Professional Documents

Culture Documents

FANUC Series 30: i/31i/32i-MODEL A

Uploaded by

Şener GÜNEYLİOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

FANUC Series 30: i/31i/32i-MODEL A

Uploaded by

Şener GÜNEYLİCopyright:

Available Formats

FANUC Series 30i/31i/32i-MODEL A

Cs contour control axis coordinate establishment

Specifications

FANUC Series 30i/31i/32i/-MODEL A

Title Cs contour control axis coordinate

establishment

Draw

A-79613E

No.

Ed. Date Design Description Page 1/11

Date June.02.’04 Design. Apprv.

Outline

Generally, position is lost just after changing serial spindle mode from speed

control mode to Cs contour control mode.

This function makes it possible to establish position without reference point

return by setting Cs axis coordinate establishment request signal

CSFIx<Gn274.4-7> to 1.

Note

This function is available from finish of the first reference point

return of Cs contour axis until power-off.

Setting

Set the parameter CSF (No.3712#2) and the parameter CSPTRE

(No.4353#5) to 1 in order to use Cs axis coordinate establishment.

(The parameter RFCHK3 (No.4016#7) is set to 0 in order to use this

function.)

And, the M code that sets Cs axis coordinate establishment request signal

CSFIx<Gn274.4-7> to 1 must be preventing buffering. Set the value of the

M code to parameter No.3411 to 3432.

Method of Cs axis coordinate establishment

(1) According to M code, change serial spindle mode to Cs contour control

mode and set Cs axis coordinate establishment request signal

CSFIx<Gn274.4-7> to 1.

(2) If Cs axis zero point establishment state signal CSPENx is 1, absolute

coordinate, relative coordinate, and machine coordinate of Cs axis are

counted up in order to establish them.

(3) After coordinate has been established, reference point establishment

signal ZRFx<Fn0120.0-7> is set to 1. Then, set Cs axis coordinate

establishment request signal CSFIx<Gn274.4-> to 0.

(4) Execute FIN sequence for M code.

Note

- Set correctly the signals MRDY, SFR, SRV of the direct input

signals from the PMC to the serial spindle via the CNC.

- In case of the emergency stop or the servo alarm on the Cs

axis occurs, Cs axis coordinate establishment is not executed.

- Do not move the Cs axis during the Cs axis coordinate

establishment be executed.

FANUC Series 30i/31i/32i/-MODEL A

Title Cs contour control axis coordinate

establishment

Draw

A-79613E

No.

Ed. Date Design Description Page 2/11

Date June.02.’04 Design. Apprv.

In case of failure to establish Cs axis coordinate

When Cs axis coordinate establishment is failed, PS alarm 5346 occurs on

the path that counts up absolute coordinate (work coordinate).

Causes of Cs axis coordinate establishment failure are as follows.

- Cs axis zero point establishment state signal CSPENx is 0.

- Position data was not transferred from spindle amplifier.

- Servo off is activated at start of Cs axis coordinate establishment

- Cs axis is under synchronous control or superimposed control.

- Emergency stop is applied during Cs axis establishing coordinate.

- Composite control of Cs axis is released during Cs axis establishing

coordinate.

- Synchronous/composite/superimposed control starts during Cs axis

establishing coordinate.

And, Cs axis coordinate establishment alarm signal CSFOx<Fn274.4-7> is

set to 1 on the path connected with spindle. Then, set Cs axis coordinate

establishment request signal CSFIx<Gn274.4 -7> to 0.

When you set Cs axis coordinate establishment request signal

CSFIx<Gn274.4-7> to 0, Cs axis coordinate establishment alarm signal

CSFOx<Fn274.4-7> is set to 0.

Clear P/S alarm 5346

PS alarm 5346 cannot be cleared until reference point of Cs axis is

established.

Perform manual reference point return of Cs axis on the path where PS alarm

5346 occurred. After reference point is established, PS alarm 5346 can be

cleard with reset.

Or, PS alarm 5346 can be cleard with reset after changing serial spindle

mode to speed control mode.

FANUC Series 30i/31i/32i/-MODEL A

Title Cs contour control axis coordinate

establishment

Draw

A-79613E

No.

Ed. Date Design Description Page 3/11

Date June.02.’04 Design. Apprv.

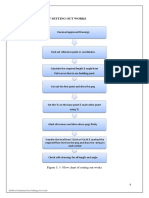

Sequence(Time Chart)

In case that Cs axis coordinate establishment is completed correctly.

M code for Cs contour

M code

control <F010∼013>

MF<F007.0>

CSPENA<F048.4>

CSFIx<G274.4-7>

CON<G027.7>

or

CONSx<G274.0-3>

FSCSL<F044.1>

or

FCSSx<F274.0-3>

Count up coordinate

ZRFx<F120.0-7>

CSFOx<F274.4-7>

FIN<G004.3>

Cs axis coordinate establishment is availalbe only in Cs contour contorl

mode.

Cs axis coordinate establishment request signal CSFIx<Gn274.4-7> is

ignored in speed control mode.

FANUC Series 30i/31i/32i/-MODEL A

Title Cs contour control axis coordinate

establishment

Draw

A-79613E

No.

Ed. Date Design Description Page 4/11

Date June.02.’04 Design. Apprv.

In cast that Cs axis coordinate establishment is failed.

M code for Cs contour

M code

control<F010 - 013>

MF<F007.0>

CSPENA<F048.4>

CSFIx<G274.4-7>

CON<G027.7>

or

CONSx<G274.0-3>

FSCSL<F044.1>

or

FCSSx<F274.0-3> Abort

Count up coordinate

ZRFx<F120.0-7>

CSFOx<F274.4-7>

FIN<G004.3>

When coordinate establishment is failed, ZRFx signal<F0120.0-7> is not set to 1.

FANUC Series 30i/31i/32i/-MODEL A

Title Cs contour control axis coordinate

establishment

Draw

A-79613E

No.

Ed. Date Design Description Page 5/11

Date June.02.’04 Design. Apprv.

Example) Under composite control of Cs axis in two-path system

M code for Cs contor

M code

control <F010 - 013>

MF<F0007.0>

CSPENA<F1048.4>

CSFIx<G1274.4-7>

CON<G1027.7>

FSCSL<F1044.1>

Count up coordinate

ZRFx<F1120>

CSFOx<F1274.4-7>

FIN<G0004.3>

(1) Excute M code on path-1. Then, MF signal <F0007.0> is set to 1.

(2) Check that Cs axis zero point establishment state signal on path-2

CSPENA <F1048.4> is 1. And, Set both Cs axis coordinate

establishment request signal on path-2 CSFI1<G1274.4> and spindle

contour control change signal on path-2 CON<G1027.7> to 1.

(3) Absolute coordinate on path-1, relative coordinate on path-1, and

machine coordinate on path-2 are counted up.

(4) After complete of count up, reference point establishment signal on

path-2 ZRFx<F0120> is set to 1. So, set Cs axis coordinate

establishment request signal on path-2 CSFI1<G1274.4> to 0.

(5) Excute FIN sequence for M code on path-1.

FANUC Series 30i/31i/32i/-MODEL A

Title Cs contour control axis coordinate

establishment

Draw

A-79613E

No.

Ed. Date Design Description Page 6/11

Date June.02.’04 Design. Apprv.

Note

CMR

Set the same value of CMR( parameter No.1820) for all Cs axes to establish

their coordinate in composite control. If value of CMR are different,

coordinate establishment is not completed correctly.

Feed axis synchronization control

Feed axis synchronization control is not available under Cs contour control.

Synchronous control

If Cs axis coordinate establishment request signal CSFIx <Gn274.4-7> is set

to 1 during synchronous control, PS alarm 5346 occurs.

Start synchronous control after Cs axis coordinate is established.

Composite control

If composite control is released during establishing Cs axis coordinate, Cs

axis coordinate establishment alarm signal CSFOx<Fn274.4-7> is set to 1

and PS alarm 5346 occurs.

superimposed control

If Cs axis coordinate establishment request signal CSFIx <Gn274.4-7> is set

to 1 during superimposed control, PS alarm 5346 occurs.

Start superimposed control after Cs axis coordinate is established.

Spindle simple synchronous control

When master spindle is parked, Cs axis coordinate is established according

to position of slave spindle.

Set Cs axis coordinate establishment request signal CSFIx <Gn274.4-7> for

master spindle to 1, not for slave spindle.

Also, Cs axis coordinate establishment alarm signal CSFOx <Fn274.4-7> for

master spindle is output, not for slave spindle.

External machine coordinate shift

Do not execute the external machine coordinate shift during establishing Cs

axis coordinate.

FANUC Series 30i/31i/32i/-MODEL A

Title Cs contour control axis coordinate

establishment

Draw

A-79613E

No.

Ed. Date Design Description Page 7/11

Date June.02.’04 Design. Apprv.

Signals

Cs axis coordinate establishment request signals

CSFI1 - CSFI4<Gn274.4-7>

[Classification] Input signal

[Function] Execute Cs axis coordinate establishment

[Operation] When CSFIx is 1 in Cs contour control mode, absolute coordinate and

machine coordinate are established according to Cs axis machine position.

When CSFIx are set to 0, Cs axis coordinate establishment alarm signal

CSFOx<Fn274.4-7> are set to 0.

Cs axis coordinate establishment alarm signals

CSFO1 - CSFO4<Fn274.4-7>

[Classification] Output signal

[Function] Inform that Cs axis coordinate establishment has not been completed.

[Output condition] These signals are set to 1 in the following case:

- Cs axis coordinate establishment has not been completed.

These signals are set to 0 in the following case:

- Spindle mode is speed control mode.

- Cs axis coordinate establishment request signal CSFIx<Gn274.4-7> are

set to 0.

Cs axis zero point establishment state signal

The 1st spindle : CSPENA<Fn048.4>, The 2nd spindle : CSPENB<Fn052.4>,

The 3rd spindle : CSPENC<nF171.4>, The 4th spindle : CSPEND<Fn269.4>

[Classification] Output signal

[Function] Inform that Cs axis coordinate establishment is available.

[Output condition] These signals are set to 1 in the following case:

- Reference point return has been completed correctly in Cs contour control

mode.

These signals are set to 0 in the following case:

- Spindle alarm occured.

- Spindle motor rotates at the speed over maximum speed.

(parameter No.4020)

FANUC Series 30i/31i/32i/-MODEL A

Title Cs contour control axis coordinate

establishment

Draw

A-79613E

No.

Ed. Date Design Description Page 8/11

Date June.02.’04 Design. Apprv.

Signal Address

#7 #6 #5 #4 #3 #2 #1 #0

Gn274 CSFI4 CSFI3 CSFI2 CSFI1

#7 #6 #5 #4 #3 #2 #1 #0

Fn048 CSPENA

#7 #6 #5 #4 #3 #2 #1 #0

Fn052 CSPENB

#7 #6 #5 #4 #3 #2 #1 #0

Fn171 CSPENC

#7 #6 #5 #4 #3 #2 #1 #0

Fn269 CSPEND

#7 #6 #5 #4 #3 #2 #1 #0

Fn274 CSFO4 CSFO3 CSFO2 CSFO1

FANUC Series 30i/31i/32i/-MODEL A

Title Cs contour control axis coordinate

establishment

Draw

A-79613E

No.

Ed. Date Design Description Page 9/11

Date June.02.’04 Design. Apprv.

Parameter

#7 #6 #5 #4 #3 #2 #1 #0

1005 ZRN

[Data type] Bit axis

ZRNx When a command specifying the movement except for G28 is issued in

automatic operation (MEM or MDI) and when a return to the reference

position has not been performed since the power was turned on

0: An alarm is generated (PS alarm 0224).

1: An alarm is not generated.

Note

We recommend you to set ZRNx to 0 for Cs axis coordinate

establishment function.

#7 #6 #5 #4 #3 #2 #1 #0

3712 CSF

[Data type] Bit system common

CSF Cs axis coordinate establishment is

0: Not used

1: Used

#7 #6 #5 #4 #3 #2 #1 #0

(2)

4353 CSPTRE

[Data type] Bit spindle

CSPTRE The function that transfer position data of Cs axis is

0: Not used

1: Used

Set parameter RFCHK3 (No.4016#7) to 0 in order to use this function.

FANUC Series 30i/31i/32i/-MODEL A

Title Cs contour control axis coordinate

establishment

Draw

A-79613E

No.

Ed. Date Design Description Page 10/11

Date June.02.’04 Design. Apprv.

Alarm and message

Number Message Description

PS5346 RETURN TO REFERENCE Cs coordinate establishment was aborted.

POINT Perform manual reference point return of Cs axis.

1. CSFIx was set to 1 when Cs axis zero point establishment

state signal CSPENx is 0.

2. Position data was not transferred from spindle amplifier.

3. Servo off is activated at start of Cs axis coordinate

establishment.

4. Cs axis is under synchronous control or superimposed

control.

5. Emergency stop is applied during Cs axis establishing

coordinate.

6. Composite control of Cs axis is released during Cs axis

establishing coordinate.

7. Synchronous/composite/superimposed control starts

during Cs axis establishing coordinate.

FANUC Series 30i/31i/32i/-MODEL A

Title Cs contour control axis coordinate

establishment

Draw

A-79613E

No.

Ed. Date Design Description Page 11/11

Date June.02.’04 Design. Apprv.

You might also like

- 8200T CNC Lathe Programming Manual V2.2Document330 pages8200T CNC Lathe Programming Manual V2.2ahmed kamalNo ratings yet

- Tessent Ijtag ManualDocument10 pagesTessent Ijtag ManualJecsNo ratings yet

- Fanuc 0M 0T C Alarm 401Document3 pagesFanuc 0M 0T C Alarm 401ognen8875% (4)

- Fanuc CNC Parts: Rigid Tapping TroubleshootingDocument6 pagesFanuc CNC Parts: Rigid Tapping TroubleshootingTony AntonyNo ratings yet

- TCP FanucDocument51 pagesTCP FanucAnonymous PJP78mSx33% (3)

- s120!30!003 Hino DX II ToolDocument23 pagess120!30!003 Hino DX II ToolPHÁT NGUYỄN THẾ100% (1)

- Specifications: FANUC Series 16/18-MB/TB/MC/TC FANUC Series 16Document15 pagesSpecifications: FANUC Series 16/18-MB/TB/MC/TC FANUC Series 16avalente112No ratings yet

- Open CNC Chapter 09 Linear and Circular InterpolationDocument30 pagesOpen CNC Chapter 09 Linear and Circular InterpolationΑποστόλης ΠαπαπαύλουNo ratings yet

- Computerized Numerical Control (CNC) SystemDocument42 pagesComputerized Numerical Control (CNC) SystemChristian Joy HerreraNo ratings yet

- 01 en M552 Geometry BasicsDocument8 pages01 en M552 Geometry BasicsAli ZarehNo ratings yet

- SCCOverview PDFDocument3 pagesSCCOverview PDFdevriesenNo ratings yet

- Lining of Track : Anurag RastogiDocument100 pagesLining of Track : Anurag RastogitejeswarNo ratings yet

- FANUC Series 16i/18i-TA: EDT DesigDocument4 pagesFANUC Series 16i/18i-TA: EDT DesigHiten MaruNo ratings yet

- MTB Tech BlogDocument41 pagesMTB Tech Blog이종훈No ratings yet

- Heidenhain 920Document68 pagesHeidenhain 920Angel Alvarez CarrilloNo ratings yet

- Servo Adjustment Manual 640mDocument37 pagesServo Adjustment Manual 640malexandre100% (1)

- ADC MasterDocument8 pagesADC MasterSaranga BhavaniNo ratings yet

- Remove - Install Crankshaft Position Sensor m271 PDFDocument1 pageRemove - Install Crankshaft Position Sensor m271 PDFAlex AndreiNo ratings yet

- AUTO TRACK PLOT PROCEDURE (Autosaved)Document21 pagesAUTO TRACK PLOT PROCEDURE (Autosaved)Cik IerahNo ratings yet

- Siemens DocumentationDocument3 pagesSiemens DocumentationVignesh WaranNo ratings yet

- Chap 6-1Document22 pagesChap 6-1Mareyam DnglNo ratings yet

- rm0455-STM32H7A3 - 7B3 및 STM32H7B0 Value line 고급 Arm® 기반 32비트 MCU9-22Document293 pagesrm0455-STM32H7A3 - 7B3 및 STM32H7B0 Value line 고급 Arm® 기반 32비트 MCU9-22임대진No ratings yet

- Lab 22Document3 pagesLab 22devilene nayazakoNo ratings yet

- 212 Wire 2axis To 4axis ProcessingDocument6 pages212 Wire 2axis To 4axis ProcessingMinh PhươngNo ratings yet

- Datasheet m35055 - Video Character GeneratorDocument51 pagesDatasheet m35055 - Video Character Generatormaster -DvNo ratings yet

- L5 Crankshaft Position Sensor: Remove/install Risk of Death Danger!Document1 pageL5 Crankshaft Position Sensor: Remove/install Risk of Death Danger!Ludmila CroitoruNo ratings yet

- CCNP1 Lab 3 4 A enDocument12 pagesCCNP1 Lab 3 4 A enpercyNo ratings yet

- Okuma FIXTURE OFFSET FUNCTIONDocument12 pagesOkuma FIXTURE OFFSET FUNCTIONEdwardNo ratings yet

- 0id SkipDocument34 pages0id SkipKen FitzpatrickNo ratings yet

- General SurveyingDocument3 pagesGeneral SurveyingLasantha WeerasekaraNo ratings yet

- KVH 6HPDocument95 pagesKVH 6HPNishant PandyaNo ratings yet

- Chine Systems Inc Rob Zahensky FR Yer Ma Chine Systems Inc Rob ZahenskyDocument1 pageChine Systems Inc Rob Zahensky FR Yer Ma Chine Systems Inc Rob Zahenskymoisii teodoraNo ratings yet

- 211 4 Axis Wire Output ProcessingDocument12 pages211 4 Axis Wire Output ProcessingHoang LamNo ratings yet

- All-in-One PLC: KV Nano Application Guide Vol. 2Document12 pagesAll-in-One PLC: KV Nano Application Guide Vol. 2Phạm Thế HiệpNo ratings yet

- From Mech: Jump ToDocument16 pagesFrom Mech: Jump ToMohammed Abu SufianNo ratings yet

- Lab 4.9.4 Configuring ISDN PRI: ObjectiveDocument5 pagesLab 4.9.4 Configuring ISDN PRI: ObjectiveCharles MorrisonNo ratings yet

- Setting Out: Section 5Document16 pagesSetting Out: Section 5freddy ramdinNo ratings yet

- Standby Compass CalibrationDocument3 pagesStandby Compass CalibrationHarry NuryantoNo ratings yet

- EN - 840D SL - 5-Axis Training Manual - v26Document388 pagesEN - 840D SL - 5-Axis Training Manual - v26emir_delic2810No ratings yet

- Cams SynthesisDocument36 pagesCams SynthesisShinchanus Monyetus GeblekusNo ratings yet

- Ee 381A: Digital Circuits and Microprocessors 2021-2022/II Experiment 2 Prbs & Sequence Generators Using Shift RegistersDocument2 pagesEe 381A: Digital Circuits and Microprocessors 2021-2022/II Experiment 2 Prbs & Sequence Generators Using Shift RegistersAKANSH AGRAWALNo ratings yet

- Assignment - 2 CNC Programming: Prof. R.O.VDocument11 pagesAssignment - 2 CNC Programming: Prof. R.O.VAnkit NandwaniNo ratings yet

- COGO+ v4 Chapter6Document13 pagesCOGO+ v4 Chapter6bedoed2140No ratings yet

- Kinematics and Dynamics of Machinery Linkage Synthesis: Sourav Rakshit 204 Machine Design Section Srakshit@iitm - Ac.inDocument27 pagesKinematics and Dynamics of Machinery Linkage Synthesis: Sourav Rakshit 204 Machine Design Section Srakshit@iitm - Ac.inManoj ManuNo ratings yet

- CAM Lab MtechDocument33 pagesCAM Lab MtechrkNo ratings yet

- Tacheometry - Stadia System: KS SinDocument48 pagesTacheometry - Stadia System: KS SindoggyNo ratings yet

- 08 - BSC Integration To Rel4Document14 pages08 - BSC Integration To Rel4AmirBayatNo ratings yet

- Synchronous 4-Bit Binary CounterDocument17 pagesSynchronous 4-Bit Binary Counteryogendra.shethNo ratings yet

- Chine Systems Inc Rob Zahensky FR Yer Ma Chine Systems Inc Rob ZahenskyDocument1 pageChine Systems Inc Rob Zahensky FR Yer Ma Chine Systems Inc Rob ZahenskyIonut RabanNo ratings yet

- CW20T G Code222Document48 pagesCW20T G Code222Leo LeoNo ratings yet

- SynchronizationDocument3 pagesSynchronizationMubariz MohamedNo ratings yet

- Post Mastercam 4 AxisDocument62 pagesPost Mastercam 4 AxisGiacongcokhi CokhihotroNo ratings yet

- CGV Module 03Document49 pagesCGV Module 03Amarjeeth R SNo ratings yet

- A700 VFD With Sscnet IIIDocument29 pagesA700 VFD With Sscnet IIIJuvenal Copa PerezNo ratings yet

- Lami-Kappa Technote 18 Vibxpert Shaftorbit Centerline en 2Document6 pagesLami-Kappa Technote 18 Vibxpert Shaftorbit Centerline en 2Kamolwan WeerachatsakulNo ratings yet

- 1477 Service Manual PDFDocument44 pages1477 Service Manual PDFHenry BarbozaNo ratings yet

- Fast Spin Echo Adj L2E-BM5032-13Document38 pagesFast Spin Echo Adj L2E-BM5032-13Rafael Ortega - meajudarafaNo ratings yet

- 3D Marine Geometry: Overview of Processing MethodologyDocument24 pages3D Marine Geometry: Overview of Processing MethodologyShenina KnightleyNo ratings yet

- 6-Bit Magnetic Angular Position Encoder With Serial InterfaceDocument11 pages6-Bit Magnetic Angular Position Encoder With Serial InterfacePankaj D PatelNo ratings yet

- WAN TECHNOLOGY FRAME-RELAY: An Expert's Handbook of Navigating Frame Relay NetworksFrom EverandWAN TECHNOLOGY FRAME-RELAY: An Expert's Handbook of Navigating Frame Relay NetworksNo ratings yet

- FANUC Series 30 I /31i /32i-MODEL A: Simple Spindle Electronic Gear BoxDocument7 pagesFANUC Series 30 I /31i /32i-MODEL A: Simple Spindle Electronic Gear BoxŞener GÜNEYLİNo ratings yet

- The Notice of Using The High-Speed Skip Function: FANUC Series 30Document4 pagesThe Notice of Using The High-Speed Skip Function: FANUC Series 30Şener GÜNEYLİNo ratings yet

- Solidsurfacer Addendum: Gibbs and Associates 323 Science Drive Moorpark, CA 93021 (805) 523-0004Document42 pagesSolidsurfacer Addendum: Gibbs and Associates 323 Science Drive Moorpark, CA 93021 (805) 523-0004Şener GÜNEYLİNo ratings yet

- GE Fanuc Automation: Operator Panels For I Series ControlsDocument112 pagesGE Fanuc Automation: Operator Panels For I Series ControlsŞener GÜNEYLİNo ratings yet

- GE Fanuc Automation: Computer Numerical Control ProductsDocument81 pagesGE Fanuc Automation: Computer Numerical Control ProductsŞener GÜNEYLİNo ratings yet

- ADM12864HDocument14 pagesADM12864HluinksNo ratings yet

- Occ CompleteDocument25 pagesOcc CompleteMayur Mestry100% (1)

- Bailey DCS Simulator API: PreviseDocument33 pagesBailey DCS Simulator API: PreviseRio YuwandiNo ratings yet

- Software Requirements Specification: Version 1.0 ApprovedDocument14 pagesSoftware Requirements Specification: Version 1.0 ApprovedRAMINEDI SANTHOSH 20BCE1477No ratings yet

- Dynalink Telemetry System: Reliable Wireless Downhole Telemetry TechnologyDocument2 pagesDynalink Telemetry System: Reliable Wireless Downhole Telemetry TechnologyRefisal BonnetNo ratings yet

- QSG0028v3-UR20-EIP Commissioning With Allen-Bradley MicroLogix 1400Document12 pagesQSG0028v3-UR20-EIP Commissioning With Allen-Bradley MicroLogix 1400Sergio TrujilloNo ratings yet

- Numerical Over Current Relay Ocr With Earth Fault Relay EfrDocument5 pagesNumerical Over Current Relay Ocr With Earth Fault Relay EfrMohsin NaushadNo ratings yet

- Choppers TheoryDocument63 pagesChoppers TheoryLokesh SinghNo ratings yet

- Angular Js Quick Walkthrough: Nginit ( )Document6 pagesAngular Js Quick Walkthrough: Nginit ( )Keerthi MaddiralaNo ratings yet

- Design of Mm-Wave Mic Frequency Multipliers and Mixers Using Simple Microstrip High-Pass FiltersDocument4 pagesDesign of Mm-Wave Mic Frequency Multipliers and Mixers Using Simple Microstrip High-Pass Filterskoke_8902No ratings yet

- tmf610 tmf6000Document1 pagetmf610 tmf6000api-467243003No ratings yet

- Um en SW FL Switch 2000 108998 en 04Document158 pagesUm en SW FL Switch 2000 108998 en 04Anton BatsaevNo ratings yet

- Java Fundamentals For Android DevelopmentDocument64 pagesJava Fundamentals For Android DevelopmentMarco Antonio AvendañoNo ratings yet

- Embedded Programming BasicsDocument15 pagesEmbedded Programming BasicsPriyancyNo ratings yet

- Regin Regio Midi EngDocument2 pagesRegin Regio Midi EngMc EswaranNo ratings yet

- Eee PC 1225b Service Manual PDFDocument2 pagesEee PC 1225b Service Manual PDFaldi 88No ratings yet

- PolyChromeDSP McRocklinSuite ManualDocument23 pagesPolyChromeDSP McRocklinSuite ManualJeff BachNo ratings yet

- Direct PWM Drive Brushless Pre-Driver For Household Appliance MotorsDocument17 pagesDirect PWM Drive Brushless Pre-Driver For Household Appliance MotorsnguoidiquaNo ratings yet

- DNS Rebinding Attack LabDocument7 pagesDNS Rebinding Attack LabTty SmithNo ratings yet

- Int CATALOGUE TransmetteursDocument23 pagesInt CATALOGUE TransmetteurssarahrouNo ratings yet

- Eyeball Based Cursor Movement ControlDocument5 pagesEyeball Based Cursor Movement ControlVijay VijjuNo ratings yet

- RACI MatrixDocument3 pagesRACI MatrixJoydip MukhopadhyayNo ratings yet

- Type ScriptDocument119 pagesType ScriptTrung TrungNo ratings yet

- School of Electrical and Computer Engineering Projected Schedule of Graduate CoursesDocument5 pagesSchool of Electrical and Computer Engineering Projected Schedule of Graduate CoursesRana Muhammad UmerNo ratings yet

- CSE 2005 - Operating Systems Lab Final Assessment TestDocument3 pagesCSE 2005 - Operating Systems Lab Final Assessment TestMansi SinghNo ratings yet

- Practical - 2Document18 pagesPractical - 2Who I amNo ratings yet

- Ogdcl Test 2018Document8 pagesOgdcl Test 2018MuhammadNaveed100% (1)

- Nonprofit Offers GuideDocument3 pagesNonprofit Offers GuideviniciusemanuelNo ratings yet