Professional Documents

Culture Documents

8BVI0055HWD0.000-1: 1 General Information

Uploaded by

Andrey KapustaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

8BVI0055HWD0.000-1: 1 General Information

Uploaded by

Andrey KapustaCopyright:

Available Formats

8BVI0055HWD0.

000-1

8BVI0055HWD0.000-1

1 General information

• Uncontrolled and safe stops integrated

• Integrated connection for motor holding brake and temperature sensor

• 2 slots for ACOPOSmulti plug-in modules

• 2-axis modules contain two complete standalone inverters in one inverter module

2 Order data

Model number Short description Figure

Wall mounting

8BVI0055HWD0.000-1 ACOPOSmulti inverter module 7.6 A, HV, wall mounting, 2 axes

Required accessories

Terminal block sets

8BZVI0055D0.000-1A Screw clamp set for ACOPOSmulti 8BVI00xxHxD0 modules: 1x

8TB2112.2010-00, 1x 8TB2108.2010-00, 1x 8TB2104.203L-00,

1x 8TB2104.203F-00, 1x 8TB3104.204G-11, 1x

8TB3104.204K-11

8BZVI0055D0.500-1A 50x Screw clamp terminal block set for ACOPOS-

multi modules 8BVI00xxHxD0: 1x 8TB2112.2010-00, 1x

8TB2108.2010-00, 1x 8TB2104.203L-00, 1x 8TB2104.203F-00,

1x 8TB3104.204G-11, 1x 8TB3104.204K-11

8BZVI0055D0.A00-1A 100x Screw clamp terminal block set for ACOPOS-

multi modules 8BVI00xxHxD0: 1x 8TB2112.2010-00, 1x

8TB2108.2010-00, 1x 8TB2104.203L-00, 1x 8TB2104.203F-00,

1x 8TB3104.204G-11, 1x 8TB3104.204K-11

Optional accessories

Accessory sets

8BXB000.0000-00 ACPmulti accessory set for encoder buffering consisting of: 1

lithium battery AA 3.6 V; 1 protective cap for battery holder

Fan modules

8BXF001.0000-00 ACOPOSmulti fan module, replacement fan for ACOPOSmulti

modules (8BxP / 8B0C / 8BVI / 8BVE / 8B0K)

Plug-in modules

8BAC0120.000-1 ACOPOSmulti plug-in module, EnDat 2.1 interface

8BAC0120.001-2 ACOPOSmulti plug-in module, EnDat 2.2 interface

8BAC0121.000-1 ACOPOSmulti plug-in module, HIPERFACE interface

8BAC0122.000-1 ACOPOSmulti plug-in module, resolver interface 10 kHz

8BAC0123.000-1 ACOPOSmulti plug-in module, incremental encoder and SSI ab-

solute encoder interface for RS422 signals

8BAC0123.001-1 ACOPOSmulti plug-in module, incremental encoder interface for

5 V single-ended and 5 V differential signals

8BAC0123.002-1 ACOPOSmulti plug-in module, incremental encoder interface for

24 V single-ended and 24 V differential signals

8BAC0124.000-1 ACOPOSmulti plug-in module, SinCos interface

8BAC0125.000-1 ACOPOSmulti plug-in module, SinCos EnDat 2.1/SSI interface

8BAC0130.000-1 ACOPOSmulti plug-in module, 2 digital outputs, 50 mA, max.

62.5 kHz, 2 digital outputs, 500 mA, max. 1.25 kHz, 2 digital

inputs 24 VDC

8BAC0130.001-1 ACOPOSmulti plug-in module, 2 digital outputs, 50 mA, max.

62.5 kHz, 4 digital outputs, 500 mA, max. 1.25 kHz

8BAC0132.000-1 ACOPOSmulti plug-in module, 4 analog inputs ±10 V

8BAC0133.000-1 ACOPOSmulti plug-in module, 3 RS422 outputs for ABR en-

coder emulation, 1 Mhz

POWERLINK cable

X20CA0E61.00020 POWERLINK connection cable, RJ45 to RJ45, 0.2 m

X20CA0E61.00025 POWERLINK connection cable, RJ45 to RJ45, 025 m

X20CA0E61.00030 POWERLINK connection cable, RJ45 to RJ45, 03 m

X20CA0E61.00035 POWERLINK connection cable, RJ45 to RJ45, 035 m

X20CA0E61.00050 POWERLINK connection cable, RJ45 to RJ45, 0.5 m

X20CA0E61.00100 POWERLINK connection cable, RJ45 to RJ45, 1 m

Shield component sets

8SCS000.0000-00 ACOPOSmulti shield component set: 1 shield plate 1x type 0, 1

hose clamp, B 9 mm, D 12-22 mm

8SCS002.0000-00 ACOPOSmulti shield component set: 1x clamping plate; 2x

clamps D 4-13.5 mm; 4x screws

Table 1: 8BVI0055HWD0.000-1 - Order data

Data sheet V 1.3 1

8BVI0055HWD0.000-1

Model number Short description Figure

8SCS005.0000-00 ACOPOSmulti shield component set: 1x slot cover/shield plate

8SCS009.0000-00 ACOPOSmulti shield component set: 1x ACOPOSmulti holding

plate SK8-14; 1x shield terminal SK14

Terminal blocks

8TB2104.203F-00 4-pin screw clamp, single row, spacing: 5.08 mm, label 3: T- T

+ B- B+, F keying: 0101

8TB2104.203L-00 4-pin screw clamp, single row, spacing: 5.08 mm, label 3: T- T

+ B- B+, L keying: 1010

8TB2108.2010-00 8-pin screw clamp, single row, spacing: 5.08 mm, label 1: num-

bered serially

8TB2112.2010-00 12-pin screw clamp, single row, spacing: 5.08 mm, label 1: num-

bered serially

8TB3104.204G-11 4-pin screw clamp, single row, spacing: 7.62 mm, label 4: PE W

V U, G keying: 0110

8TB3104.204K-11 4-pin screw clamp, single row, spacing: 7.62 mm, label 4: PE W

V U, K keying: 1001

Undefined

8SCSE01.0100-00 ACOPOS P3 Schirmkomponentenset: 1x Schirmblech 4fach

Typ 1; 1x Schlauchschelle, B 9 mm, D 12-22 mm

8SCSE02.0100-00 ACOPOS P3 Schirmkomponentenset: 1x Klemmbügelblech; 2x

Klemmbügel D 4-13,5 mm; 2x Schrauben

8SCSE02.0200-00 ACOPOS P3 Schirmkomponentenset: 1x Klemmbügelblech; 2x

Klemmbügel D 4-13,5 mm; 2x Schrauben

Table 1: 8BVI0055HWD0.000-1 - Order data

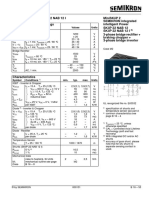

3 Technical data

Model number 8BVI0055HWD0.000-1

General information

B&R ID code 0x20B5

Cooling and mounting method Wall mounting

Slots for plug-in modules 2

Certification

CE Yes

KC Yes

UL cULus E225616

Power Conversion Equipment

Functional Safety1) Yes

DC bus connection

Voltage

Nominal 750 VDC

Continuous power consumption 2) 11.19 kW

Power loss depending on switching frequency 3)

Switching frequency 5 kHz [1.2 * IM² + 2.62 * IM + 100] W

Switching frequency 10 kHz [2.56 * IM² + 2.8 * IM + 200] W

Switching frequency 20 kHz [6 * IM² - 9.4 * IM + 430] W

DC bus capacitance 330 µF

Design ACOPOSmulti backplane

24 VDC supply

Input voltage 25 VDC ±1.6%

Input capacitance 23.5 µF

Max. power consumption 16 W + PSLOT1 + PSLOT2 + P24 V Out + PHoldingBrake(s)4)

Design ACOPOSmulti backplane

24 VDC output

Quantity 2

Output voltage

DC bus voltage (UDC): 260 to 315 VDC 25 VDC * (UDC/ 315)

DC bus voltage (UDC): 315 to 800 VDC 24 VDC ±6%

Protection 250 mA (slow-blow) electronic, automatic reset

Motor connection

Quantity 2

Continuous power per motor connection 2) 5.5 kW

Continuous current per motor connection 2) 7.6 Aeff

Reduction of continuous current depending on

switching frequency 5)

Switching frequency 5 kHz No reduction 6)

Switching frequency 10 kHz 0.22 A/K (from 43°C)

Switching frequency 20 kHz 0.15 A/K (from -14°C) 7)

Reduction of continuous current depending on the

installation elevation

Starting at 500 m above sea level 0.76 Aeff per 1000 m

Peak current per motor connection 18.9 Aeff

Table 2: 8BVI0055HWD0.000-1 - Technical data

2 Data sheet V 1.3

8BVI0055HWD0.000-1

Model number 8BVI0055HWD0.000-1

Nominal switching frequency 5 kHz

Possible switching frequencies 8) 5 / 10 / 20 kHz

Electrical stress of the connected motor in accor- Limit value curve A

dance with IEC TS 60034-25 9)

Protective measures

Overload protection Yes

Short circuit and ground fault protection Yes

Max. output frequency 598 Hz 10)

Design

U, V, W, PE Male connector

Shield connection Yes

Terminal connection cross section

Flexible and fine wire lines

With wire end sleeves 0.25 to 6 mm²

Approbation data

UL/C-UL-US 30 to 10

CSA 28 to 10

Terminal cable cross section dimension of shield 12 to 22 mm

connection

Max. motor line length depending on switching fre-

quency

Switching frequency 5 kHz 25 m

Switching frequency 10 kHz 25 m

Switching frequency 20 kHz 10 m

Motor holding brake connection

Quantity 2

Output voltage 11) 24 VDC +5.8% / -0% 12)

Continuous current 1.1 A

Max. internal resistance 0.5 Ω

Extinction potential Approx. 30 V

Max. extinction energy per switching operation 1.5 Ws

Max. switching frequency 0.5 Hz

Protective measures

Overload and short circuit protection Yes

Open circuit monitoring Yes

Undervoltage monitoring Yes

Response threshold for open circuit monitoring Approx. 0.25 A

Response threshold for undervoltage monitoring 24 VDC +0% / -4%

Enable inputs

Quantity 4 (2 per axis)

Wiring Sink

Electrical isolation

Input - Inverter module Yes

Input - Input Yes

Input voltage

Nominal 24 VDC

Maximum 30 VDC

Input current at nominal voltage Approx. 30 mA

Switching threshold

Low <5 V

High >15 V

Switching delay at nominal input voltage

Enable 1 -> 0, PWM off Max. 20.5 ms

Enable 0 -> 1, ready for PWM Max. 100 µs

Modulation compared to ground potential Max. ±38 V

OSSD signal connections 13) permitted

Max. test pulse length: 500 µs

Trigger inputs

Quantity 2

Wiring Sink

Electrical isolation

Input - Inverter module Yes

Input - Input Yes

Input voltage

Nominal 24 VDC

Maximum 30 VDC

Switching threshold

Low <5 V

High >15 V

Input current at nominal voltage Approx. 10 mA

Switching delay

Rising edge 52 µs ±0.5 µs (digitally filtered)

Falling edge 53 µs ±0.5 µs (digitally filtered)

Table 2: 8BVI0055HWD0.000-1 - Technical data

Data sheet V 1.3 3

8BVI0055HWD0.000-1

Model number 8BVI0055HWD0.000-1

Modulation compared to ground potential Max. ±38 V

Electrical characteristics

Discharge capacitance 0.2 µF

Operating conditions

Permitted mounting orientations

Hanging vertically Yes

Lying horizontally Yes

Standing horizontally No

Installation at elevations above sea level

Nominal 0 to 500 m

Maximum 14) 4000 m

Degree of pollution in accordance with EN 2 (non-conductive pollution)

61800-5-1

Overvoltage category in accordance with EN III

61800-5-1

EN 60529 protection IP20

Environmental conditions

Temperature

Operation

Nominal 5 to 40°C

Maximum 15) 55°C

Storage -25 to 55°C

Transport -25 to 70°C

Relative humidity

Operation 5 to 85%

Storage 5 to 95%

Transport Max. 95% at 40°C

Mechanical characteristics

Dimensions 16)

Width 53 mm

Height 317 mm

Depth

Wall mounting 263 mm

Weight Approx. 2.9 kg

Module width 1

Table 2: 8BVI0055HWD0.000-1 - Technical data

1) Achievable safety classifications (safety integrity level, safety category, performance level) are documented in the user's manual (section "Safety technology").

2) Valid in the following conditions: 750 VDC DC bus voltage, 5 kHz switching frequency, 40°C ambient temperature, installation elevation <500 m above sea

level, no derating due to cooling type.

3) IM = 0.5 * (IX5A + IX5B)

IX5A ... Current on X5A motor connection [AEff]

IX5B ... Current on X5B motor connection [AEff]

4) PSLOT1 ... Max. power consumption P8BAC [W] of the plug-in module in SLOT1 (see the technical data for the respective plug-in module).

PSLOT2 ... Max. power consumption P8BAC [W] of the plug-in module in SLOT2 (see the technical data for the respective plug-in module).

P24 V Out... Power [W] that is output to the connections X2/+24 V Out 1 and X2/+24 V Out 2 on the module (max. 10 W).

5) Valid in the following conditions: 750 VDC DC bus voltage. The temperature specifications refer to the ambient temperature.

6) Value for the nominal switching frequency.

7) The module cannot supply the full continuous current at this switching frequency. This unusual value for the ambient temperature, at which derating of the

continuous current must be taken into account, ensures that the derating of the continuous current can be determined in the same manner as at other

switching frequencies.

8) B&R recommends operating the module at its nominal switching frequency. Operating the module at a higher switching frequency for application-specific

reasons reduces the continuous current and increases the CPU load. When using 2-axis modules, the increased CPU load reduces the functionality of the

drive; if this is not taken into consideration, the computing time can be exceeded in extreme cases.

9) If necessary, the stress of the motor isolation system can be reduced by an additional externally wired dv/dt choke. For example, the RWK 305 three-phase

du/dt choke from Schaffner (www.schaffner.com) can be used. Important: Even when using a dv/dt choke, it is necessary to ensure that an EMC-compatible,

low inductance shield connection is used!

10) The module's electrical output frequency (SCTRL_SPEED_ACT * MOTOR_POLEPAIRS) is monitored to protect against dual use in accordance with EC

regulation 428/2009 | 3A225. If the electrical output frequency of the module exceeds the limit value of 598 Hz uninterrupted for more than 0.5 s, then the

current movement is aborted and error 6060 is output (Power element: Limit speed exceeded).

11) During project development, it is necessary to check if the minimum voltage can be maintained on the holding brake with the specified wiring. The operating

voltage range of the holding brake can be found in the user's manual for the respective motor.

12) The specified value is only valid under the following conditions:

- The 24 VDC supply for the module is provided by an 8B0C auxiliary supply module installed on the same mounting plate.

- Connection between S1 and S2 (activation of the external holding brake) using a jumper with a max. length of 10 cm.

If the 24 VDC supply for the module is applied to the mounting plate using an 8BVE expansion module, then the output voltage is reduced because of voltage

drops on the expansion cable. In this case, undervoltage monitoring must be disabled.

If jumpers longer than 10 cm are used to connect S1 and S2, then the output voltage is reduced because of voltage drops on the jumpers.

13) OSSD (open signal switching device) signals are used to monitor signal lines for short circuits and cross faults.

14) Continuous operation at elevations ranging from 500 m to 4000 m above sea level is possible (taking the specified continuous current reductions into

consideration). Requirements that go above and beyond this must be arranged with B&R.

15) Continuous operation at ambient temperatures ranging from 40°C to max. 55°C is possible (taking the specified continuous current reductions into consid-

eration), but this will result in a shorter service life.

16) These dimensions refer to the actual device dimensions including the respective mounting plate. Make sure to leave additional space above and below the

devices for mounting, connections and air circulation.

4 Data sheet V 1.3

8BVI0055HWD0.000-1

4 Status indicators

Status indicators are located on the black cover of each module.

Encoder SLOT1 Encoder SLOT2

Status of backup battery

Power supply POWERLINK

Inverter axis 1 Inverter axis 2

Figure 1: Indicator groups for 8BVI inverter modules (2-axis modules)

LED status indicators

Status indicator group Label Color Function Description

POWERLINK R/E Green/Red Ready/Error see "POWERLINK - LED status indicators" on page 6

L/D1 Green Link/Data activity on port 1

L/D2 Green Link/Data activity on port 2

Inverter axis 1 RDY Green Ready see "RDY, RUN, ERR (8BVI, 8BVP, 8B0P) - LED status indica-

RUN Orange Run tors" on page 6

ERR Red Error

Inverter axis 2 RDY Green Ready See inverter axis 1

RUN Orange Run

ERR Red Error

Status of backup battery BAT Green/Red Ready/Error see "Backup battery - LED status indicators" on page 6

Power supply 24 V Green 24 V OK The 24 V module supply voltage is within the tolerance range.

Encoder SLOT1 UP Orange Encoder direction of rotation + Indicates that the position of the connected encoder is chang-

ing in the positive direction. The faster the encoder position

changes, the brighter the LED is lit.

DN Orange Encoder direction of rotation - Indicates that the position of the connected encoder is chang-

ing in the negative direction. The faster the encoder position

changes, the brighter the LED is lit.

Encoder SLOT2 UP Orange Encoder direction of rotation + see Encoder SLOT1

DN Orange Encoder direction of rotation -

Table 3: LED status indicators - 8BVI inverter modules (2-axis modules)

Data sheet V 1.3 5

8BVI0055HWD0.000-1

4.1 RDY, RUN, ERR (8BVI, 8BVP, 8B0P) - LED status indicators

Label Color Function Description

RDY Green Ready Solid green The module is operational and the power stage can be enabled (operating sys-

tem present and booted, no permanent or temporary errors).

Blinking green 1) The module is not ready for operation.

Examples:

• No signal on one or both enable inputs

• DC bus voltage outside the tolerance range

• Overtemperature on the motor (temperature sensor)

• Motor feedback not connected or defective

• Motor temperature sensor not connected or defective

• Overtemperature on the module (IGBT junction, heat sink, etc.)

• Disturbance on network

RUN Orange Run Solid orange The module's power stage is enabled.

ERR Red Error Solid red 1) There is a permanent error on the module.

Examples:

• Permanent overcurrent

• Invalid data in EPROM

Blinking red • LED status "Status changes when booting the operating system loader"

on page 7

Table 4: RDY, RUN, ERR (8BVI, 8BVP, 8B0P) - LED status indicators

1) Firmware V2.130 and later.

Firmware V2.130 and later.

4.2 POWERLINK - LED status indicators

Label Color Function Description

R/E Green/Red Ready/Error LED off The module is not receiving power or initialization of the network interface has

failed.

Solid red The POWERLINK node number of the module is 0.

Blinking red/green The client is in an error state (drops out of cyclic operation).

Blinking green The client detects a valid POWERLINK frame on the network.

(1x)

Blinking green Cyclic operation on the network is taking place, but the client itself is not yet a

(2x) participant.

Blinking green Cyclic operation of the client is in preparation.

(3x)

Solid green The client is participating in cyclic operation.

Flickering green The client is not participating in cyclic operation and also does not detect any

other stations on the network participating in cyclic operation.

L/D1 Green Link/Data activity Solid green A physical connection has been established to another station on the network.

Port 1 Blinking green Activity on port 1

L/D2 Green Link/Data activity Solid green A physical connection has been established to another station on the network.

Port 2 Blinking green Activity on port 2

Table 5: POWERLINK - LED status indicators

4.3 Backup battery - LED status indicators

Label Color Function Description

BAT Green/Red Ready/Error LED off Possible causes:

• The voltage of the installed backup battery is within the tolerance range,

but an EnDat encoder with backup battery is not connected.

• An EnDat encoder with backup battery is connected and registering "Bat-

tery OK", but the module's firmware version does not support EnDat en-

coders with battery backup.

Solid green An EnDat encoder with battery backup is connected and registering "Battery

OK" (voltage of the installed backup battery is within the tolerance range).

Solid red An EnDat encoder with battery backup is connected and registering "Battery not

OK".

Possible causes:

• Voltage of the installed backup battery outside of tolerance range

• No backup battery installed in module

Table 6: Backup battery - LED status indicators

6 Data sheet V 1.3

8BVI0055HWD0.000-1

4.4 Status changes when booting the operating system loader

The following timing is used for the LED status indicators:

Block size: 50 ms

Repeats after: 3,000 ms

Status LED Indicator

1. Boot procedure for base hardware RDY

active RUN

ERR

2. Network configuration active RDY

RUN

ERR

3. Waiting for network telegram RDY

RUN

ERR

4. Network communication active RDY

RUN

ERR

5. ACOPOS operating system being RDY

transferred/burned 1) RUN

ERR

Table 7: Status changes when booting the operating system loader

1) Firmware V2.140 and higher.

Data sheet V 1.3 7

8BVI0055HWD0.000-1

5 Dimension diagram and installation dimensions

Permitted

mounting orientations

3)

2)

1)

Hanging vertically

Lying horizontally

Impermissible

mounting orientations

Standing horizontally

2)

2)

Hanging horizontally

Figure 2: Dimension diagram and installation dimensions

1) n... Number of slots on the mounting plate

2) For proper air circulation, at least 60 mm clearance must be available above the mounting plate as well as below the module.

To ensure that the fan modules in the mounting plate can be replaced easily, at least 250 mm clearance must be available below the module.

3) nnnn indicates the number of slots (e.g. 0160 refers to 16 slots).

8 Data sheet V 1.3

8BVI0055HWD0.000-1

6 Wiring

6.1 Pinout overview - Two-axis modules (single-width)

+24 V

0V

POWERLINK

POWERLINK

8 7 6 5 4 3 2 1 12 11 10 9 8 7 6 5 4 3 2 1

Slot1

Slot2

Enable 1

Trigger1

+24V Out 1

Enable 1

Enable 2

Enable 2

Trigger2

S1/B+

S1/B+

+24V Out 2

COM (3)

COM (8)

COM (5)

COM (4)

COM (1)

S2/B-

COM (7)

S2/B-

COM (1)

COM (9)

X3A X3B

X1

X2

X1 X2 1

X2

X1 1

1 X3B

X3A

Slot1 Slot2

X5A X5B

X5A X5B

X4A X4B

12...EnDat 12...EnDat

X4A X5A 6...Resolver X4B X5B 6...Resolver

PE

PE

ACOPOSmulti

B+/S1

B+/S1

B-/S2

B-/S2

W

W

T+

T+

U

U

V

V

T-

T-

8BVI0014HxD0.000-1

8BVI0028HxD0.000-1

4 3 2 1 4 3 2 1

8BVI0055HxD0.000-1

4

4

3

3

2

2

1

M M

T 3 T T 3 T

Figure 3: Pinout overview - 8BVI0014HxD0.000-1, 8BVI0028HxD0.000-1, 8BVI0055HxD0.000-1

Data sheet V 1.3 9

8BVI0055HWD0.000-1

6.1.1 X1 connector - Pinout

X1 Pin Name Function

1 Enable 1 1) Axis 2: Enable 1

2 COM (1) Axis 2: Enable 1 0 V

1 3 Enable 2 1) Axis 2: Enable 2

2 4 COM (3) Axis 2: Enable 2 0 V

5 S1/B+ 2) Axis 2: Brake + / Activation of the external holding brake

3

6 S2/B- 2) Axis 2: Brake - / Activation of the external holding brake

4

7 Enable 1 1) Axis 1: Enable 1

5 8 COM (7) Axis 1: Enable 1 0 V

6 9 Enable 2 1) Axis 1: Enable 2

10 COM (9) Axis 1: Enable 2 0 V

7

11 S1/B+ 2) Axis 1: Brake + / Activation of the external holding brake

8 12 S2/B- 2) Axis 1: Brake - / Activation of the external holding brake

9

10

11

12

Table 8: X1 connector - Pinout

1) Wiring is not permitted to exceed a total length of 30 m.

2) If the connection is used to activate the external holding brake (S1/S2), then the cabling is not permitted to exceed a total length of 3 m.

If the holding brake is connected via an additional external relay contact (ground-in e.g. via the S1/S2 connections) instead of via the internal transistor, then

the internal quenching circuit has no effect! In this case, the customer must make sure that neither the relay contact nor the braking coil are damaged when

switching off the brake. This can be done by interconnecting the coil or - better still - interconnecting the contact with a quenching circuit.

Danger!

The connections for the motor holding brake are isolated circuits. These connections are therefore

only permitted to be connected to devices or components that have sufficient isolation in accordance

with IEC 60364-4-41 or EN 61800-5-1.

Caution!

If B+ and B- are swapped when connecting the permanent magnet holding brakes, then the brakes

cannot be opened! ACOPOSmulti inverter modules cannot determine if a holding brake is connected

with reverse polarity!

6.1.2 X2 connector - Pinout

X2 Pin Name Function

1 Trigger1 Trigger 1

2 COM (1) Trigger 1 0 V

1 3 COM (4) +24 V output 1 0 V

2 4 +24 V Out 1 +24 V output 1

5 Trigger2 Trigger 2

3

6 COM (5) Trigger 2 0 V

4

7 COM (8) +24 V output 2 0 V

5 8 +24 V Out 2 +24 V output 2

6

Table 9: X2 connector - Pinout

10 Data sheet V 1.3

8BVI0055HWD0.000-1

6.1.3 X3A, X3B connectors - Pinout

X3A, X3B Pin Name Function

1 RXD Receive signal

2 RXD\ Receive signal inverted

3 TXD Transmit signal

1

4 Shield Shield

5 Shield Shield

6 TXD\ Transmit signal inverted

7 Shield Shield

8 Shield Shield

Table 10: X3A, X3B connectors - Pinout

6.1.4 X4A connector - Pinout

X4A Name Function

T- Axis 1: Temperature sensor -

T+ Axis 1: Temperature sensor +

B-/S2 1) Axis 1: Brake - / Activation of the external holding brake

B+/S1 1) Axis 1: Brake + / Activation of the external holding brake

B+ B- T+ T-

Table 11: X4A connector - Pinout

1) If the connection is used to activate the external holding brake (S1/S2), then the cabling is not permitted to exceed a total length of 3 m.

If the holding brake is connected via an additional external relay contact (ground-in e.g. via the S1/S2 connections) instead of via the internal transistor, then

the internal quenching circuit has no effect! In this case, the customer must make sure that neither the relay contact nor the braking coil are damaged when

switching off the brake. This can be done by interconnecting the coil or - better still - interconnecting the contact with a quenching circuit.

Danger!

The connections for the motor holding brake are isolated circuits. These connections are therefore

only permitted to be connected to devices or components that have sufficient isolation in accordance

with IEC 60364-4-41 or EN 61800-5-1.

Caution!

If B+ and B- are swapped when connecting the permanent magnet holding brakes, then the brakes

cannot be opened! ACOPOSmulti inverter modules cannot determine if a holding brake is connected

with reverse polarity!

Warning!

Temperature sensors are only permitted to be connected to the X4A/T+ and X4A/T- connectors on an

ACOPOSmulti module under the following conditions:

• There is no ACOPOSmulti plug-in module in SLOT1 on the ACOPOSmulti module with a tem-

perature sensor connected to T+ and T-

Otherwise, the temperature monitoring functions on the ACOPOSmulti module may become ineffec-

tive, which in extreme cases can cause the hardware (e.g. motors) connected to the ACOPOSmulti

module to be destroyed!

Data sheet V 1.3 11

8BVI0055HWD0.000-1

6.1.5 Pinout - X4B plug

X4B Name Function

T- Axis 2: Temperature sensor -

T+ Axis 2: Temperature sensor +

B-/S2 1) 2) Axis 2: Brake - / Activation of the external holding brake

B+/S1 1) 2) Axis 2: Brake + / Activation of the external holding brake

B+ B- T+ T-

Table 12: Pinout - X4B plug

1) Wiring is not permitted to exceed a total length of 3 m.

2) If the holding brake is connected via an additional external relay contact (ground-in e.g. via the S1/S2 connections) instead of via the internal transistor, then

the internal quenching circuit has no effect! In this case, the customer must make sure that neither the relay contact nor the braking coil are damaged when

switching off the brake. This can be done by interconnecting the coil or - better still - interconnecting the contact with a quenching circuit.

Danger!

The connections for the motor temperature sensors and the motor holding brake are safely isolated

circuits. These connections are therefore only permitted to be connected to devices or components

that have sufficient isolation in accordance with IEC 60364-4-41 or EN 61800-5-1.

Caution!

If B+ and B- are swapped when connecting the permanent magnet holding brakes, then the brakes

cannot be opened! ACOPOSmulti inverter modules cannot determine if a holding brake is connected

with reverse polarity!

Warning!

Temperature sensors are only permitted to be connected to the X4B/T+ and X4B/T- connectors on an

ACOPOSmulti module under the following conditions:

• There is no ACOPOSmulti plug-in module in SLOT2 on the ACOPOSmulti module with a tem-

perature sensor connected to T+ and T-

Otherwise, the temperature monitoring functions on the ACOPOSmulti module may become ineffec-

tive, which in extreme cases can cause the hardware (e.g. motors) connected to the ACOPOSmulti

module to be destroyed!

6.1.6 X5A connector - Pinout

X5A Name Function

Axis 1: Protective ground conductor

W Axis 1: Motor connection W

V Axis 1: Motor connection V

U Axis 1: Motor connection U

U V W

Table 13: X5A connector - Pinout

12 Data sheet V 1.3

8BVI0055HWD0.000-1

6.1.7 X5B connector - Pinout

X5B Name Function

Axis 2: Protective ground conductor

W Axis 2: Motor connection W

V Axis 2: Motor connection V

U Axis 2: Motor connection U

U V W

Table 14: X5B connector - Pinout

6.1.8 Input/output circuit diagram

Figure 4: Enable

Data sheet V 1.3 13

8BVI0055HWD0.000-1

Figure 5: Holding brake

Plug-in module

8BAC0120.000-1

8BAC0121.000-1

8BAC0122.000-1

8BAC0123.00x-1

8BAC0124.000-1

8BAC0125.000-1

Plug-in module

8BAC0120.000-1

8BAC0121.000-1

8BAC0122.000-1

8BAC0123.00x-1

8BAC0124.000-1

8BAC0125.000-1

Figure 6: Temperature sensor

14 Data sheet V 1.3

8BVI0055HWD0.000-1

Figure 7: Motor

Data sheet V 1.3 15

You might also like

- AVR10D Vnet Router PDFDocument3 pagesAVR10D Vnet Router PDFNiyi AdetunjiNo ratings yet

- 05 Interface C ConnectorsDocument31 pages05 Interface C ConnectorsjjcanoolivaresNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- ABB DCS400 ManualDocument202 pagesABB DCS400 ManualDavid ZammitNo ratings yet

- CSS History of Indo Pak NotesDocument23 pagesCSS History of Indo Pak NotesASAD ULLAH100% (2)

- 8BVI0055HWD0.000-3 en V1.3Document21 pages8BVI0055HWD0.000-3 en V1.3Dorin SerbanNo ratings yet

- 8BVP0440HW00.000-1 en V1.8Document13 pages8BVP0440HW00.000-1 en V1.8Dorin SerbanNo ratings yet

- 8BVI0055HWDS.000-1_enDocument10 pages8BVI0055HWDS.000-1_enReativa Engenharia ElétricaNo ratings yet

- Datasheet_8BVI_1_HWS_E_039 ACOPOS MULTI 0-901-37-385-4Document14 pagesDatasheet_8BVI_1_HWS_E_039 ACOPOS MULTI 0-901-37-385-4fernandocushwakeNo ratings yet

- 8BVE0500HW00.000-1_en_V1.6Document12 pages8BVE0500HW00.000-1_en_V1.6Reativa Engenharia ElétricaNo ratings yet

- Wide Input Voltage Range Power Supply ModuleDocument13 pagesWide Input Voltage Range Power Supply ModuleDiego FortunaNo ratings yet

- 8EI8X8HWT10.XXXX-1: 1 Order DataDocument13 pages8EI8X8HWT10.XXXX-1: 1 Order DataLaerte MeloNo ratings yet

- 8B0C0160HW00.001-1: 1 General InformationDocument6 pages8B0C0160HW00.001-1: 1 General InformationИльнур ТагировNo ratings yet

- Datasheet 8B0C0160HW00.001-1 E 039Document9 pagesDatasheet 8B0C0160HW00.001-1 E 039pimentel.o.alexandreNo ratings yet

- 1 General Information: Model Number Short Description Servo DrivesDocument14 pages1 General Information: Model Number Short Description Servo DrivesMr.K ch100% (1)

- B&R Automation 8BVP0440HW00.000-1 Power Supply DatasheetDocument17 pagesB&R Automation 8BVP0440HW00.000-1 Power Supply DatasheetGerman PachecoNo ratings yet

- 8V1320.001-2 en V1.8Document14 pages8V1320.001-2 en V1.8JlavieraNo ratings yet

- 8B0C0160HW00.001-1: 1 General InformationDocument6 pages8B0C0160HW00.001-1: 1 General InformationDiego FortunaNo ratings yet

- GPC Ed3 en Contactors TORDocument100 pagesGPC Ed3 en Contactors TORmiguelcastilloNo ratings yet

- 8V1090.001-2 en V1.8Document14 pages8V1090.001-2 en V1.8JlavieraNo ratings yet

- Puente Rectificador PDFDocument4 pagesPuente Rectificador PDFrickypinaNo ratings yet

- 8V1640.001-2 en V1.8Document14 pages8V1640.001-2 en V1.8JlavieraNo ratings yet

- Datasheet Relay ENG, DS, OMI, OMIH SeriesDocument3 pagesDatasheet Relay ENG, DS, OMI, OMIH SeriesrealaffiliateNo ratings yet

- Hcmos Compatible, High CMR, 10 MBD OptocouplersDocument16 pagesHcmos Compatible, High CMR, 10 MBD Optocouplersnithinmundackal3623No ratings yet

- 8V1090.00-2 en V1.7Document13 pages8V1090.00-2 en V1.7JlavieraNo ratings yet

- 8v1045.00-2 Datasheet - Centrale D'usinage 3axesDocument13 pages8v1045.00-2 Datasheet - Centrale D'usinage 3axesJoel MAKOLLENo ratings yet

- NSS12201L DDocument5 pagesNSS12201L DjamesabowdenNo ratings yet

- c547b TransistorDocument7 pagesc547b TransistorRaul Sanchez Roy100% (1)

- Tda 7266Document9 pagesTda 7266Nenad DejanovićNo ratings yet

- 1096 B R Automation 8v1090 00 2 Acopos 1090Document13 pages1096 B R Automation 8v1090 00 2 Acopos 1090Anonymous 6Mb7PZjNo ratings yet

- Electronic Timer CT-VBS.17+18: OFF-delayed Without Auxiliary Voltage, For DC Contactors Data SheetDocument7 pagesElectronic Timer CT-VBS.17+18: OFF-delayed Without Auxiliary Voltage, For DC Contactors Data SheetRoga29No ratings yet

- CNY70 Reflective Optical Sensor With Transistor Output: Vishay SemiconductorsDocument11 pagesCNY70 Reflective Optical Sensor With Transistor Output: Vishay SemiconductorsHector Ivan Urzua VargasNo ratings yet

- 8V1090.00-2 DatasheetDocument13 pages8V1090.00-2 DatasheetAmrit Pal SinghNo ratings yet

- Stahl PDFDocument10 pagesStahl PDFMidfiild CosminNo ratings yet

- ILD205T, ILD206T, ILD207T, ILD211T, ILD213T: Vishay SemiconductorsDocument8 pagesILD205T, ILD206T, ILD207T, ILD211T, ILD213T: Vishay SemiconductorsRohit SainiNo ratings yet

- Relee Din Gama 38Document6 pagesRelee Din Gama 38andy175No ratings yet

- Schrack Miniature Relay PT: General Purpose RelaysDocument4 pagesSchrack Miniature Relay PT: General Purpose RelaysMelih GuneriNo ratings yet

- MTL7000 SeriesDocument13 pagesMTL7000 SeriesquocvttNo ratings yet

- PN100/PN100A/MMBT100/MMBT100A: NPN General Purpose AmplifierDocument7 pagesPN100/PN100A/MMBT100/MMBT100A: NPN General Purpose Amplifierctt10No ratings yet

- Bc546b, Bc547a, B, C, Bc548b, CDocument7 pagesBc546b, Bc547a, B, C, Bc548b, CAlfredo Valencia RodriguezNo ratings yet

- Stahl11 eDocument144 pagesStahl11 eCarlos Veron100% (1)

- Harmony Electromechanical Relays - RSB2A080B7SDocument6 pagesHarmony Electromechanical Relays - RSB2A080B7SMirela SimijdeanNo ratings yet

- 2008 Easypact CatalogueDocument80 pages2008 Easypact Cataloguebeckam88No ratings yet

- LIT1126 ACT20M Datasheet 03 14Document16 pagesLIT1126 ACT20M Datasheet 03 14alltheloveintheworldNo ratings yet

- TDA7073A DatasheetDocument17 pagesTDA7073A Datasheetsergio_741No ratings yet

- 8000io CutsheetDocument2 pages8000io CutsheetPadmo PadmundonoNo ratings yet

- 2N3442 DDocument4 pages2N3442 DIonut SimaNo ratings yet

- Elevador VoltajeDocument10 pagesElevador VoltajeFernando AugustoNo ratings yet

- ENG DS OMI 2 Pole Series Relay Data Sheet E 0411Document3 pagesENG DS OMI 2 Pole Series Relay Data Sheet E 0411letterniNo ratings yet

- 4N32, 4N33 Optocoupler Technical DocumentDocument6 pages4N32, 4N33 Optocoupler Technical Documentthijo19No ratings yet

- Schneider NS MCCBDocument42 pagesSchneider NS MCCBEnder Ali Leon Valero100% (1)

- Brochure en Ac500 Eco 1sbc125001l0203Document6 pagesBrochure en Ac500 Eco 1sbc125001l0203Ramiro RojasNo ratings yet

- V 23148Document3 pagesV 23148nelucurtaNo ratings yet

- 22 MM Push Buttons XB4 Electrical Components: Table 19.89: Body/Mounting CollarDocument2 pages22 MM Push Buttons XB4 Electrical Components: Table 19.89: Body/Mounting CollarMohammed AbdelsalamNo ratings yet

- HS25 Incremental EncoderDocument4 pagesHS25 Incremental Encoderoswaldo58No ratings yet

- Schrack RM732024 DatasheetDocument4 pagesSchrack RM732024 Datasheetpaula09No ratings yet

- Millenium 2 InstallationDocument12 pagesMillenium 2 Installationron36No ratings yet

- AC500-eCo Catalogo Atualizado 2Document2 pagesAC500-eCo Catalogo Atualizado 2Multidrive BauruNo ratings yet

- Audio IC Projects: A Collection of Useful Circuits Based on Readily Available ChipsFrom EverandAudio IC Projects: A Collection of Useful Circuits Based on Readily Available ChipsNo ratings yet

- Guide to the IET Wiring Regulations: IET Wiring Regulations (BS 7671:2008 incorporating Amendment No 1:2011)From EverandGuide to the IET Wiring Regulations: IET Wiring Regulations (BS 7671:2008 incorporating Amendment No 1:2011)Rating: 4 out of 5 stars4/5 (2)

- 110 Waveform Generator Projects for the Home ConstructorFrom Everand110 Waveform Generator Projects for the Home ConstructorRating: 4 out of 5 stars4/5 (1)

- Uni DriveDocument57 pagesUni DriveAndrey KapustaNo ratings yet

- MVE Soft Starter: User ManualDocument82 pagesMVE Soft Starter: User ManualAndrey KapustaNo ratings yet

- Service Manual: Downloaded From Manuals Search EngineDocument22 pagesService Manual: Downloaded From Manuals Search EngineAndrey KapustaNo ratings yet

- EMX4i Soft Starter: User ManualDocument126 pagesEMX4i Soft Starter: User ManualAndrey KapustaNo ratings yet

- S210 1FK2 Op Instr 092019 en-US PDFDocument666 pagesS210 1FK2 Op Instr 092019 en-US PDFAndrey KapustaNo ratings yet

- VLT 6000 Hvac QuickDocument29 pagesVLT 6000 Hvac QuickAndrey KapustaNo ratings yet

- System Manual R360 - 2007 01 - EDocument251 pagesSystem Manual R360 - 2007 01 - EMuhammad NaveedNo ratings yet

- 6 SN 11110 Aa 000 Da 1Document1 page6 SN 11110 Aa 000 Da 1Andrey KapustaNo ratings yet

- Fanuc Manuals 520Document268 pagesFanuc Manuals 520danielstancu883296100% (2)

- System Manual R360 - 2007 01 - EDocument251 pagesSystem Manual R360 - 2007 01 - EMuhammad NaveedNo ratings yet

- 2005 ManualDocument658 pages2005 Manualstgpereira100% (1)

- Um Acs400Document160 pagesUm Acs400hoactmNo ratings yet

- MN 63489 0013 en FPX PDFDocument544 pagesMN 63489 0013 en FPX PDFAndrey KapustaNo ratings yet

- Inovance - MD300Document85 pagesInovance - MD300bernabasNo ratings yet

- 1Document5 pages1JESUSCALVILLONo ratings yet

- Java syntax and data types tutorialDocument3 pagesJava syntax and data types tutorialpeter chan100% (1)

- Mens Care Active Concepts PDFDocument19 pagesMens Care Active Concepts PDFFredy MendocillaNo ratings yet

- 1161 Article+Text 5225 1 4 20220712Document9 pages1161 Article+Text 5225 1 4 20220712Warman FatraNo ratings yet

- DP-10/DP-10T/DP-11/DP-15/DP-18 Digital Ultrasonic Diagnostic Imaging SystemDocument213 pagesDP-10/DP-10T/DP-11/DP-15/DP-18 Digital Ultrasonic Diagnostic Imaging SystemDaniel JuarezNo ratings yet

- Chapter 11 RespirationDocument2 pagesChapter 11 Respirationlock_jaw30No ratings yet

- Madagascar SslevMg v2Document11 pagesMadagascar SslevMg v2Thyan AndrianiainaNo ratings yet

- Course Code Part Sem Paper Code Paper NameDocument3 pagesCourse Code Part Sem Paper Code Paper Nameshiv mishraNo ratings yet

- AFPRP Final Group 25Document19 pagesAFPRP Final Group 25Pranay NitnawareNo ratings yet

- Filipino Essay 4Document3 pagesFilipino Essay 4IqbalNo ratings yet

- Architect Curriculum VitaeDocument4 pagesArchitect Curriculum VitaeMehboob AlamNo ratings yet

- The Greatest Showman PDFDocument22 pagesThe Greatest Showman PDFMJ RecordNo ratings yet

- Strawberry GenerationDocument2 pagesStrawberry GenerationImat12No ratings yet

- Narrative Report of Landfill VisitDocument3 pagesNarrative Report of Landfill VisitNestor Jan Kenneth P BorromeoNo ratings yet

- MPX English Final Version VOLUME 3Document878 pagesMPX English Final Version VOLUME 3Adrian MacayaNo ratings yet

- Developing Website Information ArchitectureDocument39 pagesDeveloping Website Information ArchitectureBizuNo ratings yet

- Standard JKR Spec For Bridge LoadingDocument5 pagesStandard JKR Spec For Bridge LoadingHong Rui ChongNo ratings yet

- RLT-Guideline Certification: Herstellerverband Raumlufttechnische Geräte E. V. AHU Manufacturer AssociationDocument22 pagesRLT-Guideline Certification: Herstellerverband Raumlufttechnische Geräte E. V. AHU Manufacturer AssociationJorge RoblesNo ratings yet

- Guidelines For Selecting Materials For Downhole Completions Equipment (Jewellery)Document32 pagesGuidelines For Selecting Materials For Downhole Completions Equipment (Jewellery)Slim.BNo ratings yet

- ds923 Virtex Ultrascale PlusDocument81 pagesds923 Virtex Ultrascale Plusismail topcuNo ratings yet

- Accounting Project Topics and Materials in NigeriaDocument97 pagesAccounting Project Topics and Materials in NigeriaProject Championz100% (2)

- Mikes ResumeDocument2 pagesMikes Resumeapi-312645878No ratings yet

- DANGEL 4as LESSON PLANNINGDocument2 pagesDANGEL 4as LESSON PLANNINGCarlz BrianNo ratings yet

- Economics Principles and Policy 13th Edition Baumol Solutions ManualDocument2 pagesEconomics Principles and Policy 13th Edition Baumol Solutions ManualCraigGonzalezaxzgd100% (17)

- Pag-IBIG Employer Enrollment FormDocument1 pagePag-IBIG Employer Enrollment FormDarlyn Etang100% (1)

- Coaching, Mentoring & OnboardingDocument43 pagesCoaching, Mentoring & OnboardingosvehNo ratings yet

- SHSHA Report PresentationDocument27 pagesSHSHA Report PresentationPatrick JohnsonNo ratings yet

- Opera Arias and Sinfonias: VivaldiDocument22 pagesOpera Arias and Sinfonias: VivaldiDardo CocettaNo ratings yet

- Material 01 - Human-Computer InteractionDocument8 pagesMaterial 01 - Human-Computer InteractionIlangmi NutolangNo ratings yet

- New Translation and Deciphering of ChineDocument14 pagesNew Translation and Deciphering of ChineRémyNo ratings yet