Professional Documents

Culture Documents

Job Safety Analysis Sheet:: Grit Blasting

Job Safety Analysis Sheet:: Grit Blasting

Uploaded by

Hasanuddin HAMIDOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Job Safety Analysis Sheet:: Grit Blasting

Job Safety Analysis Sheet:: Grit Blasting

Uploaded by

Hasanuddin HAMIDCopyright:

Available Formats

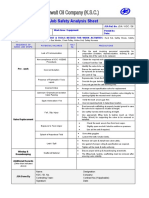

Job Safety Analysis Sheet

Job Description: Grit Blasting JSA Ref. No. JSA / KOC / 22

Facility: Work Area / Equipment: Permit No:

Date:

Personal Protective Equipment & Tools Needed For Work Activities: Hard Hat, Safety Shoes, Airline Respirator, Blasting Hood, Gloves,

Ear Muffs, Coverall, Apron, Blasting Gun, Air Supply Hose, Regulator, Filter, Gas Detector, Mobile Air Compressor, Dust Mask.

SEQUENCE OF Yes /

POTENTIAL HAZARDS PRECAUTIONS

BASIC JOB STEPS No

• Refer HSEMS Procedure SA.KOC.011 “High Pressure

Non-compliance of KOC -HSEMS Water Jetting, Abrasive Blast Cleaning & Steam Cleaning”

Procedures, F & S Regulations and Chapter 9 Of KOC F & S Regulations

• Obtain hot work permit & conduct Tool Box Talk

Untrained Workers

• Ensure workers involved in grit blasting are trained &

competent to carry out the work safely.

• Never use instrument air for grit blasting work.

Facility Shutdown due to Low • Keep a watch on instrument air pressure header.

Pre - Work Instrument Pressure

• Arrange approved Mobile Air Compressor to supply air for

grit blasting work & place it securely at proper location.

Presence of Flammable / Toxic • Ensure the area where grit blasting will take place is

Vapors free from flammable / toxic vapor.

• Never use sand / crystalline silica in place of grit for

abrasive cleaning.

Incorrect or Defective Material / • Ensure the respiratory equipment such as air line

Equipment hose, pressure regulator, filter is free from defect.

• Ensure flexible hose, bull dog clamps & joints for grit

blasting are suitable for pressure rating of the system.

• Ensure workers involved in grit blasting are wearing

required PPEs.

• Enclose the grit blasting area with tarpaulin and post

warning notice.

Exposure of Dust, Noise & Injury • Ensure the blast gun is fitted with Emergency Release

to Workers Handle (Dead man’s Handle), and it is functional.

• Ensure continuous supply of breathing air to the blast

hood.

• Do not leave the grit blast equipment un- attended with

air supply on.

Work

• Ensure the presence of Grit Blasting Supervisor in the

area.

Lack of Communication

• Establish emergency communication between Grit

Blasting Supervisor and Grit Blaster.

• Never allow any spray painting at the location; where grit

Fire & Explosion blasting is in progress.

• Stop mobile compressor while fueling.

• Check all pipe work / equipment to be grit blasted is

Static Electricity adequately bonded to prevent accumulation of electrostatic

charges.

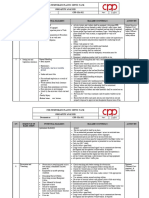

• Arrange the recovery and safe disposal of spent grit.

House Keeping Scattered Materials • Ensure proper wind up of equipment, tools & tidiness of the

work area.

Additional Hazards

(Other than indicated

above)

Name: Designation:

KOC / ID. No. Company:

JSA Done By

Controlling Team: Contract No.(If Applicable):

Signature: Date:

You might also like

- 1.JSA-Mechanical Work Hydrant InstallationDocument9 pages1.JSA-Mechanical Work Hydrant InstallationMuhammad Umar GondalNo ratings yet

- Job Safety Analysis Sheet: FacilityDocument1 pageJob Safety Analysis Sheet: Facilitywahyu nugrohoNo ratings yet

- JSA #36-Valve ReplacementDocument1 pageJSA #36-Valve ReplacementVishal PrasadNo ratings yet

- JSA For Pipe Line DemolitionDocument7 pagesJSA For Pipe Line DemolitionSiraj Mohamed Ikbal80% (5)

- Job Safety Analysis Sheet: FacilityDocument1 pageJob Safety Analysis Sheet: Facilitysanjeev kumar100% (1)

- JSA - Sand Blasting and PaintngDocument8 pagesJSA - Sand Blasting and PaintngJohn100% (1)

- Jsa 18 Cold Cutting PDF FreeDocument1 pageJsa 18 Cold Cutting PDF FreegurumoorthyNo ratings yet

- Sand BlastingDocument1 pageSand BlastingReynaldo PesqueraNo ratings yet

- 052 Sand BlastingDocument2 pages052 Sand Blastingwilson mantilla100% (1)

- JSA Confined Sapce EntryDocument1 pageJSA Confined Sapce EntryprasongNo ratings yet

- Separators For Oil and GasDocument175 pagesSeparators For Oil and GasAbhishek Yamini0% (1)

- JSA #19 Grinding, Welding, Gas CuttingDocument2 pagesJSA #19 Grinding, Welding, Gas CuttingSubham Sohal100% (1)

- JSA #37-Flange ReplacementDocument1 pageJSA #37-Flange ReplacementSanjeet SinghNo ratings yet

- JSA 04 Confined Sapce EntryDocument1 pageJSA 04 Confined Sapce Entrywahyu nugrohoNo ratings yet

- Job Safety Analysis Sheet: Pig RetrievalDocument1 pageJob Safety Analysis Sheet: Pig RetrievalprasadNo ratings yet

- Cutting & Grinding & WeldingDocument2 pagesCutting & Grinding & Weldingghazi kallelNo ratings yet

- JSA 08 Gas WeldingDocument1 pageJSA 08 Gas Weldingyveskav31No ratings yet

- JSA For Welding of HVACDocument4 pagesJSA For Welding of HVACMohammed Minhaj100% (1)

- Job Safety AnalysisDocument2 pagesJob Safety AnalysisAris RNNo ratings yet

- Gunitting Operation JSA HSE ProfessionalsDocument1 pageGunitting Operation JSA HSE ProfessionalsSamadov 13No ratings yet

- Soft Cut Saw Operations (Generic) : Job Safety AnalysisDocument1 pageSoft Cut Saw Operations (Generic) : Job Safety AnalysisBorislav VulićNo ratings yet

- JSA For Purging NitrogenDocument1 pageJSA For Purging Nitrogenlina ekawati100% (1)

- Jsa n2 Purging PDF FreeDocument1 pageJsa n2 Purging PDF FreeSKH CultureNo ratings yet

- JSA #34 - N2 PurgingDocument1 pageJSA #34 - N2 PurgingHelza RahmanniaNo ratings yet

- JSA For Errection of Batching PlantDocument4 pagesJSA For Errection of Batching Plantasamrat582No ratings yet

- JSA-012-Welding and Gas CuttingDocument2 pagesJSA-012-Welding and Gas Cuttingk dharma100% (1)

- Job Safety Analysis Worksheet: JGC Penthouse Extension BLDGDocument2 pagesJob Safety Analysis Worksheet: JGC Penthouse Extension BLDGCherry BetonioNo ratings yet

- Job Safety Analysis Sheet: Pre - WorkDocument2 pagesJob Safety Analysis Sheet: Pre - Workmalimsaidi_160040895100% (1)

- Spray PaintingDocument2 pagesSpray PaintingAkhilSRzNo ratings yet

- JSA DrillingDocument12 pagesJSA DrillingAbdus SamadNo ratings yet

- Job Safety Analysis Sheet: Manual ExcavationDocument1 pageJob Safety Analysis Sheet: Manual Excavationwahyu nugroho100% (1)

- JSA - 0026 Chipping & Granite Cutting and Lying Work at PB-19Document2 pagesJSA - 0026 Chipping & Granite Cutting and Lying Work at PB-19Koneti JanardhanaraoNo ratings yet

- Safe Work Method Statement Hot Works: OST Constructional Projects LLCDocument8 pagesSafe Work Method Statement Hot Works: OST Constructional Projects LLCIrfan UllahNo ratings yet

- JSA-02-trench Excavation by EquipmentDocument1 pageJSA-02-trench Excavation by Equipmentabou bakarNo ratings yet

- JSA For TIE in of Utility Water With Fire Water Line Near Train 1 AreaDocument4 pagesJSA For TIE in of Utility Water With Fire Water Line Near Train 1 AreaMohammed Minhaj100% (1)

- JHSA For Temporary Plastic Septic TankDocument4 pagesJHSA For Temporary Plastic Septic TankAnna JisabaNo ratings yet

- Job Safety Analysis Sheet: KOC Emergency-160 90030980 (PIL)Document5 pagesJob Safety Analysis Sheet: KOC Emergency-160 90030980 (PIL)Sreeraj Reghunathan Nair Vanmazhy100% (1)

- Job Safety Analysis Sheet: Arc Welding, Cutting, GrindingDocument1 pageJob Safety Analysis Sheet: Arc Welding, Cutting, GrindingGudduNo ratings yet

- Water ProofingDocument2 pagesWater Proofingmark jayson yabesNo ratings yet

- Enter Confined Sapce (Cellar)Document2 pagesEnter Confined Sapce (Cellar)DQE040 HSSENo ratings yet

- Job Safety Analysis Sheet: Manual ExcavationDocument1 pageJob Safety Analysis Sheet: Manual ExcavationSafety ProfessionalNo ratings yet

- Gas Cutting Work JsaDocument2 pagesGas Cutting Work JsaAKBAR ALINo ratings yet

- Awning Install JhaDocument2 pagesAwning Install JhafatimahNo ratings yet

- PaintingDocument1 pagePaintingReynaldo PesqueraNo ratings yet

- JSA 02-Rev.01 - Blinding & DeblindingDocument1 pageJSA 02-Rev.01 - Blinding & DeblindinggolusinghdataNo ratings yet

- Copy (2) of JSA For Welding, Cutting and Grinding (Alam Engineering)Document5 pagesCopy (2) of JSA For Welding, Cutting and Grinding (Alam Engineering)Viron BaxhiaNo ratings yet

- 0017 JS A Hot Job (Welding, Grinding & Cutting)Document4 pages0017 JS A Hot Job (Welding, Grinding & Cutting)Positivesolution100% (2)

- 015 - Heating Skid ConnectivityDocument4 pages015 - Heating Skid ConnectivitySiddhant choudharyNo ratings yet

- 008 JSA - Manual BoringDocument3 pages008 JSA - Manual BoringMohammed MinhajNo ratings yet

- Confined Space EntryDocument27 pagesConfined Space EntrymuhammedazamNo ratings yet

- Job Safety Analysis Sheet: LP/HP Compressor AreaDocument1 pageJob Safety Analysis Sheet: LP/HP Compressor AreashahzadNo ratings yet

- Job Safety Analysis: Work Sequence Potential Hazards Recommended Action / Control MeasuresDocument3 pagesJob Safety Analysis: Work Sequence Potential Hazards Recommended Action / Control Measuresmuhammad imtiaz100% (1)

- DrillingDocument22 pagesDrillingMandhatt KyleNo ratings yet

- Core Drilling Saw Cutting Concrete or Asphalt (Wet Method)Document2 pagesCore Drilling Saw Cutting Concrete or Asphalt (Wet Method)rajesh kumar100% (2)

- Permit To WorkDocument1 pagePermit To WorkIshtiaq AhmadNo ratings yet

- Jsa Welding & Gas CuttingDocument3 pagesJsa Welding & Gas CuttingM M PRADHANNo ratings yet

- Job Safety Analysis (JSA) - CONCRETE WORKS - DateDocument2 pagesJob Safety Analysis (JSA) - CONCRETE WORKS - Datenabeel100% (1)

- Soil CompactionDocument1 pageSoil CompactionLebohang ChakaNo ratings yet

- Soil Compaction With Plate Compactor JSA HSE ProfessionalsDocument1 pageSoil Compaction With Plate Compactor JSA HSE ProfessionalsSamadov 13No ratings yet

- PunctuationDocument28 pagesPunctuationAbhishek YaminiNo ratings yet

- This Presentation Is Brought To You By, ©2015 by Robin L. Simmons. This Presentation Is Brought To You By, ©2015 by Robin L. SimmonsDocument28 pagesThis Presentation Is Brought To You By, ©2015 by Robin L. Simmons. This Presentation Is Brought To You By, ©2015 by Robin L. SimmonsAbhishek YaminiNo ratings yet

- Gas Leak Checklist: ActionDocument1 pageGas Leak Checklist: ActionAbhishek YaminiNo ratings yet

- MembeanDocument4 pagesMembeanAbhishek YaminiNo ratings yet

- This Presentation Is Brought To You By, ©2015 by Robin L. Simmons. This Presentation Is Brought To You By, ©2015 by Robin L. SimmonsDocument20 pagesThis Presentation Is Brought To You By, ©2015 by Robin L. Simmons. This Presentation Is Brought To You By, ©2015 by Robin L. SimmonsAbhishek YaminiNo ratings yet

- Gift DeedDocument1 pageGift DeedAbhishek YaminiNo ratings yet

- PG Course-IDocument15 pagesPG Course-IAbhishek YaminiNo ratings yet

- 2 09 ContactDocument16 pages2 09 ContactAbhishek YaminiNo ratings yet

- Vacuum Tribology: Guided byDocument7 pagesVacuum Tribology: Guided byAbhishek YaminiNo ratings yet

- Concept Check AnswersDocument64 pagesConcept Check AnswersAbhishek Yamini100% (1)

- Matlab CommandsDocument5 pagesMatlab CommandsAbhishek YaminiNo ratings yet

- Dante Alighieri - The Divine ComedyDocument429 pagesDante Alighieri - The Divine ComedyAbhishek YaminiNo ratings yet

- Irctcs E Ticketing Service Electronic Reservation Slip (Personal User)Document1 pageIrctcs E Ticketing Service Electronic Reservation Slip (Personal User)Abhishek YaminiNo ratings yet

- Flash Point: Volatile Temperature AirDocument3 pagesFlash Point: Volatile Temperature AirAbhishek YaminiNo ratings yet