Professional Documents

Culture Documents

Manual Grimme GT300

Uploaded by

FabianoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Manual Grimme GT300

Uploaded by

FabianoCopyright:

Available Formats

GT 300

The new special class: 3-row, trailed elevator harvester

GT 300: the new

performance class

The new trailed elevator harvester GT 300, harvests innovative share depth guidance TERRA-CONTROL,

one row more with every pass. Advantage – this which is gentle to the harvest and maximising

simply means 50 % more performance! The yield – and thanks to the separators MULTISEP

operator has a clear view of the digging units and and the high-performance double MULTISEP,

the large sieving areas due to the proven frame harvesting is possible on any type of soil.

and drive design. Grimme ensures the highest Harvest success with the GT 300, because it

impact force and best results based on our gets more done.

For your maximum success:

the new MAXI-Bed system

Basically there is a difference between harvested in the fall with a two-row Grimme has developed the new bed

two cultivation systems, the traditional machine. Allied to this, vegetables former BF 300, the soil separator

system to plant the potatoes in rows are cultivated on 1.5 m wide and CS 240 and the soil tilla RT 280,

and the so-called bed-separated 1.8 m wide beds. With the new the planter GL 33 T and the elevator

system. With the latter method, two MAXI-Bed system, a 2.7 m wide bed harvester GT 300.

rows are planted into a previously is formed and three rows of potatoes

separated 1.8 m wide bed and are planted in it. For this new system,

MAXI-BED SYSTEM

4

Advantages of the MAXI-Bed system

1. 10 % higher net cultivation surface 5. Shorter time for transport vehicles in the

and hence higher yield field, leading to higher impact logistics

2. 50 % higher hectare performance 6. Unproductive turning times on the

due to the 1.5 times wider bed headland are considerably less

3. Improved water management due to 7. The MAXI-Bed system can also

wider beds and less traffic in the beds be used for potato growing

4. Much higher seasonal performance 8. Less edges for damaging rows

than regular system resulting

in a reduction in operating costs

Comparison between

conventional systems and

the MAXI-Bed system:

Instead of 1.8 m track width, the

MAXI-Bed works with a width of

2.7 m. This reduces passes. The

number of plants which grow

under different light conditions

at the edge of the bed is

reduced considerably. Therefore,

the MAXI-Bed ensures more

homogenous goods.

GT 300: This machine

“makes a great impression” –

not only for potatoes

but also for numerous

other vegetables.

MAXI-BED SYSTEM

Grimme machines for a new

cultivation system: the MAXI-Bed!

The MAXI-Bed places proven

1.8 m 1.8 m 1.8 m system steps onto a new, wide

basis. Machines widths are

5.4 m aligned during bed forming , via

separating (1) and planting (2)

all the way to the harvest. They

provide 50 % more surface yield

during each work sequence.

2.7 m 2.7 m

5.4 m

CS 240 (1): Sieve the stones and

1 crush the clods: This gives an evenly

aerated bed and will provide optimal

growth conditions for potatoes and

other vegetables – and this in a

whole new width.

GL 33 T (2): The new 3-row

2 planter for the planting of

potatoes in 3-row bed.

GT 300

Combining the proven and the new:

4-row planting and 3-row harvesting

Real life shows that it works:

1 4-row planting with GPS

technology (1) ensures exact,

even row spacing. This ensures

harvesting in 3 rows.

Harvesting with the offset system:

2 3 the tractor drives over 2 instead of

3 rows (2), the GT 300 continues

offset behind the tractor and

therefore harvests an additional

row to the left of the tractor.

Avoid lateral forces on the

machine: The wide tractor track (3)

drives over 3 rows, the GT 300

follows centered behind the tractor.

Grimme offers you the

4 alternative: Usually, potatoes

that are harvested in 3 rows (4)

are also planted in 3 or 6 rows.

We give you the choice.

The look into the new dimension:

5 3-row digging with the GT 300 (5).

The proven straight-lined harvest

flow and the slight incline of the

main webs make this machine

very gentle to the crop and ensure

high performing.

GT 300

Individual solutions

in a new dimension!

Different weather conditions, different soil types, a number of potato

varieties and many, many more factors. – Briefly said: Harvesting

conditions change from one harvest to the next. If looking for more

than standard solutions, the GT 300 offers the right answer: Equip the

machine according to the requirements and move up to the new 3-row

performance class. Harvest success – with 50 % more performance!

11

6

3 8

9

7 10

1

4

2

6

5

1 Tractor connection 3 Cable conduit to protect 5 Intake web 7 Haulm roller 10 Transfer web

540 or 1,000 U/min. the electric cables and against main web (a short and a

6 1st main web with

2 Drawbar eye

hydraulic hoses long transfer web)

agitator models 8 2 nd main web

below or hitch 4 Swing frame with 11 Cart elevator

9 MULTISEP

intake unit

I N TA K E

Hydraulic ridge relief (option):

Work better without pressure.

And dig. The DLG awarded “Grimme

Innovation 2005”: TERRA-CONTROL!

This is how the GT 300 will become

even more effective: with TERRA-

CONTROL, the hydraulic share depth

guidance system with integrated

ridge pressure adjustment. The swing

4

frame (1) is held in place by two

cylinders (2). With TERRA-CONTROL,

the diablo rollers (3) are supported

by two special hydraulic cylinders

with integrated distance measuring

system (4). These hydraulic cylinders 1

register every deviation of the ridge 4

crown height and transmit the signal 2

electro-hydraulically to the two swing

frame cylinders. The result: The

digging depth and the ridge pressure 3

remain constant – at any time and

with any ground contour –

individually in every row!

SIEVING SUPPORT H A U L M S E PA R A T I O N

The GT 300 is standard equipped

1 3 with a rotor agitator (1). A swing

agitator (2) is available as an

option for a more gentle screening

process.

The combination of a spiral segment

roller with a double haulm roller

2 3 into one haulm system (option) (3)

ensures that the potatoes are not

separated against the bars of the

main web but against a soft spiral

segment roller.

S E PA R A T O R S

For universal use: the 4-lip

1 spiral segment rollers are

standard for the MULTISEP

4-Lip-Spiral-Segment.

With the Grimme MULTISEP (1) one

For difficult harvesting conditions: has the ability to separate thrash

the 3-lip spiral segment rollers effectively and without losses – even

with a lip height of 10 mm are

used for better soil separation

on cloddy, sticky and soil with small

for medium to large potatoes stones: 4 pairs of rollers, consisting

in the MULTISEP. of a chosen PU spiral segment roller

as well as a rubber-coated smooth

For extremely wet harvesting

roller make a “clean slate”. For very

conditions: the 3-lip spiral

segment rollers with a lip height

small or loose-skinned potatoes and

of 20 mm are used for large for vegetable harvesting, smooth

potatoes in the MULTISEP. steel rollers are also available.

A Steel spiral roller for dry soils with The Roller separator RS (2): an

2 stones and hard clods option for tough cases. Even

extremely heavy, sticky soils and

B Rubber spiral roller (basic equipment)

the most adverse digging

for universal use

conditions are not a problem for

C Rubber smooth roller ø 90 mm the roll separator – consisting of

D Rubber smooth roller ø 85 mm 12 rubber-coated roller pairs

arranged the long way (a spiral

E Rubber smooth roller ø 80 mm and a smooth roller together).

F Rubber smooth roller ø 75 mm There are a total of 8 models

available for different conditions.

G Rubber smooth roller ø 70 mm

H Steel smooth roller for use on dry soils

A B C D E F G H

More success with the double

3 4 pack: Combine the MULTISEP (3)

or the Roller separator (4) with an

additional MULTISEP. The separator

units can be operated separately

in their feeding and cleaning

performance; therefore, they can

react optimally to changing

conditions.

TRANSFER ELEVATOR

Deep unloading – high flexibility:

the innovative transfer technique

Evenly good: the transfers in the A very gentle feeding. Highest possible

elevator. A two-piece transfer web, 1

consisting of a long and a short flexibility. And 160 t/h feed performance! –

supply web (1) warrants a steady This makes the cart elevator of the GT 300

and even fill of the 1.2 m wide

transfer elevator or a high- so special. The active lateral parts as well

performance transfer.

as the length and flexibility of the elevator

One step better: Due to the length

of the cart elevator, high transport

ensure a smooth and gentle feeding of the

vehicles are no longer a problem. harvest stream.

The head dips deep into the cart (2)

8 and ensures low drops.

Reverse: With the optional function

of windrowing, the cart elevator can 3 4

be reversed. I.e. the deposit funnel

ensures the swath deposit between

the two adjacent rows (3).

Gently treated all the way into

the box: With the optional box

fill funnel (4), the potatoes are

transported very gently deep

into the box.

Harvest success gently: The cart elevator

dips deep into the transfer vehicle. It

transfers the potatoes through the 1.2 m

wide pockets gently.

MACHINE CONTROL

Simple. Comfortable. Intelligent:

the machine control by Grimme

With the VC 50 control terminal (B), all

adjustments can be comfortably and

intuitively made via a touch screen. The

A intelligent electronics offers the opportunity

to directly analyse and repair faults. The

additional GBX box (C) can be freely

programmed. Thus, the axle steering or

the levelling of the machine can be 9

adjusted via the joysticks. Respond faster:

The option CAN bus controlled video

B surveillance system VISUAL-PROTECT

allows an all-round functional monitoring

D

of the harvester. If there is a problem

This is how to retain an

with the machine, the monitor will overview: With the video

cameras (option) (D) and

C automatically switch to the respective monitor (option) (A) the

camera. The driver can immediately operator will no longer miss

a thing whilst harvesting.

gain an impression of the problem.

WHEEL DRIVE

Drive in the track of success

Stable in the field – compact

1 2 on the road. In spite of its

impressive dimensions (1), the

machine can be driven on

any road that is 3.3 m wide (2)

without any problem. For

this, the right tyre can be

hydraulically retracted and

extended.

Harvest in a relaxed manner –

3 even under the most adverse

conditions: with the hydrostatic

wheel drive (option) (3).

The correct tyres

for every use:

A B C

A 500/60-22.5

(standard tyres)

B 600/50-22.5

C 600/55-26.5

Technical data

GT 300

Measurement

Length From 10,730 mm

Width From 3,280 mm

Height 3,360 mm

Weight Depending on the model from 8,600 kg

Required power From 95 kW/130 HP

Basic equipment Option

Axle Hydraulic axle steering (displays on Self-centring steering

the operating terminal) Hydrostatic wheel drive

Levelling on the right hand side Automatic levelling

Tyres 500/60-22.5 (standard) 600/50-22.5; 600/55-26.5

Compressed air brake (standard in Germany)

Hydraulic brake (standard in some countries)

Drawbar Choice of towing eye with ø 40, ø 50 or extra long Hydraulic drawbar steering

hitch coupling with ø 50 mm

Intake 3 shares, 2- or 3-piece Centre share

540, 580 or 620 mm intake width per row, Bed digging unit

750 to 900 mm row width Vegetable digging unit

Pulled diablo rollers and disc coulters TERRA-CONTROL (hydraulic share depth guidance with integrated

diablo pressure adjustment)

Hydraulic ridge relief

Intake web 2,230 mm wide, separating surface 3.45 m 2 –

Choice of pitch 28/32/35/40/45/50 mm

1st main web 2,230 mm wide Rubber-coated bars

Separating surface 7.4 m 2 Additional swing agitator

Choice of pitch 28/32/35/40/45/50 mm Hydraulic height adjustment of the rotor agitator

Bar diameter 9/10/10/10/11/11 mm Further options: agitation unit, cleaning basket, clod breaker

Hydraulic rotor agitator height-adjustable

Pitch independent rubber drive

1st separator Extracting roller directly against 1st main web Extracting unit: segment roller with double roller

2 nd main web 2,230 mm wide, separating surface 2.09 m2 Rubber-coated bars

Choice of pitch 28/32/35/40/45/50 mm

Separator for trash – MULTISEP/Double-MULTISEP

and haulm separation Roller separator

TwinSep/Bypass-kit (for the roller separator)

2nd separator Extracting roller directly against 2 nd main web –

Transfer web A long and a short transfer web for –

the even filling of the cart elevator

Cart elevator Hydraulic drive, capacity 120 t/h, transfer width Windrowing on the left between the rows

3,500 mm, transfer height 4,000 mm Box filling chute

Machine operation VC 50 operating terminal Monitor with video cameras

VISUAL-PROTECT

02/10/1000

Your Grimme Partner for advice and service:

L05.0917.EN

We reserve the right of alterations.

Grimme Landmaschinenfabrik GmbH & Co. KG · Hunteburger Straße 32 · D-49401 Damme

Phone +49 5491 666-0 · Fax +49 5491 666-2298

grimme@grimme.de · www.grimme.com

You might also like

- The Machinery of Grain Production - With Information on Threshing, Seeding and Repairing the Machinery of Grain Production on the FarmFrom EverandThe Machinery of Grain Production - With Information on Threshing, Seeding and Repairing the Machinery of Grain Production on the FarmNo ratings yet

- GB Separating TechnologyDocument11 pagesGB Separating TechnologySooraj Kannan, P.V.No ratings yet

- Type2 1200 1600 Shop Manual PDFDocument258 pagesType2 1200 1600 Shop Manual PDFYenni Katherine Jaimes GallardoNo ratings yet

- Jinma20 30a PDFDocument73 pagesJinma20 30a PDFMark ONo ratings yet

- 455zx - Brochure PDFDocument16 pages455zx - Brochure PDFDhru Ti100% (1)

- Capello Bro Quasar en 2016Document8 pagesCapello Bro Quasar en 2016AdamNo ratings yet

- Kubota M7500Document2 pagesKubota M7500Pinto RaharjoNo ratings yet

- TPCD1350E4Document370 pagesTPCD1350E4Andrei BaiNo ratings yet

- Agt Tractor Broshure English enDocument6 pagesAgt Tractor Broshure English enLuciusNo ratings yet

- ENTAM+recogs - 05.217 Caffini - Starter 3300 24 BL AirDocument9 pagesENTAM+recogs - 05.217 Caffini - Starter 3300 24 BL AirPaul DanNo ratings yet

- Sonalika WT 90Document2 pagesSonalika WT 90Vivek SapariaNo ratings yet

- AG150 250 Part 3Document6 pagesAG150 250 Part 3aritmeticsNo ratings yet

- Brake & Clutch Master CylindersDocument37 pagesBrake & Clutch Master CylindersMarcin Wośko100% (1)

- 75 76 OverhaulDocument46 pages75 76 OverhaulAntidottoNo ratings yet

- S 70302UR2-ZetorDocument94 pagesS 70302UR2-ZetorBrent HNo ratings yet

- Belarus 1523-EngDocument210 pagesBelarus 1523-Engpaky1111No ratings yet

- Agrimir Tractor PartsDocument13 pagesAgrimir Tractor Partsinfo2481No ratings yet

- Megu Bushing: Silent Block (MEGU-seal) - 647429 Claas - ReinforcedDocument5 pagesMegu Bushing: Silent Block (MEGU-seal) - 647429 Claas - ReinforcedGiorgi100% (1)

- 3975 Mint Chopper Paerts ManualDocument252 pages3975 Mint Chopper Paerts ManualRayNo ratings yet

- Casqe IhDocument244 pagesCasqe IhAlvaro GarciaNo ratings yet

- Manual Datos Tecnicos ZetorDocument127 pagesManual Datos Tecnicos ZetoredhuamNo ratings yet

- Same Laser 125 150 2009Document2 pagesSame Laser 125 150 2009Silvia De Pedro CamoeirasNo ratings yet

- 6100-6900 SerieDocument1 page6100-6900 Serieinfo7879No ratings yet

- ZX17U-2 - Specs Ecxa HitachiDocument4 pagesZX17U-2 - Specs Ecxa HitachiGalib Imam MarhaenNo ratings yet

- Cih CvxbrochureDocument24 pagesCih CvxbrochurePatrik GubinaNo ratings yet

- Track-Type Tractor: Engine - XL/LGP WeightsDocument20 pagesTrack-Type Tractor: Engine - XL/LGP WeightsRas-Sherwin A. Jalani100% (2)

- Massey FergusonDocument28 pagesMassey FergusonDyfanNo ratings yet

- B50 Rops enDocument8 pagesB50 Rops engioconda122No ratings yet

- 2012 Duetz TractorsDocument47 pages2012 Duetz TractorsAgus Yulfizar100% (1)

- Agricultural Tractors Brake Performance TestDocument7 pagesAgricultural Tractors Brake Performance Testniloy_67No ratings yet

- SB Series BreakersDocument12 pagesSB Series BreakersManuel Pedro InácioNo ratings yet

- Cali Brat or 2003Document50 pagesCali Brat or 2003EuroTech - KarolNo ratings yet

- Catalog Piese BalotiereDocument51 pagesCatalog Piese BalotiereSava SergiuNo ratings yet

- Broshure Face Master 1.4Document3 pagesBroshure Face Master 1.4lorenzo henerNo ratings yet

- Westfield WR AugerDocument16 pagesWestfield WR AugerAlvaro GarciaNo ratings yet

- Acme A349 Service ManualDocument34 pagesAcme A349 Service ManualCristian DavidNo ratings yet

- Massey Ferguson 7600 Engine ComponentsDocument15 pagesMassey Ferguson 7600 Engine ComponentsVasile PopoviciNo ratings yet

- 6 Different Excavator Types & Their Uses - BigRentzDocument11 pages6 Different Excavator Types & Their Uses - BigRentzShuvoVattNo ratings yet

- 8018 BrochurDocument12 pages8018 BrochurGábor KutasiNo ratings yet

- Compact Track Loaders: CT322 CT332Document16 pagesCompact Track Loaders: CT322 CT332Christopher SchabenNo ratings yet

- New Cx8000 Elevation: Super Conventional CombinesDocument12 pagesNew Cx8000 Elevation: Super Conventional CombinesAnonymous 1XBCMXNo ratings yet

- 6 Speed Transmission Gears & Related PartsDocument5 pages6 Speed Transmission Gears & Related PartsMarcela Liliana MolnarNo ratings yet

- XTX PDFDocument338 pagesXTX PDFAndrei MihaiNo ratings yet

- ContiTech RubberTrack Manual WarrantyGuide enDocument61 pagesContiTech RubberTrack Manual WarrantyGuide eneastNo ratings yet

- DF-904 Parts ManualDocument185 pagesDF-904 Parts ManualAldo ChavezNo ratings yet

- UntitledDocument31 pagesUntitledMarcelo Baeza TalentoNo ratings yet

- Indo Farm Company Profile PDFDocument28 pagesIndo Farm Company Profile PDFƎɯox SatíshNo ratings yet

- CoximDocument16 pagesCoximRoberto MarianoNo ratings yet

- Manual Transmission & Transaxle PDFDocument33 pagesManual Transmission & Transaxle PDFtavi2meNo ratings yet

- Filtri Landini PDFDocument59 pagesFiltri Landini PDFAndrei MihaiNo ratings yet

- Competence in Baling.: 30 Years of Claas RollantDocument24 pagesCompetence in Baling.: 30 Years of Claas RollantJózsef CsendesNo ratings yet

- Instrukcja Obsługi I Katalog Cześci URSUS C-330 PDFDocument332 pagesInstrukcja Obsługi I Katalog Cześci URSUS C-330 PDFElzbieta RynNo ratings yet

- Hatat Workshop MannualDocument327 pagesHatat Workshop MannualKissLászloNo ratings yet

- Swaraj Price ListDocument277 pagesSwaraj Price ListAdarsh SPARECARENo ratings yet

- Application Center Municipal VehiclesDocument8 pagesApplication Center Municipal VehiclesQXNNo ratings yet

- 2-Row, Offset Trailed Potato Harvester With Large Bunker and High Separating Performance in All SoilsDocument7 pages2-Row, Offset Trailed Potato Harvester With Large Bunker and High Separating Performance in All SoilsFabianoNo ratings yet

- Deutz Fahr - C7000 PDFDocument28 pagesDeutz Fahr - C7000 PDFArkadiusz KowalskiNo ratings yet

- Adx 2023 EngDocument8 pagesAdx 2023 Engr.gorunescuNo ratings yet

- Plansifter Quadro - DpakDocument4 pagesPlansifter Quadro - DpakManuel Javier G'No ratings yet

- 2559 Lex l2 500 Series - 1209 - Sing DataDocument40 pages2559 Lex l2 500 Series - 1209 - Sing DataДмитро ВівсянникNo ratings yet

- Grimme 260 DDDocument3 pagesGrimme 260 DDFabianoNo ratings yet

- ML Pro Leaflet Feb 16Document1 pageML Pro Leaflet Feb 16FabianoNo ratings yet

- Unistar: High Capacity Soil SeparatorDocument6 pagesUnistar: High Capacity Soil SeparatorFabianoNo ratings yet

- 1-Row, Offset Trailed Potato Harvester With Large BunkerDocument18 pages1-Row, Offset Trailed Potato Harvester With Large BunkerFabianoNo ratings yet

- 2-Row Potato Topper: Powerful, Efficient, ReliableDocument2 pages2-Row Potato Topper: Powerful, Efficient, ReliableFabianoNo ratings yet

- MANUAL COLHEDEIRA Dewulf KwatroDocument10 pagesMANUAL COLHEDEIRA Dewulf KwatroFabianoNo ratings yet

- Manual R3060 Gii Eng LRDocument20 pagesManual R3060 Gii Eng LRFabiano100% (1)

- 2-Row, Offset Trailed Potato Harvester With Large Bunker and High Separating Performance in All SoilsDocument7 pages2-Row, Offset Trailed Potato Harvester With Large Bunker and High Separating Performance in All SoilsFabianoNo ratings yet

- Potato Harvester: in Partnership With ProfessionalsDocument2 pagesPotato Harvester: in Partnership With ProfessionalsFabianoNo ratings yet

- Haulm Cutter: Solves Problems Before Mechanical Harvesting!Document6 pagesHaulm Cutter: Solves Problems Before Mechanical Harvesting!FabianoNo ratings yet

- Grimme 170 DetalhesDocument10 pagesGrimme 170 DetalhesFabianoNo ratings yet

- TSP-1900 Manual 2016Document4 pagesTSP-1900 Manual 2016FabianoNo ratings yet

- Varitron 470: The New 4-Row Self-Propelled Harvester For A High-Output Potato HarvestDocument9 pagesVaritron 470: The New 4-Row Self-Propelled Harvester For A High-Output Potato HarvestFabianoNo ratings yet

- Manual Empacotadeira KuhnDocument24 pagesManual Empacotadeira KuhnFabianoNo ratings yet

- CompleteManual 6-09 Maquina em Cima Da CaminhoneteDocument35 pagesCompleteManual 6-09 Maquina em Cima Da CaminhoneteFabianoNo ratings yet

- AGCO 3906313 WW401005-1 ISOBUS HarnessDocument2 pagesAGCO 3906313 WW401005-1 ISOBUS HarnessFabianoNo ratings yet

- Safe T Pull Pro Users Manual 3.25.2015 PRDocument19 pagesSafe T Pull Pro Users Manual 3.25.2015 PRFabianoNo ratings yet

- Operating Instructions: Control Terminal Cci-IsobusDocument38 pagesOperating Instructions: Control Terminal Cci-IsobusFabianoNo ratings yet

- Catalogo HydacDocument192 pagesCatalogo HydacFabianoNo ratings yet

- Manual MuellerDocument36 pagesManual MuellerFabianoNo ratings yet

- Operating Instructions: Control Terminal Cci-IsobusDocument38 pagesOperating Instructions: Control Terminal Cci-IsobusFabianoNo ratings yet

- Manual MuellerDocument36 pagesManual MuellerFabianoNo ratings yet

- Manual Isobus RavenDocument86 pagesManual Isobus RavenFabianoNo ratings yet

- AGCO 3906313 WU311003-1 Aboard ComputerDocument2 pagesAGCO 3906313 WU311003-1 Aboard ComputerFabianoNo ratings yet

- AGCO 3906313 WU331002-1 Electrical Plug Cigar LighterDocument2 pagesAGCO 3906313 WU331002-1 Electrical Plug Cigar LighterFabianoNo ratings yet

- Manual Isobus RavenDocument86 pagesManual Isobus RavenFabianoNo ratings yet

- Manual MuellerDocument36 pagesManual MuellerFabianoNo ratings yet

- Manual HorschDocument74 pagesManual HorschFabianoNo ratings yet

- GMO 0313 CONV MillingDocument66 pagesGMO 0313 CONV MillinghudarusliNo ratings yet

- WExcav TransmDocument2 pagesWExcav Transmrafasel otubo guatiaNo ratings yet

- Resource Guide Material HandlingDocument76 pagesResource Guide Material HandlingSarinNo ratings yet

- Audi 1992-1996 - MPI Fuel Injection and Ignition System (6-Cylinder) 07.94 Engine ID AAHDocument199 pagesAudi 1992-1996 - MPI Fuel Injection and Ignition System (6-Cylinder) 07.94 Engine ID AAHnenume 00No ratings yet

- Dong's Research PaperDocument24 pagesDong's Research PaperJose BrinNo ratings yet

- Yale SM NR035 040 045AD - NDR030 ADB815 - NS040 050 AEB816Document331 pagesYale SM NR035 040 045AD - NDR030 ADB815 - NS040 050 AEB816Marcel LarinNo ratings yet

- Brochure Ecr58plus Ecr88plus t3 en 21 20000631 DDocument12 pagesBrochure Ecr58plus Ecr88plus t3 en 21 20000631 DJo SmåliNo ratings yet

- CFX Xe 290 7.12.2022Document2 pagesCFX Xe 290 7.12.2022daggerYisus “Dagger” Yisus100% (1)

- How To Inspect A Used Car ChecklistDocument4 pagesHow To Inspect A Used Car ChecklistBrendan ChenNo ratings yet

- 02 - Vehicle Body TypesDocument79 pages02 - Vehicle Body TypesMr. MuditNo ratings yet

- I.Manual For FSADocument11 pagesI.Manual For FSAVu DangNo ratings yet

- Sutara AN - Stepper Motor Speed Control Methods-1Document9 pagesSutara AN - Stepper Motor Speed Control Methods-1Chayan MondalNo ratings yet

- Glink Tracking and Fuel Monitoring Presentation PDFDocument20 pagesGlink Tracking and Fuel Monitoring Presentation PDFaugusto100% (1)

- ALP Cultivator Users-GuideDocument27 pagesALP Cultivator Users-GuidePașala Mihai LucianNo ratings yet

- dt912d Specification Sheet EnglishDocument4 pagesdt912d Specification Sheet EnglishRenzo LizarzaburuNo ratings yet

- PHQC 3036 - Pull Part Manual 2016 1010Document9 pagesPHQC 3036 - Pull Part Manual 2016 1010VladimirNo ratings yet

- TRIMS Product DesignDocument15 pagesTRIMS Product Designvishal pandeyNo ratings yet

- 6-1. Work EquipmentDocument87 pages6-1. Work EquipmentSaidi JalelNo ratings yet

- Hydraulic BrakeDocument7 pagesHydraulic BrakeA. A. SherpedoNo ratings yet

- Reference Data Sheet: Design Conditions Fuel Gas DataDocument1 pageReference Data Sheet: Design Conditions Fuel Gas Data周庆卓100% (1)

- Fuel Sistem D4EB 2.2 PDFDocument544 pagesFuel Sistem D4EB 2.2 PDFcarnori100% (1)

- Next Gen Ford Everest Digital BrochureDocument12 pagesNext Gen Ford Everest Digital Brochureyanafic282No ratings yet

- Market Analysis For Ford Motor CompanyDocument12 pagesMarket Analysis For Ford Motor CompanyHND Assignment Help100% (6)

- Preliminary Preflight Procedure: CaptainDocument10 pagesPreliminary Preflight Procedure: CaptainCamilo RestrepoNo ratings yet

- Filler BreatherDocument2 pagesFiller BreatherVilasNo ratings yet

- 2014-2015+M70 Retro+Manual+Document93 pages2014-2015+M70 Retro+Manual+Bass is heavyNo ratings yet

- School of Maritime Studies Vels University ThalamburDocument5 pagesSchool of Maritime Studies Vels University ThalamburAayush AgrawalNo ratings yet

- PB 30 Parts Manual 2013 1001Document11 pagesPB 30 Parts Manual 2013 1001VladimirNo ratings yet

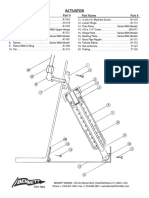

- Actuator: Part Name Part # Part Name Part #Document1 pageActuator: Part Name Part # Part Name Part #musebladeNo ratings yet

- Portafolio de Productos Petronas Sudamerica - Peru 2019-2020-3Document47 pagesPortafolio de Productos Petronas Sudamerica - Peru 2019-2020-3wilsonschmittNo ratings yet