Professional Documents

Culture Documents

GPPS

Uploaded by

Eslam A. FahmyCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

GPPS

Uploaded by

Eslam A. FahmyCopyright:

Available Formats

Item Test conditions Test method Test data

Density ISO 1183:1987 1040kg/m3

Water absorption ISO 62:1999 <0.1%

Melt flow rate 200°C/5kg ISO 1133:1997 8cm3/10min

Process shrinkage ISO 294-4:1997 1eU

Charpy impact strength 1eU ISO 179:1993 15kj/m2

Tensile modulus 1mm/min ISO 527-2:1993 3300MPa

Elongation 50mm/min ISO 527-2:1993 3%

Tensile strength at break 50mm/min ISO 527-2:1993 55MPa

Ball indentation hardness H 358N/30s ISO 2039-1:1993 150N/mm2

Bending strength 2mm/min ISO 178:1993 100MPa

HDT 1.8MPa ISO 75-2:1993 84°C

Linear coefficient of thermal expansion (23-80)°C DIN 53 752 0.8-1.0K-1

Heat conduction DIN 52 612 0.16W/mK

Vicat softening point B50/oil ISO 306:1994 93°C

Flame retardance >1.4mm UL-Standard 94 94HBCla

Testing Test

tem Units PG-22 PG-33 PG-80 PG-383

standards Conditions

Melt flow index D-1238 200°C*5kg g/10min. 17.5 7.4 4.0 3.0

Softening point D-1525 1kg. °C 87.0 94.0 97.7 105.0

Tensile strength D-638 Kg/cm² 420 470 500 560

Tensile modulus D-638 26460 26220 26720 28140

Bending strength D-790 Kg/cm² 540 670 690 820

Flexural modulus D-790 Kg/cm² 31000 31000 31000 33000

Heat distortion

D-648 °C 75 79 81 86

temperature

Mixed Injection

Use Injection level level

leveling level

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5807)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- HYDROSTATIC PARTICULARS OF Ship A (MCA Stability)Document102 pagesHYDROSTATIC PARTICULARS OF Ship A (MCA Stability)Ragunath RamasamyNo ratings yet

- Pacv D PDFDocument61 pagesPacv D PDFUmen AryanNo ratings yet

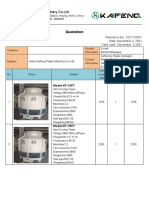

- KAIFENG Quotation For 150T Cooling TowerDocument13 pagesKAIFENG Quotation For 150T Cooling TowerEslam A. FahmyNo ratings yet

- General Purpose Polystyrene, GPPS, LabDocument1 pageGeneral Purpose Polystyrene, GPPS, LabEslam A. FahmyNo ratings yet

- Background: Amy Saunders, Global Insulation SectionDocument5 pagesBackground: Amy Saunders, Global Insulation SectionEslam A. FahmyNo ratings yet

- 2020 Catalog EnglishDocument27 pages2020 Catalog EnglishEslam A. FahmyNo ratings yet

- CO2 Supply Agreement - A-ZDocument13 pagesCO2 Supply Agreement - A-ZEslam A. FahmyNo ratings yet

- Supplied ChainDocument81 pagesSupplied ChainEslam A. FahmyNo ratings yet

- SG Foam 32-36Document1 pageSG Foam 32-36Eslam A. FahmyNo ratings yet

- SG Foam 28-32Document1 pageSG Foam 28-32Eslam A. FahmyNo ratings yet

- I V Savelyev Fundametals of Theoretical Physics Vol 1 PDFDocument425 pagesI V Savelyev Fundametals of Theoretical Physics Vol 1 PDFpfael100% (4)

- Video Chapter 1 - Antenna ParametersDocument12 pagesVideo Chapter 1 - Antenna Parametersnorfatin fadzlinda nordinNo ratings yet

- Math 2263 - HW1Document2 pagesMath 2263 - HW1cemaliNo ratings yet

- Autonics - BTS Series - DatasheetDocument6 pagesAutonics - BTS Series - DatasheetTjhandNo ratings yet

- Hydraulics Lecture Notes 6 - Stability of Floating BodiesDocument2 pagesHydraulics Lecture Notes 6 - Stability of Floating BodiesAugosto FraceNo ratings yet

- Phosphors For LED-based Solid-State Lighting: by Anant A. SetlurDocument5 pagesPhosphors For LED-based Solid-State Lighting: by Anant A. SetlurArun AchalamNo ratings yet

- Humidification and Air Conditioning: Lecture No. 8Document6 pagesHumidification and Air Conditioning: Lecture No. 8Anonymous UFa1z9XUANo ratings yet

- Water Transmission and Distribution SystemsDocument71 pagesWater Transmission and Distribution SystemsDr. Akepati Sivarami Reddy100% (6)

- T6: Type Abbreviations: Selection TableDocument1 pageT6: Type Abbreviations: Selection TableRicardo MotaNo ratings yet

- Monte Carlo Simulations ExcelDocument164 pagesMonte Carlo Simulations Exceljijo morijoNo ratings yet

- Tantalum: Arihant Jain 6 PeriodDocument7 pagesTantalum: Arihant Jain 6 PeriodbudyNo ratings yet

- ACS1000: Estimation of Induction Motor Parameters How To Use These SheetsDocument4 pagesACS1000: Estimation of Induction Motor Parameters How To Use These SheetsLuis Gustavo MollinedoNo ratings yet

- Project Report of Air Cooler Using PeltierDocument49 pagesProject Report of Air Cooler Using PeltierSantosh BansodeNo ratings yet

- Physics 3204: Worksheet5: Motor PrincipleDocument4 pagesPhysics 3204: Worksheet5: Motor PrincipleVasile NicoletaNo ratings yet

- Borah - 2020 - Finite Element Modelling of Confined Masonry Wall Under Cyclic LoadDocument8 pagesBorah - 2020 - Finite Element Modelling of Confined Masonry Wall Under Cyclic LoadAdolfo Gálvez VillacortaNo ratings yet

- Atasheet en 201508 T58I-E-02 Rev3 2Document17 pagesAtasheet en 201508 T58I-E-02 Rev3 2deri mardiNo ratings yet

- Harpa Concert Hall & Conference CenterDocument18 pagesHarpa Concert Hall & Conference Centershenaz AfroseNo ratings yet

- Gazi University Department of Electrical and Electronics EngineeringDocument4 pagesGazi University Department of Electrical and Electronics EngineeringemreNo ratings yet

- Keli XK3118 T1 Manual TecnicoDocument3 pagesKeli XK3118 T1 Manual Tecnicofabian almeidaNo ratings yet

- New ScientistDocument39 pagesNew Scientistmohammad Usman100% (1)

- Lintel and Sunshade DesignDocument17 pagesLintel and Sunshade DesignNikhilNo ratings yet

- TM Fatigue Life Assessment of GT Rotor Through ReliabilityDocument8 pagesTM Fatigue Life Assessment of GT Rotor Through ReliabilitykkaytugNo ratings yet

- NIH Public AccessDocument15 pagesNIH Public AccessAjaykumarNo ratings yet

- Dry Vacuum Pump - LS SeriesDocument4 pagesDry Vacuum Pump - LS SeriesFardhal Virgiawan RamadhanNo ratings yet

- BASF NAS Technical Data SheetDocument2 pagesBASF NAS Technical Data SheetLesiba AmosNo ratings yet

- Draft of Is 1893 (Part-2) ..Scribd-2Document24 pagesDraft of Is 1893 (Part-2) ..Scribd-2anirudh modhalavalasaNo ratings yet

- Enhancing The Effectiveness of The Use of PT Chevron Pacific Indonesia's Active Single-Line Diagram System in Minas Area 3 & 4Document41 pagesEnhancing The Effectiveness of The Use of PT Chevron Pacific Indonesia's Active Single-Line Diagram System in Minas Area 3 & 4Rivaldo VariantoNo ratings yet

- F 1945 - 98 Rje5nduDocument3 pagesF 1945 - 98 Rje5nduHernan MartNo ratings yet