Professional Documents

Culture Documents

Ultraform N 2320 003 UNC Q600: Polyoxymethylene (POM)

Uploaded by

juliushasan2Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ultraform N 2320 003 UNC Q600: Polyoxymethylene (POM)

Uploaded by

juliushasan2Copyright:

Available Formats

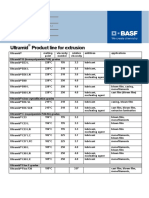

Product Information Ultraform® N 2320 003 UNC

Feb 2020 Q600

Polyoxymethylene (POM)

Product Description

Ultraform N 2320 003 UNC Q600 is a rapidly freezing general-purpose injection-molding POM

grade. It contains a mold release agent.

Applications

Typical applications include spring elements, clips, gas filler caps, gear wheels, small motor parts,

curtain hooks and release buttons for safety belts.

PHYSICAL ASTM Test Method Property Value

Specific Gravity D-792 1.40

Mold Shrinkage (1/8" bar, in/in) 0.02

Moisture, % D-570

(50% RH) 0.2

(Saturation) 0.8

MECHANICAL ASTM Test Method Property Value

Tensile Strength, Yield, MPa (psi) D-638

23C (73F) 65 (9,430)

Elongation, Yield, % D-638

23C (73F) 9.4

Flexural Modulus, MPa (psi) D-790

23C (73F) 2,470 (358,000)

IMPACT ASTM Test Method Property Value

Notched Izod Impact, J/M (ft-lbs/in) D-256

-40C (-40F) 59.8 (1.1)

23C (73F) 69.4 (1.3)

THERMAL ASTM Test Method Property Value

Melting Point, C(F) D-3418 167 (332)

Heat Deflection @ 264 psi (1.8 MPa) C(F) D-648 99 (210)

Heat Deflection @ 66 psi (.45 MPa) C(F) D-648 154 (309)

Coef. of Linear Thermal Expansion, mm/mm C E-831 0.6 X10-4

(in/in F)

UL RATINGS UL Test Method Property Value

Flammability Rating, 1.5mm UL94 HB

Relative Temperature Index, 1.5mm UL746B

Mechanical w/o Impact, C 90

Mechanical w/ Impact, C 90

Electrical, C 105

Flammability Rating, 3.0mm UL94 HB

Relative Temperature Index, 3.0mm UL746B

Mechanical w/o Impact, C 105

Mechanical w/ Impact, C 90

Electrical, C 105

ELECTRICAL ASTM Test Method Property Value

BASF Corporation General Information: 800-BC-RESIN

Engineering Plastics Technical Assistance: 800-527-TECH (734-324-5150)

1609 Biddle Avenue Web address: http://www.plasticsportal.com/usa

Wyandotte, MI 48192 Page 1 of 2

Ultraform® N 2320 003 UNC Q600

Volume Resistivity (Ohm-m) D-257 1E13

Surface Resistivity (Ohm) D-257 1E13

Processing Guidelines

Material Handling

Max. Water content: 0.15%

Product is supplied in polyethylene bags and drying prior to molding is not required. However, after

relatively long storage or when handling material from previously opened containers, preliminary

drying is recommended in order to remove any moisture which has been absorbed. If drying is

required, a dehumidifying or desiccant dryer operating at 80 - 110C (176 - 230F) is recommended.

Drying time is dependent on moisture level, however 2-4 hours is generally sufficient. Further

information concerning safe handling procedures can be obtained from the Safety Data Sheet.

Alternatively, please contact your BASF representative.

Typical Profile

Melt Temperature 190-230C (375-446F)

Mold Temperature 60-120C (140-248F)

Injection and Packing Pressure 35-70 bar (500-1000psi)

Mold Temperatures

A mold temperature of 80-90C (176-194F) is recommended, however temperatures of as low as

45C (113F) and as high as 105C (221F) can be used where applicable.

Pressures

Injection speed must be optimized. A filling rate which is too high results in anisotropic mechanical

properties, while a filling rate which is too low yields parts with poor surface finish. The tool must be

vented to avoid burn marks and prevent mold deposits. Injection pressure controls the filling of the

part and should be applied for 90% of ram travel. Packing pressure affects the final part and can be

used effectively in controlling sink marks and shrinkage. It should be applied and maintained until

the gate area is completely frozen off.

Back pressure can be utilized to provide uniform melt consistency and reduce trapped air and gas.

Fill Rate

Injection speed must be optimized. A filling rate which is too high results in anisotropic mechanical

properties, while a filling rate which is too low yields parts with poor surface finish. The tool must be

vented to avoid burn marks and prevent mold deposits.

Note

Although all statements and information in this publication are believed to be accurate and reliable,

they are presented gratis and for guidance only, and risks and liability for results obtained by use of

the products or application of the suggestions described are assumed by the user. NO

WARRANTIES OF ANY KIND, EITHER EXPRESS OR IMPLIED, INCLUDING WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE, ARE MADE REGARDING

PRODUCTS DESCRIBED OR DESIGNS, DATA OR INFORMATION SET FORTH. Statements or

suggestions concerning possible use of the products are made without representation or warranty

that any such use is free of patent infringement and are not recommendations to infringe any

patent. The user should not assume that toxicity data and safety measures are indicated or that

other measures may not be required.

BASF Corporation General Information: 800-BC-RESIN

Engineering Plastics Technical Assistance: 800-527-TECH (734-324-5150)

1609 Biddle Avenue Web address: http://www.plasticsportal.com/usa

Wyandotte, MI 48192 Page 2 of 2

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Brochure-Kynar & Kynarflex For Cables 04-2002Document16 pagesBrochure-Kynar & Kynarflex For Cables 04-2002juliushasan2No ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Flexpro R80 MSDSDocument3 pagesFlexpro R80 MSDSjuliushasan2No ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- MSDS Rilsan B, K and L Moulding (13.04.2017)Document10 pagesMSDS Rilsan B, K and L Moulding (13.04.2017)juliushasan2No ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Mitsui Pet Sa 145Document1 pageMitsui Pet Sa 145juliushasan2No ratings yet

- Morpholine PDSDocument1 pageMorpholine PDSjuliushasan2No ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- RILSAN® BESN NOIR P20 TLDocument5 pagesRILSAN® BESN NOIR P20 TLjuliushasan2No ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- FCP Vultac 5 - v5Document1 pageFCP Vultac 5 - v5juliushasan2No ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- MSDS Rilsan BESNDocument10 pagesMSDS Rilsan BESNjuliushasan2No ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- EKALAND & VULTAC Range For: Rubber ApplicationDocument1 pageEKALAND & VULTAC Range For: Rubber Applicationjuliushasan2No ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Rubber ChemistryDocument94 pagesRubber ChemistryOğuzhan TuranNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- AIBN Radikal Polimerisasi InisiasiDocument13 pagesAIBN Radikal Polimerisasi Inisiasijuliushasan2No ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Kynar PVDF Components - Solving The World'S Water ChallengesDocument8 pagesKynar PVDF Components - Solving The World'S Water Challengesjuliushasan2No ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- MSDS ZbecDocument10 pagesMSDS Zbecjuliushasan2No ratings yet

- MSDS Sc-1100urDocument8 pagesMSDS Sc-1100urjuliushasan2No ratings yet

- Ultramid Product Range (Extrusion)Document2 pagesUltramid Product Range (Extrusion)juliushasan2No ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Rilsamid® Aesno TL: Main CharacteristicsDocument2 pagesRilsamid® Aesno TL: Main Characteristicsjuliushasan2No ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Hydrazine Hydrate Safety Data SheetDocument16 pagesHydrazine Hydrate Safety Data Sheetjuliushasan2No ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Tpex Flexpro R80Document1 pageTpex Flexpro R80juliushasan2No ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Estane Skythane S190A TPU: TypeDocument2 pagesEstane Skythane S190A TPU: Typejuliushasan2No ratings yet

- Azdn E: 2,2' Azobis Isobutyronitrile - AZDN - AIBN C H NDocument2 pagesAzdn E: 2,2' Azobis Isobutyronitrile - AZDN - AIBN C H Njuliushasan2No ratings yet

- Ultramid B40 L: Product InformationDocument2 pagesUltramid B40 L: Product Informationjuliushasan2No ratings yet

- Declaration of Rohs Status: Soul Best Co., LTDDocument1 pageDeclaration of Rohs Status: Soul Best Co., LTDjuliushasan2No ratings yet

- Tertiododecylmercaptan: Specifications Values MethodsDocument1 pageTertiododecylmercaptan: Specifications Values Methodsjuliushasan2No ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- BESN Noir P20 TLDocument2 pagesBESN Noir P20 TLjuliushasan2No ratings yet

- Dfg1 IV 1.1 - 1.34: Item UnitDocument1 pageDfg1 IV 1.1 - 1.34: Item Unitjuliushasan2No ratings yet

- 20200626-Arkema Solutions For Personal Protective Equipment-PPEDocument13 pages20200626-Arkema Solutions For Personal Protective Equipment-PPEjuliushasan2No ratings yet

- Estane Skythane S185A TPU: TypeDocument1 pageEstane Skythane S185A TPU: Typejuliushasan2No ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Rilsamid® Aesno TL: Main CharacteristicsDocument2 pagesRilsamid® Aesno TL: Main Characteristicsjuliushasan2No ratings yet

- Inspirasi OtomotifDocument1 pageInspirasi Otomotifjuliushasan2No ratings yet

- Cse Reviewer - MathDocument58 pagesCse Reviewer - MathLyne LerinNo ratings yet

- 3 Pipe Mod For Vectra BDocument2 pages3 Pipe Mod For Vectra BEmirhan DöngelNo ratings yet

- Thyrotronic enDocument4 pagesThyrotronic enVladimirNo ratings yet

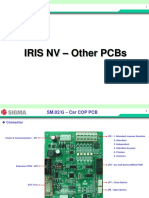

- 07 IRIS NV PCB OtherDocument15 pages07 IRIS NV PCB OtherArnaldo cordovaNo ratings yet

- Fit For WashingDocument85 pagesFit For WashingIyaka YoeNo ratings yet

- Generador APD550PEDocument4 pagesGenerador APD550PEFTL1990No ratings yet

- Manufacturing Airbrushes Since 1904Document20 pagesManufacturing Airbrushes Since 1904Sa MiNo ratings yet

- Midwifery All Year ProgramDocument3 pagesMidwifery All Year Programfiraol mokonnenNo ratings yet

- Chap 5. Beam Analysis and Design PDFDocument61 pagesChap 5. Beam Analysis and Design PDFRafael Joshua LedesmaNo ratings yet

- GLOBAL GAME AFK IN THE ZOMBIE APOCALYPSE GAME Chapter 201-250Document201 pagesGLOBAL GAME AFK IN THE ZOMBIE APOCALYPSE GAME Chapter 201-250ganesh sarikondaNo ratings yet

- SteelsDocument72 pagesSteelsLLNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Computer Engineering SyllabusDocument47 pagesComputer Engineering SyllabusLily ChanNo ratings yet

- PSUTIL Documentation for Monitoring System ResourcesDocument77 pagesPSUTIL Documentation for Monitoring System ResourcesImam RiadiNo ratings yet

- Simulation of bitumen upgrading processes modelling and optimisationDocument6 pagesSimulation of bitumen upgrading processes modelling and optimisationDonato MontroneNo ratings yet

- FLIR Blackfly Users ManualDocument53 pagesFLIR Blackfly Users ManualPavan Kumar BittuNo ratings yet

- AbstractDocument2 pagesAbstractramyaNo ratings yet

- Pharmaceutical Ingredients and Excipient - LastpptDocument72 pagesPharmaceutical Ingredients and Excipient - LastpptFANTANo ratings yet

- Diagrama 4 AMBIENT AIR TEMPER..Document1 pageDiagrama 4 AMBIENT AIR TEMPER..Gustavo PérezNo ratings yet

- Validation of Correlations Between A NSPT PDFDocument12 pagesValidation of Correlations Between A NSPT PDFAgus WahyudiNo ratings yet

- QRP Yu1lm SDR-RX TXDocument299 pagesQRP Yu1lm SDR-RX TXD BNo ratings yet

- Kyle 106 - 119 - 131 - 141Document1 pageKyle 106 - 119 - 131 - 141Gerson SouzaNo ratings yet

- Conduction Calorimetric Investigation of The Effect of Retarders On The Hydration of Portland CementDocument15 pagesConduction Calorimetric Investigation of The Effect of Retarders On The Hydration of Portland CementAlfredo Landaverde GarcíaNo ratings yet

- Ras Abu Aboud Stadium Daily Report 040 (20190613)Document4 pagesRas Abu Aboud Stadium Daily Report 040 (20190613)tuan50% (2)

- Pip Venix LRDocument2 pagesPip Venix LRThanh VoNo ratings yet

- Ship Construction: Second Mates - HANDOUTDocument117 pagesShip Construction: Second Mates - HANDOUTmaneeshNo ratings yet

- Partial Discharge - Open ElectricalDocument2 pagesPartial Discharge - Open ElectricalBHALAJI BIRLANo ratings yet

- Fair Directory 02-2016Document44 pagesFair Directory 02-2016Ravichandran SNo ratings yet

- Anchor Systems.: Hilti. Outperform. OutlastDocument49 pagesAnchor Systems.: Hilti. Outperform. Outlastthapa786mNo ratings yet

- STP1236 Eb.1415051 1 PDFDocument208 pagesSTP1236 Eb.1415051 1 PDFpaolaNo ratings yet

- The Storage Handling and Transportation of Ammonium Nitrate Based Fertilisers 2015Document58 pagesThe Storage Handling and Transportation of Ammonium Nitrate Based Fertilisers 2015Minh Đức TạNo ratings yet

- Functional Safety from Scratch: A Practical Guide to Process Industry ApplicationsFrom EverandFunctional Safety from Scratch: A Practical Guide to Process Industry ApplicationsNo ratings yet

- The ISO 45001:2018 Implementation Handbook: Guidance on Building an Occupational Health and Safety Management SystemFrom EverandThe ISO 45001:2018 Implementation Handbook: Guidance on Building an Occupational Health and Safety Management SystemNo ratings yet

- Introduction to Petroleum Process SafetyFrom EverandIntroduction to Petroleum Process SafetyRating: 3 out of 5 stars3/5 (2)

- A Poison Like No Other: How Microplastics Corrupted Our Planet and Our BodiesFrom EverandA Poison Like No Other: How Microplastics Corrupted Our Planet and Our BodiesRating: 5 out of 5 stars5/5 (1)

- Trevor Kletz Compendium: His Process Safety Wisdom Updated for a New GenerationFrom EverandTrevor Kletz Compendium: His Process Safety Wisdom Updated for a New GenerationNo ratings yet

- A Complete Guide to Safety Officer Interview Questions and AnswersFrom EverandA Complete Guide to Safety Officer Interview Questions and AnswersRating: 4 out of 5 stars4/5 (1)

- Guidelines for Initiating Events and Independent Protection Layers in Layer of Protection AnalysisFrom EverandGuidelines for Initiating Events and Independent Protection Layers in Layer of Protection AnalysisRating: 5 out of 5 stars5/5 (1)