Professional Documents

Culture Documents

Cap2 Air Distribution - Tabelas

Uploaded by

Rafael MendesOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cap2 Air Distribution - Tabelas

Uploaded by

Rafael MendesCopyright:

Available Formats

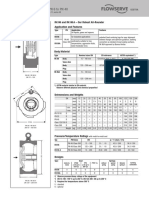

Part 2. Air Distribution | Chapter 2.

Air Duct Design

CHART 7 – FRECTION LOSS FOR ROUND DUCT

Part 2. Air Distribution | Chapter 2. Air Duct Design

TABLE 6 – CIRCULAR EQUIVALENT DIAMETER,*EQUIVALENT AREA AND DUCT CLASS†

OF RECTANGULAR DUCTS FOR EQUAL FRICTION.

Part 2. Air Distribution | Chapter 2. Air Duct Design

TABLE 6 – CIRCULAR EQUIVALENT DIAMETER,*EQUIVALENT AREA AND DUCT CLASS†

OF RECTANGULAR DUCT FOR EQUAL FRICTION. (Cont.)

Part 2. Air Distribution | Chapter 2. Air Duct Design

TABLE 6 – CIRCULAR EQUIVALENT DIAMETER,*EQUIVALENT AREA AND DUCT CLASS†

OF RECTANGULAR DUCTS FOR EQUAL FRICTION. (Cont.)

Part 2. Air Distribution | Chapter 2. Air Duct Design

Part 2. Air Distribution | Chapter 2. Air Duct Design

TABLE 10 – FRICTION OF RECTANGULAR DUCT SYSTEM ELEMENTS

Part 2. Air Distribution | Chapter 2. Air Duct Design

TABLE 10 – FRICTION OF RECTANGULAR DUCT SYSTEM ELEMENTS (Contd)

Part 2. Air Distribution | Chapter 2. Air Duct Design

NOTES FOR TABLE 9 NOTES FOR TABLE 10

*L and D are in feet. D is the elbow diameter. L is the additional equivalent length *1.25 is standard for an unvaned full radius elbow.

of duct added to the measured length. The equivalent length L equals D in feet †L and D are in feet. D is the duct diameter illustrated in the drawing. L is the

times the ratio listed. additional equivalent length of duct added to the measured duct. The equivalent

†The value of n is the loss in velocity heads and may be converted to additional length L equals D in feet times the ratio listed.

equivalent length of duct by the following equation. ‡The value n is the number of velocity heads or differences in velocity heads

lost or gained at a fitting, and may be converted to additional equivalent length of

L = n x hv x 100 duct by the following equation.

hf

Where : L = additional equivalent length, ft

L = n x hv x 100

hv = velocity pressure at V2, in. wg (conversion line on hf

Chart 7 or Table 8). Where : L = additional equivalent length, ft

hf = friction loss/100 ft, duct diameter at V2, in. wg hv = velocity pressure for V1, V2 or the differences in. velocity pressure,

(Chart 7). in wg (conversion line on Chart 7 or

n = value for tee or cross Table 8).

‡ Tee or cross may be either reduced or the same size in the straight thru hf = friction loss/100 ft, duct cross selection at hv, in. wg

portion (Chart 7).

n = value for particular fitting.

TABLE 11 – FRICTION OF ROUND ELBOWS

Part 2. Air Distribution | Chapter 2. Air Duct Design

TABLE 12 – FRICTION OF RECTANGULAR ELBOWS

Part 2. Air Distribution | Chapter 2. Air Duct Design

TABLE 12 – FRICTION OF RECTANGULAR ELBOWS (CONT.)

Part 2. Air Distribution | Chapter 2. Air Duct Design

CHART 9 – LOSSES FOR ROUND FITTINGS

Elbows, Tees and Crosses

Part 2. Air Distribution | Chapter 2. Air Duct Design

Supply air temperature diff = 16.4 – 1.1 = 15.3 F HIGH ALTITUDE DUCT DESIGN

Outler cfm adjusted for temperature rise When an air distribution system is designed to operate

= 18

500 x 15.3 = 588 cfm above 2000 feet altitude, below 30 F, or above 120 F

temperature, the friction loss obtained from Chart 7, page

Allowance for duct cooling 33, must be corrected for the air density. Chart 15

= (

588 – 588 x 1.1

15.3 ) = 546 cfm presents the correction factors for temperature and

altitude. The actual cfm is used to find the friction loss

5. Check for total cfm: from Chart 7 and this loss is multiplied by the correction

492 + 498 + 546 = 1536 cfm factor or factors from Chart 15 to obtain the actual friction

This compares favorably with the 1540 cfm entering loss.

room. Fig. 57 shows original and corrected outlet air

quantities.

CHART 15 – AIR DENSITY CORRECTION FACTORS

You might also like

- Equal FrictionDocument20 pagesEqual FrictionAijaz MalikNo ratings yet

- CARRIER Duct DesignDocument16 pagesCARRIER Duct DesignBudiman Raharjo'bjo'82% (17)

- Pipe Flow CalculationsDocument12 pagesPipe Flow CalculationsUmair KhanNo ratings yet

- Friction FactorDocument30 pagesFriction FactorSomnath JagtapNo ratings yet

- Transport PhenomenaDocument7 pagesTransport PhenomenannpeelaNo ratings yet

- Chapter Seven - Ducts and Fans SystemsDocument23 pagesChapter Seven - Ducts and Fans SystemsalhussenyNo ratings yet

- Southern Marine Engineering Desk Reference: Second Edition Volume IFrom EverandSouthern Marine Engineering Desk Reference: Second Edition Volume INo ratings yet

- 13 - Fluids at Rest and Piped FluidsDocument7 pages13 - Fluids at Rest and Piped FluidsVinay GuptaNo ratings yet

- NPSH and Head Calculation SamplesDocument40 pagesNPSH and Head Calculation SamplesArjonaJoséNo ratings yet

- Carier Tablas Método de Regeneración EstáticaDocument11 pagesCarier Tablas Método de Regeneración EstáticaFernandoNo ratings yet

- Experiment 1 - Friction Losses in PipesDocument34 pagesExperiment 1 - Friction Losses in PipesKhairil Ikram33% (3)

- Chapter 8 Oil and Gas Transport - 1987 - Developments in Petroleum ScienceDocument67 pagesChapter 8 Oil and Gas Transport - 1987 - Developments in Petroleum ScienceFalokid RaboNo ratings yet

- Ductwork Design ProgramDocument69 pagesDuctwork Design Programsalmaan khanNo ratings yet

- Pipe Flow ContdDocument28 pagesPipe Flow ContdAlif RifatNo ratings yet

- Pipe Flow Calculations PDFDocument12 pagesPipe Flow Calculations PDFharrypop418No ratings yet

- Pipe Flow: Laminar Flow or Viscous FlowDocument34 pagesPipe Flow: Laminar Flow or Viscous FlowBalaguruNo ratings yet

- Energy Loses in PipesDocument6 pagesEnergy Loses in PipesrianrureNo ratings yet

- 4 - Pipe Fitting LossesDocument4 pages4 - Pipe Fitting LossesstarykltNo ratings yet

- Energy Loses in Pipes PDFDocument6 pagesEnergy Loses in Pipes PDFAlexander MugabeNo ratings yet

- Duct DesignDocument49 pagesDuct DesignabianshbaralNo ratings yet

- RMS Inlet Pressure Calculation TheoryDocument22 pagesRMS Inlet Pressure Calculation TheoryRajesh SarkarNo ratings yet

- E4 Lab Sheet Minor Losses in PipeDocument17 pagesE4 Lab Sheet Minor Losses in PipeHoongNo ratings yet

- Air Cooler DesignDocument19 pagesAir Cooler Designnafees ahmadNo ratings yet

- Total Head, N.P.S.H. and Other Calculation Examples: Jacques Chaurette P. Eng., June 2003Document41 pagesTotal Head, N.P.S.H. and Other Calculation Examples: Jacques Chaurette P. Eng., June 2003Anonymous 1fyKr9XSeGNo ratings yet

- Engineering Bernoulli Equation PDFDocument19 pagesEngineering Bernoulli Equation PDFkhairul hisyamNo ratings yet

- Friction in Pipes and FittingsDocument23 pagesFriction in Pipes and FittingsEmmanuelNo ratings yet

- Aircooled ExchangersDocument20 pagesAircooled ExchangersTAHIR MAHMOODNo ratings yet

- Friction Loss in Valves and FittingsDocument4 pagesFriction Loss in Valves and FittingsEdu CordonNo ratings yet

- Pipe Flow Friction Factor CalculationsDocument13 pagesPipe Flow Friction Factor CalculationspelotoNo ratings yet

- Smacna Duct Designfundamentals PDFDocument151 pagesSmacna Duct Designfundamentals PDFandi nainggolan100% (1)

- Vent Axia Vent GuideDocument23 pagesVent Axia Vent GuideblasderNo ratings yet

- Lab - Pipe - Fittings (3) - 1-2Document13 pagesLab - Pipe - Fittings (3) - 1-2Abidul IslamNo ratings yet

- 10 Analysis of Pipe Flows: The Moody ChartDocument8 pages10 Analysis of Pipe Flows: The Moody ChartMiguel Angel Alvarez BoreaNo ratings yet

- Pipe Flow Friction Factor CalculationsDocument11 pagesPipe Flow Friction Factor CalculationsVictor ValenciaNo ratings yet

- EEE Pipe FrictionDocument7 pagesEEE Pipe FrictionmahabubNo ratings yet

- Lect. 2Document24 pagesLect. 2Hashim AbadaNo ratings yet

- Mod 5-Fan Measurement and TestingDocument227 pagesMod 5-Fan Measurement and TestinglovjnxNo ratings yet

- SBD 6479 WaterCalcWorksheet 01 12Document4 pagesSBD 6479 WaterCalcWorksheet 01 12Avinash SharmaNo ratings yet

- SBD-6479 WaterCalcWorksheet 01-12Document4 pagesSBD-6479 WaterCalcWorksheet 01-12Victor ValenciaNo ratings yet

- SBD-6479 WaterCalcWorksheet 01-12Document4 pagesSBD-6479 WaterCalcWorksheet 01-12Victor ValenciaNo ratings yet

- SBD 6479 WaterCalcWorksheet 01 12Document4 pagesSBD 6479 WaterCalcWorksheet 01 12NghiaNo ratings yet

- Pipe Flow: 1 Basic PrinciplesDocument6 pagesPipe Flow: 1 Basic PrinciplesadityaNo ratings yet

- Transmission of Air in Air Conditioning Ducts: LessonDocument18 pagesTransmission of Air in Air Conditioning Ducts: Lessoncaptainhass100% (1)

- 8.pressure Drop in Piping PDFDocument41 pages8.pressure Drop in Piping PDFStalin Apolo100% (1)

- Pressure Drop in PipingDocument41 pagesPressure Drop in PipingFrancisco Rivas50% (2)

- Heat Exchanger Design Using Bell's MethodDocument37 pagesHeat Exchanger Design Using Bell's MethodVRUSHABH100% (1)

- Heat Transfer and Pressure Drop in Circular TubesDocument0 pagesHeat Transfer and Pressure Drop in Circular TubesParminder SinghNo ratings yet

- NASA Tests On 13 Navy Type Model PropellersDocument15 pagesNASA Tests On 13 Navy Type Model PropellersDavid Jiménez MenaNo ratings yet

- Frictional Losses in Hydraulic Pipelines: Reynolds No. yDocument10 pagesFrictional Losses in Hydraulic Pipelines: Reynolds No. yMuhammed RazzaqueNo ratings yet

- Pressure Losses in Pipe Network Name: University: CodeDocument7 pagesPressure Losses in Pipe Network Name: University: CodeshagsNo ratings yet

- College of Engineering: CSU Vision CSU Mission Core Values Csu IgaDocument51 pagesCollege of Engineering: CSU Vision CSU Mission Core Values Csu IgaJomhel CalluengNo ratings yet

- Energy Losses in Pipe PDFDocument7 pagesEnergy Losses in Pipe PDFnadiselNo ratings yet

- ArchSmarterEnergyModelingCourse DStine-1554561630495Document131 pagesArchSmarterEnergyModelingCourse DStine-1554561630495Rafael MendesNo ratings yet

- ARTIGO - Ventilação Controlada Por Demanda - Portal EADocument5 pagesARTIGO - Ventilação Controlada Por Demanda - Portal EARafael MendesNo ratings yet

- ARTIGO - Qualidade Do Ambiente Interno - Portal EADocument8 pagesARTIGO - Qualidade Do Ambiente Interno - Portal EARafael MendesNo ratings yet

- Spectrum Details: Project New Project Spectrum Name Spectrum 1Document8 pagesSpectrum Details: Project New Project Spectrum Name Spectrum 1Rafael MendesNo ratings yet

- Lab Manual CVG2116Document47 pagesLab Manual CVG2116Arash Kamali100% (1)

- Fire Fighting BoqDocument13 pagesFire Fighting BoqJoe GrosirNo ratings yet

- Energies: New HFC/HFO Blends As Refrigerants For The Vapor-Compression Refrigeration System (VCRS)Document20 pagesEnergies: New HFC/HFO Blends As Refrigerants For The Vapor-Compression Refrigeration System (VCRS)Jayakumar ANo ratings yet

- STP Project ReportDocument23 pagesSTP Project ReportYogesh75% (4)

- Exam in Soil MechanicsDocument4 pagesExam in Soil MechanicsAngelo Montelibano Patron100% (3)

- Thermodynamics Assignment SheetDocument3 pagesThermodynamics Assignment SheetSatwikMohantyNo ratings yet

- DMfit Catalog 18.09.15Document23 pagesDMfit Catalog 18.09.15Sinergroup Water Filters Water Purifiers Water SoftenersNo ratings yet

- Answer All Question: Sk027 / Chapter 3: Reaction Kinetics / Exercise 1Document5 pagesAnswer All Question: Sk027 / Chapter 3: Reaction Kinetics / Exercise 1kjjkimkmkNo ratings yet

- Framo Instruction and Service ManualDocument16 pagesFramo Instruction and Service Manualerol100% (1)

- P2104-VD-LEBS-TS-STD-0012 - 0C - RAM Study ReportDocument56 pagesP2104-VD-LEBS-TS-STD-0012 - 0C - RAM Study ReportaddypurnamaNo ratings yet

- REDLINE Product Data Sheet - Gas Panel S201 - tcm899-92293Document6 pagesREDLINE Product Data Sheet - Gas Panel S201 - tcm899-92293Daj NemojNo ratings yet

- HES Bid Set Fire Protection DrawingsDocument5 pagesHES Bid Set Fire Protection DrawingsMansoor Abdul KhaderNo ratings yet

- 2955 0720 00 - XAHS 146 DD - Parts ListDocument132 pages2955 0720 00 - XAHS 146 DD - Parts ListAyub SetiawanNo ratings yet

- Colibri StorkDocument4 pagesColibri Storkbruce1312No ratings yet

- Water and Wastewater Engineering Prof. C. Venkobacher Department of Civil Engineering Indian Institute of Technology, Madras Lecture-16Document18 pagesWater and Wastewater Engineering Prof. C. Venkobacher Department of Civil Engineering Indian Institute of Technology, Madras Lecture-16kaushal patelNo ratings yet

- ScrubberDocument3 pagesScrubberriz2010No ratings yet

- PEDUCA, JoshuaDocument6 pagesPEDUCA, Joshuayeng botzNo ratings yet

- Ventilation in Hospital ProjectsDocument18 pagesVentilation in Hospital ProjectsMAGDY KAMELNo ratings yet

- Balancing EquationDocument5 pagesBalancing EquationJessan Ybañez JoreNo ratings yet

- rk86 enDocument2 pagesrk86 enMohd Farhan ZulkepliNo ratings yet

- Xample: Internal Incompressible Viscous FlowDocument2 pagesXample: Internal Incompressible Viscous Flowวีรินทร์ ขนิษดาNo ratings yet

- Atlas PDFDocument6 pagesAtlas PDFFlávia GustavoNo ratings yet

- Effect of Free SilicaDocument2 pagesEffect of Free Silicamahendra senNo ratings yet

- Main Frame Hydraulics (Blade Lift, Rear Steer and Blade Control Valves) (04D07) - 2160-42Document3 pagesMain Frame Hydraulics (Blade Lift, Rear Steer and Blade Control Valves) (04D07) - 2160-42Cesar Cauper CardenasNo ratings yet

- API 570 Part 2 - Pipe DesignDocument34 pagesAPI 570 Part 2 - Pipe Designpeach5100% (10)

- Mixtures (Grade 8) - Free Printable Tests and WorksheetsDocument1 pageMixtures (Grade 8) - Free Printable Tests and Worksheetsnona wayne dela peña100% (2)

- KBR Technology: Houston, USA Instrument Data Summary Sheet Control ValvesDocument1 pageKBR Technology: Houston, USA Instrument Data Summary Sheet Control ValvesamitNo ratings yet

- DistributionatalogueDocument38 pagesDistributionatalogued22027lingmail.comNo ratings yet

- Chapter 8: Convection in External Turbulent Flow: - (A) Mixing ProcessesDocument38 pagesChapter 8: Convection in External Turbulent Flow: - (A) Mixing ProcessesephremNo ratings yet

- Evo Mini Brochure VAMDocument2 pagesEvo Mini Brochure VAMYoga Windhu WardhanaNo ratings yet

- Functional Safety from Scratch: A Practical Guide to Process Industry ApplicationsFrom EverandFunctional Safety from Scratch: A Practical Guide to Process Industry ApplicationsNo ratings yet

- Practical Industrial Safety, Risk Assessment and Shutdown SystemsFrom EverandPractical Industrial Safety, Risk Assessment and Shutdown SystemsRating: 4 out of 5 stars4/5 (11)

- Guidelines for Initiating Events and Independent Protection Layers in Layer of Protection AnalysisFrom EverandGuidelines for Initiating Events and Independent Protection Layers in Layer of Protection AnalysisRating: 5 out of 5 stars5/5 (1)

- A Complete Guide to Safety Officer Interview Questions and AnswersFrom EverandA Complete Guide to Safety Officer Interview Questions and AnswersRating: 4 out of 5 stars4/5 (1)

- Workbook to Accompany Maintenance & Reliability Best PracticesFrom EverandWorkbook to Accompany Maintenance & Reliability Best PracticesRating: 3.5 out of 5 stars3.5/5 (3)

- Rules of Thumb for Maintenance and Reliability EngineersFrom EverandRules of Thumb for Maintenance and Reliability EngineersRating: 4.5 out of 5 stars4.5/5 (12)

- Introduction to Petroleum Process SafetyFrom EverandIntroduction to Petroleum Process SafetyRating: 3 out of 5 stars3/5 (2)

- Culture, Health and Illness: An Introduction for Health ProfessionalsFrom EverandCulture, Health and Illness: An Introduction for Health ProfessionalsNo ratings yet

- The Invisible Rainbow: A History of Electricity and LifeFrom EverandThe Invisible Rainbow: A History of Electricity and LifeRating: 4.5 out of 5 stars4.5/5 (21)

- Guidelines for Implementing Process Safety ManagementFrom EverandGuidelines for Implementing Process Safety ManagementNo ratings yet

- Fire Protection Engineering in Building DesignFrom EverandFire Protection Engineering in Building DesignRating: 4.5 out of 5 stars4.5/5 (5)

- Safety and Intelligent Transport Systems Development in the People’s Republic of ChinaFrom EverandSafety and Intelligent Transport Systems Development in the People’s Republic of ChinaNo ratings yet

- Electrical Safety Code Manual: A Plain Language Guide to National Electrical Code, OSHA and NFPA 70EFrom EverandElectrical Safety Code Manual: A Plain Language Guide to National Electrical Code, OSHA and NFPA 70ERating: 3 out of 5 stars3/5 (6)

- Guidelines for Auditing Process Safety Management SystemsFrom EverandGuidelines for Auditing Process Safety Management SystemsNo ratings yet

- The ISO 45001:2018 Implementation Handbook: Guidance on Building an Occupational Health and Safety Management SystemFrom EverandThe ISO 45001:2018 Implementation Handbook: Guidance on Building an Occupational Health and Safety Management SystemNo ratings yet

- Guidelines for Fire Protection in Chemical, Petrochemical, and Hydrocarbon Processing FacilitiesFrom EverandGuidelines for Fire Protection in Chemical, Petrochemical, and Hydrocarbon Processing FacilitiesNo ratings yet

- Pre-Accident Investigations: An Introduction to Organizational SafetyFrom EverandPre-Accident Investigations: An Introduction to Organizational SafetyRating: 5 out of 5 stars5/5 (2)

- Incidents That Define Process SafetyFrom EverandIncidents That Define Process SafetyNo ratings yet

- Workers' Inferno: The untold story of the Esso workers 20 years after the Longford explosionFrom EverandWorkers' Inferno: The untold story of the Esso workers 20 years after the Longford explosionNo ratings yet

- Establishing an occupational health & safety management system based on ISO 45001From EverandEstablishing an occupational health & safety management system based on ISO 45001Rating: 4 out of 5 stars4/5 (5)

- Redefining Work Health and Safety: Systems, Strategies, and Progressive ApproachesFrom EverandRedefining Work Health and Safety: Systems, Strategies, and Progressive ApproachesNo ratings yet