Professional Documents

Culture Documents

Dsi Stressing Record - Bridge IC12

Uploaded by

Rama Subba Rao chebroluOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Dsi Stressing Record - Bridge IC12

Uploaded by

Rama Subba Rao chebroluCopyright:

Available Formats

Project : Al Sharqiyah Express Way Section II Part 2 ( Al Kamil To Sur)

Contractor : Khalid Bin Ahmed & Sons LLC

Subcontractor : DSI / Al Ammar International

Client : Minisitry of transport & communications DGR LT

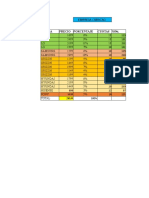

Strand Distribution at Interchange bridge - IC12

Actual Cross-Sectional Actual Modulus Average Average Average Average

Tendon # Coil # # of Strands Correction Factor

Area ( A ) of Elasticity ( E ) Actual A Theo. A Actual E Theo. E

1 1741329718 19 139.95 196.89 139.95 140.00 196.89 195.00 99.10%

2 1741329718 19 139.95 196.89 139.95 140.00 196.89 195.00 99.10%

1741329718 7 139.95 196.89

3 139.95 140.00 196.79 195.00 99.10%

1741329719 12 139.95 196.73

4 1741329715 19 139.95 196.89 139.95 140.00 196.89 195.00 99.10%

5 1741329715 19 139.95 196.89 139.95 140.00 196.89 195.00 99.10%

6 1741329715 19 139.95 196.89 139.95 140.00 196.89 195.00 99.10%

7 1741329717 19 139.95 196.89 139.95 140.00 196.89 195.00 99.10%

8 1741329717 19 139.95 196.89 139.95 140.00 196.89 195.00 99.10%

1741329717 15 139.95 196.89

9 139.95 140.00 196.89 195.00 99.10%

1741329716 4 139.95 196.89

10 1741329716 19 139.95 196.89 139.95 140.00 196.89 195.00 99.10%

11 1741329716 19 139.95 196.89 139.95 140.00 196.89 195.00 99.10%

1741329716 11 139.95 196.89

12 139.95 140.00 196.89 195.00 99.10%

1741329718 8 139.95 196.89

1741329716 1 139.95 196.89

1741329717 1 139.95 196.89

13 139.95 140.00 196.76 195.00 99.10%

1741329718 1 139.95 196.89

1741329719 16 139.95 196.73

14 1741329719 19 139.95 196.73 139.95 140.00 196.73 195.00 99.20%

15 1741329719 19 139.95 196.73 139.95 140.00 196.73 195.00 99.20%

1741329719 13 139.95 196.73

16 140.03 140.00 197.30 195.00 98.80%

1741329714 6 140.20 198.52

17 1741329714 19 140.20 198.52 140.20 140.00 198.52 195.00 98.10%

18 1741329714 19 140.20 198.52 140.20 140.00 198.52 195.00 98.10%

Note:

Correction Factor Average Theo. A x E 195x140

99.10%

Average Actual A x E 139.95x196.89

Main Tendon

Calculation of Pressure

Al Sharqiyah Express Way Section II Part 2 ( Al

Project : Kamil To Sur) Client : Minisitry of transport & communications DGR LT

Contractor : Khalid Bin Ahmed & Sons LLC DSI Approval : ETA - 130815

Subcontractor : DSI / Al Ammar International Structure : Interchange bridge - 12

Drawing Number : KAS/BS2P/SDW/TD/IC13/006-005-R02

For 3711 kN (19 No of strands)

Type of jack : HOZ 5400 /250

As per calibration certificate 2016-0191 2016-0119

Jack N° : 06-086 975448

Relative piston friction around jacking for 0.18 % 0.38 %

Average relative psiton friction for both ja 0.28 %

Piston area (Sp) 894.57 cm²

Required pressure gauge (bar) for stressi = `

= 3711 / ((894,57 x 0,01) / (1 - 0,0028))

= 416 bars

Hence required gauge pressure (bar) for s = 418 bars corrected according to pressure gauge certificate of calibration

Stressing record - from both ends

Project : Al Sharqiyah Express Way Section II Part 2 ( Al Client : Minisitry of transport & communications DGR LT

Kamil To Sur)

Contractor : Khalid Bin Ahmed & Sons LLC DSI Approval : ETA - 130815

Subcontractor : DSI / Al Ammar International Structure : Interchange bridge - 12

Drawing Number : KAS/BS2P/SDW/TD/IC13/006-005-R02

Tendon characteristics Stressing equipment

Tendon number 8 Type of jack : HOZ 5400 /250

Stressing sequence 1 Type of pump : R6.4

Number of strands 19

Coil Number 1741329717 End : Abuitment 1 Jack N° : 975448

Theoritical tendon lenght = 51.217 m Piston area (Sp) 894.57 cm² Pump N°: 934676

Theoritical elongation (2) = 344 mm Friction at jacking force (f 0.38 % Mano N°: 1104UZF4

Theoritical elongation protrusion len = 11 mm End : Abuitment 2 Jack N° : 06-086

Correction factor = 0.991 Piston area (Sp) 894.57 cm² Pump N°: 8301

Total corrected theoritical elongation (3) = 352 mm Friction at jacking force (f 0.18 % Mano N°: 110701V4

Maximum elongation ( + 5%) = 370 mm

Theoritical elongation protrusion = L Jack X load Jacking force = 3,711 kN

lenghts 2 jacks E X S Tendons Jacking pressure - jack correction (4) = 416 bars

.8X3711X10^6 2968800000 jacking pressure - jack and manometer correction (5) 418 bars

= = 11 mm

195000x140x19 518700000 Maximal jacking pressure - (+ 5%) 439 bars

(2)

value from the table in the document KAS/BS2P/SDW/TD/IC13/006-005-R02

(3)

correcting factor (for actual cross section and elastic modukus) x theorotical elongation

(4)

Calcultated with the following formula : P (bar) = F(kN) / (Sp(cm²) x 0,01 x (1-fr)), at both jacks. The average value has to be considered.

(5)

Includes the deviation of the manometer, according to certificate of calibration, in the area of the jacking pressure ( » 2bars)

End : Abuitment 1 End : Abuitment 2

Pressure Partial elongation sum

(Bars) Partial Elongation Partial Elongation (1) + (2) total elongation

Reading (mm) (1) Reading (mm) (2)

40 42 81

100 167 165 81

35 37 72

200 132 128 153

44 44 88

300 88 84 241

40 44 84

400 48 40 325

16 12 28

418 32 28 353

The partial elongation at 100 bars is a calculated value. It is the average of the partial elongation of the stages : 100 to 200 bars / 200 to 300 bars / 300 to 400

bars.

Pressure shall not exceed maximal pressure (+ 5%). Elongation shall not exceed maximum elongation (+5%).

Observations on stressing operation :

Al Ammar Int Trd & Cont KAS Renardet :

Name : Syed Kareemuddin Name : Name :

Date : Date : Date :

Signature: Signature: Signature:

Stressing record - from both ends

Al Sharqiyah Express Way Section II Part 2 ( Al

Project : Kamil To Sur) Client : Minisitry of transport & communications DGR LT

Contractor : Khalid Bin Ahmed & Sons LLC DSI Approval : ETA - 130815

Subcontractor : DSI / Al Ammar International Structure : Interchange bridge - 12

Drawing Number : KAS/BS2P/SDW/TD/IC13/006-005-R02

Tendon characteristics Stressing equipment

Tendon number 12 Type of jack : HOZ 5400 /250

Stressing sequence 3 Type of pump : R6.4

Number of strands 19

Coil Number 1741329716/1741329718 End : Abuitment 1 Jack N° : 975448

Theoritical tendon lenght = 51.288 m Piston area (Sp) 894.57 cm² Pump N°: 934676

Theoritical elongation (2) = 338 mm Friction at jacking force (f 0.38 % Mano N°: 1104UZF4

Theoritical elongation protrusion len = 11 mm End : Abuitment 2 Jack N° : 06-086

Correction factor = 0.991 Piston area (Sp) 894.57 cm² Pump N°: 8301

Total corrected theoritical elongation (3) = 346 mm Friction at jacking force (f 0.18 % Mano N°: 110701V4

Maximum elongation ( + 5%) = 364 mm

Theoritical elongation protrusion = L Jack X load Jacking force = 3,711 kN

lenghts 2 jacks E X S Tendons Jacking pressure - jack correction (4) = 416 bars

.8X3711X10^6 2968800000 jacking pressure - jack and manometer correction (5) 418 bars

= = 11 mm

195000x140x19 518700000 Maximal jacking pressure - (+ 5%) 439 bars

(2)

value from the table in the document KAS/BS2P/SDW/TD/IC13/006-005-R02

(3)

correcting factor (for actual cross section and elastic modukus) x theorotical elongation

(4)

Calcultated with the following formula : P (bar) = F(kN) / (Sp(cm²) x 0,01 x (1-fr)), at both jacks. The average value has to be considered.

(5)

Includes the deviation of the manometer, according to certificate of calibration, in the area of the jacking pressure ( » 2bars)

End : Abuitment 1 End : Abuitment 2

Pressure Partial elongation sum

(Bars) Partial Elongation Partial Elongation (1) + (2) total elongation

Reading (mm) Reading (mm)

(1) (2)

41 44 85

100 174 173 85

41 43 84

200 133 130 169

41 45 86

300 92 85 255

42 44 86

400 50 41 341

11 10 21

418 39 31 362

The partial elongation at 100 bars is a calculated value. It is the average of the partial elongation of the stages : 100 to 200 bars / 200 to 300 bars / 300 to 400

bars.

Pressure shall not exceed maximal pressure (+ 5%). Elongation shall not exceed maximum elongation (+5%).

Observations on stressing operation :

Al Ammar Int Trd & Cont KAS Renardet :

Name : Syed Kareemuddin Name : Name :

Date : Date : Date :

Signature: Signature: Signature:

Stressing record - from both ends

Al Sharqiyah Express Way Section II Part 2 ( Al

Project : Kamil To Sur) Client : Minisitry of transport & communications DGR LT

Contractor : Khalid Bin Ahmed & Sons LLC DSI Approval : ETA - 130815

Subcontractor : DSI / Al Ammar International Structure : Interchange bridge - 12

Drawing Number : KAS/BS2P/SDW/TD/IC13/006-005-R02

Tendon characteristics Stressing equipment

Tendon number 5 Type of jack : HOZ 5400 /250

Stressing sequence 2 Type of pump : R6.4

Number of strands 19

Coil Number 1741329715 End : Abuitment 1 Jack N° : 975448

Theoritical tendon lenght = 51.217 m Piston area (Sp) 894.57 cm² Pump N°: 934676

Theoritical elongation (2) = 344 mm Friction at jacking force (f 0.38 % Mano N°: 1104UZF4

Theoritical elongation protrusion len = 11 mm End : Abuitment 2 Jack N° : 06-086

Correction factor = 0.991 Piston area (Sp) 894.57 cm² Pump N°: 8301

Total corrected theoritical elongation (3) = 352 mm Friction at jacking force (f 0.18 % Mano N°: 110701V4

Maximum elongation ( + 5%) = 370 mm

Theoritical elongation protrusion = L Jack X load Jacking force = 3,711 kN

lenghts 2 jacks E X S Tendons Jacking pressure - jack correction (4) = 416 bars

.8X3711X10^6 2968800000 jacking pressure - jack and manometer correction (5) 418 bars

= = 11 mm

195000x140x19 518700000 Maximal jacking pressure - (+ 5%) 439 bars

(2)

value from the table in the document KAS/BS2P/SDW/TD/IC13/006-005-R02

(3)

correcting factor (for actual cross section and elastic modukus) x theorotical elongation

(4)

Calcultated with the following formula : P (bar) = F(kN) / (Sp(cm²) x 0,01 x (1-fr)), at both jacks. The average value has to be considered.

(5)

Includes the deviation of the manometer, according to certificate of calibration, in the area of the jacking pressure ( » 2bars)

End : Abuitment 1 End : Abuitment 2

Pressure Partial elongation sum

Partial Elongation Partial Elongation total elongation

(Bars) Reading (mm) Reading (mm) (1) + (2)

(1) (2)

41 43 84

100 170 165 84

41 41 82

200 129 124 166

41 44 85

300 88 80 251

42 44 86

400 46 36 337

10 9 19

418 36 27 356

The partial elongation at 100 bars is a calculated value. It is the average of the partial elongation of the stages : 100 to 200 bars / 200 to 300 bars / 300 to 400

bars.

Pressure shall not exceed maximal pressure (+ 5%). Elongation shall not exceed maximum elongation (+5%).

Observations on stressing operation :

Al Ammar Int Trd & Cont KAS Renardet :

Name : Syed Kareemuddin Name : Name :

Date : Date : Date :

Signature: Signature: Signature:

Stressing record - from both ends

Al Sharqiyah Express Way Section II Part 2 ( Al

Project : Kamil To Sur) Client : Minisitry of transport & communications DGR LT

Contractor : Khalid Bin Ahmed & Sons LLC DSI Approval : ETA - 130815

Subcontractor : DSI / Al Ammar International Structure : Interchange bridge - 12

Drawing Number : KAS/BS2P/SDW/TD/IC13/006-005-R02

Tendon characteristics Stressing equipment

Tendon number 3 Type of jack : HOZ 5400 /250

Stressing sequence 4 Type of pump : R6.4

Number of strands 19

Coil Number 1741329718/1741329719 End : Abuitment 1 Jack N° : 975448

Theoritical tendon lenght = 51.288 m Piston area (Sp) 894.57 cm² Pump N°: 934676

Theoritical elongation (2) = 338 mm Friction at jacking force (f 0.38 % Mano N°: 1104UZF4

Theoritical elongation protrusion len = 11 mm End : Abuitment 2 Jack N° : 06-086

Correction factor = 0.991 Piston area (Sp) 894.57 cm² Pump N°: 8301

Total corrected theoritical elongation (3) = 346 mm Friction at jacking force (f 0.18 % Mano N°: 110701V4

Maximum elongation ( + 5%) = 364 mm

Theoritical elongation protrusion = L Jack X load Jacking force = 3,711 kN

lenghts 2 jacks E X S Tendons Jacking pressure - jack correction (4) = 416 bars

.8X3711X10^6 2968800000 jacking pressure - jack and manometer correction (5) 418 bars

= = 11 mm

195000x140x19 518700000 Maximal jacking pressure - (+ 5%) 439 bars

(2)

value from the table in the document KAS/BS2P/SDW/TD/IC13/006-005-R02

(3)

correcting factor (for actual cross section and elastic modukus) x theorotical elongation

(4)

Calcultated with the following formula : P (bar) = F(kN) / (Sp(cm²) x 0,01 x (1-fr)), at both jacks. The average value has to be considered.

(5)

Includes the deviation of the manometer, according to certificate of calibration, in the area of the jacking pressure ( » 2bars)

End : Abuitment 1 End : Abuitment 2

Pressure Partial elongation sum total elongation

(Bars) Partial Elongation Partial Elongation (1) + (2)

Reading (mm) Reading (mm)

(1) (2)

42 43 85

100 172 167 85

43 42 85

200 129 125 170

40 44 84

300 89 81 254

44 43 87

400 45 38 341

10 9 19

418 35 29 360

The partial elongation at 100 bars is a calculated value. It is the average of the partial elongation of the stages : 100 to 200 bars / 200 to 300 bars / 300 to 400

bars.

Pressure shall not exceed maximal pressure (+ 5%). Elongation shall not exceed maximum elongation (+5%).

Observations on stressing operation :

Al Ammar Int Trd & Cont KAS Renardet :

Name : Syed Kareemuddin Name : Name :

Date : Date : Date :

Signature: Signature: Signature:

Stressing record - from both ends

Al Sharqiyah Express Way Section II Part 2 ( Al

Project : Kamil To Sur) Client : Minisitry of transport & communications DGR LT

Contractor : Khalid Bin Ahmed & Sons LLC DSI Approval : ETA - 130815

Subcontractor : DSI / Al Ammar International Structure : Interchange bridge - 12

Drawing Number : KAS/BS2P/SDW/TD/IC13/006-005-R02

Tendon characteristics Stressing equipment

Tendon number 18 Type of jack : HOZ 5400 /250

Stressing sequence 5 Type of pump : R6.4

Number of strands 19

Coil Number 1741329714 End : Abuitment 1 Jack N° : 975448

Theoritical tendon lenght = 31.287 m Piston area (Sp) 894.57 cm² Pump N°: 934676

Theoritical elongation (2) = 212 mm Friction at jacking force (f 0.38 % Mano N°: 1104UZF4

Theoritical elongation protrusion len = 11 mm End : Abuitment 2 Jack N° : 06-086

Correction factor = 0.981 Piston area (Sp) 894.57 cm² Pump N°: 8301

Total corrected theoritical elongation (3) = 219 mm Friction at jacking force (f 0.18 % Mano N°: 110701V4

Maximum elongation ( + 5%) = 230 mm

Theoritical elongation protrusion = L Jack X load Jacking force = 3,711 kN

lenghts 2 jacks E X S Tendons Jacking pressure jack correction

- (4)

= 416 bars

.8X3711X10^6 2968800000 jacking pressure - jack and manometer correction (5) 418 bars

= = 11 mm

195000x140x19 518700000 Maximal jacking pressure - (+ 5%) 439 bars

(2)

value from the table in the document KAS/BS2P/SDW/TD/IC13/006-005-R02

(3)

correcting factor (for actual cross section and elastic modukus) x theorotical elongation

(4)

Calcultated with the following formula : P (bar) = F(kN) / (Sp(cm²) x 0,01 x (1-fr)), at both jacks. The average value has to be considered.

(5)

Includes the deviation of the manometer, according to certificate of calibration, in the area of the jacking pressure ( » 2bars)

End : Abuitment 1 End : Abuitment 2

Pressure Partial elongation sum

Partial Elongation Partial Elongation total elongation

(Bars) Reading (mm) Reading (mm) (1) + (2)

(1) (2)

27 28 55

100 174 171 55

27 26 53

200 147 145 108

27 30 57

300 120 115 165

28 27 55

400 92 88 220

4 2 6

418 88 86 226

The partial elongation at 100 bars is a calculated value. It is the average of the partial elongation of the stages : 100 to 200 bars / 200 to 300 bars / 300 to 400

bars.

Pressure shall not exceed maximal pressure (+ 5%). Elongation shall not exceed maximum elongation (+5%).

Observations on stressing operation :

Al Ammar Int Trd & Cont KAS Renardet :

Name : Syed Kareemuddin Name : Name :

Date : Date : Date :

Signature: Signature: Signature:

Signature: Signature: Signature:

Stressing record - from both ends

Al Sharqiyah Express Way Section II Part 2 ( Al

Project : Client : Minisitry of transport & communications DGR LT

Kamil To Sur)

Contractor : Khalid Bin Ahmed & Sons LLC DSI Approval : ETA - 130815

Subcontractor : DSI / Al Ammar International Structure : Interchange bridge - 12

Drawing Number : KAS/BS2P/SDW/TD/IC13/006-005-R02

Tendon characteristics Stressing equipment

Tendon number 13 Type of jack : HOZ 5400 /250

Stressing sequence 6 Type of pump : R6.4

Number of strands 19

Coil Number 1741329716/7/8/9 End : Abuitment 1 Jack N° : 975448

Theoritical tendon lenght = 31.287 m Piston area (Sp) 894.57 cm² Pump N°: 934676

Theoritical elongation (2) = 212 mm Friction at jacking force (f 0.38 % Mano N°: 1104UZF4

Theoritical elongation protrusion len = 11 mm End : Abuitment 2 Jack N° : 06-086

Correction factor = 0.991 Piston area (Sp) 894.57 cm² Pump N°: 8301

Total corrected theoritical elongation (3) = 221 mm Friction at jacking force (f 0.18 % Mano N°: 110701V4

Maximum elongation ( + 5%) = 233 mm

Theoritical elongation protrusion = L Jack X load Jacking force = 3,711 kN

lenghts 2 jacks E X S Tendons Jacking pressure - jack correction (4) = 416 bars

.8X3711X10^6 2968800000 jacking pressure - jack and manometer correction (5) 418 bars

= = 11 mm

195000x140x19 518700000 Maximal jacking pressure - (+ 5%) 439 bars

End : Abuitment 1 End : Abuitment 2

Pressure Partial elongation sum

Partial Elongation Partial Elongation total elongation

(Bars) Reading (mm) Reading (mm) (1) + (2)

(1) (2)

28 28 56

100 187 185 56

26 27 53

200 161 158 109

29 28 57

300 132 130 166

28 30 58

400 104 100 224

4 3 7

418 100 97 231

The partial elongation at 100 bars is a calculated value. It is the average of the partial elongation of the stages : 100 to 200 bars / 200 to 300 bars / 300 to 400

bars.

Pressure shall not exceed maximal pressure (+ 5%). Elongation shall not exceed maximum elongation (+5%).

Observations on stressing operation :

Pressure has been released at 300 bars => second reading at 300 bars.

Al Ammar Int Trd & Cont KAS Renardet :

Name : Syed Kareemuddin Name : Name :

Date : Date : Date :

Signature: Signature: Signature:

Signature: Signature: Signature:

Stressing record - from both ends

Al Sharqiyah Express Way Section II Part 2 ( Al

Project : Kamil To Sur) Client : Minisitry of transport & communications DGR LT

Contractor : Khalid Bin Ahmed & Sons LLC DSI Approval : ETA - 130815

Subcontractor : DSI / Al Ammar International Structure : Interchange bridge - 12

Drawing Number : KAS/BS2P/SDW/TD/IC13/006-005-R02

Tendon characteristics Stressing equipment

Tendon number 9 Type of jack : HOZ 5400 /250

Stressing sequence 7 Type of pump : R6.4

Number of strands 19

Coil Number 1741329717/16 End : Abuitment 1 Jack N° : 975448

Theoritical tendon lenght = 51.235 m Piston area (Sp) 894.57 cm² Pump N°: 934676

Theoritical elongation (2) = 342 mm Friction at jacking force (f 0.38 % Mano N°: 1104UZF4

Theoritical elongation protrusion len = 11 mm End : Abuitment 2 Jack N° : 06-086

Correction factor = 0.991 Piston area (Sp) 894.57 cm² Pump N°: 8301

Total corrected theoritical elongation (3) = 350 mm Friction at jacking force (f 0.18 % Mano N°: 110701V4

Maximum elongation ( + 5%) = 368 mm

Theoritical elongation protrusion = L Jack X load Jacking force = 3,711 kN

lenghts 2 jacks E X S Tendons Jacking pressure - jack correction (4) = 416 bars

.8X3711X10^6 2968800000 jacking pressure - jack and manometer correction (5) 418 bars

= = 11 mm

195000x140x19 518700000 Maximal jacking pressure - (+ 5%) 439 bars

(2)

value from the table in the document KAS/BS2P/SDW/TD/IC13/006-005-R02

(3)

correcting factor (for actual cross section and elastic modukus) x theorotical elongation

(4)

Calcultated with the following formula : P (bar) = F(kN) / (Sp(cm²) x 0,01 x (1-fr)), at both jacks. The average value has to be considered.

(5)

Includes the deviation of the manometer, according to certificate of calibration, in the area of the jacking pressure ( » 2bars)

End : Abuitment 1 End : Abuitment 2

Pressure Partial elongation sum total elongation

(Bars) Reading (mm) Partial Elongation Reading (mm) Partial Elongation (1) + (2)

(1) (2)

41 45 86

100 175 160 86

37 43 80

200 138 117 166

44 46 90

300 94 71 256

41 47 88

400 53 24 344

11 7 18

418 42 17 362

The partial elongation at 100 bars is a calculated value. It is the average of the partial elongation of the stages : 100 to 200 bars / 200 to 300 bars / 300 to 400

bars.

Pressure shall not exceed maximal pressure (+ 5%). Elongation shall not exceed maximum elongation (+5%).

Observations on stressing operation :

Al Ammar Int Trd & Cont KAS Renardet :

Name : Syed Kareemuddin Name : Name :

Date : Date : Date :

Signature: Signature: Signature:

Stressing record - from both ends

Al Sharqiyah Express Way Section II Part 2 ( Al

Project : Kamil To Sur) Client : Minisitry of transport & communications DGR LT

Contractor : Khalid Bin Ahmed & Sons LLC DSI Approval : ETA - 130815

Subcontractor : DSI / Al Ammar International Structure : Interchange bridge - 12

Drawing Number : KAS/BS2P/SDW/TD/IC13/006-005-R02

Tendon characteristics Stressing equipment

Tendon number 6 Type of jack : HOZ 5400 /250

Stressing sequence 8 Type of pump : R6.4

Number of strands 19

Coil Number 1741329715 End : Abuitment 1 Jack N° : 975448

Theoritical tendon lenght = 51.235 m Piston area (Sp) 894.57 cm² Pump N°: 934676

Theoritical elongation (2) = 342 mm Friction at jacking force (f 0.38 % Mano N°: 1104UZF4

Theoritical elongation protrusion len = 11 mm End : Abuitment 2 Jack N° : 06-086

Correction factor = 0.991 Piston area (Sp) 894.57 cm² Pump N°: 8301

Total corrected theoritical elongation (3) = 350 mm Friction at jacking force (f 0.18 % Mano N°: 110701V4

Maximum elongation ( + 5%) = 368 mm

Theoritical elongation protrusion = L Jack X load Jacking force = 3,711 kN

lenghts 2 jacks E X S Tendons Jacking pressure - jack correction (4) = 416 bars

.8X3711X10^6 2968800000 jacking pressure - jack and manometer correction (5) 418 bars

= = 11 mm

195000x140x19 518700000 Maximal jacking pressure - (+ 5%) 439 bars

(2)

value from the table in the document KAS/BS2P/SDW/TD/IC13/006-005-R02

(3)

correcting factor (for actual cross section and elastic modukus) x theorotical elongation

(4)

Calcultated with the following formula : P (bar) = F(kN) / (Sp(cm²) x 0,01 x (1-fr)), at both jacks. The average value has to be considered.

(5)

Includes the deviation of the manometer, according to certificate of calibration, in the area of the jacking pressure ( » 2bars)

End : Abuitment 1 End : Abuitment 2

Pressure Partial elongation sum total elongation

(Bars) Partial Elongation Partial Elongation (1) + (2)

Reading (mm) Reading (mm)

(1) (2)

41 44 85

100 168 164 85

41 41 82

200 127 123 167

40 44 84

300 87 79 251

43 47 90

400 44 32 341

14 7 21

418 30 25 362

The partial elongation at 100 bars is a calculated value. It is the average of the partial elongation of the stages : 100 to 200 bars / 200 to 300 bars / 300 to 400

bars.

Pressure shall not exceed maximal pressure (+ 5%). Elongation shall not exceed maximum elongation (+5%).

Observations on stressing operation :

Al Ammar Int Trd & Cont KAS Renardet :

Name : Syed Kareemuddin Name : Name :

Date : Date : Date :

Signature: Signature: Signature:

Stressing record - from both ends

Al Sharqiyah Express Way Section II Part 2 ( Al

Project : Kamil To Sur) Client : Minisitry of transport & communications DGR LT

Contractor : Khalid Bin Ahmed & Sons LLC DSI Approval : ETA - 130815

Subcontractor : DSI / Al Ammar International Structure : Interchange bridge - 12

Drawing Number : KAS/BS2P/SDW/TD/IC13/006-005-R02

Tendon characteristics Stressing equipment

Tendon number 1 Type of jack : HOZ 5400 /250

Stressing sequence 9 Type of pump : R6.4

Number of strands 19

Coil Number 1741329718 End : Abuitment 1 Jack N° : 975448

Theoritical tendon lenght = 51.287 m Piston area (Sp) 894.57 cm² Pump N°: 934676

Theoritical elongation (2) = 342 mm Friction at jacking force (f 0.38 % Mano N°: 1104UZF4

Theoritical elongation protrusion len = 11 mm End : Abuitment 2 Jack N° : 06-086

Correction factor = 0.991 Piston area (Sp) 894.57 cm² Pump N°: 8301

Total corrected theoritical elongation (3) = 350 mm Friction at jacking force (f 0.18 % Mano N°: 110701V4

Maximum elongation ( + 5%) = 368 mm

Theoritical elongation protrusion = L Jack X load Jacking force = 3,711 kN

lenghts 2 jacks E X S Tendons Jacking pressure - jack correction (4) = 416 bars

.8X3711X10^6 2968800000 jacking pressure - jack and manometer correction (5) 418 bars

= = 11 mm

195000x140x19 518700000 Maximal jacking pressure - (+ 5%) 439 bars

(2)

value from the table in the document KAS/BS2P/SDW/TD/IC13/006-005-R02

(3)

correcting factor (for actual cross section and elastic modukus) x theorotical elongation

(4)

Calcultated with the following formula : P (bar) = F(kN) / (Sp(cm²) x 0,01 x (1-fr)), at both jacks. The average value has to be considered.

(5)

Includes the deviation of the manometer, according to certificate of calibration, in the area of the jacking pressure ( » 2bars)

End : Abuitment 1 End : Abuitment 2

Pressure Partial elongation sum total elongation

(Bars) Partial Elongation Partial Elongation (1) + (2)

Reading (mm) Reading (mm)

(1) (2)

40 44 84

100 172 167 84

38 43 81

200 134 124 165

43 43 86

300 91 81 251

39 47 86

400 52 34 337

12 8 20

418 40 26 357

The partial elongation at 100 bars is a calculated value. It is the average of the partial elongation of the stages : 100 to 200 bars / 200 to 300 bars / 300 to 400

bars.

Pressure shall not exceed maximal pressure (+ 5%). Elongation shall not exceed maximum elongation (+5%).

Observations on stressing operation :

Al Ammar Int Trd & Cont KAS Renardet :

Name : Syed Kareemuddin Name : Name :

Date : Date : Date :

Signature: Signature: Signature:

Stressing record - from both ends

Al Sharqiyah Express Way Section II Part 2 ( Al

Project : Kamil To Sur) Client : Minisitry of transport & communications DGR LT

Contractor : Khalid Bin Ahmed & Sons LLC DSI Approval : ETA - 130815

Subcontractor : DSI / Al Ammar International Structure : Interchange bridge - 12

Drawing Number : KAS/BS2P/SDW/TD/IC13/006-005-R02

Tendon characteristics Stressing equipment

Tendon number 10 Type of jack : HOZ 5400 /250

Stressing sequence 10 Type of pump : R6.4

Number of strands 19

Coil Number 1741329716 End : Abuitment 1 Jack N° : 975448

Theoritical tendon lenght = 51.287 m Piston area (Sp) 894.57 cm² Pump N°: 934676

Theoritical elongation (2) = 342 mm Friction at jacking force (f 0.38 % Mano N°: 1104UZF4

Theoritical elongation protrusion len = 11 mm End : Abuitment 2 Jack N° : 06-086

Correction factor = 0.991 Piston area (Sp) 894.57 cm² Pump N°: 8301

Total corrected theoritical elongation (3) = 350 mm Friction at jacking force (f 0.18 % Mano N°: 110701V4

Maximum elongation ( + 5%) = 368 mm

Theoritical elongation protrusion = L Jack X load Jacking force = 3,711 kN

lenghts 2 jacks E X S Tendons Jacking pressure - jack correction (4) = 416 bars

.8X3711X10^6 2968800000 jacking pressure - jack and manometer correction (5) 418 bars

= = 11 mm

195000x140x19 518700000 Maximal jacking pressure - (+ 5%) 439 bars

(2)

value from the table in the document KAS/BS2P/SDW/TD/IC13/006-005-R02

(3)

correcting factor (for actual cross section and elastic modukus) x theorotical elongation

(4)

Calcultated with the following formula : P (bar) = F(kN) / (Sp(cm²) x 0,01 x (1-fr)), at both jacks. The average value has to be considered.

(5)

Includes the deviation of the manometer, according to certificate of calibration, in the area of the jacking pressure ( » 2bars)

End : Abuitment 1 End : Abuitment 2

Pressure Partial elongation sum

Partial Elongation Partial Elongation total elongation

(Bars) Reading (mm) Reading (mm) (1) + (2)

(1) (2)

42 44 86

100 167 178 86

46 43 89

200 121 135 175

42 42 84

300 79 93 259

39 47 86

400 40 46 345

12 7 19

418 28 39 364

The partial elongation at 100 bars is a calculated value. It is the average of the partial elongation of the stages : 100 to 200 bars / 200 to 300 bars / 300 to 400

bars.

Pressure shall not exceed maximal pressure (+ 5%). Elongation shall not exceed maximum elongation (+5%).

Observations on stressing operation :

Al Ammar Int Trd & Cont KAS Renardet :

Name : Syed Kareemuddin Name : Name :

Date : Date : Date :

Signature: Signature: Signature:

Signature: Signature: Signature:

Stressing record - from both ends

Al Sharqiyah Express Way Section II Part 2 ( Al

Project : Kamil To Sur) Client : Minisitry of transport & communications DGR LT

Contractor : Khalid Bin Ahmed & Sons LLC DSI Approval : ETA - 130815

Subcontractor : DSI / Al Ammar International Structure : Interchange bridge - 12

Drawing Number : KAS/BS2P/SDW/TD/IC13/006-005-R02

Tendon characteristics Stressing equipment

Tendon number 14 Type of jack : HOZ 5400 /250

Stressing sequence 11 Type of pump : R6.4

Number of strands 19

Coil Number 1741329719 End : Abuitment 1 Jack N° : 975448

Theoritical tendon lenght = 212 m Piston area (Sp) 894.57 cm² Pump N°: 934676

Theoritical elongation (2) = 216 mm Friction at jacking force (f 0.38 % Mano N°: 1104UZF4

Theoritical elongation protrusion len = 11 mm End : Abuitment 2 Jack N° : 06-086

Correction factor = 0.992 Piston area (Sp) 894.57 cm² Pump N°: 8301

Total corrected theoritical elongation (3) = 226 mm Friction at jacking force (f 0.18 % Mano N°: 110701V4

Maximum elongation ( + 5%) = 237 mm

Theoritical elongation protrusion = L Jack X load Jacking force = 3,711 kN

lenghts 2 jacks E X S Tendons Jacking pressure - jack correction (4) = 416 bars

.8X3711X10^6 2968800000 jacking pressure - jack and manometer correction (5) 418 bars

= = 11 mm

195000x140x19 518700000 Maximal jacking pressure - (+ 5%) 439 bars

(2)

value from the table in the document KAS/BS2P/SDW/TD/IC13/006-005-R02

(3)

correcting factor (for actual cross section and elastic modukus) x theorotical elongation

(4)

Calcultated with the following formula : P (bar) = F(kN) / (Sp(cm²) x 0,01 x (1-fr)), at both jacks. The average value has to be considered.

(5)

Includes the deviation of the manometer, according to certificate of calibration, in the area of the jacking pressure ( » 2bars)

End : Abuitment 1 End : Abuitment 2

Pressure Partial elongation sum

Partial Elongation Partial Elongation total elongation

(Bars) Reading (mm) Reading (mm) (1) + (2)

(1) (2)

27 28 55

100 176 174 55

26 26 52

200 150 148 107

27 28 55

300 123 120 162

28 30 58

400 95 90 220

6 5 11

418 89 85 231

The partial elongation at 100 bars is a calculated value. It is the average of the partial elongation of the stages : 100 to 200 bars / 200 to 300 bars / 300 to 400

bars.

Pressure shall not exceed maximal pressure (+ 5%). Elongation shall not exceed maximum elongation (+5%).

Observations on stressing operation :

Al Ammar Int Trd & Cont KAS Renardet :

Name : Syed Kareemuddin Name : Name :

Date : Date : Date :

Signature: Signature: Signature:

Signature: Signature: Signature:

Stressing record - from both ends

Al Sharqiyah Express Way Section II Part 2 ( Al

Project : Kamil To Sur) Client : Minisitry of transport & communications DGR LT

Contractor : Khalid Bin Ahmed & Sons LLC DSI Approval : ETA - 130815

Subcontractor : DSI / Al Ammar International Structure : Interchange bridge - 12

Drawing Number : KAS/BS2P/SDW/TD/IC13/006-005-R02

Tendon characteristics Stressing equipment

Tendon number 17 Type of jack : HOZ 5400 /250

Stressing sequence 12 Type of pump : R6.4

Number of strands 19

Coil Number 1741329714 End : Abuitment 1 Jack N° : 975448

Theoritical tendon lenght = 31.287 m Piston area (Sp) 894.57 cm² Pump N°: 934676

Theoritical elongation (2) = 212 mm Friction at jacking force (f 0.38 % Mano N°: 1104UZF4

Theoritical elongation protrusion len = 11 mm End : Abuitment 2 Jack N° : 06-086

Correction factor = 0.981 Piston area (Sp) 894.57 cm² Pump N°: 8301

Total corrected theoritical elongation (3) = 219 mm Friction at jacking force (f 0.18 % Mano N°: 110701V4

Maximum elongation ( + 5%) = 230 mm

Theoritical elongation protrusion = L Jack X load Jacking force = 3,711 kN

lenghts 2 jacks E X S Tendons Jacking pressure - jack correction (4) = 416 bars

.8X3711X10^6 2968800000 jacking pressure - jack and manometer correction (5) 418 bars

= = 11 mm

195000x140x19 518700000 Maximal jacking pressure - (+ 5%) 439 bars

(2)

value from the table in the document KAS/BS2P/SDW/TD/IC13/006-005-R02

(3)

correcting factor (for actual cross section and elastic modukus) x theorotical elongation

(4)

Calcultated with the following formula : P (bar) = F(kN) / (Sp(cm²) x 0,01 x (1-fr)), at both jacks. The average value has to be considered.

(5)

Includes the deviation of the manometer, according to certificate of calibration, in the area of the jacking pressure ( » 2bars)

End : Abuitment 1 End : Abuitment 2

Pressure Partial elongation sum total elongation

(Bars) Partial Elongation Partial Elongation (1) + (2)

Reading (mm) Reading (mm)

(1) (2)

27 28 55

100 185 183 55

28 27 55

200 157 156 110

27 28 55

300 130 128 165

27 29 56

400 103 99 221

5 4 9

418 98 95 230

The partial elongation at 100 bars is a calculated value. It is the average of the partial elongation of the stages : 100 to 200 bars / 200 to 300 bars / 300 to 400

bars.

Pressure shall not exceed maximal pressure (+ 5%). Elongation shall not exceed maximum elongation (+5%).

Observations on stressing operation :

Al Ammar Int Trd & Cont KAS Renardet :

Name : Syed Kareemuddin Name : Name :

Date : Date : Date :

Signature: Signature: Signature:

Stressing record - from both ends

Al Sharqiyah Express Way Section II Part 2 ( Al

Project : Kamil To Sur) Client : Minisitry of transport & communications DGR LT

Contractor : Khalid Bin Ahmed & Sons LLC DSI Approval : ETA - 130815

Subcontractor : DSI / Al Ammar International Structure : Interchange bridge - 12

Drawing Number : KAS/BS2P/SDW/TD/IC13/006-005-R02

Tendon characteristics Stressing equipment

Tendon number 15 Type of jack : HOZ 5400 /250

Stressing sequence 13 Type of pump : R6.4

Number of strands 19

Coil Number 1741329719 End : Abuitment 1 Jack N° : 975448

Theoritical tendon lenght = 31.287 m Piston area (Sp) 894.57 cm² Pump N°: 934676

Theoritical elongation (2) = 212 mm Friction at jacking force (f 0.38 % Mano N°: 1104UZF4

Theoritical elongation protrusion len = 11 mm End : Abuitment 2 Jack N° : 06-086

Correction factor = 0.992 Piston area (Sp) 894.57 cm² Pump N°: 8301

Total corrected theoritical elongation (3) = 222 mm Friction at jacking force (f 0.18 % Mano N°: 110701V4

Maximum elongation ( + 5%) = 233 mm

Theoritical elongation protrusion = L Jack X load Jacking force = 3,711 kN

lenghts 2 jacks E X S Tendons Jacking pressure - jack correction (4) = 416 bars

.8X3711X10^6 2968800000 jacking pressure - jack and manometer correction (5) 418 bars

= = 11 mm

195000x140x19 518700000 Maximal jacking pressure - (+ 5%) 439 bars

(2)

value from the table in the document KAS/BS2P/SDW/TD/IC13/006-005-R02

(3)

correcting factor (for actual cross section and elastic modukus) x theorotical elongation

(4)

Calcultated with the following formula : P (bar) = F(kN) / (Sp(cm²) x 0,01 x (1-fr)), at both jacks. The average value has to be considered.

(5)

Includes the deviation of the manometer, according to certificate of calibration, in the area of the jacking pressure ( » 2bars)

End : Abuitment 1 End : Abuitment 2

Pressure Partial elongation sum total elongation

(Bars) Partial Elongation Partial Elongation (1) + (2)

Reading (mm) Reading (mm)

(1) (2)

27 28 55

100 185 183 55

26 27 53

200 159 156 108

30 28 58

300 129 128 166

26 28 54

400 103 100 220

5 5 10

418 98 95 230

The partial elongation at 100 bars is a calculated value. It is the average of the partial elongation of the stages : 100 to 200 bars / 200 to 300 bars / 300 to 400

bars.

Pressure shall not exceed maximal pressure (+ 5%). Elongation shall not exceed maximum elongation (+5%).

Observations on stressing operation :

Al Ammar Int Trd & Cont KAS Renardet :

Name : Syed Kareemuddin Name : Name :

Date : Date : Date :

Signature: Signature: Signature:

Stressing record - from both ends

Al Sharqiyah Express Way Section II Part 2 ( Al

Project : Kamil To Sur) Client : Minisitry of transport & communications DGR LT

Contractor : Khalid Bin Ahmed & Sons LLC DSI Approval : ETA - 130815

Subcontractor : DSI / Al Ammar International Structure : Interchange bridge - 12

Drawing Number : KAS/BS2P/SDW/TD/IC13/006-005-R02

Tendon characteristics Stressing equipment

Tendon number 16 Type of jack : HOZ 5400 /250

Stressing sequence 14 Type of pump : R6.4

Number of strands 19

Coil Number 1741329719/1741329714 End : Abuitment 1 Jack N° : 975448

Theoritical tendon lenght = 31.287 m Piston area (Sp) 894.57 cm² Pump N°: 934676

Theoritical elongation (2) = 212 mm Friction at jacking force (f 0.38 % Mano N°: 1104UZF4

Theoritical elongation protrusion len = 11 mm End : Abuitment 2 Jack N° : 06-086

Correction factor = 0.988 Piston area (Sp) 894.57 cm² Pump N°: 8301

Total corrected theoritical elongation (3) = 221 mm Friction at jacking force (f 0.18 % Mano N°: 110701V4

Maximum elongation ( + 5%) = 232 mm

Theoritical elongation protrusion = L Jack X load Jacking force = 3,711 kN

lenghts 2 jacks E X S Tendons Jacking pressure - jack correction (4) = 416 bars

.8X3711X10^6 2968800000 jacking pressure - jack and manometer correction (5) 418 bars

= = 11 mm

195000x140x19 518700000 Maximal jacking pressure - (+ 5%) 439 bars

(2)

value from the table in the document KAS/BS2P/SDW/TD/IC13/006-005-R02

(3)

correcting factor (for actual cross section and elastic modukus) x theorotical elongation

(4)

Calcultated with the following formula : P (bar) = F(kN) / (Sp(cm²) x 0,01 x (1-fr)), at both jacks. The average value has to be considered.

(5)

Includes the deviation of the manometer, according to certificate of calibration, in the area of the jacking pressure ( » 2bars)

End : Abuitment 1 End : Abuitment 2

Pressure Partial elongation sum

(Bars) Partial Elongation Partial Elongation (1) + (2) total elongation

Reading (mm) (1) Reading (mm) (2)

27 28 55

100 189 186 55

22 27 49

200 167 159 104

32 29 61

300 135 130 165

28 28 56

400 107 102 221

5 4 9

418 102 98 230

The partial elongation at 100 bars is a calculated value. It is the average of the partial elongation of the stages : 100 to 200 bars / 200 to 300 bars / 300 to 400

bars.

Pressure shall not exceed maximal pressure (+ 5%). Elongation shall not exceed maximum elongation (+5%).

Observations on stressing operation :

Al Ammar Int Trd & Cont KAS Renardet :

Name : Syed Kareemuddin Name : Name :

Date : Date : Date :

Signature: Signature: Signature:

Signature: Signature: Signature:

Stressing record - from both ends

Al Sharqiyah Express Way Section II Part 2 ( Al

Project : Kamil To Sur) Client : Minisitry of transport & communications DGR LT

Contractor : Khalid Bin Ahmed & Sons LLC DSI Approval : ETA - 130815

Subcontractor : DSI / Al Ammar International Structure : Interchange bridge - 12

Drawing Number : KAS/BS2P/SDW/TD/IC13/006-005-R02

Tendon characteristics Stressing equipment

Tendon number 4 Type of jack : HOZ 5400 /250

Stressing sequence 15 Type of pump : R6.4

Number of strands 19

Coil Number 1741329715 End : Abuitment 1 Jack N° : 975448

Theoritical tendon lenght = 51.205 m Piston area (Sp) 894.57 cm² Pump N°: 934676

Theoritical elongation (2) = 345 mm Friction at jacking force (f 0.38 % Mano N°: 1104UZF4

Theoritical elongation protrusion len = 11 mm End : Abuitment 2 Jack N° : 06-086

Correction factor = 0.991 Piston area (Sp) 894.57 cm² Pump N°: 8301

Total corrected theoritical elongation (3) = 353 mm Friction at jacking force (f 0.18 % Mano N°: 110701V4

Maximum elongation ( + 5%) = 371 mm

Theoritical elongation protrusion = L Jack X load Jacking force = 3,711 kN

lenghts 2 jacks E X S Tendons Jacking pressure - jack correction (4) = 416 bars

.8X3711X10^6 2968800000 jacking pressure - jack and manometer correction (5) 418 bars

= = 11 mm

195000x140x19 518700000 Maximal jacking pressure - (+ 5%) 439 bars

(2)

value from the table in the document KAS/BS2P/SDW/TD/IC13/006-005-R02

(3)

correcting factor (for actual cross section and elastic modukus) x theorotical elongation

(4)

Calcultated with the following formula : P (bar) = F(kN) / (Sp(cm²) x 0,01 x (1-fr)), at both jacks. The average value has to be considered.

(5)

Includes the deviation of the manometer, according to certificate of calibration, in the area of the jacking pressure ( » 2bars)

End : Abuitment 1 End : Abuitment 2

Pressure Partial elongation sum total elongation

(Bars) Reading (mm) Partial Elongation Reading (mm) Partial Elongation (1) + (2)

(1) (2)

42 45 87

100 170 169 87

43 45 88

200 127 124 175

42 45 87

300 85 79 262

41 46 87

400 44 33 349

8 6 14

418 36 27 363

The partial elongation at 100 bars is a calculated value. It is the average of the partial elongation of the stages : 100 to 200 bars / 200 to 300 bars / 300 to 400

bars.

Pressure shall not exceed maximal pressure (+ 5%). Elongation shall not exceed maximum elongation (+5%).

Observations on stressing operation :

Al Ammar Int Trd & Cont KAS Renardet :

Name : Syed Kareemuddin Name : Name :

Date : Date : Date :

Signature: Signature: Signature:

Stressing record - from both ends

Al Sharqiyah Express Way Section II Part 2 ( Al

Project : Kamil To Sur) Client : Minisitry of transport & communications DGR LT

Contractor : Khalid Bin Ahmed & Sons LLC DSI Approval : ETA - 130815

Subcontractor : DSI / Al Ammar International Structure : Interchange bridge - 12

Drawing Number : KAS/BS2P/SDW/TD/IC13/006-005-R02

Tendon characteristics Stressing equipment

Tendon number 7 Type of jack : HOZ 5400 /250

Stressing sequence 16 Type of pump : R6.4

Number of strands 19

Coil Number 1741329717 End : Abuitment 1 Jack N° : 975448

Theoritical tendon lenght = 51.205 m Piston area (Sp) 894.57 cm² Pump N°: 934676

Theoritical elongation (2) = 345 mm Friction at jacking force (f 0.38 % Mano N°: 1104UZF4

Theoritical elongation protrusion len = 11 mm End : Abuitment 2 Jack N° : 06-086

Correction factor = 0.991 Piston area (Sp) 894.57 cm² Pump N°: 8301

Total corrected theoritical elongation (3) = 353 mm Friction at jacking force (f 0.18 % Mano N°: 110701V4

Maximum elongation ( + 5%) = 371 mm

Theoritical elongation protrusion = L Jack X load Jacking force = 3,711 kN

lenghts 2 jacks E X S Tendons Jacking pressure - jack correction (4) = 416 bars

.8X3711X10^6 2968800000 jacking pressure - jack and manometer correction (5) 418 bars

= = 11 mm

195000x140x19 518700000 Maximal jacking pressure - (+ 5%) 439 bars

(2)

value from the table in the document KAS/BS2P/SDW/TD/IC13/006-005-R02

(3)

correcting factor (for actual cross section and elastic modukus) x theorotical elongation

(4)

Calcultated with the following formula : P (bar) = F(kN) / (Sp(cm²) x 0,01 x (1-fr)), at both jacks. The average value has to be considered.

(5)

Includes the deviation of the manometer, according to certificate of calibration, in the area of the jacking pressure ( » 2bars)

End : Abuitment 1 End : Abuitment 2

Pressure Partial elongation sum total elongation

(Bars) Partial Elongation Partial Elongation (1) + (2)

Reading (mm) Reading (mm)

(1) (2)

43 44 88

100 170 167 88

43 42 85

200 127 125 173

43 44 87

300 84 81 260

44 47 91

400 40 34 351

8 6 14

418 32 28 365

The partial elongation at 100 bars is a calculated value. It is the average of the partial elongation of the stages : 100 to 200 bars / 200 to 300 bars / 300 to 400

bars.

Pressure shall not exceed maximal pressure (+ 5%). Elongation shall not exceed maximum elongation (+5%).

Observations on stressing operation :

Al Ammar Int Trd & Cont KAS Renardet :

Name : Syed Kareemuddin Name : Name :

Date : Date : Date :

Signature: Signature: Signature:

Stressing record - from both ends

Al Sharqiyah Express Way Section II Part 2 ( Al

Project : Kamil To Sur) Client : Minisitry of transport & communications DGR LT

Contractor : Khalid Bin Ahmed & Sons LLC DSI Approval : ETA - 130815

Subcontractor : DSI / Al Ammar International Structure : Interchange bridge - 12

Drawing Number : KAS/BS2P/SDW/TD/IC13/006-005-R02

Tendon characteristics Stressing equipment

Tendon number 2 Type of jack : HOZ 5400 /250

Stressing sequence 17 Type of pump : R6.4

Number of strands 19

Coil Number 1741329718 End : Abuitment 1 Jack N° : 975448

Theoritical tendon lenght = 51.277 m Piston area (Sp) 894.57 cm² Pump N°: 934676

Theoritical elongation (2) = 341 mm Friction at jacking force (f 0.38 % Mano N°: 1104UZF4

Theoritical elongation protrusion len = 11 mm End : Abuitment 2 Jack N° : 06-086

Correction factor = 0.991 Piston area (Sp) 894.57 cm² Pump N°: 8301

Total corrected theoritical elongation (3) = 349 mm Friction at jacking force (f 0.18 % Mano N°: 110701V4

Maximum elongation ( + 5%) = 367 mm

Theoritical elongation protrusion = L Jack X load Jacking force = 3,711 kN

lenghts 2 jacks E X S Tendons Jacking pressure - jack correction (4) = 416 bars

.8X3711X10^6 2968800000 jacking pressure - jack and manometer correction (5) 418 bars

= = 11 mm

195000x140x19 518700000 Maximal jacking pressure - (+ 5%) 439 bars

(2)

value from the table in the document KAS/BS2P/SDW/TD/IC13/006-005-R02

(3)

correcting factor (for actual cross section and elastic modukus) x theorotical elongation

(4)

Calcultated with the following formula : P (bar) = F(kN) / (Sp(cm²) x 0,01 x (1-fr)), at both jacks. The average value has to be considered.

(5)

Includes the deviation of the manometer, according to certificate of calibration, in the area of the jacking pressure ( » 2bars)

End : Abuitment 1 End : Abuitment 2

Pressure Partial elongation sum total elongation

(Bars) Partial Elongation Partial Elongation (1) + (2)

Reading (mm) Reading (mm)

(1) (2)

41 44 85

100 147 141 85

41 44 85

200 106 97 170

40 43 83

300 66 54 253

42 44 86

400 24 10 339

10 8 18

418 14 2 357

The partial elongation at 100 bars is a calculated value. It is the average of the partial elongation of the stages : 100 to 200 bars / 200 to 300 bars / 300 to 400

bars.

Pressure shall not exceed maximal pressure (+ 5%). Elongation shall not exceed maximum elongation (+5%).

Observations on stressing operation :

Al Ammar Int Trd & Cont KAS Renardet :

Name : Syed Kareemuddin Name : Name :

Date : Date : Date :

Signature: Signature: Signature:

Signature: Signature: Signature:

Stressing record - from both ends

Al Sharqiyah Express Way Section II Part 2 ( Al

Project : Kamil To Sur) Client : Minisitry of transport & communications DGR LT

Contractor : Khalid Bin Ahmed & Sons LLC DSI Approval : ETA - 130815

Subcontractor : DSI / Al Ammar International Structure : Interchange bridge - 12

Drawing Number : KAS/BS2P/SDW/TD/IC13/006-005-R02

Tendon characteristics Stressing equipment

Tendon number 11 Type of jack : HOZ 5400 /250

Stressing sequence 18 Type of pump : R6.4

Number of strands 19

Coil Number 1741329716 End : Abuitment 1 Jack N° : 975448

Theoritical tendon lenght = 51.277 m Piston area (Sp) 894.57 cm² Pump N°: 934676

Theoritical elongation (2) = 341 mm Friction at jacking force (f 0.38 % Mano N°: 1104UZF4

Theoritical elongation protrusion len = 11 mm End : Abuitment 2 Jack N° : 06-086

Correction factor = 0.991 Piston area (Sp) 894.57 cm² Pump N°: 8301

Total corrected theoritical elongation (3) = 349 mm Friction at jacking force (f 0.18 % Mano N°: 110701V4

Maximum elongation ( + 5%) = 367 mm

Theoritical elongation protrusion = L Jack X load Jacking force = 3,711 kN

lenghts 2 jacks E X S Tendons Jacking pressure - jack correction (4) = 416 bars

.8X3711X10^6 2968800000 jacking pressure - jack and manometer correction (5) 418 bars

= = 11 mm

195000x140x19 518700000 Maximal jacking pressure - (+ 5%) 439 bars

(2)

value from the table in the document KAS/BS2P/SDW/TD/IC13/006-005-R02

(3)

correcting factor (for actual cross section and elastic modukus) x theorotical elongation

(4)

Calcultated with the following formula : P (bar) = F(kN) / (Sp(cm²) x 0,01 x (1-fr)), at both jacks. The average value has to be considered.

(5)

Includes the deviation of the manometer, according to certificate of calibration, in the area of the jacking pressure ( » 2bars)

End : Abuitment 1 End : Abuitment 2

Pressure Partial elongation sum

Partial Elongation Partial Elongation total elongation

(Bars) Reading (mm) Reading (mm) (1) + (2)

(1) (2)

41 44 85

100 157 154 85

41 35 76

200 116 119 161

40 53 93

300 76 66 254

41 45 86

400 35 21 340

10 8 18

418 25 13 358

The partial elongation at 100 bars is a calculated value. It is the average of the partial elongation of the stages : 100 to 200 bars / 200 to 300 bars / 300 to 400

bars.

Pressure shall not exceed maximal pressure (+ 5%). Elongation shall not exceed maximum elongation (+5%).

Observations on stressing operation :

Al Ammar Int Trd & Cont KAS Renardet :

Name : Syed Kareemuddin Name : Name :

Date : Date : Date :

Signature: Signature: Signature:

Signature: Signature: Signature:

You might also like

- David Brown 1390 ManualDocument109 pagesDavid Brown 1390 Manualswan1234567100% (9)

- Case International 1190 1194 1290 1294 1390 1394 1490 1494 1594 1690 Shop ManualDocument10 pagesCase International 1190 1194 1290 1294 1390 1394 1490 1494 1594 1690 Shop Manualpeter100% (46)

- Insulation of Turbogenerators by VPI Process PDFDocument65 pagesInsulation of Turbogenerators by VPI Process PDFprinceshankerNo ratings yet

- Pamphlet 167 - Edition 3 - May 2014Document32 pagesPamphlet 167 - Edition 3 - May 2014Victor JardimNo ratings yet

- EXTEC X44 Parts ManualDocument115 pagesEXTEC X44 Parts ManualSport Diet Music SDMNo ratings yet

- Conveyor Belt EquationsDocument6 pagesConveyor Belt EquationsWaris La Joi WakatobiNo ratings yet

- Chery QR019CHB CVTDocument134 pagesChery QR019CHB CVTossoski50% (4)

- 2-3-4 M41 PDFDocument6 pages2-3-4 M41 PDFJaved SamaNo ratings yet

- Afs Casting Design WhitepaperDocument11 pagesAfs Casting Design Whitepaperstevenminhtam100% (1)

- Comparison of Bricks SpecificationsDocument1 pageComparison of Bricks SpecificationsSaji KumarNo ratings yet

- Tính Chiều Rộng Tôn BưngDocument20 pagesTính Chiều Rộng Tôn BưngVăn ChinhNo ratings yet

- Cartera de Credito 14Document6 pagesCartera de Credito 14adelahuamanNo ratings yet

- Inaltim Ea (CM) Sex (1 Mas Culin 0 Femi Nin) Inaltim e Tata (CM)Document23 pagesInaltim Ea (CM) Sex (1 Mas Culin 0 Femi Nin) Inaltim e Tata (CM)Irina BarabasNo ratings yet

- Pro-Shift STD Ps150-16 Transmission Parts Catalog: Bulletin No T210-PS0-16 Revised June 1999Document39 pagesPro-Shift STD Ps150-16 Transmission Parts Catalog: Bulletin No T210-PS0-16 Revised June 1999jacintoNo ratings yet

- Maintenance - BR-V 1.5 MalaysiaDocument1 pageMaintenance - BR-V 1.5 MalaysiaMAT HIDUP RIDHUAN BIN ABDUL WAHAB KPM-GuruNo ratings yet

- Maintenance - City 1.5Document1 pageMaintenance - City 1.5FARIDAH BINTI OTHMAN MoeNo ratings yet

- Full Table Report 1835716Document4 pagesFull Table Report 1835716DESPACHO MIQNo ratings yet

- BRV Maintenance SheetDocument1 pageBRV Maintenance SheetdharhennaNo ratings yet

- Aggregate PlanningDocument3 pagesAggregate Planningmohamed matarNo ratings yet

- OutputDocument1 pageOutputamit sharmaNo ratings yet

- Realme 8 (Cyber Silver, 128 GB) : Grand Total 13749.00Document1 pageRealme 8 (Cyber Silver, 128 GB) : Grand Total 13749.00amit sharmaNo ratings yet

- Maintenance - City Hatchback 1.5Document1 pageMaintenance - City Hatchback 1.5jatkure2No ratings yet

- Mix Design SheetDocument17 pagesMix Design SheetQadir UllahNo ratings yet

- Part (B)Document5 pagesPart (B)shrushro123No ratings yet

- Hystea: TransmissionDocument33 pagesHystea: TransmissionMelwyn FernandesNo ratings yet

- Mix Design SheetDocument17 pagesMix Design SheetAmar WadoodNo ratings yet

- Side Bearer Mounts From GMTDocument1 pageSide Bearer Mounts From GMTGMT Rubber-Metal-TechnicNo ratings yet

- Trọng lượng 165.1 165.2 165.2 165.3 165.6 165.8 165.9 166 166.2 166.4 166.8 166.9 167.1 167.3 167.4 167.4 167.7 167.8 168.1 168.7 168.9 170 170.2 170.6Document8 pagesTrọng lượng 165.1 165.2 165.2 165.3 165.6 165.8 165.9 166 166.2 166.4 166.8 166.9 167.1 167.3 167.4 167.4 167.7 167.8 168.1 168.7 168.9 170 170.2 170.6Trâm BùiNo ratings yet

- Naive & Cumulative ForecastDocument3 pagesNaive & Cumulative ForecastSandeep MandalNo ratings yet

- CASE 1190 Shop ManualDocument23 pagesCASE 1190 Shop ManualRytis SiaulysNo ratings yet

- COntoh LOLPDocument17 pagesCOntoh LOLPYudaSetyaRahmadaniNo ratings yet

- Maintenance - City 1.5Document1 pageMaintenance - City 1.5sukrry roseliNo ratings yet

- ProxiesDocument201 pagesProxiesKhaled ElboreyNo ratings yet

- Important Information: Section 1C - General InformationDocument21 pagesImportant Information: Section 1C - General InformationDr. Centelha Mecânica NaúticaNo ratings yet

- Pipe Pressure Loss Calculation MethodsDocument8 pagesPipe Pressure Loss Calculation MethodsaerqwerNo ratings yet

- Maintenance WRV 1.5Document1 pageMaintenance WRV 1.5NOR HIKMAH LUBIS MHD ZAINNo ratings yet

- Fire Pump Acceptance Test: Name: Vintage Denim Studio LTDDocument1 pageFire Pump Acceptance Test: Name: Vintage Denim Studio LTDMd Nazrul Islam AzadNo ratings yet

- Department of Chemical Engineering: To Study Temperature Distribution Along The Length of Fin PinDocument8 pagesDepartment of Chemical Engineering: To Study Temperature Distribution Along The Length of Fin PinSANIKA TALATHINo ratings yet

- Calculo AlimentadoresDocument2 pagesCalculo AlimentadoresLuciana SaldivarNo ratings yet

- ADU4518F1Document3 pagesADU4518F1Derka DemNo ratings yet

- Chart Title: PBDM IntervalDocument6 pagesChart Title: PBDM IntervalRiandrika Iman SetyonoNo ratings yet

- Robinson Track and Balance PDFDocument42 pagesRobinson Track and Balance PDFJoao Abelange0% (1)

- Georg Fischer - P20 Injector - Datasheet PDFDocument1 pageGeorg Fischer - P20 Injector - Datasheet PDFindra irawanNo ratings yet

- Mix Design SheetDocument17 pagesMix Design SheetThaigroup CementNo ratings yet

- Full Table Report 2289516Document7 pagesFull Table Report 2289516DESPACHO MIQNo ratings yet

- 605 00 207 - RevA - Z2 - TuningGuide Bomber z2Document12 pages605 00 207 - RevA - Z2 - TuningGuide Bomber z2Andreas FortniteNo ratings yet

- Seminar 3 (ASE-2020)Document3 pagesSeminar 3 (ASE-2020)ValentinNo ratings yet

- New AG Parallel Shaft Gear DriveDocument6 pagesNew AG Parallel Shaft Gear Drivejose BalderasNo ratings yet

- Guia Cal MarcDocument10 pagesGuia Cal MarcErick Arthur Prieto TejadaNo ratings yet

- Blue Moon Private Limited (BMPL)Document7 pagesBlue Moon Private Limited (BMPL)ADAM NUR ALIF MOHD KHALIDNo ratings yet

- Daily Report Piping 1400.10.23Document1 pageDaily Report Piping 1400.10.23MohammadNo ratings yet

- Frecuencias Xi fi X*fi (X-μ) ² (X-μ) ² *fi Marcas de Clase: Sueldo emn miles de pesos trabajadoresDocument4 pagesFrecuencias Xi fi X*fi (X-μ) ² (X-μ) ² *fi Marcas de Clase: Sueldo emn miles de pesos trabajadoresJulian David HurtadoNo ratings yet

- Catalogo Auto Lighting 2009Document318 pagesCatalogo Auto Lighting 2009DAIMLERBNo ratings yet

- Nama: Sulistiani Nim: 1713027 Mata Kuliah: Rekayasa Drainase (UTS)Document2 pagesNama: Sulistiani Nim: 1713027 Mata Kuliah: Rekayasa Drainase (UTS)Sulis TianiNo ratings yet

- YTD Statement 2017 - 2018Document1 pageYTD Statement 2017 - 2018HanumanthNo ratings yet

- Listapreciosxls (8) 05-06Document504 pagesListapreciosxls (8) 05-06Jhoselyn Rubi Valverde BallenaNo ratings yet

- Lincoln Spares MRP - 190409Document19 pagesLincoln Spares MRP - 190409Pranay JoshiNo ratings yet

- Hydrology Assignment-1Document9 pagesHydrology Assignment-1Arun BhattaNo ratings yet

- 2Document1 page2Ahmed Samir SalimNo ratings yet

- All New - City 2GC 1.5 HYBRID 2017YM: Engine Oil + Drain Plug WasherDocument1 pageAll New - City 2GC 1.5 HYBRID 2017YM: Engine Oil + Drain Plug WasherWanNo ratings yet

- Experiment 3Document3 pagesExperiment 3Promit MandalNo ratings yet

- Power Settings HuskyDocument1 pagePower Settings HuskyQue Te ImportaNo ratings yet

- Cable Size Recommendations 12VdcDocument2 pagesCable Size Recommendations 12VdcJoaquim ReisNo ratings yet

- Belarus MTZ Termekcsalad Katalogus EngDocument97 pagesBelarus MTZ Termekcsalad Katalogus EngjovicasurNo ratings yet

- Flexural Strength Comparison of GCP and GICDocument22 pagesFlexural Strength Comparison of GCP and GICAli FaridiNo ratings yet

- BAroda BOQDocument16 pagesBAroda BOQTomNo ratings yet

- 2 - Ashby Method: 2.1 - Introduction To Materials SelectionDocument25 pages2 - Ashby Method: 2.1 - Introduction To Materials Selectionsgr_kansagraNo ratings yet

- Chapter - 6 Geomorphic Processes: 1. Why Earth Is Uneven?Document12 pagesChapter - 6 Geomorphic Processes: 1. Why Earth Is Uneven?Sahil Affriya YadavNo ratings yet

- ACI Spring 2016 - Thixotropy - Kawashima - FinalDocument20 pagesACI Spring 2016 - Thixotropy - Kawashima - FinalerosNo ratings yet

- 1 Preliminaries: 252221971.xls - Ms - Office - Rev1 BQ - 1Document26 pages1 Preliminaries: 252221971.xls - Ms - Office - Rev1 BQ - 1Anonymous UUw70xirblNo ratings yet

- Chapter 11 Introduction To Organic Chemistry: AlkanesDocument11 pagesChapter 11 Introduction To Organic Chemistry: AlkanesLeila AgtarapNo ratings yet

- Violations of The Octet Rule - Chemistry LibretextsDocument9 pagesViolations of The Octet Rule - Chemistry Libretextsapi-368121935No ratings yet

- 40 90 Mechanical Seal Kits SWIDocument2 pages40 90 Mechanical Seal Kits SWIWong DaNo ratings yet

- Velocity Boundary LayerDocument3 pagesVelocity Boundary LayerThe UltimateNo ratings yet

- L.D College of Engineering: A Report On Construction Site VisitDocument15 pagesL.D College of Engineering: A Report On Construction Site VisitNeel TurkhiyaNo ratings yet

- Datasheet - CoronaShield SC - 217.01 - EN - GL - 2012Document3 pagesDatasheet - CoronaShield SC - 217.01 - EN - GL - 2012LECTORNo ratings yet

- Fluid Mechanics - Unit 2 - Week 1 - INTRODUCTION PDFDocument5 pagesFluid Mechanics - Unit 2 - Week 1 - INTRODUCTION PDFAkhilesh KumarNo ratings yet

- Bearings Material Solutions in The Rolling Technology: August 2018Document25 pagesBearings Material Solutions in The Rolling Technology: August 2018Nano KusumaNo ratings yet

- اسئلة امتحان تنافسيDocument26 pagesاسئلة امتحان تنافسيHamed MasterNo ratings yet

- Loogbook 8 - 12 FebuaryDocument10 pagesLoogbook 8 - 12 FebuaryIkhwanul MuttaqienNo ratings yet

- CBSE 10th Science Sample Paper 1Document5 pagesCBSE 10th Science Sample Paper 1Aditya AcharyaNo ratings yet

- Module in Organic Chemistry: Aklan State UniversityDocument50 pagesModule in Organic Chemistry: Aklan State UniversityEj FerrerNo ratings yet

- Fundamental of Metal FormingDocument5 pagesFundamental of Metal FormingAnuj BhardwajNo ratings yet

- P-Block Elements & Compounds - 6Document12 pagesP-Block Elements & Compounds - 6rashidNo ratings yet

- US4753444Document5 pagesUS4753444Hadi KoraniNo ratings yet

- Improving Descale Performance With The Descalejet ProDocument7 pagesImproving Descale Performance With The Descalejet ProAdmiral FighterNo ratings yet

- FF-N-105B - Federal Specification - Nails, Brads, Staples and Spikes: Wire, Cut and WroughtDocument48 pagesFF-N-105B - Federal Specification - Nails, Brads, Staples and Spikes: Wire, Cut and WroughtAlberto NuñezNo ratings yet

- Lab Report Experiment 3 CHM457Document3 pagesLab Report Experiment 3 CHM457aremyrah AzlanNo ratings yet