Professional Documents

Culture Documents

Ultrasound and Vibration Analysis - Two Key Elements of Predictive Maintenance

Ultrasound and Vibration Analysis - Two Key Elements of Predictive Maintenance

Uploaded by

ukasz-sznajder-16240 ratings0% found this document useful (0 votes)

22 views13 pagesOriginal Title

Ultrasound and Vibration analysis_ two key elements of predictive maintenance

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

22 views13 pagesUltrasound and Vibration Analysis - Two Key Elements of Predictive Maintenance

Ultrasound and Vibration Analysis - Two Key Elements of Predictive Maintenance

Uploaded by

ukasz-sznajder-1624Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 13

Mee Oe OE iia

Improvement Success?

er

THEWORLO'S MOST .

“ADVANCED AUTOMATION pe,

Er ccrmariene. MantWortutn_medum-banoeNov201 Stat campgnsICONICS)

jonal Connections in Industrial Maintenance

Maintworld - Building Intern:

MAINTWORLD (MAINTWORLD)

[MEDIA INFORMATION (MEDIA-INFORMATION)

SUBSCRIBE JSUBSCRIBE)

EDITORIAL ARCHIVE EDITORUAL-ARCHIVE)

maintwor

magazine for maintenance & asset management professionals

0

Search

Ultrasound and Vibration analysis: two key elements of predictive maintenance

ssets, However, in

Vibration analysis has been for many years the technology of choice for maintenance professionals to moniter the condition of rotating

‘the last years ultrasound has also emerged as avery popula technology for condition monitoring. The question that many are now asking themselves is:

‘which one Is best? Ultrasound ovbraton? In ths article we wl focus on the role of ultrasound as condition monitoring tol, and why using vibration and

Ultrasound together isthe best way to reach excellence In your maintenance practices.

(varleruchin ste/strasa dalimages/lap hspecra002 ang 08/PI son Aearnguth Seactaa)

Why vibration analysis?

‘ration analyses an increta oa: detect ahd messes sal vbvatios a whats causing them hus alowing mabtnance professionals to detect ety atures on

toting equpment Futhemare, wration arabe gve va avery deep agnostic and allow us to deny te flue’ root cae, and thus crest 0 avld further lsu Inthe

future. Plus, thee ar a gret ruber of woration sensors and sltons onthe market to choose fo so malntenance team can find 2 sluton thats utable forthe needs

Why Ultrasound?

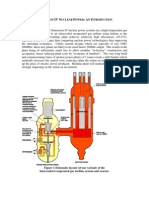

Utrasoundis considered by many the fst ne of defence when tomes to bearing ales since it can pve avery ary warning ofa potential problem even wth Mbrcation issues

‘The way ulresouns does tha by montring the ton lovls on ating eavpment The concept ssl: a # beating stats oa oft has ol been reatea prope

(vider or over ubieated, th ition evel ie Fieion reatesutraound emission that canbe pikes unt an uvaoni hall device o: seer andeaslted oom

frequency sounds thatthe iepectr can het Uttascund equipment wl also provide a decibel lve ~ and the igher te deste the highe the ton

Ceol

WAXTINE FOR PANNING

i F

‘Waaclezwshin ste(sivage/imanes/meda/images/e! cuvet/200h ano-GR/e cue.

Ultrasound or vibration?

‘There easy answer to this question, but one things fr sure: fa maintenance eam wants to teach excellence both technologies shouldbe use Utrascurd wil pondethe

‘eatlst warning ffl andi ala very easy use sie eles on seply vending decbellevele. Vibration alysis is extremely complete and wll gvemattenance

professionals a Seep overview ofthe ese andthe root cave of euch eeu, most ef ulraeovnd ithe doctor ho detect the problem and ration ethe hea specialist hat

‘ll eiagrose propery. We willow tac abot a few stuatons wherein general. uvasound can be used instead of wration analy,

Amplitude

Time

jesibeatingexamp-cveibe e-002/64000- an 8/Rearng example Quetbe E002 of)

Slow speed bearings

‘Slow sped bearings are ticul to mnitor. Sine they rotate vey sony te ficult fr vibration sensor lek up slgfcant changes in vbration. Even with an utrasound

instrument maybe aul to plc up eure we ely only on deel vel sne extreme slow spesdbeerng spplcation (usualy leas tan 25rpr). the beating wll produce

lle no erasenc nose. However high-end ulvasniccevies wl abo fr sound recording by recoding the sound ofthe batng and checking tina specu analysis

software, we cen easy find peaks nthe sound spectrum ample whch indicate a fuk inthe Bear.

First line of defence, easy to use

Fora maltonanesprofesionalto properly work ath vation analysis sgnicant tring and experience ae needed, On the other sid, rasoundhas a eh ike laring

‘ate Bnd this because of ow the ecology work: sine ts monitoring fcton lvls an Vanssting them 08 values, we can easily check or potetia problems wth our

rotating equpment Once we setup a4 baseline for 3 bearing we jl need tote the eB vale overtime. Sa, essen fer «bearing ie 2088, but he Ulasencrsrument

‘ead 32, we already know there problem sina by eorpahg va

Lubrication

‘gin, because ultrasound i based onthe ction lvls, ts erecyadequste fr besring lubrication. the bearing lacking lubietion? Then the friction eels wl ineease and

‘wo can hear that hough the ulvasoni instrument ang seein the evel we star ubvieating the bearing rast ely we wl ee a decease inthe sound testy a hed

Tels. id he bearing receive too much ubricant? Ten ag, ton levels wl rcreese and we wl now thar using the ulesoni istrumet. Thus, lvascund is perfect te aoid

‘inden and overbreston cues

Versatility

‘te vation ara i an extremely powerful to ts uses ae ited to mechareal equipment On the ther har uvasound has a wide ange of application which mekes ie

very vesaletechnalogy.One af he mest popula aplication of utvesouns besides codon monttig a energy savings. Since turbulence ake cleats tvasound emissions,

‘be ulrasonc instruments can easy be used fr leak detection (compressed a and athe gases), steam Vaps inspection and even fr eecieal inspections detect sues uh

235 corona rackg and arcing

Conclusion

bole, as many other maintenance professionals nowadays tha sing multiple echnaogies that complement each others he way ogo. Teefore the questions ht

Lraeound ve vation, but instead laze AND wration ad when we sould be sing ane othe other Bath are very power contin montering teeneloges an, when

‘se proper toga can really ake any maintenance ard ela My program tothe excellence lv

Share Artic

f # htpastrcomy/shate? in

(hpevrwantacebook com/share php? u-ttpev/wmmalntworldcomv/Asst:(tp/wwallnkein.comisharearicle?

N

"Uggound nd

FORMANCE 40

ISTER

images

Cac!

Ce eure

ae tr

Workshop day: Oct. 2

ea Se an Register Now | October 26- 28, 2021

Asset Performance Awards: Oct, 27, 2021 = Antwerp, Belgium

5 Preventive Maintenance Benefits That Show Why Organizations Need it (/Asset-Management/5-

Preventive-Maintenance-Benefits-That-Show-Why-Organizations-Need-it)

Maintenance managements finally geting the attention it deserves. Earl, mast organizations had no choice but to implement reactive maintenance, that is,

maintenance that's done after the machine malfunctions. While i's more of an “if ain't broke, dont fix" approach it was never rally practical t did't help

improve asset reliability, incurred costs, and caused production disruptions via unplanned machine downtime

(Asset Management/SPreventive Maintenance Benefts-That-Show-Why-Organizations-Neee-t)

‘Aan nance 8122

(Unesct Management Heavy Duty. and Customized Shock Absorbers NoMatter Whereou-ar)

Heavy-Duty and Customized Shock Absorbers, No Matter Where you are (/Asset-Management/Heavy-

Duty-and-Customized-Shock-Absorbers-No-Matter-Where-you-are)

ADVERTISEMENT

Rise, | ga

eae

ero

(peeve drectndusty.com)

wireless vibration

monitoring

through embedded

prescriptive

analytics.

4

EMERSON.

up Waco)

(asset Management/Bearin- Grease Managementusing-Utrasound)

Bearing Grease Management using Ultrasound (/Asset-Management/Bearing-Grease-Management-

using- Ultrasound)

Reliability is About Two Things! (/Asset-Management/Reliability-is-About-Two-Things)

hese ManagementRelablipe About TweThings)

Have you ever experienced a Reliabilty and Maintenance Improvement Project wher feels Ike you are drowning? High level project plans lot of meetings

and the latest buzzwords being thrown around to describe what you should do. Sound familiar?

(Asset Management/Relibily s-About Two-Things)

sao wannseaeeissetasacenent 462021

standalone

Permanent

Uttrasound

Sensor

‘ups/sdutrasound comyproducts/sensors:ransmittersconmensenserarge!)

ADVERTISEMENT

FEED Improve Reliability

‘8 Performance

FY Got Your

gy) Three-Book

BS cundie

- ‘ORDER TODAY!

psn mobiusnstvte com/profesionagrowh/assetseabily-ransformatonar-books/)

(Uassct Management Higher

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5814)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Petrochemicals in Nontechnical Language 3rd Edition PDFDocument462 pagesPetrochemicals in Nontechnical Language 3rd Edition PDFukasz-sznajder-1624No ratings yet

- The True Impact of in Pharma: Machine FailureDocument6 pagesThe True Impact of in Pharma: Machine Failureukasz-sznajder-1624No ratings yet

- 100 Ways To Eliminate Downtime - Trackunit - ENDocument35 pages100 Ways To Eliminate Downtime - Trackunit - ENukasz-sznajder-1624No ratings yet

- Total's SmartConnect - SmartSignalDocument26 pagesTotal's SmartConnect - SmartSignalukasz-sznajder-1624No ratings yet

- Prediction of Uncertainty of 10-Coefficient Compressor Maps For Extreme Operating ConditionsDocument10 pagesPrediction of Uncertainty of 10-Coefficient Compressor Maps For Extreme Operating Conditionsukasz-sznajder-1624No ratings yet

- Nitulescu-2015-New Projects Developed by COMOTI in Gas Industry-144 B PDFDocument10 pagesNitulescu-2015-New Projects Developed by COMOTI in Gas Industry-144 B PDFukasz-sznajder-1624No ratings yet

- The Development of A Small High Speed Steam Microturbine Generator SystemDocument11 pagesThe Development of A Small High Speed Steam Microturbine Generator Systemukasz-sznajder-1624No ratings yet

- Alford-2015-The Development of A Control System For A Small High Speed Steam Microturbine Generator System-58 BDocument12 pagesAlford-2015-The Development of A Control System For A Small High Speed Steam Microturbine Generator System-58 Bukasz-sznajder-1624No ratings yet

- 8 - GE - PaulV - IPRC MadridDocument19 pages8 - GE - PaulV - IPRC Madridukasz-sznajder-1624No ratings yet

- 4 - ENI - Marco Ilaria - Eni Presentation 2014 European Predictive Analytics and Big Data Summit FINALDocument38 pages4 - ENI - Marco Ilaria - Eni Presentation 2014 European Predictive Analytics and Big Data Summit FINALukasz-sznajder-1624No ratings yet

- 7 - Laborelec - Tom Wouter - 2014 European Predictive Analytics and Big Data Summit V2Document31 pages7 - Laborelec - Tom Wouter - 2014 European Predictive Analytics and Big Data Summit V2ukasz-sznajder-1624No ratings yet

- 3 - BP - Jorge - EUGM 2014 SmartSignal Return of Experience at BP CastellonDocument24 pages3 - BP - Jorge - EUGM 2014 SmartSignal Return of Experience at BP Castellonukasz-sznajder-1624No ratings yet

- Generation IV Nuclear Power IntroDocument2 pagesGeneration IV Nuclear Power Introukasz-sznajder-1624No ratings yet

- 1 - GE - Courtney - The Industrial Internet and Industrial Big Data - Madrid June-2014Document35 pages1 - GE - Courtney - The Industrial Internet and Industrial Big Data - Madrid June-2014ukasz-sznajder-1624No ratings yet