Professional Documents

Culture Documents

Straight Center Pins With Tip Process: Dies Steel

Straight Center Pins With Tip Process: Dies Steel

Uploaded by

Sahil JhambOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Straight Center Pins With Tip Process: Dies Steel

Straight Center Pins With Tip Process: Dies Steel

Uploaded by

Sahil JhambCopyright:

Available Formats

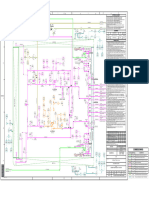

Dies steel

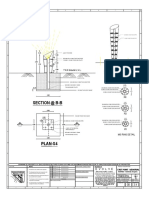

Straight Center Pins with Tip Process

P −0.01

−0.02

Standard

H13+Nitrided

P −0.01 L

−0.02

−Shaft diameter(P)0.1mm designation type−

4mm head JIS head Catalog No.

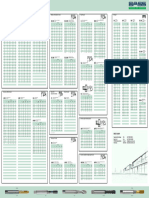

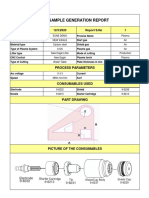

Type Shaft diameter Head Thickness Head Thickness Applicable ejector L P

(P) (T) (T) sleeve hole tolerance Type Shape

(Tip type)

H T H T Shape No. 0.01mm increments 0.1mm increments

4mm head JIS head

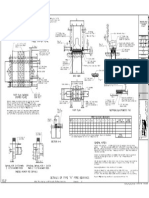

0 4 2 1.5∼ 1.9

−0.02 70.00∼300.00 Shape C C…0.1mm increments

4mm 5 − 2.5 2.0∼ 2.4

CPNG−5L − −

( )

(T4) L>300 6 3 2.5∼ 2.9

−0.01 0

T −0.05

−0.02 +0.01 3.5 3.0∼ 3.4 Shape G K…1°increments

0 or H7 7 70.00∼400.00

4 3.5∼ 3.9

8

P>12 C 4.5 4.0∼ 4.4

Details P.1083 8 Shape T S…0.1mm increments

H13+Nitrided Range of guaranteed shaft diameter precision(Details P.1079) P −0.01 G 5 4.5∼ 4.9

−0.03

6・8mm

9

6

CPNG−5L 5.5 5.0∼ 5.4 K…1°increments

Surface 900HV∼ Range of guaranteed base material hardness(Details P.1081 ) CPJG−5L

0 4

Base material 40∼45HRC Range of guaranteed surface hardness for nitriding(Details P.1082 )

(JIS) −0.05 9

10

T 6 5.5∼ 5.9

No nitriding on the tip. R 6.5 6.0∼ 6.4 Shape R R…0.1mm increments

10 11 CPJG−5L 7 6.5∼ 6.9

B 70.00∼500.00

11 13 8 7.0∼ 7.9 P

Shape B Default R(SR)= 2

Shape

(Tip type) 15 15 10 8.0∼ 9.9 (R…0.1mm increments possible)

17 17 8 12 10.0∼11.9

Shape C R≦0.5(P≦2 R≦0.3) For the limit of processing,

C ±0.05 20 15 12.0∼14.9

(C chamfered) − − − refer to the specification drawing.

45°

±30′ 21 16 15.0∼15.9

H−0.3

C…0.1mm increments Catalog

No. L P Tip size(C・S・K・R) (KC・WKC…etc.)

0

P−0.2 Alteration CPNG−5LC5 100.00 P4.9 C1.0 HC7.0

0.1≦C≦ 2 CPJG−5LT5 100.00 P4.9 S2.0 K30 HC7.0

Alteration details P.235

T

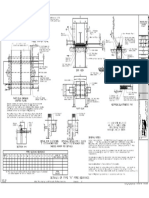

Alterations Code Spec. $/1Code Alterations Code Spec. $/1Code

+0.02 +0.05

L 0 (L>200 L )

0 HC=0.1mm increments

HCC −0.02 HC−0.3

Single flat cutting

0

KC 1.00 HC P≦HC<H 2.00

H

0 P/2≦KC<H/2

R≦0.5(P≦2 R≦0.3) KC −0.1 About Designation In relation to the head diameter tolerance, alteration may create

Shape G a straight piece with little diameter difference between the head and shaft.

Unit and Tolerance

(Cone) K°

±30′ for Key Flat Cutting

Two flats cutting HCC=0.1mm increments

0

WKC P/2≦WKC<H/2 2.00 HCC 4.00

H

0 P+1≦HCC<H−0.3

K…1°increments (1)To align the key

−0.3

WKC−0.1

0

H

flat with the

P

Varied width parallel flats cutting TC=0.1mm increments

45≦K<90 KAC P/2≦KAC<H/2 shaft diameter 0 T/2≦TC<T

0 3.00 TC−0.05 TC 2.00

KAC KBC−0.1 KBC KBC=0.1mm increments only Unit of designation T−TC≦Lmax.−L

T KAC<KBC<H/2 T (Dimension L remains unchanged.)

+0.05 +0.1

0.05mm increments possible +0.1

L 0 (L>200

L ) 0 −0 d 0 Dowel hole boring T d

Two flats (right angled) cutting Tolerance −0.1

r

RKC

r

4 2 3

RKC 2.00 NC Combination with other than 2.00

H

0 P/2≦RKC<H/2 0 6

RKC−0.1 It remains at −0.1 NHC/NHN not available. 8

3 5

T

Shape T R≦0.5(P≦2 R≦0.3) S ±0.05 even when P/2 is

S…0.1mm increments K…1°increments

DKC

designated to fit

r1

(Tapered) d Dowel hole boring+Spring pin driving T d r1

K°

±30′ Three flats cutting shaft diameter. 4 2

DKC 3.00 NCW Combination with other than 2.00

H

(LーS)

≧50 1≦K≦45 0 P/2≦DKC<H/2 NHC/NHN not available.

6

3

5

DKC DKC−0.1 (2)To designate T 8

H−0.3

and

0

AG゜

±0.5 Two flats (angled) cutting arbitrary key flat

P

0 1 Numbering on the head

0. dimensions 217

0.1≦S≦P×2 0゜ C− KGC P/2≦KGC<H/2

3.00 NHC How to order P.236 1.00

KG AG=1°increments Unit of designation

and KGC Available when H≧2

T 0<AG<360

P −StanK≧0.1 0.1mm

120゜

L +0.02

0 (L>200

+0.05

L 0 )

2 120゜ Three flats cutting at 120° Tolerance −0

Automatic sequential numbering on the head

KTC −0.1 4.00 1 2 3

NHN How to order P.236 1.00

120゜ 0 P/2≦KTC<H/2

KTC−0.1 Available when H≧2

R≦0.5(P≦2 R≦0.3)

Shape R R±0.1 H13

(R chamfered) +

■Volume discount rate P.35 Nitrided

Price Quantity 1∼4 5∼12 13∼19 20∼

H−0.3

R…0.1mm increments Rate ―

0

5% 10% 15%

P

0.2≦R≦ P−0.2

2

$ Unit price for 1∼4

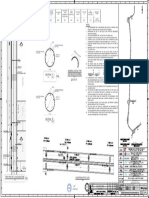

No. L70.00∼150.00 L150.01∼250.00 L250.01∼350.00 L350.01∼450.00 L450.01∼500.00

T C・G・T R B C・G・T R B C・G・T R B C・G・T R B C・G・T R B

L +0.02 +0.05 2 12.90 9.00 15.10 13.10 9.20 15.30 13.30 9.40 15.50

0 (L>200

L 0 )

− − −

2.5 12.90 9.00 15.10 13.10 9.20 15.30 13.30 9.40 15.50

3 10.80 8.70 13.20 11.00 8.90 13.40 11.20 9.10 13.60 13.40 11.60 15.40

− − −

R≦0.5(P≦2 R≦0.3) R(SR)±0.1 3.5 11.20 8.70 13.40 11.40 8.90 13.60 11.60 9.10 13.80 13.60 11.60 15.40

Shape B 4 11.00 8.50 13.40 11.30 8.80 13.70 11.60 9.10 14.00 13.60 11.60 15.60

(Spherical surface) 4.5 11.20 8.80 13.70 11.50 9.10 14.00 11.80 9.40 14.30 13.80 11.70 15.90

Default R(SR)=P/2

5 11.40 9.00 13.80 11.70 9.30 14.10 12.00 9.60 14.40 14.00 11.90 16.00 16.00 14.20 17.60

5.5 12.50 9.90 15.10 12.80 10.20 15.40 13.10 10.50 15.70 15.30 12.80 17.50 17.50 15.10 19.30

H−0.3

*When required, designation

0

6 12.80 10.10 15.30 13.10 10.40 15.60 13.40 10.70 15.90 15.60 13.00 17.50 17.80 15.30 19.10

P

of SR in the range of 6.5 14.00 11.00 16.40 14.40 11.40 16.80 14.80 11.80 17.20 17.00 14.10 18.80 19.20 16.40 20.40

P/2<R≦2×P is possible. 7 14.70 11.70 17.10 15.10 12.10 17.50 15.50 12.50 17.90 17.50 14.80 19.50 19.50 17.10 21.10

T 8 17.20 13.60 19.10 17.60 14.00 19.50 18.00 14.40 19.90 20.20 16.70 21.50 22.40 19.00 23.10

R…0.1mm increments possible 19.90 18.30 21.90 20.40 18.80 22.40 20.90 19.30 22.90 22.90 21.60 24.50 24.90 23.90 26.10

10

L +0.05

0 (L>200 +0.1

L 0 )

12 21.70 18.40 25.90 22.20 18.90 26.40 22.70 19.40 26.90 26.30 22.60 30.10 29.90 25.80 33.30

15 26.70 23.40 30.90 27.20 23.90 31.40 27.70 24.40 31.90 31.30 27.60 35.10 34.90 30.80 38.30

16 28.20 24.90 32.40 28.70 25.40 32.90 29.20 25.90 33.40 32.80 29.10 36.60 36.40 32.30 39.80

Catalog

No. L P Tip size

(C・S・K・R)

Order

Example

Production

Time 8 Days

CPNG−5LC5 100.00 P4.9 C1.0

CPJG−5LT5 100.00 P4.9 S2.0−K30

247 Phone 1-800-681-7475 Fax 1-800-681-7402

248

(1-847-843-9105) www.misumiusa.com (1-847-843-9107)

You might also like

- Chart - August 2011: Pressure VesselDocument1 pageChart - August 2011: Pressure Vesselabo151067% (3)

- S4 PDFDocument1 pageS4 PDFSowmya ShreeNo ratings yet

- Ashrae 15 A Review and Update MN Chapter 2013Document43 pagesAshrae 15 A Review and Update MN Chapter 2013MoriyasuNguyenNo ratings yet

- Oxidation of Ethylene (Production)Document4 pagesOxidation of Ethylene (Production)Alperen AydınNo ratings yet

- RollingDocument22 pagesRollingSahil JhambNo ratings yet

- (Lecture 4) - Investment Appraisal Under UncertaintyDocument12 pages(Lecture 4) - Investment Appraisal Under UncertaintyAjay Kumar TakiarNo ratings yet

- Tabel Filete EMUGEDocument1 pageTabel Filete EMUGEgiorgio_gex4758100% (1)

- Aip-Shs 2023Document13 pagesAip-Shs 2023Lovely CamposanoNo ratings yet

- Sheet Metal Mounting Plate / Brackets (For Sensors) Sheet Metal Mounting Plate / Brackets (For Sensors)Document1 pageSheet Metal Mounting Plate / Brackets (For Sensors) Sheet Metal Mounting Plate / Brackets (For Sensors)Karim SamhyNo ratings yet

- Steel Worms: Bronze Worm Wheels & Gray Iron Worm WheelsDocument7 pagesSteel Worms: Bronze Worm Wheels & Gray Iron Worm WheelsKresnaFajarNo ratings yet

- Stainless Steel Worms: Spur Gears Spur GearsDocument3 pagesStainless Steel Worms: Spur Gears Spur GearsOriental BearingNo ratings yet

- Kabel Feeder Dan Posisi Panel-TestDocument1 pageKabel Feeder Dan Posisi Panel-TestEddy Shaka AMTNo ratings yet

- Details of Type "N" Ptfe Bearings: CountyDocument1 pageDetails of Type "N" Ptfe Bearings: CountyMiguel Angel Montaña PeñaNo ratings yet

- brg07 Ptfe STL 4stpDocument1 pagebrg07 Ptfe STL 4stpMiguel Angel Montaña PeñaNo ratings yet

- General Detail For Lap Splice of Spiral A Section: NotesDocument1 pageGeneral Detail For Lap Splice of Spiral A Section: NotesPravin AwalkondeNo ratings yet

- ZX230 270 Eng e PDFDocument1 pageZX230 270 Eng e PDFIksan RadenNo ratings yet

- Estructura Metálica 2Document1 pageEstructura Metálica 2Juan CarlosNo ratings yet

- 3 P 132 9301 1a3a N 04 - Rev01Document1 page3 P 132 9301 1a3a N 04 - Rev0146 JOSHI SWAPNIL OMNo ratings yet

- Aluminum Extrusion Types and Parts Selection Aluminum Extrusion Tolerance DataDocument1 pageAluminum Extrusion Types and Parts Selection Aluminum Extrusion Tolerance DataKmgsa BandaraNo ratings yet

- Sector Huancapata 03Document1 pageSector Huancapata 03Carlos BustamanteNo ratings yet

- 3 P 132 9301 1a3a N 01 - Rev01Document1 page3 P 132 9301 1a3a N 01 - Rev0146 JOSHI SWAPNIL OMNo ratings yet

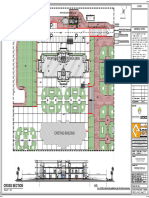

- 06.office Tower 8,9,10floor (R5) 07042017-Go PrintDocument1 page06.office Tower 8,9,10floor (R5) 07042017-Go PrintHari AlfandiNo ratings yet

- A101a - Proposed Site PlanDocument1 pageA101a - Proposed Site PlanØwięs MØhãmmedNo ratings yet

- Pre-ABD - Banjar Tengah Tinyeb-FDT 1Document1 pagePre-ABD - Banjar Tengah Tinyeb-FDT 1Dika Illfeel Jr.No ratings yet

- Moves Change From Rev 1 To 1F1: Singapore Expansion ProjectDocument2 pagesMoves Change From Rev 1 To 1F1: Singapore Expansion ProjectLocus Jhun MichaelNo ratings yet

- 3 P 132 9401 1a3a N 03 - Rev01Document1 page3 P 132 9401 1a3a N 03 - Rev0146 JOSHI SWAPNIL OMNo ratings yet

- Hydraulic Diagram Main HPU: Loose Delivery No IHC Hytop Supply TT-059161-000 59161Document1 pageHydraulic Diagram Main HPU: Loose Delivery No IHC Hytop Supply TT-059161-000 59161mahdi beheshtiNo ratings yet

- Threading Catalog: CAT2016THD FRONTCOVER - Indd 1 8/24/16 10:37 AMDocument156 pagesThreading Catalog: CAT2016THD FRONTCOVER - Indd 1 8/24/16 10:37 AMagung wijayaNo ratings yet

- Diagrama de AuditorioDocument1 pageDiagrama de AuditorioRauman Guillermo RamosNo ratings yet

- 172 I1909e 000 46 DW 0109Document2 pages172 I1909e 000 46 DW 0109Jose Carlos Moraga LópezNo ratings yet

- Planta 1 Cancha OlimpicaDocument1 pagePlanta 1 Cancha OlimpicaRaul BarreroNo ratings yet

- Nozzle Joints / Two-Fluid Nozzles Spray Nozzles: Male, Female Ends Female, Female EndsDocument1 pageNozzle Joints / Two-Fluid Nozzles Spray Nozzles: Male, Female Ends Female, Female EndsAmpera marzelaNo ratings yet

- Dr. Reddy's Annual Report 2010Document200 pagesDr. Reddy's Annual Report 2010biswajitdNo ratings yet

- Material List: Nameplate Bracket NameplateDocument1 pageMaterial List: Nameplate Bracket NameplateMohamed SamirNo ratings yet

- Cv-00 Proposed Linear Heat Detection Layout 1Document1 pageCv-00 Proposed Linear Heat Detection Layout 1Ramces AsisiNo ratings yet

- Leveling ScrewsDocument1 pageLeveling ScrewsdbaNo ratings yet

- 072744C-RA1-DW-SW-31126-1-01 - 0 Change Joint TypeDocument3 pages072744C-RA1-DW-SW-31126-1-01 - 0 Change Joint TypeLocus Jhun MichaelNo ratings yet

- ST SD Ta 0036 0046 - 00Document11 pagesST SD Ta 0036 0046 - 00Muneeswaran BalaguruNo ratings yet

- 3 P 132 9501 1a3a N 02 - Rev01Document1 page3 P 132 9501 1a3a N 02 - Rev0146 JOSHI SWAPNIL OMNo ratings yet

- Axens Technip India Ltd. Mumbai, India.: Bill of MaterialDocument9 pagesAxens Technip India Ltd. Mumbai, India.: Bill of MaterialSiddhu DudwadkarNo ratings yet

- Pinion CatalogueDocument8 pagesPinion CatalogueMarlon EvangelistaNo ratings yet

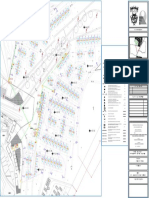

- Cable Route DetailsDocument1 pageCable Route Detailsshabiq93No ratings yet

- Estructura de Cubierta PDFDocument1 pageEstructura de Cubierta PDFAndres SuarezNo ratings yet

- 172 I1909e 000 46 DW 0105Document2 pages172 I1909e 000 46 DW 0105Jose Carlos Moraga LópezNo ratings yet

- Star Knobs / Cross Knobs / Five Lobed Knobs / Six Lobed KnobsDocument1 pageStar Knobs / Cross Knobs / Five Lobed Knobs / Six Lobed KnobsDipak KumarNo ratings yet

- Spd-Ar-Abd-C-004-Type C - Elevation and SectionDocument1 pageSpd-Ar-Abd-C-004-Type C - Elevation and Sectionruthersto_tomas7793No ratings yet

- Planos de Instalacion ElectricaDocument4 pagesPlanos de Instalacion ElectricaiquispemNo ratings yet

- Refrigerant Pipe Refrigerant Pipe Refrigerant Pipe: ProjectDocument7 pagesRefrigerant Pipe Refrigerant Pipe Refrigerant Pipe: ProjectfebousNo ratings yet

- NORTH Elevation: House GDocument1 pageNORTH Elevation: House GNana BarimaNo ratings yet

- Chain 1 - CHE50Document1 pageChain 1 - CHE50eng.mark.iskanderNo ratings yet

- DA05Document1 pageDA05Johann Nick Flores AparicioNo ratings yet

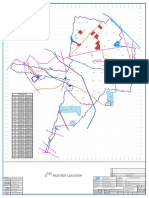

- p45-Dwg-civ-20-Pile Load Test Location-Sh 1 of 2Document1 pagep45-Dwg-civ-20-Pile Load Test Location-Sh 1 of 2Maan JiiNo ratings yet

- C-2 C-1 C-1 C-2: Simbolo Altura DescripcionDocument1 pageC-2 C-1 C-1 C-2: Simbolo Altura DescripcionJoel E. López GastélumNo ratings yet

- F122 76-10526-Detail Design: Fire Protection Services - Ground Level PlanDocument1 pageF122 76-10526-Detail Design: Fire Protection Services - Ground Level PlanMazen IsmailNo ratings yet

- PHG - 2800-003 - Et-03 ChoDocument1 pagePHG - 2800-003 - Et-03 ChoComercializadora S&ENo ratings yet

- DA04Document1 pageDA04Johann Nick Flores AparicioNo ratings yet

- Elevation of Tower - 1 (Facing West) Part 1 of 3: Section A-ADocument1 pageElevation of Tower - 1 (Facing West) Part 1 of 3: Section A-AHozien OnofreNo ratings yet

- Elevation of Tower - 2 (Facing West) Part 3 of 3: LegendsDocument1 pageElevation of Tower - 2 (Facing West) Part 3 of 3: LegendsHozien OnofreNo ratings yet

- Bore Hole DiametersDocument1 pageBore Hole DiametersVladislavNo ratings yet

- I-DE-3010.92-5335-944-OVX-002 - Engine Room Ballast SysDocument1 pageI-DE-3010.92-5335-944-OVX-002 - Engine Room Ballast SysAdalton BritoNo ratings yet

- 172 I1909e 000 46 DW 0104Document1 page172 I1909e 000 46 DW 0104Jose Carlos Moraga LópezNo ratings yet

- 03 How To Use CatalogDocument4 pages03 How To Use CatalogSahil JhambNo ratings yet

- New PlasmaDocument9 pagesNew PlasmaSahil JhambNo ratings yet

- Nptel: Steel Making - Web CourseDocument2 pagesNptel: Steel Making - Web CourseSahil JhambNo ratings yet

- Assembly ViewDocument1 pageAssembly ViewSahil JhambNo ratings yet

- PLC-based Load Management in Steel Rolling MillsDocument17 pagesPLC-based Load Management in Steel Rolling MillsSahil JhambNo ratings yet

- The Cutting Force in Punching and Blanking Operati 5a02c556c3a95b0d489e6f93Document2 pagesThe Cutting Force in Punching and Blanking Operati 5a02c556c3a95b0d489e6f93Sahil JhambNo ratings yet

- Chemical Composition SteelDocument6 pagesChemical Composition SteelSahil JhambNo ratings yet

- Experimental Investigations and FEM Simulations of Parameters in Uencing The Fe - (wt.3%) Si Shearing ProcessDocument9 pagesExperimental Investigations and FEM Simulations of Parameters in Uencing The Fe - (wt.3%) Si Shearing ProcessSahil JhambNo ratings yet

- Quality Management System (QMS) : Terms and DefinitionsDocument44 pagesQuality Management System (QMS) : Terms and DefinitionsSahil JhambNo ratings yet

- Six Sigma Yellow. BeltDocument63 pagesSix Sigma Yellow. BeltSahil JhambNo ratings yet

- Group 3 AssignmentDocument11 pagesGroup 3 AssignmentEmmanuel A. MirimboNo ratings yet

- Signal ItDocument17 pagesSignal ItLionel JosephNo ratings yet

- t-6b Hydraulic DiagramDocument1 paget-6b Hydraulic DiagramSanty SalumNo ratings yet

- Spelling Words For Adults PDFDocument7 pagesSpelling Words For Adults PDFluther jay astronomoNo ratings yet

- Ohms Law and PowerDocument32 pagesOhms Law and PowerGilbert TamayoNo ratings yet

- WTWDocument84 pagesWTWVildanaNo ratings yet

- Steps in A Chemical AnalysisDocument13 pagesSteps in A Chemical Analysisقناص المدينهNo ratings yet

- Manar Al Omran Table Form SystemDocument17 pagesManar Al Omran Table Form SystemSamar YasserNo ratings yet

- The 6502 in TerminatorDocument10 pagesThe 6502 in TerminatorKarelBRGNo ratings yet

- An Interview With Sensorband: Bert BongersDocument12 pagesAn Interview With Sensorband: Bert BongersTrisha JacksonNo ratings yet

- NCM 131 Unit IIIC Interaction Oriented Nursing TheoriesDocument143 pagesNCM 131 Unit IIIC Interaction Oriented Nursing TheoriesMariah Angela PonceNo ratings yet

- Lu8 Stf1053 Biodiversity - How Can Biodiversity Be SustainedDocument42 pagesLu8 Stf1053 Biodiversity - How Can Biodiversity Be SustainedKanchana KanchuNo ratings yet

- Case Study Transportation MGTDocument3 pagesCase Study Transportation MGTHải Đăng0% (1)

- Chemical Bonds ProjectDocument3 pagesChemical Bonds ProjectGerlie VelascoNo ratings yet

- Logic 24,30,35Document68 pagesLogic 24,30,35Richard DruryNo ratings yet

- Case Study Chapter 2Document2 pagesCase Study Chapter 2Grace CaparinoNo ratings yet

- Divorce MeenakshiDocument1 pageDivorce MeenakshiMeenakshi ThakurNo ratings yet

- Experimental Investigation of Performance Improvement of Household Refrigerator Using Phase Change MaterialDocument8 pagesExperimental Investigation of Performance Improvement of Household Refrigerator Using Phase Change MaterialArley Salazar HincapieNo ratings yet

- Figueiredo 2016Document22 pagesFigueiredo 2016Annisa RahmadayantiNo ratings yet

- Embedded Systems: Laboratory ManualDocument10 pagesEmbedded Systems: Laboratory Manualmunib zafarNo ratings yet

- Ingenium I4 2.0l PetrolDocument1,502 pagesIngenium I4 2.0l Petrolkhaledserag23No ratings yet

- Multiple Choice Type Questions and Answers 201-250 - Free Online NTA UGC NET Guide Book December 2019 PDFDocument12 pagesMultiple Choice Type Questions and Answers 201-250 - Free Online NTA UGC NET Guide Book December 2019 PDFrajeshwari glNo ratings yet

- Act. #9 Related LiteratureDocument4 pagesAct. #9 Related LiteratureChristine DiazNo ratings yet

- Qas 125-150 Vod (LS)Document2 pagesQas 125-150 Vod (LS)Sico LabenNo ratings yet

- Whatfix - Sales Predictable Hiring MetricsDocument4 pagesWhatfix - Sales Predictable Hiring MetricsVignesh ManiNo ratings yet

- 1-8DEC Pg1043Document1 page1-8DEC Pg1043Mariano CruzNo ratings yet