinkaus & Burkhardt KGaA, Düsseldorf 300 308 80 527 009 Geschäftsführer: Lothar Bühne

e-mail: info@ABUS-Kransysteme.de Commerzbank AG, Gummersbach 384 400 16 77 49 500 Dr. Eckhard Bube

www.ABUS-Kransysteme.de Sparkasse Gummersbach-Bergneustadt 384 500 00 200 030

© ABUS Kransysteme GmbH, ABUKonfis Version 5.16w37

Kransysteme

quotation 001900-0000000-20210927-20 dated 27/09/2021 page 2 of 4

description of the scope of supply and of services

pos. description price

1,0 1 pc(s) 10.050,00 €

HB crane system consisting of:

ABUS Double Girder Crane ZHB

number / crane no. 1 unit(s) / crane no.: 1

load capacity 1250 kg

crane girder length 4800 mm

crane girder projections 70/70 mm

crane span 4660 mm

crane profile HB150S

galvanised and with foil in colour RAL 1007

daffodil yellow

design basis according to DIN 15018

crane rating H1/B3

crane travel manual

Double-rail trolley – raised up 700 mm trolley span

operating voltage 3/PE~50 Hz 400 V

type of control direct control (DAC)

degree of protection IP 55

trolley power supply

festoon cable, cable sag approx. 800 mm,

with flat cable moving inside the profile by means of cable sliders.

Number of poles: 4 (3 Ph/PE)

Control operated from floor level via push button pendant control

The push button pendant control with 2 stage push buttons is mounted on and travelling with

the trolley. Brand: ABUS

Length of control cable including push button pendant control: 1560 mm

ABUS electric chain hoist

version Double-rail trolley

type of chain hoist GM 4 1250.4-2, 2-falls

painted in colour RAL 5017 traffic blue

load capacity 1,25 t

hook path 3000 mm

highest hook position 2306 mm

design basis FEM 9.901

FEM group 1Am / M4

hoisting, two-stage (pole-changing) 1 / 4 m/min

lifting performance 0.22 / 0.9 kW

duty cycle 60 % ED

switching cycles 360 c/h

trolley travelling manual

Overload protection

Mechanical friction clutch as overload protection. The friction clutch has been preset.

ABUS crane track 2-tracks

track length 5800 mm

suspension distance 2500 / 2500 mm

track projection 400 / 400 mm

track profile HB190S

galvanised and with foil in colour RAL 1007

daffodil yellow

ABUS crane track mounting

6 pc(s).

mounting on reinforced concrete ceiling via dowel placing

© ABUS Kransysteme GmbH, ABUKonfis Version 5.16w37

Kransysteme

quotation 001900-0000000-20210927-20 dated 27/09/2021 page 3 of 4

FHB 4 x M12

ceiling thickness >=140 mm

permitted suspension load of the dowel max. 16 kN

inclination of connection surface max. 3 °

The data sheet “Technical pre-clarification of conditions for dowel mounting” is attached.

These specifications must be strictly observed and are an integral part of the contract in the

event of an order.

suspension height 177 mm

mains power supply on track 1

festoon cable, cable sag approx. 800 mm,

with flat cable moving inside the profile by means of cable sliders.

Number of poles: 4 (3 Ph/PE)

3 pole mains switch, (for surface mounting, lockable) included in the scope of delivery.

Not included in the scope of delivery:

- building's mains connection cable up to the mains switch and fitting of the connection

cable as well as the connecting line (riser) between mains switch and feed unit of the

mains power supply

- mounting of mains switch

Notes

The crane system complies with the requirements of the Machine Directive 2006/42/EG as

well as with the currently valid Accident Prevention Regulations DGUV rule 52 (in the past

UVV BGV D6).

A risk assessment has to be carried out by the operator if the action radii of several means

used to hoisting loads are overlapping on any given work station.

Verification of the structural analysis of a building

The customer must provide a verifiable structural analysis that establishes that the resulting

loads arising from the crane installation (including any additional steel structures which may

be required) can be supported by the structure of the ceiling or building. This structural

analysis must be available at the inspection before the system is initially put into operation.

Maximum suspension load at the suspension point: 14.3 kN

simultaneously occurring suspension load in the other track: 3.4 kN

Documentation

1 unit test book in printed form in German

including declaration of installation according to CE machinery directive 2006/42/EG

1 unit(s) of file or folder in German, consisting of:

- Product manual "Operating the ABUS Crane"

- Product manual "General product manual for ABUS Cranes"

- Wiring diagrams

- USB flash drive including product manuals/operating instructions,

spare parts list and wiring diagrams

Packing

disposable packing for transport (profiles in foil packing)

Delivery time: ready for dispatch in approx.

Conditions

price validity

28/12/2021

term of payment

30 days net

© ABUS Kransysteme GmbH, ABUKonfis Version 5.16w37

Kransysteme

quotation 001900-0000000-20210927-20 dated 27/09/2021 page 4 of 4

mode of dispatch

via forwarder

terms and conditions of sale

EXW Gummersbach/Marienheide, excl. VAT

Warranty

Warranty in accordance with our standard Conditions of Sale. In addition, we offer a special 5-year manufacturer's

warranty. You will find further details and conditions in the attached document.

attachments

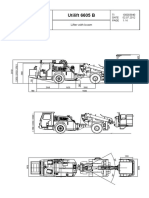

general drawing(s)

© ABUS Kransysteme GmbH, ABUKonfis Version 5.16w37

You might also like

- Cable Mounting Grips: With 1 Side Eyelet, Without ThimbleDocument1 pageCable Mounting Grips: With 1 Side Eyelet, Without Thimblemanojpathak24No ratings yet

- Geotextiles and Geomembranes HandbookFrom EverandGeotextiles and Geomembranes HandbookT.S. IngoldRating: 5 out of 5 stars5/5 (1)

- Baler HPK EN PDFDocument4 pagesBaler HPK EN PDFliu zhao liu zhaoNo ratings yet

- Brochure MONA BEKA HospitecDocument4 pagesBrochure MONA BEKA HospitecAPPLENo ratings yet

- Hydrostatic Vibratory Plates 365-712 Kilos AVH 5020 / 6020 / 7010Document6 pagesHydrostatic Vibratory Plates 365-712 Kilos AVH 5020 / 6020 / 7010Aurelian BogdanNo ratings yet

- mmc-Assetspdfslecturaammannaph5020AVH 5020 6020 7010 en (E94) PDFDocument6 pagesmmc-Assetspdfslecturaammannaph5020AVH 5020 6020 7010 en (E94) PDFMacNo ratings yet

- ABUS LPK Mobile GantryDocument2 pagesABUS LPK Mobile Gantrynxhoa222No ratings yet

- ProductDataSheet Rail-Lr16-45x90h28 0820 0EN 20221108Document1 pageProductDataSheet Rail-Lr16-45x90h28 0820 0EN 20221108EugenNo ratings yet

- Stein Grab k610Document1 pageStein Grab k610Edwin WaissNo ratings yet

- Abus LightweightDocument2 pagesAbus LightweightGloria RomicNo ratings yet

- Colunma ESAB - Cab600mDocument2 pagesColunma ESAB - Cab600mabelardo100% (1)

- Surfmet 1: Metallographic and Spectrographic Belt SurfacersDocument2 pagesSurfmet 1: Metallographic and Spectrographic Belt SurfacersArnold CoavasNo ratings yet

- Bruchora AMMANN AVH 6020Document6 pagesBruchora AMMANN AVH 6020augustoNo ratings yet

- Ace Crane Systems LLC: Description of System & Technical Data ABUS Wall Jib Crane, Model VWDocument2 pagesAce Crane Systems LLC: Description of System & Technical Data ABUS Wall Jib Crane, Model VWMichael WoodNo ratings yet

- Data Sheet US - A2E250AM0601 KM96928Document6 pagesData Sheet US - A2E250AM0601 KM96928Ariel GilNo ratings yet

- Sd02967den 0122-00Document12 pagesSd02967den 0122-00Alvaro Daniel Aguilar PerezNo ratings yet

- Be Flyer VinksonsDocument7 pagesBe Flyer VinksonsTushar GohelNo ratings yet

- Esab Cab 460MDocument2 pagesEsab Cab 460MSadashiva sahooNo ratings yet

- DMH Machine Catalogue 2023Document41 pagesDMH Machine Catalogue 2023Carlos DiezNo ratings yet

- Blanking Dimensions: Connection Diameter Nominal Weigth Wall Thickness API DriftDocument1 pageBlanking Dimensions: Connection Diameter Nominal Weigth Wall Thickness API DriftKapilNo ratings yet

- SOR NS 12 Electric: City, Intercity TouristDocument2 pagesSOR NS 12 Electric: City, Intercity TouristFWEFWEFWNo ratings yet

- Bfou I 150 250v Cable - 1Document3 pagesBfou I 150 250v Cable - 1Santosh KumarNo ratings yet

- Modular Structure Precise Servo Technology Substantial Positioning Freedom Space Saving ConstructionDocument2 pagesModular Structure Precise Servo Technology Substantial Positioning Freedom Space Saving ConstructionIulia CostacheNo ratings yet

- Product Flyer - PRS 500 C - V4.0 - 2021-07-09Document6 pagesProduct Flyer - PRS 500 C - V4.0 - 2021-07-09bassem besbesNo ratings yet

- Wabeco D2000 D24000 D3000 LatheDocument184 pagesWabeco D2000 D24000 D3000 LatheTAREQ_BELALNo ratings yet

- Esab Cab 300SDocument2 pagesEsab Cab 300SSadashiva sahooNo ratings yet

- Haven Brochure 12Document1 pageHaven Brochure 12Aurelian BogdanNo ratings yet

- Haven Brochure 12 PDFDocument1 pageHaven Brochure 12 PDFAurelian BogdanNo ratings yet

- Sieve Shaker EFL 300: General InformationDocument2 pagesSieve Shaker EFL 300: General InformationSupriyo PNo ratings yet

- Data - Sheet - FP1 - 2102-100 - Active - Digital - 1060 (Refurb or Newer)Document2 pagesData - Sheet - FP1 - 2102-100 - Active - Digital - 1060 (Refurb or Newer)Basil HwangNo ratings yet

- ESAB Fabricator EM500i - Complete SetDocument7 pagesESAB Fabricator EM500i - Complete SetElwyn Rahmat HidayatNo ratings yet

- Woehner PortafusiblesDocument5 pagesWoehner PortafusiblesmerdaNo ratings yet

- Knauf ENBS Ceiling Manual PDFDocument16 pagesKnauf ENBS Ceiling Manual PDFMohammad UmmerNo ratings yet

- 3NH5463 Datasheet enDocument5 pages3NH5463 Datasheet ensuadNo ratings yet

- Utilift 6605 B: Lifter With BoomDocument4 pagesUtilift 6605 B: Lifter With BoomDiego GonzalesNo ratings yet

- Dent Master QuotationDocument5 pagesDent Master QuotationImrooz KhanNo ratings yet

- Auger Compactor - ENDocument4 pagesAuger Compactor - ENEugene Jin LeowNo ratings yet

- TDS - J Tow737 CDocument1 pageTDS - J Tow737 CAhmad Yani S Noor100% (1)

- Modular Structure Precise Servo Technology Substantial Positioning Freedom Space Saving ConstructionDocument2 pagesModular Structure Precise Servo Technology Substantial Positioning Freedom Space Saving ConstructionIulia CostacheNo ratings yet

- DBXLH 9090B VTMDocument5 pagesDBXLH 9090B VTMvaldemarfgNo ratings yet

- Twinmaster 16 III EDocument2 pagesTwinmaster 16 III ECristian HenaoNo ratings yet

- PW BRO TPSi Intelligent Revolution enDocument4 pagesPW BRO TPSi Intelligent Revolution enKAVINNo ratings yet

- Hs Hi-R Neo 900A: 26.04.2021 Page 1/10Document10 pagesHs Hi-R Neo 900A: 26.04.2021 Page 1/10BOZIDAR VASAREVICNo ratings yet

- BDS Vam+top+® 0 4.500 23.70Document1 pageBDS Vam+top+® 0 4.500 23.70Quality controllerNo ratings yet

- Technical Specification: Positive LiftsDocument8 pagesTechnical Specification: Positive LiftsKrishan singhNo ratings yet

- Polimobil PlusDocument8 pagesPolimobil Plusrossi100% (1)

- WELDSTAR FRONIUS DeltaSpot C300Document2 pagesWELDSTAR FRONIUS DeltaSpot C300vinodtiwari808754No ratings yet

- Material SXK10920161Document2 pagesMaterial SXK10920161antonio.moreno.ofgNo ratings yet

- Helix Engineers Brochure - PDF (1) - 1Document9 pagesHelix Engineers Brochure - PDF (1) - 1kunjansutharNo ratings yet

- Autopsy RoomDocument61 pagesAutopsy RoomEdgar OrtizNo ratings yet

- ProductSheet AUDAC ASP20 06 11 2023 23 00Document3 pagesProductSheet AUDAC ASP20 06 11 2023 23 00Juan Camilo NunezNo ratings yet

- PantografeDocument12 pagesPantografeAlex GeorgeNo ratings yet

- DWG Cable Trench - 850x800 PDFDocument1 pageDWG Cable Trench - 850x800 PDFAnshuman Pandey100% (1)

- DWG Cable Trench - 850x800Document1 pageDWG Cable Trench - 850x800Anshuman PandeyNo ratings yet

- En Bmp-265e PDFDocument1 pageEn Bmp-265e PDFBadea AlexandruNo ratings yet

- Product Specifications: HBXX-9014DS-VTMDocument3 pagesProduct Specifications: HBXX-9014DS-VTMАнтонNo ratings yet

- Galvanizing Cranes PDFDocument1 pageGalvanizing Cranes PDFArshath FleminNo ratings yet

- Technical Description: 1 Demag Wall Mounted Slewing Jib Crane 1000 KG X 4000 MM JC-W-270-KBK-BR-M-1000-4000Document3 pagesTechnical Description: 1 Demag Wall Mounted Slewing Jib Crane 1000 KG X 4000 MM JC-W-270-KBK-BR-M-1000-4000nasif andriantoNo ratings yet

- MB8 Automatic Sheet Metal Press Brake Bending Machine With DA56S SystemDocument8 pagesMB8 Automatic Sheet Metal Press Brake Bending Machine With DA56S SystemryneleeNo ratings yet

- How To Calibrate Weighing.9508943.powerpointDocument3 pagesHow To Calibrate Weighing.9508943.powerpointAhmad shayebNo ratings yet

- ORA-LAB - QM ORA Laboratory Manual of Quality Policies (v03)Document47 pagesORA-LAB - QM ORA Laboratory Manual of Quality Policies (v03)Ahmad shayebNo ratings yet

- LAB 5 Reporting Calibration ResultsDocument10 pagesLAB 5 Reporting Calibration ResultsAhmad shayebNo ratings yet

- Sadcas TR 14 - Sadcas Policy - Iso Iec 17025-2017 TransitionDocument10 pagesSadcas TR 14 - Sadcas Policy - Iso Iec 17025-2017 TransitionAhmad shayebNo ratings yet

- Check List 2017Document7 pagesCheck List 2017Ahmad shayebNo ratings yet

- Cisco-Voice-simple Lab Voice 2 Ip PhonesDocument10 pagesCisco-Voice-simple Lab Voice 2 Ip PhonesSalvador GillespieNo ratings yet

- B700 Error CodesDocument3 pagesB700 Error Codescastlelvania23No ratings yet

- Mapeo Traktor HerculesDocument10 pagesMapeo Traktor HerculesPepperonipizza Cuerpoh EhpardahNo ratings yet

- Lexmark™ X6100 Series All-In-One 4408-XXXDocument66 pagesLexmark™ X6100 Series All-In-One 4408-XXXSalsa AdrianNo ratings yet

- Implementation Cryptography: RNS-Enhanced Microprocessor Public KeyDocument5 pagesImplementation Cryptography: RNS-Enhanced Microprocessor Public KeyMario GlezPNo ratings yet

- Vizio Vht210 User ManualDocument22 pagesVizio Vht210 User ManualAlbert LugoNo ratings yet

- Novus Daq (Eng)Document6 pagesNovus Daq (Eng)projgoNo ratings yet

- Ricardo Sierra ResumeDocument2 pagesRicardo Sierra ResumersierraidtNo ratings yet

- 0603 TechnisatDocument2 pages0603 TechnisatAlexander WieseNo ratings yet

- How To Install A Dedicated PhysX CardDocument23 pagesHow To Install A Dedicated PhysX CardRomán Hernández LóyzagaNo ratings yet

- Func StatsDocument14 pagesFunc StatsSkija Se StieNo ratings yet

- 1.2 Worksheet 1Document5 pages1.2 Worksheet 1Lin Latt Wai AlexaNo ratings yet

- By Ramya R (R & M)Document21 pagesBy Ramya R (R & M)Ramya RNo ratings yet

- Pic Attack1Document13 pagesPic Attack1celiaescaNo ratings yet

- Arria 10 AlteraDocument109 pagesArria 10 AlteraamoscorcinoNo ratings yet

- Access Control Lists (Acls) : Case StudyDocument20 pagesAccess Control Lists (Acls) : Case Studykevin142No ratings yet

- Chapter 1 Basic Distributed System ConceptsDocument45 pagesChapter 1 Basic Distributed System ConceptsMAFIA0% (1)

- Chameleon - A5.1 Deciphering UnitDocument1 pageChameleon - A5.1 Deciphering UnitathenaartemisNo ratings yet

- ProfileDocument9 pagesProfileNdanga Tirivepi IsaacNo ratings yet

- CFC Horse Ration GuideDocument32 pagesCFC Horse Ration Guidemarcelo leandro faria0% (1)

- Deped Computerization ProgramDocument138 pagesDeped Computerization ProgramJaeson MacarulayNo ratings yet

- 7 SCM Planning-ERP - 2019 - DISTDocument60 pages7 SCM Planning-ERP - 2019 - DISTJoe RobsonNo ratings yet

- 611520-Y-BC-D Rev 009 - B+V Manual CL 150-1000Document56 pages611520-Y-BC-D Rev 009 - B+V Manual CL 150-1000Imed Hammouda100% (2)

- Kelly H PM User ManualDocument20 pagesKelly H PM User ManualmanmonbhaNo ratings yet

- Schwinn Adult Tricycle - Owners ManualDocument106 pagesSchwinn Adult Tricycle - Owners ManualJack OffgridNo ratings yet

- K3VL Parts List Updated 8-19-09 PDFDocument17 pagesK3VL Parts List Updated 8-19-09 PDFrjan7pe100% (1)

- COA Lab ManualDocument41 pagesCOA Lab ManualRakoon Dog100% (3)

- Cloudera Introduction PDFDocument97 pagesCloudera Introduction PDFSanthosh KumarNo ratings yet

- Monitor m9000 12p EngDocument2 pagesMonitor m9000 12p Engrajawali persada indonesiaNo ratings yet

- Concurrency Control in DataBaseDocument11 pagesConcurrency Control in DataBaseMuhammad Ibrahim Khan100% (1)

- A Place of My Own: The Architecture of DaydreamsFrom EverandA Place of My Own: The Architecture of DaydreamsRating: 4 out of 5 stars4/5 (242)

- Post Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&AFrom EverandPost Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&ANo ratings yet

- The Aqua Group Guide to Procurement, Tendering and Contract AdministrationFrom EverandThe Aqua Group Guide to Procurement, Tendering and Contract AdministrationMark HackettRating: 4 out of 5 stars4/5 (1)

- Real Life: Construction Management Guide from A-ZFrom EverandReal Life: Construction Management Guide from A-ZRating: 4.5 out of 5 stars4.5/5 (4)

- Civil Engineer's Handbook of Professional PracticeFrom EverandCivil Engineer's Handbook of Professional PracticeRating: 4.5 out of 5 stars4.5/5 (2)

- Essential Building Science: Understanding Energy and Moisture in High Performance House DesignFrom EverandEssential Building Science: Understanding Energy and Moisture in High Performance House DesignRating: 5 out of 5 stars5/5 (1)

- 1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideFrom Everand1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideRating: 3.5 out of 5 stars3.5/5 (7)

- Pressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedFrom EverandPressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedRating: 5 out of 5 stars5/5 (1)

- BIM and Construction Management: Proven Tools, Methods, and WorkflowsFrom EverandBIM and Construction Management: Proven Tools, Methods, and WorkflowsNo ratings yet

- The Complete Guide to Alternative Home Building Materials & Methods: Including Sod, Compressed Earth, Plaster, Straw, Beer Cans, Bottles, Cordwood, and Many Other Low Cost MaterialsFrom EverandThe Complete Guide to Alternative Home Building Materials & Methods: Including Sod, Compressed Earth, Plaster, Straw, Beer Cans, Bottles, Cordwood, and Many Other Low Cost MaterialsRating: 4.5 out of 5 stars4.5/5 (6)

- The Complete Guide to Building With Rocks & Stone: Stonework Projects and Techniques Explained SimplyFrom EverandThe Complete Guide to Building With Rocks & Stone: Stonework Projects and Techniques Explained SimplyRating: 4 out of 5 stars4/5 (1)

- Sustainable Design and Build: Building, Energy, Roads, Bridges, Water and Sewer SystemsFrom EverandSustainable Design and Build: Building, Energy, Roads, Bridges, Water and Sewer SystemsNo ratings yet

- Estimating Construction Profitably: Developing a System for Residential EstimatingFrom EverandEstimating Construction Profitably: Developing a System for Residential EstimatingNo ratings yet

- Even More Schedule for Sale: Advanced Work Packaging, for Construction ProjectsFrom EverandEven More Schedule for Sale: Advanced Work Packaging, for Construction ProjectsNo ratings yet

- The Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialFrom EverandThe Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialNo ratings yet

- Piping Engineering Leadership for Process Plant ProjectsFrom EverandPiping Engineering Leadership for Process Plant ProjectsRating: 5 out of 5 stars5/5 (1)

- The Homeowner's DIY Guide to Electrical WiringFrom EverandThe Homeowner's DIY Guide to Electrical WiringRating: 5 out of 5 stars5/5 (2)

- How to Estimate with RSMeans Data: Basic Skills for Building ConstructionFrom EverandHow to Estimate with RSMeans Data: Basic Skills for Building ConstructionRating: 4.5 out of 5 stars4.5/5 (2)

- Starting Your Career as a Contractor: How to Build and Run a Construction BusinessFrom EverandStarting Your Career as a Contractor: How to Build and Run a Construction BusinessRating: 5 out of 5 stars5/5 (3)

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsFrom EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsRating: 3.5 out of 5 stars3.5/5 (3)

- Fire Protection Engineering in Building DesignFrom EverandFire Protection Engineering in Building DesignRating: 4.5 out of 5 stars4.5/5 (5)

- History of Smart Textiles: A Comprehensive Guide To E-TextilesFrom EverandHistory of Smart Textiles: A Comprehensive Guide To E-TextilesNo ratings yet

- EMOTIONAL EATING: How To Stop Emotional Eating Naturally And Live A Better LifeFrom EverandEMOTIONAL EATING: How To Stop Emotional Eating Naturally And Live A Better LifeRating: 4 out of 5 stars4/5 (14)

- Principles of Welding: Processes, Physics, Chemistry, and MetallurgyFrom EverandPrinciples of Welding: Processes, Physics, Chemistry, and MetallurgyRating: 4 out of 5 stars4/5 (1)

- Building Construction Technology: A Useful Guide - Part 1From EverandBuilding Construction Technology: A Useful Guide - Part 1Rating: 4 out of 5 stars4/5 (3)