Professional Documents

Culture Documents

JSA #19 Grinding, Welding, Gas Cutting

Uploaded by

Subham Sohal100%(1)100% found this document useful (1 vote)

144 views2 pagesJSA

Original Title

JSA #19 Grinding,Welding,Gas Cutting

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentJSA

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

100%(1)100% found this document useful (1 vote)

144 views2 pagesJSA #19 Grinding, Welding, Gas Cutting

Uploaded by

Subham SohalJSA

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 2

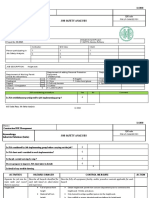

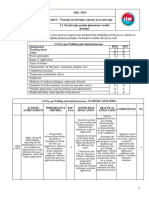

JOB SAFETY ANALYSIS SHEET

JSA REF NO: JSA/NRP-PIPELINE/19

JOB DESCRIPTION: GRINDING, WELDING, GAS CUTTING REV NO:

REV DATE:

PERMIT NO: 968945

FACILITY: NRP PIPELINE WORK AREA / EQUIPMENT:

DATE:10-10-2019

PERSONAL PROTECTIVE EQUIPMENT / TOOLS: Hard Hat, Safety Shoes, Face Shield, Safety Goggles, Hand

Gloves (Cotton & Leather), Coverall, Multi Gas Detector.

SEQUENCE OF BASIC JOB STEPS POTENTIAL HAZARDS PRECAUTIONS

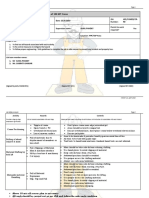

Ensure the pipeline / equipment to be gas cut is isolated,

depressurized, drained, flushed, and purged as required

Presence of Flammable / Toxic for safe execution of the job.

Vapor or Liquid

Ensure the worksite is free from flammable / toxic vapor

or liquid.

The entry of non – certified tools / equipment / Mobile

Plant are to be authorized under appropriate Work

Permit.

Fire & Explosion

Keep the fire extinguishers & fire hoses in ready

Planning condition.

Keep trained fire watch as standby.

Refer HSEMS Procedures - Doc. No. SA.KOC.021

Non- compliance of KOC-HSEMS

‘Welding & Cutting’; and Doc. No. SA.KOC.004 “Permit to

Procedure

Work”.

Unintended Shutdown of Facility / Asses & Identify the safety override (UV / IR Detector)

Equipment required for the work.

Take a Hot Work Permit and other associated permits

Unauthorized Work

from Asset Owner.

Ensure the cutting torch, hoses & gas cylinders are free

Defective Tools

from defect.

Wear the required PPE (Long Sleeve Coverall, apron,

Heat Radiation

safety Goggle etc)

Exposure to Hazardous Fumes Ensure proper ventilation at the worksite.

Wear long sleeved coverall & apron.

Cutting Burns Use leather hand gloves.

Keep First Aid Kit at site.

Enclose the work location through fire blanket.

Falling Sparks / Hot bids

Ensure no one is working below the location of gas cut.

Keep Oxy-acetylene Cylinders safely at least 5 meters

away from the work location.

Oxy-acetylene Cylinders

Never use domestic LPG cylinder for cooking.

Close the isolation valve at cylinders when not in use.

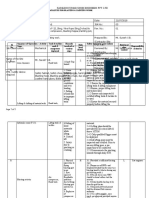

Grinding Rotating equipment sparks. Make sure guards are fitted to all moving parts

Damaged grinding disc Ensure the proper use of guards

Inspect the grinding discs prior to starting work (ring

Electrocution. test)

Make sure that disc is compatible with the grinding

High Pressure air machine

Check the RPM of disc & machine

Use Proper PPE.

Flying object/eye injuries Correct installation of Grinder Wheel.

Spark containment to be used.

Only experienced personnel to use the equipment.

Before starting welding make sure the area is clear of all

Fire Hazard

types of combustible materials

Provide fire blanket

Burns.

Make sure fire extinguishers are available on site

Electrocution/ Spatter burns Wear proper PPE for welding

Trained Fire Watch.

Damage cable Gas Monitor correctly sited.

Welding Certified Equipment and to be sited as near as possible

Hot tabs end pieces of welding to work site.

rods. Proper earthing of equipment.

Ensure that rod holder is in good condition.

Sparking

Ensure that forward and return cables are in good

working condition.

Damage cable

Use proper cable connector for extension.

If cables are crossing the road then ensure proper

UV rays

protection.

Ensure proper wind up & housekeeping at worksite.

Windup & Housekeeping Scattered Material The accessories (torch, hoses & cylinders) not being used

must be disconnected and stored separately.

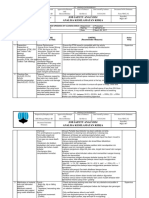

ADDITIONAL HAZARDS

(Other than indicated above)

JSA Done by Permit Applicant / Name: Controlling Team:MPT-1

Controlling Team / Asset Owner KOC ID No: Signature:

JSA Reviewed by Name: Controlling Team:MPT-1

Permit Issuer KOC ID No: Signature:

You might also like

- JSA-012-Welding and Gas CuttingDocument2 pagesJSA-012-Welding and Gas Cuttingk dharma100% (1)

- Job Safety Analysis (Jsa) : Title of Activity / Work: Hot Work ActivityDocument2 pagesJob Safety Analysis (Jsa) : Title of Activity / Work: Hot Work ActivityJayendra PatelNo ratings yet

- JSA - Structural Steel Fabrication and Installation WorksDocument3 pagesJSA - Structural Steel Fabrication and Installation Workssakthi venkatNo ratings yet

- 06 Steel Structure Erection PESB 01 PDFDocument5 pages06 Steel Structure Erection PESB 01 PDFShureendran Muniandy RajanNo ratings yet

- JSA Formet New Structural Steel ErectionDocument11 pagesJSA Formet New Structural Steel Erectionsakthi venkatNo ratings yet

- JSA Formet New Hot WorkDocument6 pagesJSA Formet New Hot Worksakthi venkat100% (1)

- 0 JsaDocument54 pages0 JsaRavi AmarlapudiNo ratings yet

- Pipe Fabrication and Erection JSADocument8 pagesPipe Fabrication and Erection JSAjithin shankarNo ratings yet

- Jsa Erection of Steel StructureDocument10 pagesJsa Erection of Steel StructureDanny DonNo ratings yet

- Shifting of Material & Equipment.: Job Safety Analysis JobDocument6 pagesShifting of Material & Equipment.: Job Safety Analysis JobPrabir PujariNo ratings yet

- SWMS Sandvik Asia Pvt Ltd Hot Work WeldingDocument14 pagesSWMS Sandvik Asia Pvt Ltd Hot Work WeldingParasNo ratings yet

- How Chin Engineering: Job Safety AnalysisDocument5 pagesHow Chin Engineering: Job Safety AnalysisHow Chin Engineering Sdn BhdNo ratings yet

- JSA for Scaffolding Erection, Dismantling and Other Construction WorksDocument9 pagesJSA for Scaffolding Erection, Dismantling and Other Construction Worksuttam mishra100% (1)

- Column Erection JSA AnalysisDocument6 pagesColumn Erection JSA AnalysisRaghava Richhu100% (2)

- 1.SW-JSA - Piping-1 - Fabrication and Erection of Piping ActivityDocument5 pages1.SW-JSA - Piping-1 - Fabrication and Erection of Piping ActivityAnwar AliNo ratings yet

- Injury & Illness Prevention Program: Job Safety Analysis FormDocument2 pagesInjury & Illness Prevention Program: Job Safety Analysis FormArif RachmanNo ratings yet

- Elcb Checking Format-TDocument1 pageElcb Checking Format-TGyanendra Narayan NayakNo ratings yet

- Height Work Safety AnalysisDocument4 pagesHeight Work Safety AnalysisNitesh KumarNo ratings yet

- JSA-Hydraulic Press Testing For PilesDocument6 pagesJSA-Hydraulic Press Testing For PilesUMUTNo ratings yet

- JSA NO 2-Piling WorkDocument3 pagesJSA NO 2-Piling WorkKarthik GanesanNo ratings yet

- JSA For Flue Gas Duct Height WorkDocument4 pagesJSA For Flue Gas Duct Height Worksubhadipmanna8No ratings yet

- JSA For Fabrication WorksDocument11 pagesJSA For Fabrication Workssurendra behera100% (3)

- Jsa PaintDocument2 pagesJsa PaintKhalid NaseemNo ratings yet

- Safe Work Method Statement for Metal Column, Rafter, Purlin InstallationDocument12 pagesSafe Work Method Statement for Metal Column, Rafter, Purlin Installationsasi kumar100% (1)

- Project: Field Erection of 15000 Bbls Tank (Ik-2545) : Job Safety Analysis / Safe Work Method Statement-SWMSDocument2 pagesProject: Field Erection of 15000 Bbls Tank (Ik-2545) : Job Safety Analysis / Safe Work Method Statement-SWMSJohn100% (1)

- JSA FOR STEEL ERECTIONDocument7 pagesJSA FOR STEEL ERECTIONRajuNo ratings yet

- Tower Crane Installation SOP SummaryDocument3 pagesTower Crane Installation SOP SummaryRashidi RahmanNo ratings yet

- Weekly All Machine Check ListDocument31 pagesWeekly All Machine Check Listmohammed mansoor100% (1)

- 11 - JSA (Tower Crane) 12-9-06Document11 pages11 - JSA (Tower Crane) 12-9-06sattiNo ratings yet

- JSA FOR WELDING, GRINDING, GAS CUTTINGDocument2 pagesJSA FOR WELDING, GRINDING, GAS CUTTINGwahyu nugroho50% (2)

- Jsa Tank CleaningDocument5 pagesJsa Tank CleaningASLAM MULANINo ratings yet

- Jsa For The Installation of I EamDocument5 pagesJsa For The Installation of I EamMohammed MinhajNo ratings yet

- JSA Hand ToolsDocument1 pageJSA Hand ToolsInoy dy hesusNo ratings yet

- JSA Mechanical Activity Risk AssessmentDocument1 pageJSA Mechanical Activity Risk Assessmentjithin shankarNo ratings yet

- JSA For The Steel Fixing and Manual Conxrete Pouring at New Flare Line Phase 2 (Brown Area)Document7 pagesJSA For The Steel Fixing and Manual Conxrete Pouring at New Flare Line Phase 2 (Brown Area)Marvin BerrensteinNo ratings yet

- JSA Format Erection of Column 903-C-02,03Document5 pagesJSA Format Erection of Column 903-C-02,03sakthi venkat100% (1)

- Hira For Fabrication Work of Steel Structure - CMRLDocument21 pagesHira For Fabrication Work of Steel Structure - CMRLmahesh naik0% (2)

- Crane Jsa TGPDocument2 pagesCrane Jsa TGPSuryakant SurajNo ratings yet

- JOB SAFETY ANALYSIS WITH TAKE TWODocument28 pagesJOB SAFETY ANALYSIS WITH TAKE TWOkresna suryadiNo ratings yet

- Job HazardDocument2 pagesJob HazardBre WirabumiNo ratings yet

- JSA For Fab Erec of STRL Steel StackDocument5 pagesJSA For Fab Erec of STRL Steel StackkrishnakumarNo ratings yet

- Job Safety Analysis Sheet: Activity Potential Hazard Likely Causes Control MeasureDocument2 pagesJob Safety Analysis Sheet: Activity Potential Hazard Likely Causes Control MeasureM Waqas HabibNo ratings yet

- 4 JSA For Structural Fabrication and Erection WorkDocument4 pages4 JSA For Structural Fabrication and Erection WorkHappy Prajapat67% (3)

- Manual Tig Welding (RRC) - Job ProcedureDocument3 pagesManual Tig Welding (RRC) - Job Proceduretitto84886100% (1)

- HIRA For Steam Drum ErectionDocument18 pagesHIRA For Steam Drum ErectionNagendra Kumar SinghNo ratings yet

- JSA Formet New Blasting & PaintingDocument5 pagesJSA Formet New Blasting & Paintingsakthi venkatNo ratings yet

- JSA Installation of GearboxDocument2 pagesJSA Installation of Gearboxprasong100% (1)

- HIRA & JSA - R1 Conveyor Gallery Dismantling and ErectionDocument26 pagesHIRA & JSA - R1 Conveyor Gallery Dismantling and ErectionkrishnaengineeringhilNo ratings yet

- SOP Grinding & CuttingDocument3 pagesSOP Grinding & CuttingIMRANNo ratings yet

- JOB SAFETY ANALYSIS FOR WELDINGDocument2 pagesJOB SAFETY ANALYSIS FOR WELDINGSravan Dasari100% (3)

- JSA For Foundation Concrete RepairDocument6 pagesJSA For Foundation Concrete RepairOvais FarooqNo ratings yet

- Slip Form Construction Safety AnalysisDocument5 pagesSlip Form Construction Safety Analysisputrasejahtra50% (2)

- Generic TPL JsaDocument83 pagesGeneric TPL JsaSanjay Kumar GhadaiNo ratings yet

- Jsa Welding Cutting and Grinding at Closing AreaDocument7 pagesJsa Welding Cutting and Grinding at Closing AreaDedy Kurniawan100% (2)

- PT-03 JSA Dismantling of Slip Form (22-05-09)Document10 pagesPT-03 JSA Dismantling of Slip Form (22-05-09)M Waqas HabibNo ratings yet

- Jsa of Boiler Drum LiftingDocument10 pagesJsa of Boiler Drum LiftingGyanendra Narayan NayakNo ratings yet

- JSA OF Fabrication and Installation Work ApproviedDocument3 pagesJSA OF Fabrication and Installation Work Approviedsakthi venkatNo ratings yet

- Job Safety Analysis Sheet: FacilityDocument1 pageJob Safety Analysis Sheet: Facilitysanjeev kumar100% (1)

- Job Safety Analysis Sheet: Arc Welding, Cutting, GrindingDocument1 pageJob Safety Analysis Sheet: Arc Welding, Cutting, GrindingGudduNo ratings yet

- Job Safety Analysis for Gas WeldingDocument4 pagesJob Safety Analysis for Gas WeldingVictor John PingkianNo ratings yet

- Broco BR 22 Plus Operation and MaintenanceDocument8 pagesBroco BR 22 Plus Operation and MaintenanceLee BalayoNo ratings yet

- GR 11 Auto RELAB Homework Teacher GuideDocument75 pagesGR 11 Auto RELAB Homework Teacher GuidesbumongiNo ratings yet

- TRUMPF 2D Laser Cutting Machines Brochure enDocument44 pagesTRUMPF 2D Laser Cutting Machines Brochure enAbc ThoiNo ratings yet

- GAS WeldingDocument6 pagesGAS WeldingsrijaNo ratings yet

- NIOSH Work Permit System NewDocument92 pagesNIOSH Work Permit System Newsanpkaru100% (1)

- KEL Industrial Visit ReportDocument18 pagesKEL Industrial Visit ReportAnoopAsokan0% (1)

- Welding & Cutting SOPDocument16 pagesWelding & Cutting SOPmahandhieNo ratings yet

- LEARNING GUIDEperforming Cuting and Welding Using Oxy AcetyleneDocument75 pagesLEARNING GUIDEperforming Cuting and Welding Using Oxy AcetyleneG/michael AregayNo ratings yet

- 2019 - 1.2. Zavarivanje Gasnim Plamenom I Srodni PostupciDocument25 pages2019 - 1.2. Zavarivanje Gasnim Plamenom I Srodni PostupciticmaNo ratings yet

- Government launches new Refrigeration and Air Conditioning Technician courseDocument63 pagesGovernment launches new Refrigeration and Air Conditioning Technician coursePrabhas RanaNo ratings yet

- MS For Welding Works For Precast ElementsDocument10 pagesMS For Welding Works For Precast ElementsJoni Carino SuniNo ratings yet

- 05 Check List For Gas Cutting Set-1-1Document1 page05 Check List For Gas Cutting Set-1-1Gyanendra Narayan Nayak100% (1)

- WOR WI OI 2 1 2 - Slip and Cut Drill LineDocument8 pagesWOR WI OI 2 1 2 - Slip and Cut Drill LineHuang Ming Chong100% (1)

- Body RepairDocument19 pagesBody RepairPUTRA SANINo ratings yet

- Machine ShopDocument6 pagesMachine ShopEjNo ratings yet

- Id Number Title Year OrganizationDocument12 pagesId Number Title Year OrganizationrabeemhNo ratings yet

- Opening and closing gas cutting equipmentDocument11 pagesOpening and closing gas cutting equipmentJebaraj VNo ratings yet

- Installation of HVAC VRF & DX Units Systems Method StatementDocument35 pagesInstallation of HVAC VRF & DX Units Systems Method Statementمقاول تكييف كهرباء وصحيNo ratings yet

- Core Smaw NC IDocument13 pagesCore Smaw NC INICOSAT CollegesNo ratings yet

- Welder Foundation Program Outline Apr 2020 HarmonizedDocument126 pagesWelder Foundation Program Outline Apr 2020 HarmonizedBin QiNo ratings yet

- Welding SlidesDocument99 pagesWelding SlidesMuhammad ImranNo ratings yet

- GCE Group Katalog Plinsko Rezanje 2016 PDFDocument164 pagesGCE Group Katalog Plinsko Rezanje 2016 PDFanhghel86No ratings yet

- Omm Clg856 Dcec IIDocument140 pagesOmm Clg856 Dcec IIPurnama Abhie100% (2)

- EW607 Safety and Health of WeldersDocument33 pagesEW607 Safety and Health of Weldersfarshid Karpasand100% (1)

- Manufacturing Process: Chapter 5 Joining ProcessesDocument53 pagesManufacturing Process: Chapter 5 Joining ProcesseshizanorhudaNo ratings yet

- Metal Joining Processes GuideDocument79 pagesMetal Joining Processes GuidePrateekNo ratings yet

- Essential Tools Checklist for Electronics and Electrical CoursesDocument13 pagesEssential Tools Checklist for Electronics and Electrical CoursesLJ RuizNo ratings yet

- Fundamentals of Mobile Heavy EquipmentDocument9 pagesFundamentals of Mobile Heavy Equipmentwin min soeNo ratings yet

- Technician GR - III Model PaperDocument10 pagesTechnician GR - III Model PaperJay patelNo ratings yet

- WelderDocument25 pagesWelderRaumil Maniar83% (6)