Professional Documents

Culture Documents

Features Description: Lt3791 60V 4-Switch Synchronous Buck-Boost Led Driver Controller

Uploaded by

Thallys BatistaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Features Description: Lt3791 60V 4-Switch Synchronous Buck-Boost Led Driver Controller

Uploaded by

Thallys BatistaCopyright:

Available Formats

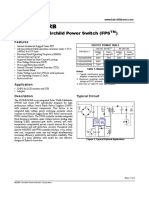

LT3791

60V 4-Switch Synchronous

Buck-Boost LED Driver

Controller

Features Description

n 4-Switch Single Inductor Architecture Allows VIN The LT®3791 is a synchronous 4-switch buck-boost LED

Above, Below or Equal to VOUT driver controller. The controller can regulate LED current

n Synchronous Switching: Up to 98.5% Efficiency up to 52V of LED string with input voltages above, below,

n Wide V Range: 4.7V to 60V or equal to the output voltage. The constant-frequency,

IN

n Wide V

OUT Range: 0V to 60V (52V LED) forced-continuous current mode architecture allows its

n ±6% LED Current Accuracy: 0V ≤ V

LED < 52V frequency to be adjusted or synchronized from 200kHz to

n True Color PWM™ and Analog Dimming 700kHz. No top MOSFET refresh switching cycle is needed

n LED and Input Current Regulation with Current in buck or boost operation. With 60V input, 60V output

Monitor Outputs capability and seamless transitions between operating

n No Top MOSFET Refresh in Buck or Boost regions, the LT3791 is ideal for LED driver applications in

n V

OUT Disconnected From VIN During Shutdown automotive, industrial, and even battery-powered systems.

n Open or Shorted LED Fault Protection

n Capable of 100W or Greater per IC

For new designs we recommend the LT8391: 60V syn-

n 38-Lead TSSOP with Exposed Pad

chronous 4-switch, buck-boost LED controller due to its

numerous performance improvements over the LT3791.

Applications L, LT, LTC, LTM, Linear Technology and the Linear logo are registered and True Color PWM

is a trademark of Analog Devices, Inc. All other trademarks are the property of their respective

owners.

n Automotive Head Lamps/Running Lamps

n General Purpose Lighting

Typical Application

98.5% Efficient 100W (33.3V 3A) Buck-Boost LED Driver

VIN 2.2µF

15V TO 58V 100V

0.003Ω

×5

VIN INTVCC

1µF 4.7µF

50Ω BST2 Efficiency vs VIN

IVINN BST1 0.1µF 4.7µF 100

470nF 50V

TG1 0.1µF 1M

499k IVINP ×5

SWI 98

EN/UVLO 10µH BOOST

OVLO BG1 34.2k BUCK

15.8k INTVCC

BUCK-BOOST

EFFICIENCY (%)

LT3791 SNSP 96

200k 200k

28k 3A, 100W

SHORTLED 0.004Ω 0.033Ω

LED POWER

OPENLED 94

SNSN

PGND

PWM 92

BG2

IVINMON

SW2

ISMON

TG2 90

CLKOUT 10 20 30 40 50 60

FB

VREF INPUT VOLTAGE (V)

ISP

CTRL 3791 TA01b

0.1µF ISN

PWMOUT

SS SYNC VC RT SGND

10nF 22nF 86.6k

300kHz

3791 TA01a

3791fc

For more information www.linear.com/LT3791 1

LT3791

Absolute Maximum Ratings Pin Configuration

(Note 1)

Supply Voltages TOP VIEW

Input Supply (VIN)......................................................60V CTRL 1 38 OVLO

SW1, SW2.......................................................–1V to 60V SS 2 37 FB

OPENLED, SHORTLED................................................15V PWM 3 36 VC

EN/UVLO, IVINP, IVINN, ISP, ISN...............................60V OPENLED 4 35 RT

5 34 SYNC

INTVCC, (BST1-SW1), (BST2-SW2)..............................6V SHORTLED

VREF 6 33 CLKOUT

TEST2, SYNC, RT, CTRL, OVLO, PWM........................6V

ISMON 7 32 TEST2

IVINMON, ISMON, FB, SS, VC, VREF.............................6V 8

IVINMON 31 PWMOUT

IVINP-IVINN, ISP-ISN, SNSP-SNSN........................±0.5V EN/UVLO 9 30 SGND

SNSP, SNSN............................................................±0.3V IVINP 10

39

29 TEST1

SGND

Operating Junction Temperature (Notes 2, 3) IVINN 11 28 SNSN

LT3791E/LT3791I................................ –40°C to 125°C VIN 12 27 SNSP

LT3791H............................................. –40°C to 150°C INTVCC 13 26 ISN

LT3791MP.......................................... –55°C to 150°C TG1 14 25 ISP

Storage Temperature Range................... –65°C to 150°C BST1 15 24 TG2

Lead Temperature (Soldering, 10 sec).................... 300°C SW1 16 23 NC

PGND 17 22 BST2

BG1 18 21 SW2

BG2 19 20 PGND

FE PACKAGE

38-LEAD PLASTIC TSSOP

TJMAX = 150°C, θJA = 28°C/W

EXPOSED PAD (PIN 39) IS SGND, MUST BE SOLDERED TO PCB

Order Information http://www.linear.com/product/LT3791#orderinfo

LEAD FREE FINISH TAPE AND REEL PART MARKING* PACKAGE DESCRIPTION TEMPERATURE RANGE

LT3791EFE#PBF LT3791EFE#TRPBF LT3791FE 38-Lead Plastic TSSOP –40°C to 125°C

LT3791IFE#PBF LT3791IFE#TRPBF LT3791FE 38-Lead Plastic TSSOP –40°C to 125°C

LT3791HFE#PBF LT3791HFE#TRPBF LT3791FE 38-Lead Plastic TSSOP –40°C to 150°C

LT3791MPFE#PBF LT3791MPFE#TRPBF LT3791FE 38-Lead Plastic TSSOP –55°C to 150°C

Consult LTC Marketing for parts specified with wider operating temperature ranges. *The temperature grade is identified by a label on the shipping container.

For more information on lead free part marking, go to: http://www.linear.com/leadfree/

For more information on tape and reel specifications, go to: http://www.linear.com/tapeandreel/. Some packages are available in 500 unit reels through

designated sales channels with #TRMPBF suffix.

Electrical

Characteristics The l denotes the specifications which apply over the full operating

junction temperature range, otherwise specifications are at TA = 25°C (Note 2). VIN = 12V, VEN/UVLO = 12V unless otherwise noted.

PARAMETER CONDITIONS MIN TYP MAX UNITS

Input

VIN Operating Voltage 4.7 60 V

VIN Shutdown IQ VEN/UVLO = 0V 0.1 1 µA

VIN Operating IQ (Not Switching) FB = 1.3V, RT = 59.0k 3.0 4 mA

3791fc

2 For more information www.linear.com/LT3791

LT3791

Electrical

Characteristics The l denotes the specifications which apply over the full operating

junction temperature range, otherwise specifications are at TA = 25°C (Note 2). VIN = 12V, VEN/UVLO = 12V unless otherwise noted.

PARAMETER CONDITIONS MIN TYP MAX UNITS

Logic Inputs

EN/UVLO Falling Threshold l 1.16 1.2 1.24 V

EN/UVLO Rising Hysteresis 15 mV

EN/UVLO Input Low Voltage IVIN Drops Below 1µA 0.3 V

EN/UVLO Pin Bias Current Low VEN/UVLO = 1V 2 3 4 µA

EN/UVLO Pin Bias Current High VEN/UVLO = 1.6V 10 100 nA

CTRL Input Bias Current VCTRL = 1V 20 50 nA

CTRL Latch-Off Threshold 175 mV

OVLO Rising Shutdown Voltage l 2.85 3 3.15 V

OVLO Falling Hysteresis 75 mV

Regulation

VREF Voltage l 1.96 2.00 2.04 V

VREF Line Regulation 4.7V < VIN < 60V 0.002 0.04 %/V

V(ISP-ISN) Threshold VCTRL = 2V 97.5 100 102.5 mV

l 94 100 106 mV

VCTRL = 1100mV 87 90 93 mV

l 84 90 96 mV

VCTRL = 700mV 47.5 50 52.5 mV

l 46 50 54 mV

VCTRL = 300mV 6.5 10 13.5 mV

l 5 10 15 mV

ISP Bias Current 110 µA

ISN Bias Current 20 µA

LED Current Sense Common Mode Range 0 60 V

LED Current Sense Amplifier gm 890 µS

ISMON Monitor Voltage V(ISP-ISN) = 100mV l 0.96 1 1.04 V

Input Current Sense Threshold V(IVINP-IVINN) 3V ≤ VIVINP ≤ 60V l 46.5 50 54 mV

IVINP Bias Current 90 µA

IVINN Bias Current 20 µA

Input Current Sense Common Mode Range 3 60 V

Input Current Sense Amplifier gm 2.12 mS

IVINMON Monitor Voltage V(IVINP-IVINN) = 50mV l 0.96 1 1.04 V

FB Regulation Voltage 1.194 1.2 1.206 V

l 1.176 1.2 1.220 V

FB Line Regulation 4.7V < VIN < 60V 0.002 0.025 %/V

FB Amplifier gm 565 µS

FB Pin Input Bias Current FB in Regulation 100 200 nA

VC Standby Input Bias Current PWM = 0V –20 20 nA

VSENSE(MAX) (VSNSP-SNSN) Boost l 42 51 60 mV

Buck l –56 –47.5 –39 mV

Fault

SS Pull-Up Current VSS = 0V 14 µA

SS Discharge Current 1.4 µA

FB Overvoltage Rising Threshold 1.22 1.25 V

Open LED Rising Threshold (VFB) V(ISP-ISN) = 0V l 1.127 1.15 1.173 V

3791fc

For more information www.linear.com/LT3791 3

LT3791

Electrical

Characteristics The l denotes the specifications which apply over the full operating

junction temperature range, otherwise specifications are at TA = 25°C (Note 2). VIN = 12V, VEN/UVLO = 12V unless otherwise noted.

PARAMETER CONDITIONS MIN TYP MAX UNITS

Open LED Falling Threshold (VFB) l 1.078 1.1 1.122 V

Open LED Falling Threshold (V(ISP-ISN)) VFB = 1.2V 5 10 15 mV

Short LED Falling Threshold (VFB) 380 400 450 mV

OPENLED Pin Output Impedance 1.1 2.0 kΩ

SHORTLED Pin Output Impedance 1.1 2.0 kΩ

SS Latch-Off Threshold 1.75 V

SS Reset Threshold 0.2 V

Oscillator

Switching Frequency RT = 147k 190 200 210 kHz

RT = 59.0k 380 400 420 kHz

RT = 29.1k 665 700 735 kHz

SYNC Frequency 200 700 kHz

SYNC Pin Resistance to GND 90 kΩ

SYNC Threshold Voltage 0.3 1.5 V

Internal VCC Regulator

INTVCC Regulation Voltage 4.8 5 5.2 V

Dropout (VIN – INTVCC) IINTVCC = –10mA, VIN = 5V 240 350 mV

INTVCC Undervoltage Lockout 3.1 3.5 3.9 V

INTVCC Current Limit VINTVCC = 4V 67 mA

PWM

PWM Threshold Voltage 0.3 1.5 V

PWM Pin Resistance to GND 90 kΩ

PWMOUT Pull-Up Resistance 10 20 Ω

PWMOUT Pull-Down Resistance 5 10 Ω

NMOS Drivers

TG1, TG2 Gate Driver On-Resistance VBST – VSW = 5V

Gate Pull-Up 2.6 Ω

Gate Pull-Down 1.7 Ω

BG1, BG2 Gate Driver On-Resistance VINTVCC = 5V

Gate Pull-Up 3 Ω

Gate Pull-Down 1.2 Ω

TG Off to BG On Delay CL = 3300pF 60 ns

BG Off to TG On Delay CL = 3300pF 60 ns

TG1, TG2, tOFF(MIN) RT = 59.0k 240 320 ns

Note 1: Stresses beyond those listed under Absolute Maximum Ratings operating junction temperature range. The LT3791MP is guaranteed to

may cause permanent damage to the device. Exposure to any Absolute meet performance specifications over the –55°C to 150°C operating

Maximum Rating condition for extended periods may affect device junction temperature range. High junction temperatures degrade operating

reliability and lifetime. lifetimes. Operating lifetime is derated for junction temperatures greater

Note 2: The LT3791E is guaranteed to meet performance from 0°C than 125°C.

to 125°C junction temperature. Specification over the -40°C to Note 3: The LT3791 includes overtemperature protection that is intended

125°C operating junction temperature range are assured by design, to protect the device during momentary overload conditions. Junction

characterization and correlation with statistical process controls. temperature will exceed the maximum operating junction temperature

The LT3791I is guaranteed to meet performance specifications over the when overtemperature protection is active. Continuous operation above

–40°C to 125°C operating junction temperature range. The LT3791H is the specified absolute maximum operating junction temperature may

guaranteed to meet performance specifications over the –40°C to 150°C impair device reliability.

3791fc

4 For more information www.linear.com/LT3791

LT3791

Typical Performance Characteristics TA = 25°C, unless otherwise noted.

INTVCC Dropout Voltage INTVCC Current Limit

vs Current, Temperature INTVCC Voltage vs Temperature vs Temperature

2.5 5.20 90

TA = 150°C

TA = 25°C 5.15 80

2.0 TA = –50°C

INTVCC CURRENT LIMIT (mA)

70

5.10

60

VIN-VINTVCC (V)

1.5 5.05 VIN = 60V

INTVCC (V)

50

5.00

VIN = 12V 40

1.0

4.95

30

4.90 20

0.5

4.85 10

0 4.80 0

0 10 20 30 40 –50 –25 0 25 50 75 100 125 150 –50 –25 0 25 50 75 100 125 150

LDO CURRENT (mA) TEMPERATURE (°C) TEMPERATURE (°C)

3791 G01 3791 G02 3791 G03

INTVCC Load Regulation VREF Voltage vs Temperature VREF Load Regulation

6.00 2.04 2.20

5.75 2.03 2.15

5.50 2.02 2.10

5.25 2.01 2.05

INTVCC (V)

VREF (V)

5.00 2.00 VREF (V) 2.00

4.75 1.99 1.95

4.50 1.98 1.90

VIN = 60V

4.25 1.97 VIN = 12V 1.85

VIN = 4.7V

4.00 1.96 1.80

0 10 20 30 40 50 60 70 –50 –25 0 25 50 75 100 125 150 0 50 100 150 200 250 300 350 400

ILOAD (mA) TEMPERATURE (°C) IREF (µA)

3791 G04 3791 G05 3791 G06

V(ISP-ISN) Threshold

V(ISP-ISN) Threshold vs VCTRL V(ISP-ISN) Threshold vs VISP vs Temperature

110 108 108

VIN = 12V

100

106 106

90

80 104 104

70

V(ISP-ISN) (mV)

V(ISP-ISN) (mV)

V(ISP-ISN) (mV)

102 102

60

100 100

50

40 98 98

30

96 96

20 VISP = 60V

94 94 VISP = 12V

10

VISP = 0V

0 92 92

0 0.2 0.4 0.6 0.8 1.0 1.2 1.4 1.6 1.8 2.0 0 10 20 30 40 50 60 –50 –25 0 25 50 75 100 125 150

VCTRL (V) VISP (V) TEMPERATURE (°C)

3791 G07 3791 G08 3791 G09

3791fc

For more information www.linear.com/LT3791 5

LT3791

Typical Performance Characteristics TA = 25°C, unless otherwise noted.

V(ISP-ISN) Threshold vs VFB ISMON Voltage vs Temperature ISMON Voltage vs V(ISP-ISN)

120 1.04 1.0

VIN = 12V

V(ISP-ISN) = 100mV 0.9

1.03

100

0.8

1.02

0.7

80

V(ISP-ISN) (mV)

1.01 0.6

VISMON (V)

VISMON (V)

60 1.00 0.5

0.4

0.99

40

0.3

0.98

20 0.2

0.97 0.1

0 0.96 0

1.17 1.18 1.19 1.20 1.21 1.22 1.23 –50 –25 0 25 50 75 100 125 150 0 10 20 30 40 50 60 70 80 90 100

VFB (V) TEMPERATURE (°C) V(ISP-ISN) (mV)

3791 G10 3791 G11 3791 G12

V(IVINP-IVINN) Threshold V(IVINP-IVINN) Threshold

vs Temperature vs VIVINP IVINMON Voltage vs Temperature

56 52.0 1.04

VIVINP = 12V

54 51.5 1.03 V(IVINP-VINN) = 50mV

51.0 1.02

52

V(IVINP-IVINN) (mV)

V(IVINP-IVINN) (mV)

VIVINP = 60V 50.5 1.01

VIVINMON (V)

50

VIVINP = 3V 50.0 1.00

48

49.5 0.99

46

49.0 0.98

44 48.5 0.97

42 48.0 0.96

–50 –25 0 25 50 75 100 125 150 0 10 20 30 40 50 60 –50 –25 0 25 50 75 100 125 150

TEMPERATURE (°C) VIVINP (V) TEMPERATURE (°C)

3791 G13 3791 G14 3791 G15

FB Regulation Voltage SHORTLED Threshold

V(IVINP-IVINN) Threshold vs VFB vs Temperature vs Temperature

60 1.24 0.500

1.23 0.475

50

1.22 0.450

V(IVINP-IVINSN) (mV)

40

FB VOLTAGE (V)

1.21 0.425 RISING

VFB (V)

30 1.20 0.400

FALLING

1.19 0.375

20

1.18 0.350

10 VIN = 60V

1.17 VIN = 12V 0.325

VIN = 4.7V

0 1.16 0.300

1.17 1.18 1.19 1.20 1.21 1.22 1.23 –50 –25 0 25 50 75 100 125 150 –50 –25 0 25 50 75 100 125 150

VFB (V) TEMPERATURE (°C) TEMPERATURE (°C)

3791 G16 3791 G17 3791 G18

3791fc

6 For more information www.linear.com/LT3791

LT3791

Typical Performance Characteristics TA = 25°C, unless otherwise noted.

OPENLED Threshold

vs Temperature OVLO Threshold vs Temperature Soft-Start Current vs Temperature

1.200 3.3 16

1.175 3.2 14 CHARGING

RISING

1.150 3.1 12

OVLO THRESHOLD (V)

RISING

FB VOLTAGE (V)

1.125 3.0 10

ISS (µA)

FALLING

1.100 2.9 FALLING 8

1.075 2.8 6

1.050 2.7 4

2.6 2 DISCHARGING

1.025

1.000 2.5 0

–50 –25 0 25 50 75 100 125 150 –50 –25 0 25 50 75 100 125 150 –50 –25 0 25 50 75 100 125 150

TEMPERATURE (°C) TEMPERATURE (°C) TEMPERATURE (°C)

3791 G19 3791 G20 3791 G21

Supply Current vs Input Voltage EN/UVLO Pin Current EN/UVLO Threshold Voltage

4.0 8 1.30

VEN/ULO = 1V

1.28

3.5 7

1.26

EN/UVLO PIN CURRENT (µA)

3.0 6

EN/UVLO THRESHOLD (V)

1.24

2.5 5 1.22 RISING

IQ (mA)

2.0 4 1.20

1.5 1.18

3 FALLING

1.16

1.0 2

TA = 150°C 1.14

0.5 TA = 25°C 1 1.12

TA = –50°C

0 0 1.10

0 10 20 30 40 50 60 –50 –25 0 25 50 75 100 125 150 –50 –25 0 25 50 75 100 125 150

VIN (V) TEMPERATURE (°C) TEMPERATURE (°C)

3791 G22 3791 G23 3791 G24

Oscillator Frequency TG1, TG2 Minimum On-Time TG1, TG2 Minimum Off-Time

vs Temperature vs Temperature vs Temperature

800 100 350

TG2

700 90 300

TG1, TG2 MINIMUM OFF-TIME (ns)

TG1, TG2 MINIMUM ON-TIME (ns)

RT = 29.1k fSW = 200kHz

SWITCHING FREQUENCY (kHz)

600 80 TG1

250

fSW = 400kHz

500 70

RT = 59.0k 200

400 60

fSW = 700kHz

150

300 50

RT = 147k 100

200 40

30 50

100

0 20 0

–50 –25 0 25 50 75 100 125 150 –50 –25 0 25 50 75 100 125 150 –50 –25 0 25 50 75 100 125 150

TEMPERATURE (°C) TEMPERATURE (°C) TEMPERATURE (˚C)

3791 G25 3791 G26 3791 G27

3791fc

For more information www.linear.com/LT3791 7

LT3791

Typical Performance Characteristics TA = 25°C, unless otherwise noted.

V(BST1-SW1), V(BST2-SW2) UVLO BG1, BG2 Driver On-Resistance TG1, TG2 Driver On-Resistance

vs Temperature vs Temperature vs Temperature

3.9 4.5 4.0

3.8 4.0 3.5

RISING PULL-UP

V(BST1-SW1), V(BST2,SW2) (V)

3.5

BG1, BG2 RESISTANCE (Ω)

TG1, TG2 RESISTANCE (Ω)

3.7 3.0 PULL-UP

3.0

3.6 2.5

2.5

PULL-DOWN

3.5 2.0

2.0

3.4 PULL-DOWN 1.5

1.5

FALLING

3.3 1.0

1.0

3.2 0.5 0.5

3.1 0 0

–50 –25 0 25 50 75 100 125 150 –50 –25 0 25 50 75 100 125 150 –50 –25 0 25 50 75 100 125 150

TEMPERATURE (°C) TEMPERATURE (°C) TEMPERATURE (°C)

3791 G28 3791 G29 3791 G30

PWMOUT On-Resistance V(SNSP-SNSN) Buck Threshold

vs Temperature VC Voltage vs Duty Cycle vs VC

14 1.6 60

V(SNSP-SNSN) = 0V

12 1.4

40

BG2

PWMOUT RESISTANCE (Ω)

1.2

10 PULL-UP

V(SNSP-SNSN) (mV)

20

1.0

8 BG1

VC (V)

0.8 0

6 PULL-DOWN

0.6

–20

4

0.4

2 –40

0.2

0 0 –60

–50 –25 0 25 50 75

100 125 150 0 20 40 60 80 100 0.6 0.8 1.0 1.2 1.4 1.6 1.8

TEMPERATURE (˚C) DUTY CYCLE (%) VC (V)

3791 G31 3791 G32 3791 G33

V(SNSP-SNSN) Buck Threshold V(SNSP-SNSN) Boost Threshold V(SNSP-SNSN) Boost Threshold

vs Temperature vs VC vs Temperature

60 60 60

VC(MIN) VC(MAX)

40 40 40

V(SNSP-SNSN) THRESHOLD (mV)

V(SNSP-SNSN) THRESHOLD (mV)

20 20

V(SNSP-SNSN) (mV)

20

0 0

0

–20 –20

–20

–40 –40

–40 VC(MAX)

–60 –60 VC(MIN)

–60 –80 –80

–50 –25 0 25 50 75 100 125 150 0.6 0.8 1.0 1.2 1.4 1.6 1.8 –50 –25 0 25 50 75 100 125 150

TEMPERATURE (°C) VC (V) TEMPERATURE (˚C)

3791 G34 3791 G35 3791 G36

3791fc

8 For more information www.linear.com/LT3791

LT3791

Pin Functions

CTRL (Pin 1): Current Sense Threshold Adjustment Pin for EN/UVLO (Pin 9): Enable Control Pin. Forcing an accurate

Analog Dimming. Regulating threshold V(ISP-ISN) is 1/10th 1.2V falling threshold with an externally programmable

of (VCTRL – 200mV). CTRL linear range is from 200mV hysteresis is generated by the external resistor divider

to 1.1V. For VCTRL > 1.3V, the current sense threshold is and a 3µA pull-down current. Above the 1.2V (typical)

constant at the full-scale value of 100mV. For 1.1V < VCTRL threshold (but below 6V), EN/UVLO input bias current is

< 1.3V, the dependence of the current sense threshold sub-µA. Below the falling threshold, a 3µA pull-down cur-

upon VCTRL transitions from a linear function to a con- rent is enabled so the user can define the hysteresis with

stant value, reaching 98% of full scale by VCTRL = 1.2V. the external resistor selection. An undervoltage condition

Connect CTRL to VREF for the 100mV default threshold. resets soft-start. Tie to 0.3V, or less, to disable the device

Force less than 175mV (typical) to stop switching. Do not and reduce VIN quiescent current below 1µA.

leave this pin open. IVINP (Pin 10): Positive Input for the Input Current Limit

SS (Pin 2): Soft-start reduces the input power sources and Monitor. Input bias current for this pin is typically 90µA.

surge current by gradually increasing the controller’s cur- IVINN (Pin 11): Negative Input for the Input Current Limit

rent limit. A minimum value of 10nF is recommended on

and Monitor. The input bias current for this pin is typically

this pin. SS is used as a timer when an open or shorted

20µA.

LED condition occurs. A 500k resistor placed from SS to

VREF will latch the part off in the event of a fault. If left VIN (Pin 12): Main Input Supply. Bypass this pin to PGND

open, a 1.4µA current source pulls down on SS and the with a capacitor.

part restarts in a fault. INTVCC (Pin 13): Internal 5V Regulator Output. The driver

PWM (Pin 3): A signal low turns off switches, idles switch- and control circuits are powered from this voltage. Bypass

ing and disconnects the VC pin from all external loads. The this pin to PGND with a minimum 4.7µF ceramic capacitor.

PWMOUT pin follows the PWM pin. PWM has an internal TG1 (Pin 14): Top Gate Drive. Drives the top N-channel

100k pull-down resistor. If not used, connect to INTVCC. MOSFET with a voltage equal to INTVCC superimposed on

OPENLED (Pin 4): An open-drain pull-down on OPENLED the switch node voltage SW1.

asserts if FB is greater than 1.15V (typical) and V(ISP-ISN) BST1 (Pin 15): Bootstrapped Driver Supply. The BST1 pin

is less than 10mV (typical). To function, the pin requires swings from a diode voltage below INTVCC up to a diode

an external pull-up resistor. voltage below VIN + INTVCC.

SHORTLED (Pin 5): An open-drain pull-down on SW1 (Pin 16): Switch Node. SW1 pin swings from a diode

SHORTLED asserts if FB is less than 400mV (typical). voltage drop below ground up to VIN.

To function, the pin requires an external pull-up resistor.

PGND (Pins 17, 20): Power Ground. Connect these pins

VREF (Pin 6): Voltage Reference Output Pin, Typically 2V. closely to the source of the bottom N-channel MOSFET.

This pin drives a resistor divider for the CTRL pin, either

for analog dimming or for temperature limit/compensa- BG1 (Pin 18): Bottom Gate Drive. Drives the gate of the

tion of the LED load. Can supply up to 200µA of current. bottom N-channel MOSFET between ground and INTVCC.

ISMON (Pin 7): Monitor pin that produces a voltage that BG2 (Pin 19): Bottom Gate Drive. Drives the gate of the

is ten times the voltage V(ISP-ISN). ISMON will equal 1V bottom N-channel MOSFET between ground and INTVCC.

when V(ISP-ISN) = 100mV. SW2 (Pin 21): Switch Node. SW2 pin swings from a diode

IVINMON (Pin 8): Monitor pin that produces a voltage voltage drop below ground up to VOUT.

that is twenty times the voltage V(IVINP-IVINN). IVINMON BST2 (Pin 22): Bootstrapped Driver Supply. The BST2 pin

will equal 1V when V(IVINP-IVINN) = 50mV. swings from a diode voltage below INTVCC up to a diode

voltage below VOUT + INTVCC.

3791fc

For more information www.linear.com/LT3791 9

LT3791

Pin Functions

NC (Pin 23): No Connect Pin. Leave this pin floating. TEST2 (Pin 32): This pin is used for testing purposes only

and must be connected to INTVCC (Pin 13) for the part to

TG2 (Pin 24): Top Gate Drive. Drives the top N-channel

operate properly.

MOSFET with a voltage equal to INTVCC superimposed on

the switch node voltage SW2. CLKOUT (Pin 33): Clock Output Pin. An in-phase clock is

provided at the oscillator frequency to allow for synchro-

ISP (Pin 25): Connection Point for the Positive Terminal nizing two devices for extending output power capability.

of the Output Current Feedback Resistor.

SYNC (Pin 34): External Synchronization Input Pin. This

ISN (Pin 26): Connection Point for the Negative Terminal pin is internally terminated to GND with a 90k resistor.

of the Output Current Feedback Resistor. The rising edge will be synchronized with the rising edge

SNSP (Pin 27): The Positive Input to the Current Sense of the SYNC signal.

Comparator. The VC pin voltage and controlled offsets RT (Pin 35): Frequency Set Pin. Place a resistor to GND

between the SNSP and SNSN pins, in conjunction with a

to set the internal frequency. The range of oscillation is

resistor, set the current trip threshold.

200kHz to 700kHz.

SNSN (Pin 28): The Negative Input to the Current Sense

VC (Pin 36): Current Control Threshold and Error Amplifier

Comparator. Compensation Point. The current comparator threshold

TEST1 (Pin 29): This pin is used for testing purposes only increases with this control voltage. The voltage ranges

and must be connected to SGND for the part to operate from 0.7V to 1.9V.

properly. FB (Pin 37): Voltage Loop Feedback Pin. FB is intended

SGND (Pin 30, Exposed Pad Pin 39): Signal Ground. for LED protection of an open or shorted LED event. The

All small-signal components and compensation should internal transconductance amplifier with output VC will

connect to this ground, which should be connected to regulate FB to 1.2V (typical) through the DC/DC converter.

PGND at a single point. Solder the exposed pad directly If the FB input is regulating the loop and V(ISP-ISN) < 10mV,

to the ground plane. the OPENLED pull-down is asserted. If the FB pin is less

than 400mV, the SHORTLED pull-down is asserted.

PWMOUT (Pin 31): Buffered Version of PWM Signal for

Driving LED Load Disconnect N-Channel MOSFET. The OVLO (Pin 38): Overvoltage Input Pin. This pin is used for

PWMOUT pin is driven from INTVCC. Use of a MOSFET OVLO, if OVLO > 3V then SS is pulled low, the part stops

with a gate cutoff voltage higher than 1V is recommended. switching and resets. Do not leave this pin open.

3791fc

10 For more information www.linear.com/LT3791

LT3791

Block Diagram

25 26 10 11 12 6 13

ISP ISN IVINP IVINN VIN VREF INTVCC

+ – + –

A2 A1

SHDN_INT REGS

A = 10 A = 10 A = 20 A = 24

ISMON

7

ISMON_INT IVINMON_INT TSD BST1

+ 15

IVINMON A13 TG1

8 A3 14

SW1

EN/UVLO – 16

9 –

3µA A4 SHDN_INT SHDN_INT BUCK

LOGIC

1.2V + SS_RESET

SS LATCH INTVCC

PWM

A14 BG1

18

PGND

17

A15 BG2

OSC 19

SLOPE_COMP_BOOST

INTVCC

RT

35

BOOST

SYNC LOGIC

34

CLKOUT SW2

33 + 21

A16 TG2

A7 24

SLOPE_COMP_BUCK BST2

– 22

SNSP

+ 27

SHORTLED A10

5

SNSN

+ 0.4V – 28

A5

– IVINMON_INT

– FB

A11 – 37

FB VREF

+ 0.2V +

+ A8 1.2V

OPENLED 14µA

4 A6

–

– 1.15V

+

CTRL

A12 + 1

SS RESET

R + – ISMON_INT

Q SS LATCH

S A9

– 1.75V

INTVCC + 3V

PWM A17 A18

3 OVLO

1.4µA – 38

SGND

PWMOUT 30, 39 SS VC

31 2 36 3791 BD

3791fc

For more information www.linear.com/LT3791 11

LT3791

Operation

The LT3791 is a current mode controller that provides an slowly charged during start-up. This “soft-start” clamping

output voltage above, equal to or below the input voltage. prevents abrupt current from being drawn from the input

The LTC proprietary topology and control architecture uses power supply. The SS can also be used as a fault timer

a current sensing resistor in buck or boost operation. The whenever an open or shorted LED is detected.

sensed inductor current is controlled by the voltage on The top MOSFET drivers are biased from floating boot-

the VC pin, which is the output of the feedback amplifiers strap capacitors C1 and C2, which are normally recharged

A11 and A12. The VC pin is controlled by three inputs, one

through an external diode when the top MOSFET is turned

input from the output current loop, one input from the

off. Schottky diodes across the synchronous switch M4

input current loop, and the third input from the feedback

and synchronous switch M2 are not required, but they do

loop. Whichever feedback input is higher takes precedence,

provide a lower drop during the dead time. The addition

forcing the converter into either a constant-current or a

of the Schottky diodes typically improves peak efficiency

constant-voltage mode.

by 1% to 2% at 500kHz.

The LT3791 is designed to transition cleanly between

the two modes of operation. Current sense amplifier A1 Power Switch Control

senses the voltage between the IVINP and IVINN pins and Figure 1 shows a simplified diagram of how the four

provides a pre-gain to amplifier A11. When the voltage power switches are connected to the inductor, VIN, VOUT

between IVINP and IVINN reaches 50mV, the output of A1 and GND. Figure 2 shows the regions of operation for the

provides IVINMON_INT to the inverting input of A11 and LT3791 as a function of duty cycle D. The power switches

the converter is in constant-current mode. If the current are properly controlled so the transfer between regions is

sense voltage exceeds 50mV, the output of A1 increases continuous. When VIN approaches VOUT, the buck-boost

causing the output of A11 to decrease, thus reducing the region is reached.

amount of current delivered to the output. In this manner

the current sense voltage is regulated to 50mV. VIN VOUT

The output current amplifier works similar to the input TG1 M1 M4 TG2

current amplifier but with a 100mV voltage instead of L1

50mV. The output current sense level is also adjustable SW1 SW2

by the CTRL pin. Forcing CTRL to less than 1.2V forces BG1 M2 M3 BG2

ISMON_INT to the same level as CTRL, thus providing

current-level control. The output current amplifier provides RSENSE

rail-to-rail operation. Similarly if the FB pin goes above 3791 F01

1.2V the output of A11 decreases to reduce the current

level and regulate the output (constant-voltage mode). Figure 1. Simplified Diagram of the Output Switches

The LT3791 provides monitoring pins IVINMON and ISMON

DMAX

that are proportional to the voltage across the input and BOOST

M1 ON, M2 OFF

output current amplifiers respectively. (BG2) BOOST REGION PWM M3, M4 SWITCHES

DMIN

The main control loop is shut down by pulling the EN/ BOOST

BUCK-BOOST REGION 4-SWITCH PWM

DMAX

UVLO pin low. When the EN/UVLO pin is higher than 1.2V, BUCK

M4 ON, M3 OFF

an internal 14µA current source charges soft-start capaci- (TG1) BUCK REGION PWM M2, M1 SWITCHES

tor CSS at the SS pin. The VC voltage is then clamped a DMIN

BUCK 3791 F02

diode voltage higher than the SS voltage while the CSS is

Figure 2. Operating Regions vs Duty Cycle

3791fc

12 For more information www.linear.com/LT3791

LT3791

Operation

Buck Region (VIN > VOUT) where D(BUCK-BOOST) is the duty cycle of the buck-boost

switch range:

Switch M4 is always on and switch M3 is always off during

this mode. At the start of every cycle, synchronous switch D(BUCK-BOOST) = 8%

M2 is turned on first. Inductor current is sensed when Figure 3 shows typical buck operation waveforms. If VIN

synchronous switch M2 is turned on. After the sensed approaches VOUT, the buck-boost region is reached.

inductor current falls below the reference voltage, which

is proportional to VC, synchronous switch M2 is turned off Buck-Boost Region (VIN ~ VOUT)

and switch M1 is turned on for the remainder of the cycle.

Switches M1 and M2 will alternate, behaving like a typical When VIN is close to VOUT, the controller is in buck-boost

synchronous buck regulator. The duty cycle of switch M1 operation. Figure 4 and Figure 5 show typical waveforms in

increases until the maximum duty cycle of the converter this operation. Every cycle the controller turns on switches

in buck operation reaches DMAX(BUCK, TG1), given by: M2 and M4, then M1 and M4 are turned on until 180° later

when switches M1 and M3 turn on, and then switches

DMAX(BUCK,TG1) = 100% – D(BUCK-BOOST) M1 and M4 are turned on for the remainder of the cycle.

M2 + M4 M2 + M4 M2 + M4

M1 + M4 M1 + M4 M1 + M4

3791 F03

Figure 3. Buck Operation (VIN > VOUT)

M1 + M4 M1 + M4 M1 + M4

M2 + M4 M2 + M4 M2 + M4

M1+ M3 M1+ M3 M1+ M3

M1 + M4 M1 + M4 M1 + M4

3791 F04

Figure 4. Buck-Boost Operation (VIN ≤ VOUT)

M1 + M4 M1 + M4 M1 + M4

M2 + M4 M2 + M4 M2 + M4

M1 + M3 M1 + M3 M1 + M3

M1 + M4 M1 + M4 M1 + M4

3791 F05

Figure 5. Buck-Boost Operation (VIN ≥ VOUT)

3791fc

For more information www.linear.com/LT3791 13

LT3791

Operation

Boost Region (VIN < VOUT) Low Current Operation

Switch M1 is always on and synchronous switch M2 is The LT3791 runs in forced continuous mode. In this mode

always off in boost operation. Every cycle switch M3 is the controller behaves as a continuous, PWM current

turned on first. Inductor current is sensed when synchro- mode synchronous switching regulator. In boost opera-

nous switch M3 is turned on. After the sensed inductor tion, switch M1 is always on, switch M3 and synchronous

current exceeds the reference voltage which is proportional switch M4 are alternately turned on to maintain the output

to VC, switch M3 turns off and synchronous switch M4 voltage independent of the direction of inductor current.

is turned on for the remainder of the cycle. Switches M3 In buck operation, synchronous switch M4 is always on,

and M4 alternate, behaving like a typical synchronous switch M1 and synchronous switch M2 are alternately

boost regulator. turned on to maintain the output voltage independent of

the direction of inductor current. In the forced continuous

The duty cycle of switch M3 decreases until the minimum

mode, the output can source or sink current.

duty cycle of the converter in boost operation reaches

DMIN(BOOST,BG2), given by:

DMIN(BOOST,BG2) = D(BUCK-BOOST)

where D(BUCK-BOOST) is the duty cycle of the buck-boost

switch range:

D(BUCK-BOOST) = 8%

Figure 6 shows typical boost operation waveforms. If VIN

approaches VOUT, the buck-boost region is reached.

M1 + M3 M1 + M3 M1 + M3

M1 + M4 M1 + M4 M1 + M4

3791 F06

Figure 6. Boost Operation (VIN < VOUT)

3791fc

14 For more information www.linear.com/LT3791

LT3791

Applications Information

The Typical Application on the front page is a basic LT3791 The rising edge of CLK_OUT corresponds to the rising edge

application circuit. External component selection is driven of SYNC thus allowing paralleling converters. The falling

by the load requirement, and begins with the selection of edge of CLK_OUT turns on switch M3 and the rising edge

RSENSE and the inductor value. Next, the power MOSFETs of CLK_OUT turns on switch M2.

are selected. Finally, CIN and COUT are selected. This circuit

can operate up to an input voltage of 60V. Inductor Selection

The operating frequency and inductor selection are inter-

Programming The Switching Frequency related in that higher operating frequencies allow the use

The RT frequency adjust pin allows the user to program the of smaller inductor and capacitor values. The inductor

switching frequency from 200kHz to 700kHz to optimize value has a direct effect on ripple current. The maximum

efficiency/performance or external component size. Higher inductor current ripple ΔIL can be seen in Figure 7. This

frequency operation yields smaller component size but is the maximum ripple that will prevent subharmonic

increases switching losses and gate driving current, and oscillation and also regulate with zero load. The ripple

may not allow sufficiently high or low duty cycle operation. should be less than this to allow proper operation over

Lower frequency operation gives better performance at the all load currents. For a given ripple the inductance terms

cost of larger external component size. For an appropriate in continuous mode are as follows:

RT resistor value see Table 1. An external resistor from

the RT pin to GND is required; do not leave this pin open. LBUCK >

( )

VOUT • VIN(MAX) – VOUT •100

f •ILED • %Ripple • VIN(MAX)

Table 1. Switching Frequency vs RT Value

fOSC (kHz)

200

RT (kΩ)

147 LBOOST >

( )

VIN(MIN)2 • VOUT – VIN(MIN) •100

f •ILED • %Ripple • VOUT2

300 84.5

400 59.0

where:

500 45.3

600 35.7 f is operating frequency

700 29.4 % ripple is allowable inductor current ripple

VIN(MIN) is minimum input voltage

Frequency Synchronization

VIN(MAX) is maximum input voltage

The LT3791 switching frequency can be synchronized

VOUT is output voltage

to an external clock using the SYNC pin. Driving SYNC

with a 50% duty cycle waveform is always a good choice, ILED is current through the LEDs

otherwise maintain the duty cycle between 10% and 90%.

3791fc

For more information www.linear.com/LT3791 15

LT3791

Applications Information

200 where ΔIL is peak-to-peak inductor ripple current. In buck

180 operation, the maximum average load current is:

160

140 ⎛ 47.5mV ΔIL ⎞

∆IL/ISENSE(MAX) (%)

IOUT(MAX _BUCK) = ⎜ +

2 ⎟⎠

BOOST ∆IL/

120

ISENSE(MAX) LIMIT ⎝ RSENSE

100

80

The maximum current sensing RSENSE value for the boost

BUCK ∆IL/

60

ISENSE(MAX) LIMIT operation is:

40

20 2 • 51mV• VIN(MIN)

RSENSE(MAX) =

0

2 •ILED • VOUT + ΔIL(BOOST) • VIN(MIN)

50 55 60 65 70 75 80 85 90 95 100

BG1, BG2 DUTY CYCLE (%)

3791 F07

The maximum current sensing RSENSE value for the buck

Figure 7. Maximum Peak-to-Peak Ripple vs Duty Cycle operation is:

2 • 47.5mV

RSENSE(MAX) =

For high efficiency, choose an inductor with low core 2 •ILED – ΔIL(BUCK)

loss. Also, the inductor should have low DC resistance to

reduce the I2R losses, and must be able to handle the peak The final RSENSE value should be lower than the calculated

inductor current without saturating. To minimize radiated RSENSE(MAX) in both the boost and buck operation. A 20%

noise, use a shielded inductor. to 30% margin is usually recommended.

RSENSE Selection and Maximum Output Current CIN and COUT Selection

RSENSE is chosen based on the required output current. The In boost operation, input current is continuous. In buck

current comparator threshold sets the peak of the induc- operation, input current is discontinuous. In buck opera-

tor current in boost operation and the maximum inductor tion, the selection of input capacitor, CIN, is driven by the

valley current in buck operation. In boost operation, the need to filter the input square wave current. Use a low ESR

maximum average load current at VIN(MIN) is: capacitor sized to handle the maximum RMS current. For

buck operation, the input RMS current is given by:

⎛ 51mV ΔIL ⎞ VIN(MIN)

IOUT(MAX _BOOST) = ⎜ – •

⎝ RSENSE 2 ⎟⎠ VOUT IRMS = ILED2 •D+

ΔIL2

•D

12

3791fc

16 For more information www.linear.com/LT3791

LT3791

Applications Information

The formula has a maximum at VIN = 2VOUT. Note that Programming VIN UVLO and OVLO

ripple current ratings from capacitor manufacturers are The falling UVLO value can be accurately set by the resistor

often based on only 2000 hours of life which makes it divider R1 and R2. A small 3µA pull-down current is active

advisable to derate the capacitor. when the EN/UVLO is below the threshold. The purpose

In boost operation, the discontinuous current shifts of this current is to allow the user to program the rising

from the input to the output, so COUT must be capable hysteresis. The following equations should be used to

of reducing the output voltage ripple. The effects of ESR determine the resistor values:

(equivalent series resistance) and the bulk capacitance R1+R2

must be considered when choosing the right capacitor VIN(UVLO–) = 1.2 •

for a given output ripple voltage. The steady ripple due to R2

charging and discharging the bulk capacitance is given by: R1+R2

VIN(UVLO+ ) = 3µA •R1+1.215 •

R2

ΔVRIPPLE (BOOST _CAP ) =

(

ILED • VOUT – VIN(MIN) ) The rising OVLO value can be accurately set by the resis-

COUT • VOUT • f

tor divider R3 and R4. The following equations should be

ΔIL used to determine the resistor values:

ΔVRIPPLE (BUCK _CAP ) ≈

8 • f •COUT R3+R4

VIN(OVLO+ ) = 3 •

where COUT is the output filter capacitor. R4

The steady ripple due to the voltage drop across the ESR R3+R4

VIN(OVLO–) = 2.925 •

is given by: R4

ΔVBOOST(ESR) = ILED • ESR

VIN

ΔVBUCK(ESR) = ILED • ESR

Multiple capacitors placed in parallel may be needed to LT3791 R1 R3

meet the ESR and RMS current handling requirements. OVLO

Output capacitors are also used for stability for the LT3791. EN/UVLO

A good starting point for output capacitors is seen in the R2 R4

Typical Applications circuits. Ceramic capacitors have 3791 F08

excellent low ESR characteristics but can have a high

voltage coefficient and are recommended for applications Figure 8. Resistor Connection to Set VIN UVLO and

less than 100W. Capacitors available with low ESR and OVLO Thresholds

high ripple current ratings, such as OS-CON and POSCAP

may be needed for applications greater than 100W.

3791fc

For more information www.linear.com/LT3791 17

LT3791

Applications Information

Programming LED Current The CTRL pin should not be left open (tie to VREF if not

used). The CTRL pin can also be used in conjunction with

The LED current is programmed by placing an appropriate

a thermistor to provide overtemperature protection for

value current sense resistor, RLED, in series with the LED

string. The voltage drop across RLED is (Kelvin) sensed the LED load, or with a resistor divider to VIN to reduce

output power and switching current when VIN is low.

by the ISP and ISN pins. The CTRL pin should be tied to

The presence of a time varying differential voltage signal

a voltage higher than 1.2V to get the full-scale 100mV

(ripple) across ISP and ISN at the switching frequency

(typical) threshold across the sense resistor. The CTRL

is expected. The amplitude of this signal is increased by

pin can also be used to dim the LED current, although

high LED load current, low switching frequency and/or a

relative accuracy decreases with the decreasing sense

smaller value output filter capacitor. Some level of ripple

threshold. When the CTRL pin voltage is less than 1V,

signal is acceptable: the compensation capacitor on the

the LED current is:

VC pin filters the signal so the average difference between

VCTRL – 200mV ISP and ISN is regulated to the user-programmed value.

ILED =

RLED •10 Ripple voltage amplitude (peak-to-peak) in excess of

20mV should not cause mis-operation, but may lead to

When the CTRL pin voltage is between 1.1V and 1.3V noticeable offset between the average value and the user-

the LED current varies with VCTRL, but departs from the programmed value.

equation above by an increasing amount as VCTRL voltage

increases. Ultimately, when VCTRL > 1.3V the LED current ISMON

no longer varies. The typical V(ISP-ISN) threshold vs VCTRL

The ISMON pin provides a linear indication of the cur-

is listed in Table 2.

rent flowing through the LEDs. The equation for VISMON

Table 2. V(ISP-ISN) Threshold vs CTRL is V(ISP–ISN) • 10. This pin is suitable for driving an ADC

VCTRL (V) V(ISP-ISN) (mV) input, however, the output impedance of this pin is 12.5kΩ

1.1 90 so care must be taken not to load this pin.

1.15 94.5

1.2 98

Programming Input Current Limit

1.25 99.5 The LT3791 has a standalone current sense amplifier. It

1.3 100 can be used to limit the input current. The input current

limit is calculated by the following equation:

When VCTRL is higher than 1.3V, the LED current is

regulated to: 50mV

IIN =

RIN

100mV

ILED =

RLED

3791fc

18 For more information www.linear.com/LT3791

LT3791

Applications Information

For loop stability a lowpass RC filter is needed. For The output overvoltage threshold can be set by selecting

most applications, a 50Ω resistor and 470nF capacitor the values of R5 and R6 (see Figure 9) according to the

is sufficient. following equation:

Table 3 R5+R6

VOUT(OVP) = 1.25 •

RIN (mΩ) ILIMIT (A)

R6

20 2.5

15 3.3 Make sure the expected VFB during normal operation does

12 4.2

not exceed 1.1V:

10 5.0 R6

VLED • ≤ 1.1

6 8.3

R5+R6

5 10.0

4 12.5 These equations set the maximum LED string voltage with

3 16.7 open LED protection for the LT3791 to be 52V.

2 25

Dimming Control

IVINMON There are two methods to control the current source for

dimming using the LT3791. One method uses the CTRL

The IVINMON pin provides a linear indication of the current pin to adjust the current regulated in the LEDs. A second

flowing through the input. The equation for VIVINMON is method uses the PWM pin to modulate the current source

V(IVINP-IVINN) • 20. This pin is suitable for driving an ADC between zero and full current to achieve a precisely pro-

input, however, the output impedance of this pin is 12.5kΩ grammed average current. To make PWM dimming more

so care must be taken not to load this pin. accurate, the switch demand current is stored on the VC

node during the quiescent phase when PWM is low. This

Programming Output Overvoltage Threshold for Open feature minimizes recovery time when the PWM signal goes

LED Protection

high. To further improve the recovery time a disconnect

For an LED driver application with small output capacitors, switch may be used in the LED current path to prevent the

the output voltage usually overshoots a lot during an open ISP node from discharging during the PWM signal low

LED event. Although the 1.2V (typical) FB regulation loop phase. The minimum PWM on- or off-time is affected by

tries to regulate the output, the loop is usually too slow to choice of operating frequency and external component

prevent the output from overshooting. Once the FB voltage selection. The best overall combination of PWM and

hits its overvoltage threshold, 1.25V (typical), the LT3791 analog dimming capabilities is available if the minimum

stops switching by turning TG1, TG2 off, and BG1, BG2 PWM pulse is at least six switching cycles and the PWM

on. In this way, the minimum overshoot is guaranteed. pulse is synchronized to the SYNC signal.

VOUT

LT3791 R5

FB

R6

3791 F09

Figure 9. Resistor Connection for Open LED Protection

3791fc

For more information www.linear.com/LT3791 19

LT3791

Applications Information

SHORTLED Pin The SS pin is also used as a fault timer. Once an open

The LT3791 provides an open-drain status pin, LED or a shorted LED fault is detected, a 1.4µA pull-

SHORTLED, which pulls low when the FB pin is below down current source is activated. With a 500k pull-up

400mV. The only time the FB pin will be below 400mV resistor to VREF on the SS pin, the LT3791 will latch off

is during start-up or if the LEDs are shorted. During until the EN/UVLO pin is toggled. Without any resistor

start-up the LT3791 ignores the voltage on the FB pin to VREF the SS pin enters a hiccup mode operation. The

until the soft-start capacitor reaches 1.75V. To prevent 1.4µA pulls SS down until 0.2V is reached, at which

false tripping after startup, a large enough soft-start point the 14µA pull-up current source turns on. If the

capacitor must be used to allow the output to get up to fault condition hasn’t been removed when SS reaches

approximately 40% to 50% of the final value. 1.75V, then the 1.4µA pull-down current source turns on

again initiating a new cycle. This will continue until the

OPENLED Pin fault is removed.

The LT3791 provides an open-drain status pin, OPENLED, Loop Compensation

which pulls low when the FB pin is above 1.15V and the

voltage across V(ISP-ISN) is less than 10mV. If the open The LT3791 uses an internal transconductance error

LED clamp voltage is programmed correctly using the FB amplifier whose VC output compensates the control loop.

pin, then the FB pin should never exceed 1.1V when the The external inductor, output capacitor and the comp-

LEDs are connected. Therefore, the only way for the FB ensation resistor and capacitor determine the loop

pin to exceed 1.15V is for an open LED event to occur. stability.

The inductor and output capacitor are chosen based on

Soft-Start, Fault Function

performance, size and cost. The compensation resis-

Soft-start reduces the input power sources’ surge currents tor and capacitor at VC are set to optimize control loop

by gradually increasing the controller’s current limit (pro- response and stability. For typical LED applications, a

portional to an internally buffered clamped equivalent of 10nF compensation capacitor at VC is adequate, and a

VC). The soft-start interval is set by the soft-start capacitor series resistor should always be used to increase the

selection according to the following equation slew rate on the VC pin to maintain tighter regulation of

1.2V LED current during fast transients on the input supply of

t SS = •C the converter.

14µA SS

Make sure CSS is large enough when there is loading

during start-up.

3791fc

20 For more information www.linear.com/LT3791

LT3791

Applications Information

Power MOSFET Selections and Efficiency Switch M2 operates in buck operation as the synchronous

Considerations rectifier. Its power dissipation at maximum output current

is given by:

The LT3791 requires four external N-channel power MOS-

FETs, two for the top switches (switch M1 and M4, shown in VIN – VOUT

PM2(BUCK) = •ILED2 • ρT •RDS(ON)

Figure 1) and two for the bottom switches (switch M2 and VIN

M3 shown in Figure 1). Important parameters for the power

MOSFETs are the breakdown voltage, VBR(DSS), threshold Switch M3 operates in boost operation as the control

voltage, VGS(TH), on-resistance, RDS(ON), reverse transfer switch. Its power dissipation at maximum current is

capacitance, CRSS, and maximum current, IDS(MAX). given by:

The drive voltage is set by the 5V INTVCC supply. Con- PM3(BOOST) =

( VOUT – VIN ) • VOUT •I

LED • T •RDS(ON)

2

sequently, logic-level threshold MOSFETs must be used VIN2

in LT3791 applications. If the input voltage is expected ILED

to drop below the 5V, then sub-logic threshold MOSFETs + k • VOUT3 • •C •f

should be considered.

VIN RSS

where CRSS is usually specified by the MOSFET manufac-

In order to select the power MOSFETs, the power dis-

turers. The constant k, which accounts for the loss caused

sipated by the device must be known. For switch M1, the

maximum power dissipation happens in boost operation, by reverse-recovery current, is inversely proportional to

the gate drive current and has an empirical value of 1.7.

when it remains on all the time. Its maximum power dis-

sipation at maximum output current is given by: For switch M4, the maximum power dissipation happens

2 in boost operation, when its duty cycle is higher than

⎛I •V ⎞ 50%. Its maximum power dissipation at maximum output

PM1(BOOST) = ⎜ LED OUT ⎟ • ρT •RDS(ON)

⎝ VIN ⎠ current is given by:

2

where ρT is a normalization factor (unity at 25°C) V ⎛I •V ⎞

PM4(BOOST) = IN • ⎜ LED OUT ⎟ • ρT •RDS(ON)

accounting for the significant variation in on-resistance VOUT ⎝ VIN ⎠

with temperature, typically 0.4%/°C as shown in Figure

10. For a maximum junction temperature of 125°C, using For the same output voltage and current, switch M1 has

a value of ρT = 1.5 is reasonable. the highest power dissipation and switch M2 has the low-

est power dissipation unless a short occurs at the output.

3791fc

For more information www.linear.com/LT3791 21

LT3791

Applications Information

From a known power dissipated in the power MOSFET, its diode to be effective, the inductance between it and the

junction temperature can be obtained using the following synchronous switch must be as small as possible, mandat-

formula: ing that these components be placed adjacently.

TJ = TA + P • RTH(JA) INTVCC Regulator

The RTH(JA) to be used in the equation normally includes

An internal P-channel low dropout regulator produces 5V

the RTH(JC) for the device plus the thermal resistance from

at the INTVCC pin from the VIN supply pin. INTVCC powers

the case to the ambient temperature (RTH(JC)). This value the drivers and internal circuitry within the LT3791. The

of TJ can then be compared to the original, assumed value

INTVCC pin regulator can supply a peak current of 67mA

used in the iterative calculation process. and must be bypassed to ground with a minimum of 4.7µF

ceramic capacitor or low ESR electrolytic capacitor. An

2.0 additional 0.1µF ceramic capacitor placed directly adjacent

to the INTVCC and PGND IC pins is highly recommended.

ρT NORMALIZED ON-RESISTANCE (Ω)

1.5

Good bypassing is necessary to supply the high transient

current required by MOSFET gate drivers.

1.0 Higher input voltage applications in which large MOSFETs

are being driven at high frequencies may cause the maxi-

mum junction temperature rating for the LT3791 to be

0.5

exceeded. The system supply current is normally dominated

by the gate charge current. Additional external loading of

0

–50 0 50 100 150

the INTVCC also needs to be taken into account for the

JUNCTION TEMPERATURE (°C) power dissipation calculations. Power dissipation for the

3791 F10 IC in this case is VIN • IINTVCC, and overall efficiency is

Figure 10. Normalized RDS(ON) vs Temperature lowered. The junction temperature can be estimated by

using the equations given

Optional Schottky Diode (D3, D4) Selection TJ = TA + (PD • θJA)

The Schottky diodes D3 and D4 shown in the Typical Ap- where θJA (in °C/W) is the package thermal impedance.

plications section conduct during the dead time between For example, a typical application operating in continuous

the conduction of the power MOSFET switches. They current operation might draw 24mA from a 24V supply:

are intended to prevent the body diode of synchronous

switches M2 and M4 from turning on and storing charge TJ = 70°C + 24mA • 24V • 28°C/W = 86°C

during the dead time. In particular, D4 significantly reduces To prevent maximum junction temperature from being

reverse-recovery current between switch M4 turn-off and exceeded, the input supply current must be checked

switch M3 turn-on, which improves converter efficiency operating in continuous mode at maximum VIN.

and reduces switch M3 voltage stress. In order for the

3791fc

22 For more information www.linear.com/LT3791

LT3791

Applications Information

Top Gate (TG) MOSFET Driver Supply (C1, D1, C2, D2) 2. Transition loss. This loss arises from the brief amount

The external bootstrap capacitors C1 and C2 connected of time switch M1 or switch M3 spends in the saturated

to the BST1 and BST2 pins supply the gate drive voltage region during switch node transitions. It depends upon

for the topside MOSFET switches M1 and M4. When the the input voltage, load current, driver strength and

top MOSFET switch M1 turns on, the switch node SW1 MOSFET capacitance, among other factors. The loss

rises to VIN and the BST1 pin rises to approximately VIN + is significant at input voltages above 20V and can be

INTVCC. When the bottom MOSFET switch M2 turns on, the estimated from:

switch node SW1 drops low and the bootstrap capacitor Transition Loss ≈ 2.7 • VIN2 • IOUT • CRSS • f

C1 is charged through D1 from INTVCC. When the bottom where CRSS is the reverse-transfer capacitance.

MOSFET switch M3 turns on, the switch node SW2 drops

low and the bootstrap capacitor C2, is charged through D2 3. INTVCC current. This is the sum of the MOSFET driver

from INTVCC. The bootstrap capacitors C1 and C2 need to and control currents.

store about 100 times the gate charge required by the top 4. CIN and COUT loss. The input capacitor has the difficult

MOSFET switch M1 and M4. In most applications a 0.1µF job of filtering the large RMS input current to the regu-

to 0.47µF, X5R or X7R ceramic capacitor is adequate. lator in buck operation. The output capacitor has the

difficult job of filtering the large RMS output current

Efficiency Considerations in boost operation. Both CIN and COUT are required to

The power efficiency of a switching regulator is equal to have low ESR to minimize the AC I2R loss and sufficient

the output power divided by the input power times 100%. capacitance to prevent the RMS current from causing

It is often useful to analyze individual losses to determine additional upstream losses in fuses or batteries.

what is limiting the efficiency and which change would 5. Other losses. Schottky diode D3 and D4 are respon-

produce the most improvement. Although all dissipative sible for conduction losses during dead time and light

elements in circuits produce losses, four main sources load conduction periods. Inductor core loss occurs

account for most of the losses in LT3791 circuits: predominately at light loads. Switch M3 causes reverse

1. DC I2R losses. These arise from the resistances of the recovery current loss in boost operation.

MOSFETs, sensing resistor, inductor and PC board

When making adjustments to improve efficiency, the input

traces and cause the efficiency to drop at high output

current is the best indicator of changes in efficiency. If you

currents.

make a change and the input current decreases, then the

efficiency has increased. If there is no change in the input

current, then there is no change in efficiency.

3791fc

For more information www.linear.com/LT3791 23

LT3791

Applications Information

PC Board Layout Checklist n The path formed by switch M1, switch M2, D1 and the

CIN capacitor should have short leads and PC trace

The basic PC board layout requires a dedicated ground

lengths. The path formed by switch M3, switch M4, D2

plane layer. Also, for high current, a multilayer board

and the COUT capacitor also should have short leads

provides heat sinking for power components.

and PC trace lengths.

n The PGND ground plane layer should not have any traces n The output capacitor (–) terminals should be connected

and it should be as close as possible to the layer with

as close as possible to the (–) terminals of the input

power MOSFETs.

capacitor.

n Place CIN, switch M1, switch M2 and D1 in one compact n Connect the top driver bootstrap capacitor, C1, closely

area. Place COUT, switch M3, switch M4 and D2 in one

to the BST1 and SW1 pins. Connect the top driver

compact area.

bootstrap capacitor, C2, closely to the BST2 and SW2

n Use immediate vias to connect the components (includ- pins.

ing the LT3791’s SGND and PGND pins) to the ground n Connect the input capacitors, CIN, and output capacitors,

plane. Use several large vias for each power component.

COUT, closely to the power MOSFETs. These capaci-

n Use planes for VIN and VOUT to maintain good voltage tors carry the MOSFET AC current in boost and buck

filtering and to keep power losses low. operation.

n Flood all unused areas on all layers with copper. Flooding n Route SNSN and SNSP leads together with minimum

with copper will reduce the temperature rise of power PC trace spacing. Avoid sense lines pass through noisy

components. Connect the copper areas to any DC net areas, such as switch nodes. Ensure accurate current

(VIN or PGND). sensing with Kelvin connections at the SENSE resistor.

n Separate the signal and power grounds. All small-signal n Connect the VC pin compensation network close to the

components should return to the SGND pin at one point, IC, between VC and the signal ground pins. The capaci-

which is then tied to the PGND pin close to the sources tor helps to filter the effects of PCB noise and output

of switch M2 and switch M3. voltage ripple voltage from the compensation loop.

n Place switch M2 and switch M3 as close to the control- n Connect the INTVCC bypass capacitor, CVCC, close to the

ler as possible, keeping the PGND, BG and SW traces IC, between the INTVCC and the power ground pins. This

short. capacitor carries the MOSFET drivers’ current peaks. An

n Keep the high dV/dT SW1, SW2, BST1, BST2, TG1 and additional 0.1µF ceramic capacitor placed immediately

TG2 nodes away from sensitive small-signal nodes. next to the INTVCC and PGND pins can help improve

noise performance substantially.

3791fc

24 For more information www.linear.com/LT3791

LT3791

Typical Applications

98% Efficient 50W (25V 2A) Buck-Boost LED Driver

VIN CIN

4.7V TO 58V 2.2µF

RIN

100V

0.003Ω VIN INTVCC

CVCC ×4

C3

TEST2 D1 D2 4.7µF

R7 1µF

50Ω BST2

IVINN C2 COUT

C7 BST1 0.1µF

R5 4.7µF

470nF TG1 M1 C1 M4 50V

R1 IVINP 1M

0.1µF ×4

332k

SWI

EN/UVLO L1 10µH R6

R2 OVLO BG1 M2 M3 44.2k

R3 121k INTVCC

1M LT3791 SNSP

R9 R10

200k 200k RSENSE RLED

R4 SHORTLED 0.004Ω 0.05Ω

54.9k

OPENLED SNSN 25V LED

SYNC TWO 100Hz 2A

PWM PGND

SIGNALS 300kHz

SYNC BG2

IVINMON SW2

ISMON TG2

CLKOUT FB

C8 VREF

R11 ISP

1M 0.1µF

ISN

CTRL

PWMOUT

R12 TEST1

SS VC RT SGND D1, D2: NXP BAT46WJ M5

237k

L1: COOPER HC9-100-R 10µH

CSS CC R8 M1, M2: RENESAS RJK0651DPB 60VDS

10nF 22nF 86.6k M3, M4: RENESAS RJK0451DPB 40VDS 3791 TA02a

300kHz M5: VISHAY Si2318CDS 40VDS

Efficiency vs VIN 100Hz 1000:1 PWM Dimming 100Hz 250:1 PWM Dimming

(VIN = 24V) (VIN = 24V)

100

98 PWM PWM

BOOST BUCK 5V/DIV 5V/DIV

96

94 BUCK-BOOST

EFFICIENCY (%)

92 IL1 IL1

5A/DIV 5A/DIV

90

ILED ILED

88 2A/DIV

2A/DIV

86

ISMON ISMON

84 1V/DIV 1V/DIV

3791 TA02c 3791 TA02d

82 5µs/DIV 5µs/DIV

80

0 10 20 30 40 50 60

INPUT VOLTAGE (V)

3791 TA02b

3791fc

For more information www.linear.com/LT3791 25

LT3791

Package Description

Please refer to http://www.linear.com/product/LT3791#packaging for the most recent package drawings.

FE Package

38-Lead Plastic TSSOP (4.4mm)

(Reference LTC DWG # 05-08-1772 Rev C)

Exposed Pad Variation AA

4.75 REF 9.60 – 9.80*

(.378 – .386)

4.75 REF

(.187)

38 20

6.60 ±0.10

2.74 REF

4.50 REF

SEE NOTE 4 6.40

2.74

0.315 ±0.05 REF (.252)

(.108)

BSC

1.05 ±0.10

0.50 BSC

RECOMMENDED SOLDER PAD LAYOUT

1 19

1.20

4.30 – 4.50* (.047)

(.169 – .177) 0.25 MAX

REF

0° – 8°

0.50

0.09 – 0.20 0.50 – 0.75 (.0196) 0.05 – 0.15

(.0035 – .0079) (.020 – .030) BSC (.002 – .006)

0.17 – 0.27

FE38 (AA) TSSOP REV C 0910

(.0067 – .0106)

TYP

NOTE:

1. CONTROLLING DIMENSION: MILLIMETERS 4. RECOMMENDED MINIMUM PCB METAL SIZE

2. DIMENSIONS ARE IN MILLIMETERS FOR EXPOSED PAD ATTACHMENT

(INCHES) *DIMENSIONS DO NOT INCLUDE MOLD FLASH. MOLD FLASH

3. DRAWING NOT TO SCALE SHALL NOT EXCEED 0.150mm (.006") PER SIDE

3791fc

26 For more information www.linear.com/LT3791

LT3791

Revision History

REV DATE DESCRIPTION PAGE NUMBER

A 08/12 Clarified Features and Description 1

Clarified graph labels/titles 8

Clarified Pin Functions 9,10

Clarified buck-boost function 13

Clarified programming output for overvoltage or open led/overvoltage threshold 19

Clarified Typical Application 25, 28

B 12/13 Clarified TG1, TG2, tOFF(MIN) parameters 4

C 05/17 Clarified last paragraph on the Description 1

Clarified FB pin input bias current limits 3

Clarified TG1, TG2, tOFF(MIN) limits 4

3791fc

Information furnished by Linear Technology Corporation is believed to be accurate and reliable.

However, no responsibility is assumed for its use. Linear Technology Corporation makes no representa-

For more

tion that the interconnection information

of its circuits www.linear.com/LT3791

as described herein will not infringe on existing patent rights. 27

LT3791

Typical Application

98.5% Efficient 100W (33.3V 3A) Buck-Boost LED Driver

RIN

0.003Ω

VIN CIN

15V TO 58V 2.2µF

100V

VIN INTVCC ×5

C3 D1 D2 CVCC

R7 1µF 4.7µF

50Ω BST2

IVINN C2

BST1 COUT

C7 0.1µF

C1 R5 4.7µF

R1 470nF TG1 M1 M4

IVINP 0.1µF 1M 50V

499k ×5

SWI

EN/UVLO L1 R6

R2 OVLO BG1 M2 10µH M3 34.2k

15.8k INTVCC

R9 R10 LT3791 SNSP

R3 200k 200k RSENSE RLED 3A, 100W

28k SHORTLED 0.004Ω 0.033Ω LED POWER

OPENLED

SNSN

PGND

PWM

BG2

IVINMON

SW2

ISMON

TG2

CLKOUT

FB

VREF

ISP

CTRL

C8 ISN

0.1µF

PWMOUT

SS SYNC VC RT SGND

D1, D2: NXP BAT46WJ

CSS CC R8 L1: COOPER HC9-100-R 10µH

10nF 22nF 86.6k M1, M2: RENESAS RJK0651DPB 60VDS

300kHz M5

M3, M4: RENESAS RJK0451DPB 40VDS

M5: VISHAY SI2318CDS 40VDS

3791 TA03

Related Parts

PART NUMBER DESCRIPTION COMMENTS

LTC 3780

®

High Efficiency, Synchronous, 4-Switch Buck-Boost VIN: 4V to 36V, VOUT Range: 0.8V to 30V, ISD < 55µA, SSOP-24, QFN-32

Controller Packages

LTC3789 High Efficiency, Synchronous, 4-Switch Buck-Boost VIN: 4V to 38V, VOUT Range: 0.8V to 38V, ISD < 40µA, 4mm × 5mm QFN-28,

Controller SSOP-28 Packages

LT3755/LT3755-1 High Side 60V, 1MHz LED Controller with True Color VIN: 4.5V to 40V, VOUT Range: 5V to 60V, 3000:1 True Color PWM, Analog,

LT3755-2 3000:1 PWM Dimming ISD < 1µA, 3mm × 3mm QFN-16, MSOP-16E Packages

LT3756/LT3756-1 High Side 100V, 1MHz LED Controller with True Color VIN: 6V to 100V, VOUT Range: 5V to 100V, 3000:1 True Color PWM, Analog,

LT3756-2 3000:1 PWM Dimming ISD < 1µA, 3mm × 3mm QFN-16, MSOP-16E Packages

LT3596 60V, 300mA Step-Down LED Driver VIN: 6V to 60V, VOUT Range: 5V to 55V, 10000:1 True Color PWM, Analog,

ISD < 1µA, 5mm × 8mm QFN-52 Package

LT3743 Synchronous Step-Down 20A LED Driver with VIN: 5.5V to 36V, VOUT Range: 5.5V to 35V, 3000:1 True Color PWM, Analog,

Thee-State LED Current Control ISD < 1µA, 4mm × 5mm QFN-28, TSSOP-28E Packages

3791fc

28

LT 0517 REV C • PRINTED IN USA

www.linear.com/LT3791

For more information www.linear.com/LT3791 LINEAR TECHNOLOGY CORPORATION 2012

You might also like

- Features Description: LT3755/LT3755-1/LT3755-2 40V, 75V LED ControllersDocument28 pagesFeatures Description: LT3755/LT3755-1/LT3755-2 40V, 75V LED ControllersMick Thomson RcNo ratings yet

- LT 8711Document38 pagesLT 8711MallikarjunBhiradeNo ratings yet

- LTC 3777Document40 pagesLTC 3777unwantedadvertisementNo ratings yet

- 3827 FFDocument36 pages3827 FFDMITRIY DOMOCHKINNo ratings yet

- LT8390ADocument30 pagesLT8390A隋玉峰No ratings yet

- 3798 FaDocument20 pages3798 FaFavio IousNo ratings yet

- Features Description: LT8631 100V, 1A Synchronous Micropower Step-Down RegulatorDocument26 pagesFeatures Description: LT8631 100V, 1A Synchronous Micropower Step-Down RegulatorAle NqnNo ratings yet

- Features Description: LTC3851 Synchronous Step-Down Switching Regulator ControllerDocument28 pagesFeatures Description: LTC3851 Synchronous Step-Down Switching Regulator ControllerDjems DjemsNo ratings yet

- Features Description: LTC3780 High Efficiency, Synchronous, 4-Switch Buck-Boost ControllerDocument30 pagesFeatures Description: LTC3780 High Efficiency, Synchronous, 4-Switch Buck-Boost ControllerjeffNo ratings yet

- Features: LT1176/LT1176-5 Step-Down Switching RegulatorDocument8 pagesFeatures: LT1176/LT1176-5 Step-Down Switching RegulatorDreavus HashirobiNo ratings yet

- 2A, 380 KHZ Step-Down Converter: The Future of Analog Ic TechnologyDocument10 pages2A, 380 KHZ Step-Down Converter: The Future of Analog Ic TechnologyAnonymous aP1FSUPoNo ratings yet

- 3728 FGDocument36 pages3728 FGcohito9260No ratings yet

- LTM8071 1504284Document25 pagesLTM8071 1504284Shahji ElectronicNo ratings yet

- Description Features: LT3957 Boost, Flyback, SEPIC and Inverting Converter With 5A, 40V SwitchDocument28 pagesDescription Features: LT3957 Boost, Flyback, SEPIC and Inverting Converter With 5A, 40V Switchsaom09No ratings yet

- Datasheet PWM PDFDocument38 pagesDatasheet PWM PDFEdnaelson SilvaNo ratings yet

- LTM4607 PDFDocument26 pagesLTM4607 PDFGiroAVNo ratings yet

- LTC3850GN Datasheet PDFDocument36 pagesLTC3850GN Datasheet PDFMiasco NestorNo ratings yet

- Description Features: Lt3754 16-Channel × 50ma Led DriverDocument30 pagesDescription Features: Lt3754 16-Channel × 50ma Led DriverMohammed MouftiNo ratings yet

- lt8356 1-2955993Document27 pageslt8356 1-2955993chawkigenieNo ratings yet

- Features Descriptio: LTC1624 High Efficiency SO-8 N-Channel Switching Regulator ControllerDocument28 pagesFeatures Descriptio: LTC1624 High Efficiency SO-8 N-Channel Switching Regulator ControllervetchboyNo ratings yet

- Features Description: Ltm4613 En55022B Compliant 36V, 15V, 8A, Dc/Dc Μmodule RegulatorDocument30 pagesFeatures Description: Ltm4613 En55022B Compliant 36V, 15V, 8A, Dc/Dc Μmodule RegulatorSergio GuimarãesNo ratings yet

- 3780 FFDocument30 pages3780 FFhonokaNo ratings yet

- LT 3741 - Controlador Corriente - VoltajeDocument24 pagesLT 3741 - Controlador Corriente - VoltajeMarta_d_eNo ratings yet

- LTC 3103Document20 pagesLTC 3103Audre Maren DayadayNo ratings yet

- TPS65631W Dual-Output AMOLED Display Power Supply: 1 Features 3 DescriptionDocument27 pagesTPS65631W Dual-Output AMOLED Display Power Supply: 1 Features 3 DescriptionIgorsNo ratings yet

- 3A, 28V, 385Khz Step-Down Converter: The Future of Analog Ic TechnologyDocument13 pages3A, 28V, 385Khz Step-Down Converter: The Future of Analog Ic TechnologyIoan TivgaNo ratings yet

- Electronic Tuning-Use FM Front End For Car Radio, Home StereosDocument8 pagesElectronic Tuning-Use FM Front End For Car Radio, Home StereosVeronicaGonzalezNo ratings yet

- 3727 FCDocument32 pages3727 FCtommy99No ratings yet

- LT 8364Document32 pagesLT 8364gtcv805No ratings yet

- A89307 DatasheetDocument36 pagesA89307 Datasheetsanthosha rkNo ratings yet

- 3757 AfeDocument36 pages3757 AfeMelric LamparasNo ratings yet

- LT3865 FBDocument38 pagesLT3865 FBarmin rahmatiNo ratings yet

- 1310 FsDocument12 pages1310 FsMohamed HaddadNo ratings yet

- Descriptio Features: Lt1370 500Khz High Efficiency 6A Switching RegulatorDocument16 pagesDescriptio Features: Lt1370 500Khz High Efficiency 6A Switching RegulatorvvvNo ratings yet

- A6211 Datasheet PDFDocument18 pagesA6211 Datasheet PDFNestor GlezNo ratings yet

- En6362qi 11656-1294653Document27 pagesEn6362qi 11656-1294653신덕기No ratings yet

- Datasheet MP2380DNDocument11 pagesDatasheet MP2380DNchevicitNo ratings yet

- 24V, High Current Synchronous Buck Converter With +/-1.5A LDO and Buffed ReferenceDocument21 pages24V, High Current Synchronous Buck Converter With +/-1.5A LDO and Buffed Reference8ctanoNo ratings yet

- DatasheetDocument12 pagesDatasheetStuxnetNo ratings yet

- 3775 FaDocument34 pages3775 FaImran AliNo ratings yet

- LTM4700 PDFDocument126 pagesLTM4700 PDFemilfrancuNo ratings yet

- LTC 3124Document28 pagesLTC 3124m3rishorNo ratings yet

- MP6001 r1.0Document13 pagesMP6001 r1.0nan keNo ratings yet

- 60V Step-Down DC/DC Converter Maintains High Effi Ciency: Design Note 269 Mark W. MarosekDocument2 pages60V Step-Down DC/DC Converter Maintains High Effi Ciency: Design Note 269 Mark W. MarosekMes BenNo ratings yet

- AD9mark PDFDocument14 pagesAD9mark PDFLe DungNo ratings yet

- 50 V Ultra-Low Noise FOC Motor Controller: Features and Benefits DescriptionDocument26 pages50 V Ultra-Low Noise FOC Motor Controller: Features and Benefits Descriptionsanthosha rkNo ratings yet

- Features Description: LTC3786 Low I Synchronous Boost ControllerDocument34 pagesFeatures Description: LTC3786 Low I Synchronous Boost ControllerSaifuddin SidikiNo ratings yet

- Lhti 001176Document5 pagesLhti 001176Sergio MuriloNo ratings yet

- NN30332ADocument43 pagesNN30332AfsdfsNo ratings yet

- 8610 AxfDocument6 pages8610 Axfbruno magalhãesNo ratings yet

- 2.75V To 17V, 6A, 1.2Mhz, Synchronous, Ultra-Thin Power Module Description FeaturesDocument22 pages2.75V To 17V, 6A, 1.2Mhz, Synchronous, Ultra-Thin Power Module Description FeaturesEugene FlexNo ratings yet

- Nb679a MpsDocument19 pagesNb679a MpswarkeravipNo ratings yet

- TLV 62085Document25 pagesTLV 62085Ramón MartinezNo ratings yet

- Features Descriptio: LTC1736 5-Bit Adjustable High Efficiency Synchronous Step-Down Switching RegulatorDocument28 pagesFeatures Descriptio: LTC1736 5-Bit Adjustable High Efficiency Synchronous Step-Down Switching RegulatorCarlos Henrique RibasNo ratings yet

- 8315 FaDocument24 pages8315 FatanmaysutariaNo ratings yet

- Arduino Nano 3 User ManualDocument20 pagesArduino Nano 3 User ManualDj PopNo ratings yet

- TPS65133 5-V, 250-Ma Dual-Output Power Supply: 1 Features 3 DescriptionDocument27 pagesTPS65133 5-V, 250-Ma Dual-Output Power Supply: 1 Features 3 DescriptionCarlos IbaNo ratings yet

- LT3469 Piezo Actuator Driver PDFDocument8 pagesLT3469 Piezo Actuator Driver PDFjacerosiete2952No ratings yet

- Workbook View Point 1Document105 pagesWorkbook View Point 1Juandacho Reina100% (1)

- Bag DumpDocument2 pagesBag DumpalirizalNo ratings yet

- Articles For HandphoneDocument11 pagesArticles For HandphoneMimiMichelleMichaelNo ratings yet

- Resume SibiDocument2 pagesResume Sibiapi-419999351No ratings yet

- 3 - A 50-125A - A Self-Priming Centrifugal PumpDocument6 pages3 - A 50-125A - A Self-Priming Centrifugal Pump3dpshabbirNo ratings yet

- 1158-Week 12Document60 pages1158-Week 12jiojung1996No ratings yet

- Nebosh D guide report structureDocument2 pagesNebosh D guide report structureNorman AinomugishaNo ratings yet

- ZXG10 B8018 (V1.00) In-Door Base Transceiver Station Technical ManualDocument128 pagesZXG10 B8018 (V1.00) In-Door Base Transceiver Station Technical ManualPrashant MaraNo ratings yet

- Senior SAS Programmer in San Francisco CA Resume Jay JaffeDocument2 pagesSenior SAS Programmer in San Francisco CA Resume Jay JaffejayjaffeNo ratings yet

- 6) Fläkts FansSystem StagECC 2009Document82 pages6) Fläkts FansSystem StagECC 2009hmaza shakeelNo ratings yet

- Basic Rotor Aerodynamics: 1D MomentumDocument6 pagesBasic Rotor Aerodynamics: 1D MomentumJagabar SathikNo ratings yet

- Value Stream MapDocument42 pagesValue Stream MapultratangoNo ratings yet

- Stationery: CatalogueDocument11 pagesStationery: Cataloguedeepak2628No ratings yet

- Sbi Po PreDocument1 pageSbi Po PreSamarjeet SinghNo ratings yet

- L&T QuestionsDocument19 pagesL&T QuestionsVALLI NNo ratings yet

- Governing System of 210mw KwuDocument21 pagesGoverning System of 210mw KwuNitesh Rasekar100% (3)

- 40Gb/s TIA AGCDocument14 pages40Gb/s TIA AGCAsif JahangirNo ratings yet

- FWRA Food Waste Survey 2016 Report FinalDocument51 pagesFWRA Food Waste Survey 2016 Report FinalIvn TznNo ratings yet