Professional Documents

Culture Documents

Vol 7 2 2 GJCR

Uploaded by

R Harshavardhana0 ratings0% found this document useful (0 votes)

4 views2 pagesOriginal Title

Vol-7-2-2-GJCR

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

4 views2 pagesVol 7 2 2 GJCR

Uploaded by

R HarshavardhanaCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

Gangadhar et. al.

, /GJCR/7(2) 2020 66-67

Vol. 7. No. 2. 2020.

©Copyright by CRDEEP Journals. All Rights Reserved.

Contents available at:

www.crdeepjournal.org

Full Length Research Article

Global Journal of Current Research (ISSN: 2320-2920) SJIF: 3.269

Full Length Research Article

Fiber Reinforced Pervious Concrete by using Banana Fiber

N. Gangadhar, P. Chinni Krishna, C.Vinod Kumar, R.Madhuri and A.Parthiban

Sanskrithi School of Engineering, Puttapatthi-515134, Andhra Pradesh, India.

ARTICLE INFORMATION ABSTRACT

Corresponding Author: Pervious concrete is a composite material consisting of coarse aggregate, Portland cement

N. Gangadhar and water. Now days the different sustainable and eco-friendly construction techniques are

being used in pavement. The pervious concrete pavement is one of the types of

Article history: pavement which capture surface infiltration in a void network allows it to pass into soil. The

Received: 23-04-2020 strength and permeability characteristics of pervious pavement using various percentage of

Revised: 27-04-2020 banana fibre with have been investigated. Compressive strength has been increase with the

Accepted: 22-05-2020 addition of banana fibre up to optimum limit. Banana fibres are added to optimum mix by

Published: 25-06-2020 0.1%, 0.2%, 0.3%, and 0.4% of weight. Hence pervious concrete of 1:3 cement:

aggregate ratio with 0.2% banana fibre has been found to be performed well under

Key words: static load condition with improved compressive strength without much sacrificing

Fiber, Reinforced, permeability. The solid waste management has also been achieved up to certain limit.

Concrete, Banana.

Introduction there is no systematic way to extract the fibers regularly.

Now a day’s infrastructure development across the world Useful applications of such fibers would regularize the

created demand for construction material. Concrete is the demand which would be reflected in a fall of the prices.

premier civil engineering construction material, concrete

contains ingredients like cement, aggregates, water and This research paper was aimed to increase the strength of the

admixtures. At present, huge quantities of constructions pervious concrete and increase the permeability and using of

materials are required in developing countries due to continued locally available material as fiber.

infrastructural growth and also huge quantities of

agricultural waste of banana crop are generated every in our Literature review

country almost all 13.5 million tons per annual. The banana Nalini Thakre, Hirendra Rajput, Jaya Saxena, Harish

waste decomposition is a very serious problem for the Mitangale (2014):

farmers because one side it goes as agriculture waste and Presented a paper on “comparative study on strength and

other side it pollutes environment. Banana forming permeability of pervious concrete by using nylon and

generates more quantity of biomass which goes as waste. polypropylene fibre. The fibres are used in various proportions

This waste material can help to increase the strength of i.e., 0.1%, 0.15%, 0.2% etc. of volume of concrete. Also the

concrete. paper says about types of fibres help to increase the

properties of pervious concrete. The fibres are glass fibres,

Natural fibers present important advantages such as low natural fibres like flax, hemp, kenaf, jute, banana and coir,

density, appropriate stiffness and mechanical properties and synthetic fibres like nylon, polypropylene, carbon, polyester

high disposability and renewability. There has been lot of etc. Natural reinforcing materials can be obtained at low

research on use of natural fibers in reinforcement. Banana cost and low levels of energy using local manpower and

fiber, a lingo- cellulosic fiber, obtain from the pseudo- technology. The test result also indicated that the

stem of banana plant (Musa sepientum), is a best fiber with compressed strength of nylon and polypropylene fibre up-to

relatively good mechanical properties. The “pseudo-stem” 0.2% of used result get increased. And the permeability of

is a clustered, cylindrical aggregation of leaf stalk bases. fibre mixed pervious concrete is increased as comparison to

Banana fiber at present is a waste product of banana the plain pervious concrete.

cultivation and either not properly utilized or partially done

so. The extraction of fiber from the pseudo stem is not a Hussam A.A Rahman (2012):

common practice and much of the stem is not used for Conducted a test on “some properties of fibre reinforced no

production of fibers. This is reflected from the relativity fine concrete”. The paper focuses on studying the

expansive price of banana fiber when compared to other mechanical characteristics of polypropylene and carbon fiber

natural fiber. The buyers for banana fiber are erratic and reinforced no fine aggregate concrete containing a different

Global Journal of Current Research 66

Gangadhar et. al., /GJCR/7(2) 2020 66-67

percentage of fibre. Tests to determine workability, density, Results

compressive strength, split tensile strength and modulus of We have casted cubes of 150×150x150mm and the water

rupture were carried out. It was found that pervious concrete cement ratio used is 0.45. The workability is determined by

mixes with fibres have higher density than normal pervious using slump test and compacting factor test. The given slump in

concrete mixes containing polypropylene and carbon. The all mix are true slump and the compacting factor value is within

test results also indicated that the inclusion of fibre to the the range between 0.8 to 0.9. So the concrete are highly

pervious concrete mixes increases compressive strength, split workable.

tensile strength and modulus of rupture.

Conclusion

Dhawal Desai (2010): Results have been analyzed taking into consideration the

Studied the “effects of material properties on porosity of strength characteristics of concrete Reinforced with the

pervious concrete.” This paper describes the effect of size of banana fibre of M30 grade.

aggregates and proportion of cement, aggregate and water 1. The experimental tests revealed that the strength

on porosity of pervious concrete. Different sample blocks properties of concrete improved with the addition of banana

were made in lab with variations in mixture to see the fibres to the concrete.

porosity for final conclusion. The samples in which 2. The addition of banana fibres considerably increased

aggregates above 20 mm were used were not porous from the strength characteristics of concrete, mainly compressive

the base because of larger voids, the cement slurry settles strength and tensile strength.

down. Also in all those cubes in which compaction was 3. The cracking resistance of the concrete has also

done, the cement slurry settles down and thus made a flat improved to a greater extent.

bottom surface. So finally the conclusion was to use 4. When compared to normal concrete, the compressive

aggregate in the range of 9.5 mm - l9 mm and to reduce strength of banana fibre reinforced concrete of M30 grade

compaction while filling to =yield has improved.

5. The compressive strength of concrete has increased

Methodology gradually up to 4% addition of banana fibre and has shown

Step1: gradual decrement in the compressive strength beyond that

Collection of coarse aggregate from beedupalli, puttaparthi, percentage.

Andhra Pradesh.

References

Step2: Prasannan. D, Nivin. S, Raj kumar. R, Giridharan. S,

Concrete is mixed with the ratios of 1:4 (cement: coarse Elavivekan. M, “Comparative Study of Banana and Sisal

aggregate). Banana fiber is added 2% of total weight of Fibre Reinforced Concrete with Conventional Concrete” in

concrete. Concrete is placed in the moulds using a trowel. International Journal of Pure and Applied Mathematics,

The moulds dimensions are 150mm*150mm*150mm. The Volume 118 No. 20, 2018, 1757-1765, ISSN: 1311-8080.

trowel is moved around the top edge is discharged in order Raphael Chacko , S Hema And M Vadivel, “ Experimental

to ensure a symmetrical distribution of the concrete and to Studies on Coconut Fibre and Banana Fibre Reinforced

minimize segregation of coarse aggregate. Concrete” in Scopus Compendex and Geobase Elsevier,

Geo- Ref Information Services-USA, List B of Scientific

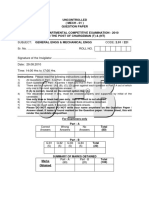

Table 1. Compressive strength for RFCby using banana fibre: Journals, Poland, Directory of Research Journals, ISSN 0974-

5904, Volume 09, No. 03, June 2016, P.P.529- 533.

% of fiber added Number of days Compressive International Journal of Engineering Research &

strength Technology (IJERT), Vol. 2 Issue 3, March – 2013, ISSN:

(N/mm2) 2278- 0181.

0% 28 64 4. S. Kesavraman, “Studies On Metakaolin Based Banana Fibre

0.5% 28 64.9 reinforced Concrete” in International Journal of Civil

Engineering and Technology (IJCIET) Volume 8, Issue 1,

1% 28 66

January 2017, pp. 532– 543, Article ID: IJCIET_08_01_061.

1.5% 28 67.5 Solomon Ikechukwu Anowai and Olorunmeye Fredrick Job,

2% 28 69 “Influence Of Lengths And Volume Fractions Of Fibre On

Step3: Mechanical Properties Of Banana Fibre Reinforced

Compaction is the removal of air from the fresh concrete. Concrete” in International Journal of Recent Innovation in

It increases the density of concrete and also the density of the Engineering and Research, Scientific Journal Impact Factor -

concrete. Concrete is placed in the moulds approximately 3.605 by SJIF, e- ISSN: 2456 – 2084.

equal to three layers of volume. Each layer is compacted Mr. Solomon Ikechukwu Anowai, Prof. Olorunmeye Fredrick

with 25 strokes with the rounded end of rod. Job, “Durability Properties Of Banana Fibre Reinforced Fly

Ash Concrete”, in International Research Journal of

Step 4: Engineering and Technology (IRJET), Volume: 04 Issue: 11 |

Final step is curing which covers the concrete with a Nov - 2017, e-ISSN: 2395-0056, p-ISSN: 2395- 0072.

layer of water, so it stays moist. By keeping the concrete

moist the bond between the paste and aggregate gets

stronger. The specimens are removed from the moulds

after 24 hours casting, specimens are placed in the water

immediately for curing. Finally specimens are tested for 3

days, 7 days, 21 days, and 28 days. Then results were

prepared in the below.

Global Journal of Current Research 67

You might also like

- Eco-efficient Rendering Mortars: Use of Recycled MaterialsFrom EverandEco-efficient Rendering Mortars: Use of Recycled MaterialsNo ratings yet

- Astm F90-14Document4 pagesAstm F90-14Rafael ScatolinNo ratings yet

- Hanu Mesh 2018Document9 pagesHanu Mesh 2018Mohd Zain KangdaNo ratings yet

- Fiber Reinforced ConcreteDocument5 pagesFiber Reinforced ConcreteJournalNX - a Multidisciplinary Peer Reviewed JournalNo ratings yet

- Effects of Waste Polypropylene Fibers On The Mechanical Behavior of Fiber Reinforced Concrete An Experimental StudyDocument4 pagesEffects of Waste Polypropylene Fibers On The Mechanical Behavior of Fiber Reinforced Concrete An Experimental StudyEditor IJTSRDNo ratings yet

- Coconut Fiber in Concrete To Enhance Its Strength and Making Lightweight ConcreteDocument5 pagesCoconut Fiber in Concrete To Enhance Its Strength and Making Lightweight ConcreteIndrawan Soleh PutraNo ratings yet

- Compressive Behavior of Rice Straw-Reinforced Concrete For Rigid PavementsDocument8 pagesCompressive Behavior of Rice Straw-Reinforced Concrete For Rigid PavementsAngelica CabreraNo ratings yet

- JSIR FibrepaperDocument6 pagesJSIR FibrepaperDon PopinoNo ratings yet

- Paper Fiber Reinforced Foam Concrete Wall Paneling SystemDocument14 pagesPaper Fiber Reinforced Foam Concrete Wall Paneling SystemMahi PathakNo ratings yet

- An Experimental Study On Waste Plastic Aggregate Based Concrete - An Initiative Towards Cleaner EnvironmentDocument5 pagesAn Experimental Study On Waste Plastic Aggregate Based Concrete - An Initiative Towards Cleaner Environmentshalom napoleonNo ratings yet

- Performance of Recron-3s Fiber On Black Cotton SoilDocument6 pagesPerformance of Recron-3s Fiber On Black Cotton SoilInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- 2.literature ReviewDocument8 pages2.literature ReviewMohanraj SubramaniNo ratings yet

- Experimental Investigation On Behavior of Pervious Concrete in Strength and Permeability by Using RHA, SCBA, Nylon and Polypropylene FiberDocument3 pagesExperimental Investigation On Behavior of Pervious Concrete in Strength and Permeability by Using RHA, SCBA, Nylon and Polypropylene FiberEditor IJTSRDNo ratings yet

- Construction and Building Materials: Jince P. Zachariah, Partha Pratim Sarkar, Barnali Debnath, Manish PalDocument10 pagesConstruction and Building Materials: Jince P. Zachariah, Partha Pratim Sarkar, Barnali Debnath, Manish PalDhirendra Kumar PandeyNo ratings yet

- Experimental Investigation On The Mechanical Properties of Natural FiberDocument15 pagesExperimental Investigation On The Mechanical Properties of Natural FiberJuan José Alvarez Tostado RiosNo ratings yet

- Irawan 2019 J. Phys. Conf. Ser. 1198 082018Document8 pagesIrawan 2019 J. Phys. Conf. Ser. 1198 082018Heri RamadhanNo ratings yet

- Studies On Fiber-Reinforced Concrete Using Industrial Hemp FibersDocument19 pagesStudies On Fiber-Reinforced Concrete Using Industrial Hemp FibersJulius Robertson FraneNo ratings yet

- Banana Fibre Reinforced Concrete 1Document18 pagesBanana Fibre Reinforced Concrete 1ved100% (1)

- IRJET-Replacement of Natural Sand in Con PDFDocument5 pagesIRJET-Replacement of Natural Sand in Con PDFRana Talal RaziNo ratings yet

- Journal.pdf With Cover Page v2Document13 pagesJournal.pdf With Cover Page v2Litan DebnathNo ratings yet

- Natural fiber reinforced concrete reviewDocument5 pagesNatural fiber reinforced concrete reviewHarshitha H DNo ratings yet

- 412653ijsetr2104 777Document5 pages412653ijsetr2104 777Raj DuttNo ratings yet

- Experimental Investigation On Properties Concrete Paver Block With The Inclusion of Natural FibersDocument5 pagesExperimental Investigation On Properties Concrete Paver Block With The Inclusion of Natural FibersCheska BustosNo ratings yet

- Construction and Building Materials: Tahereh Ansari Rad, Javad Tanzadeh, Azin PourdadaDocument11 pagesConstruction and Building Materials: Tahereh Ansari Rad, Javad Tanzadeh, Azin PourdadaKashif NazirNo ratings yet

- Mechanical and Physcial Properties of Fibre Cement Board PDFDocument5 pagesMechanical and Physcial Properties of Fibre Cement Board PDFanhnguyenhaiNo ratings yet

- Sheep Wool ConcreteDocument10 pagesSheep Wool Concretesharin vargheseNo ratings yet

- A Review On Natural Fibres in The ConcreteDocument5 pagesA Review On Natural Fibres in The Concreteasemamaw damtieNo ratings yet

- Mechanical Properties of Recycled Aggregate Concrete Using Bentonite and Robo Sand-An Experimental StudyDocument7 pagesMechanical Properties of Recycled Aggregate Concrete Using Bentonite and Robo Sand-An Experimental StudyChethan GowdaNo ratings yet

- Strengths Prediction of Plastic Fiber Reinforced Concrete (M30)Document9 pagesStrengths Prediction of Plastic Fiber Reinforced Concrete (M30)Omar KhNo ratings yet

- File ServeDocument5 pagesFile ServeSanjay EvaneNo ratings yet

- 1375-RUGC Manuscript-4763-1-10-20200425Document6 pages1375-RUGC Manuscript-4763-1-10-20200425Brinsi AnwerNo ratings yet

- Utilization of Bamboo Fiber As A Component Material in ConcreteDocument9 pagesUtilization of Bamboo Fiber As A Component Material in ConcreteJemma AbadianoNo ratings yet

- Investigation of Mechanical Properties of Sisal Epoxy Hybrid CompositesDocument7 pagesInvestigation of Mechanical Properties of Sisal Epoxy Hybrid CompositesYuvaraj RajuNo ratings yet

- Comparing strength properties of coir and jute fiber reinforced concreteDocument6 pagesComparing strength properties of coir and jute fiber reinforced concreteBenharzallah KrobbaNo ratings yet

- Construction and Building Materials: Zied Kammoun, Abderraouf TrabelsiDocument9 pagesConstruction and Building Materials: Zied Kammoun, Abderraouf TrabelsiBeyrout TahentiNo ratings yet

- Effect of Natural Fiber Reinforced Polypropylene Composite Using Resin ImpregnationDocument7 pagesEffect of Natural Fiber Reinforced Polypropylene Composite Using Resin ImpregnationchochoNo ratings yet

- Study On Durability of Natural Fibre Concrete Composites Using Mechanical Strength and Microstructural PropertiesDocument11 pagesStudy On Durability of Natural Fibre Concrete Composites Using Mechanical Strength and Microstructural PropertiesdivakarNo ratings yet

- Advocacy For The Production of Geopolymer Concrete Using Plantain Fiber and Coal AshDocument8 pagesAdvocacy For The Production of Geopolymer Concrete Using Plantain Fiber and Coal AshEmmanuel OgunjioforNo ratings yet

- International Journal of Engineering Research and DevelopmentDocument4 pagesInternational Journal of Engineering Research and DevelopmentIJERDNo ratings yet

- Experimental Work On Concrete Using Natural Leaf FibreDocument4 pagesExperimental Work On Concrete Using Natural Leaf FibreInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- 1 s2.0 S0950061822019055 MainDocument12 pages1 s2.0 S0950061822019055 MainAnang ARNo ratings yet

- Khan2020 SinergiaDocument5 pagesKhan2020 SinergiaJulio Cesar Gonzalez FelixNo ratings yet

- A Comparative Study of Basalt and Polypropylene Fibers Reinforced Concrete On Compressive and Tensile BehaviorDocument6 pagesA Comparative Study of Basalt and Polypropylene Fibers Reinforced Concrete On Compressive and Tensile BehaviorIsha PatelNo ratings yet

- Acikel - 2011 - The Use of Miscanthus (Giganteus) As A Plant FiberDocument8 pagesAcikel - 2011 - The Use of Miscanthus (Giganteus) As A Plant FibersalvadorNo ratings yet

- Comparing Impact Behavior of Natural Fiber With Termite Mound and Egg Shell Filler Added Reinforced CompositeDocument8 pagesComparing Impact Behavior of Natural Fiber With Termite Mound and Egg Shell Filler Added Reinforced CompositeTJPRC PublicationsNo ratings yet

- 1 s2.0 S0950061818315204 Main PDFDocument14 pages1 s2.0 S0950061818315204 Main PDFTroy DanielsNo ratings yet

- Fracture Toughness Improvement of Multi-Wall Carbon Nanotubes Graphene Sheets Reinforced Cement PasteDocument9 pagesFracture Toughness Improvement of Multi-Wall Carbon Nanotubes Graphene Sheets Reinforced Cement PastePutik .jajaNo ratings yet

- Investigation On Properties of Concrete As Partial Replacement of Coarse Aggregate and Sand Using Polypropylene Fiber With Foundry Sand For Rigid PavementDocument4 pagesInvestigation On Properties of Concrete As Partial Replacement of Coarse Aggregate and Sand Using Polypropylene Fiber With Foundry Sand For Rigid PavementEditor IJTSRDNo ratings yet

- Garg 2022 J. Phys. Conf. Ser. 2267 012110Document10 pagesGarg 2022 J. Phys. Conf. Ser. 2267 012110MohammedNo ratings yet

- Ingris Panjang Serat GoniDocument6 pagesIngris Panjang Serat GoniWardahNo ratings yet

- Study On Durability of Natural Fibre Concrete Composites Using Mechanical Strength and Microstructural PropertiesDocument11 pagesStudy On Durability of Natural Fibre Concrete Composites Using Mechanical Strength and Microstructural PropertiessfsdffedsNo ratings yet

- Related WorkDocument14 pagesRelated WorkAtif NawazNo ratings yet

- 324615ijsetr2070 773Document5 pages324615ijsetr2070 773Raj DuttNo ratings yet

- Effect of Fiber Length on Mechanical Properties of Coir Fiber Reinforced Epoxy CompositesDocument6 pagesEffect of Fiber Length on Mechanical Properties of Coir Fiber Reinforced Epoxy Compositesbrar_harmanpreet01No ratings yet

- Journal RevewDocument3 pagesJournal RevewALEN GEORGENo ratings yet

- Strengthening The Properties of Concrete Using Banana Fiber and Coconut FiberDocument5 pagesStrengthening The Properties of Concrete Using Banana Fiber and Coconut FiberEditor IJTSRDNo ratings yet

- Bamboo Fibre Improves Black Cotton SoilDocument3 pagesBamboo Fibre Improves Black Cotton SoilVikram NikhilNo ratings yet

- Effect of Polypropylene Fibre On The Strength Characteristics of The SoilsDocument5 pagesEffect of Polypropylene Fibre On The Strength Characteristics of The Soilsbkollarou9632No ratings yet

- Fiber 2Document21 pagesFiber 2CHHABIRANI TUDUNo ratings yet

- Fibra de CocoDocument6 pagesFibra de CocoJuliano Reis PereiraNo ratings yet

- A Comparative Study of Mechanical Properties of Zinc Acrylate Epoxy nanocomposites Reinforced by AL2O3 and Cloisite®30B and Their Mixture: Tensile Strength and Fracture Toughness: A Comparative Study of Mechanical Properties of Zinc Acrylate Epoxy nanocomposites Reinforced by AL2O3 and Cloisite®30B and Their Mixture: Tensile Strength and Fracture ToughnessFrom EverandA Comparative Study of Mechanical Properties of Zinc Acrylate Epoxy nanocomposites Reinforced by AL2O3 and Cloisite®30B and Their Mixture: Tensile Strength and Fracture Toughness: A Comparative Study of Mechanical Properties of Zinc Acrylate Epoxy nanocomposites Reinforced by AL2O3 and Cloisite®30B and Their Mixture: Tensile Strength and Fracture ToughnessNo ratings yet

- 019 - CHECKLIST FOR Grill WorkDocument1 page019 - CHECKLIST FOR Grill WorkR HarshavardhanaNo ratings yet

- 029-CHECKLIST FOR PaintingDocument1 page029-CHECKLIST FOR PaintingR HarshavardhanaNo ratings yet

- Checklist - Internal Painting WorkDocument1 pageChecklist - Internal Painting WorkR HarshavardhanaNo ratings yet

- Analysis of Strength of Pervious Concrete by Adding Rice Husk Ash and Glass FibreDocument5 pagesAnalysis of Strength of Pervious Concrete by Adding Rice Husk Ash and Glass FibreR HarshavardhanaNo ratings yet

- Experimental Investigation Into BanDocument17 pagesExperimental Investigation Into BanR HarshavardhanaNo ratings yet

- Structural Behaviour of Pervious Concrete by Using Synthetic Glass Fibre As ReinforcementDocument7 pagesStructural Behaviour of Pervious Concrete by Using Synthetic Glass Fibre As ReinforcementR HarshavardhanaNo ratings yet

- Ground improvement case studies of chemical lime piles and dynamic replacementDocument15 pagesGround improvement case studies of chemical lime piles and dynamic replacementR HarshavardhanaNo ratings yet

- Failure Theories For CompositesDocument19 pagesFailure Theories For CompositesTallat MasoodNo ratings yet

- CuSn6 Phosphor Bronze SpecificationDocument1 pageCuSn6 Phosphor Bronze SpecificationRemo StortiniNo ratings yet

- Orthodontic AdhesivesDocument144 pagesOrthodontic Adhesivessahana m jainNo ratings yet

- Maintenance Painting of Steelwork Manual Provides GuidanceDocument33 pagesMaintenance Painting of Steelwork Manual Provides GuidancerohanZorbaNo ratings yet

- CleanserDocument22 pagesCleanserMohammed HeshamNo ratings yet

- Heartlands Wrought Iron Brochure 2021 Digital v1 Converted Logo Fix CDocument16 pagesHeartlands Wrought Iron Brochure 2021 Digital v1 Converted Logo Fix CZiad MohamedNo ratings yet

- Chapter 6 - Portland Cement, Mix Wa-Ter and AdmixturesDocument41 pagesChapter 6 - Portland Cement, Mix Wa-Ter and AdmixturesLucas NguyenNo ratings yet

- Pipe Moc StressDocument7 pagesPipe Moc StressShivakumarNo ratings yet

- Group II Cation Analysis LabDocument3 pagesGroup II Cation Analysis LabNight RaveNo ratings yet

- ESR - 3572 FisherDocument29 pagesESR - 3572 FisherReinel OrjuelaNo ratings yet

- Kisa Chemistry Ak 094030Document7 pagesKisa Chemistry Ak 094030spiderglitch2099No ratings yet

- Modern and Contemporary Art Auction CatalogueDocument79 pagesModern and Contemporary Art Auction CataloguebhatepoonamNo ratings yet

- Design and Fabrication of Spur Gear Using Palm Fiber and Aluminum CompositeDocument21 pagesDesign and Fabrication of Spur Gear Using Palm Fiber and Aluminum Compositesabhari_ramNo ratings yet

- Aisi 4140 SteelDocument3 pagesAisi 4140 SteelduhkacttusNo ratings yet

- Cbse Sample Paper For Class 11 ChemistryDocument11 pagesCbse Sample Paper For Class 11 ChemistryAshutosh RautNo ratings yet

- Mech - 2010 PDFDocument8 pagesMech - 2010 PDFmurthy gNo ratings yet

- Active Doc ListDocument310 pagesActive Doc Listsalman1111aNo ratings yet

- Unit Operations and Processes of Water Treatment Systems: Subject Code: CE 305 Subject Name: Water Supply EngineeringDocument23 pagesUnit Operations and Processes of Water Treatment Systems: Subject Code: CE 305 Subject Name: Water Supply EngineeringDipankar NathNo ratings yet

- Petcoke Guide: Green, Calcined, Properties & HandlingDocument14 pagesPetcoke Guide: Green, Calcined, Properties & HandlingYevgeniy R100% (2)

- Solute Solvent Science ExamDocument3 pagesSolute Solvent Science ExamLouie Jane EleccionNo ratings yet

- Idges 25-28 PDFDocument37 pagesIdges 25-28 PDFjaganramNo ratings yet

- Bartec GlandDocument2 pagesBartec GlandjagateesanNo ratings yet

- Concept Note For (Waste Cotton To Rayon)Document12 pagesConcept Note For (Waste Cotton To Rayon)fekadeNo ratings yet

- Reference Guide Babbit BearingDocument21 pagesReference Guide Babbit BearingsnhmNo ratings yet

- Service Connections - Straps and FerrulesDocument8 pagesService Connections - Straps and FerrulesDon Clerance Denzil WeerakkodyNo ratings yet

- Argos Usa - Cements For MasonryDocument39 pagesArgos Usa - Cements For MasonryPeter Jean-jacques0% (1)

- Borang Pengiraan StokDocument13 pagesBorang Pengiraan StokLarry IchiroNo ratings yet

- ASTM D 1142 - 95 (Reapproved 2006)Document11 pagesASTM D 1142 - 95 (Reapproved 2006)Julian Felipe Noguera CruzNo ratings yet

- Haryana Chamber of Commerce and Industry Panipat Members ListDocument34 pagesHaryana Chamber of Commerce and Industry Panipat Members ListPriya Palanisamy100% (1)