Professional Documents

Culture Documents

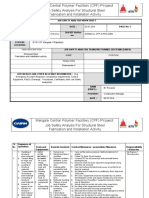

JSA FOR WELDING, GRINDING, GAS CUTTING

Uploaded by

wahyu nugrohoOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

JSA FOR WELDING, GRINDING, GAS CUTTING

Uploaded by

wahyu nugrohoCopyright:

Available Formats

JSA FOR WELDING, GRINDING, GAS CUTTING

Name of the Site - NISSAN (2ASDU PROJECT)

Date of Preparation – 22/01/2014

JSA Preparation – R.RAMESH BABU

S.NO SCOPE OF HAZARD CONTROL MEASURES REQUEST BY

ACTIVITY

1) Work start-up & 1) Unauthorized 1) Obtain a hot work permit before starting the job EHS SAFETY

obtaining PTW work 2) Get the permit validated for the specific day OFFICER/SECURITY

2) Invalid permit 3) Supervisor must ensure that all work activities are carried OFFICER

3) Lack of out by competent personnel

competency 4) Conduct Toolbox meeting,

4) Lack or poor 5) Review the Method statement and Job safety analysis to all

communication craftsmen involved in the work activities.

5) Haste or shortcut 6) Responsible person will conduct inspection,

7) Monitor the work activities and have to ensure safety

standards and procedures are strictly adhered to.

2) Grinding 1) Rotating 1) Make sure guards are fitted to all moving parts EHS SAFETY

equipment sparks. 2) Ensure the proper use of guards OFFICER/SECURITY

2) Damaged grinding 3) Inspect the grinding discs prior to starting work (ring test) OFFICER

disc 4) Make sure that disc is compatible with the grinding machine

3) Electrocution. 5) Check the RPM of disc & machine

4) High Pressure air 6) Proper PPE (Gloves + Mask).

5) Flying object/eye 7) Correct installation of Grinder Wheel.

injuries 8) Gas monitor correctly sited.

9) Spark containment to be used.

10) Only experienced personnel to use the equipment.

11) Wear a face shield while grinding

12) Make sure an eye wash station is available nearby

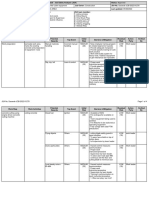

3) Gas Cutting 1) Burns. 1) Proper isolation of system. EHS SAFETY

2) Fire Hazard. 2) All cylinders to be secured. OFFICER/SECURITY

3) Explosion. 3) Flame arrestor between the cylinder & torch OFFICER

4) Tripping. 4) Hoses in good condition.

5) Damaged or 5) Proper PPE.

leaking cylinders 6) Trained Fire Watch.

JSA FOR WELDING, GRINDING, GAS CUTTING

Name of the Site - NISSAN (2ASDU PROJECT)

Date of Preparation – 22/01/2014

JSA Preparation – R.RAMESH BABU

or hoses 7) Gas Monitor correctly sited.

8) Correct Fire Extinguisher(s).

9) Deployment of Experienced personnel.

10) Cordoning of the area.

11) Fire Blanket.

12) Inspect the cylinders & hoses before starting the job

4) Welding 1) Fire Hazard 1) Before starting welding make sure the area is clear of all

2) Burns. types of combustible materials

3) Electrocution/ 2) Provide a fire blanket on site

Spatter burns 3) Make sure fire extinguishers are available on site

4) Damage cable 4) Wear proper PPE for welding ie., leather jackets, Gloves,

5) Hot tabs end welding goggles/welding mask,

pieces of welding 5) Trained Fire Watch.

rods. 6) Gas Monitor correctly sited.

6) Sparking 7) Certified Equipment and to be sited as near as possible to

7) Damage cable work site.

8) UV rays 8) Proper earthing of equipment.

9) Certified Welder.

10) Make sure spark containment is used such as a welding

hood/fire blanket.

11) Ensure that rod holder is in good condition.

12) Ensure that forward and return cables are in good working

condition.

13) Use proper cable connector for extension.

14) If cables are crossing the road then ensure proper

protection.

15) The welder & the welder helpers must wear welding goggles

You might also like

- Scrap Material Cutting, Handling & Loading Jha - 2Document3 pagesScrap Material Cutting, Handling & Loading Jha - 2Dwitikrushna Rout100% (5)

- JSA for Grinding WorkDocument5 pagesJSA for Grinding WorkM M PRADHANNo ratings yet

- Cutting, Grinding and Welding Safety ProceduresDocument3 pagesCutting, Grinding and Welding Safety ProceduresOgunwa Emmanuel100% (1)

- 4 JSA For Structural Fabrication and Erection WorkDocument4 pages4 JSA For Structural Fabrication and Erection WorkHappy Prajapat67% (3)

- JSA FOR Concerate PlacementDocument1 pageJSA FOR Concerate Placementwahyu nugrohoNo ratings yet

- Job Safety Analysis (Jsa) : Title of Activity / Work: Hot Work ActivityDocument2 pagesJob Safety Analysis (Jsa) : Title of Activity / Work: Hot Work ActivityJayendra PatelNo ratings yet

- JHA Scrap Handling HazardsDocument2 pagesJHA Scrap Handling HazardsDwitikrushna Rout100% (1)

- Job Safety Analysis for Brick Work, Tile and Glass RemovalDocument4 pagesJob Safety Analysis for Brick Work, Tile and Glass RemovalSushil Kumar YadavNo ratings yet

- JSA Epoxy Coating Machine ShopDocument10 pagesJSA Epoxy Coating Machine ShopMarhendra100% (1)

- Jsa For Operating A BobcatDocument2 pagesJsa For Operating A Bobcatsoubhagya100% (2)

- JSA FOR STEEL ERECTIONDocument7 pagesJSA FOR STEEL ERECTIONRajuNo ratings yet

- Jsa Pipe Cutting at Fire PumpDocument5 pagesJsa Pipe Cutting at Fire PumpHow Chin Engineering Sdn BhdNo ratings yet

- Job Safety Analysis: Page 1 of 4Document4 pagesJob Safety Analysis: Page 1 of 4RakeshkasarlaNo ratings yet

- Slip Form Construction Safety AnalysisDocument5 pagesSlip Form Construction Safety Analysisputrasejahtra50% (2)

- Gas Cutting JsaDocument4 pagesGas Cutting JsaMohammed Minhaj100% (1)

- Glass Installation - JOB SAFETY ANALYSIS (JSA) WORKSHEETDocument3 pagesGlass Installation - JOB SAFETY ANALYSIS (JSA) WORKSHEETusman rasheed100% (1)

- Jsa Grinding Welding Gas CuttingDocument3 pagesJsa Grinding Welding Gas CuttingRyanNo ratings yet

- JSA For Concrete PouringDocument1 pageJSA For Concrete PouringHSE fahadNo ratings yet

- PTA-JSA-005-Material Handling by Farhana F-15 CraneDocument6 pagesPTA-JSA-005-Material Handling by Farhana F-15 CraneSaiyad RiyazaliNo ratings yet

- Job Safety Analysis for Rohan Builders Construction ProjectsDocument9 pagesJob Safety Analysis for Rohan Builders Construction Projectsradeep100% (1)

- Jsa PCC & RCCDocument2 pagesJsa PCC & RCCNilesh koliNo ratings yet

- Bricks Messonary Work Job Hazard AnalysisDocument2 pagesBricks Messonary Work Job Hazard AnalysisMc Evans Magallanes100% (1)

- 11 - JSA (Tower Crane) 12-9-06Document11 pages11 - JSA (Tower Crane) 12-9-06sattiNo ratings yet

- Gas Cutting and Welding JHA Safety ChecklistDocument4 pagesGas Cutting and Welding JHA Safety ChecklistSunil apexNo ratings yet

- 02concreting & Block Bricks Work JSADocument3 pages02concreting & Block Bricks Work JSAJayendra Patel100% (1)

- Jsa PaintDocument2 pagesJsa PaintKhalid NaseemNo ratings yet

- JSA For Bobcat OperationDocument2 pagesJSA For Bobcat Operationwahyu nugrohoNo ratings yet

- Jsa Civil Work (00000002)Document6 pagesJsa Civil Work (00000002)Ali AlahmaNo ratings yet

- Nuclear power welding safetyDocument8 pagesNuclear power welding safetyPiyush SinghNo ratings yet

- JSA - CABLE TERMINATION TITLEDocument4 pagesJSA - CABLE TERMINATION TITLESyed Yousuf Ali100% (1)

- Risk Assessment for Shuttering/FormworkDocument1 pageRisk Assessment for Shuttering/FormworkHSE fahadNo ratings yet

- Environmental Change Steel Structure Dismantling and Erection JSADocument1 pageEnvironmental Change Steel Structure Dismantling and Erection JSASamuel Hugos100% (4)

- Jsa For Installation of Pipe Railing On SkidDocument6 pagesJsa For Installation of Pipe Railing On SkidLokesh Aravindan100% (1)

- JSA - Structural Steel Fabrication and Installation WorksDocument3 pagesJSA - Structural Steel Fabrication and Installation Workssakthi venkatNo ratings yet

- JSA For Concrete, Brecking, ExavationDocument6 pagesJSA For Concrete, Brecking, ExavationBinay0% (1)

- Control System Integration Project: CONTRACT NO.: EDC 13-228/GC113-036Document7 pagesControl System Integration Project: CONTRACT NO.: EDC 13-228/GC113-036Jayson Escamillan100% (1)

- SWMS Sandvik Asia Pvt Ltd Hot Work WeldingDocument14 pagesSWMS Sandvik Asia Pvt Ltd Hot Work WeldingParasNo ratings yet

- EPC-3 Gasoline package Assembly & Erection JSADocument3 pagesEPC-3 Gasoline package Assembly & Erection JSAFrancis Vinoj100% (1)

- PTW JHA Electrical Wiring Installation Work at Air Dryer RoomDocument4 pagesPTW JHA Electrical Wiring Installation Work at Air Dryer RoomPHH9834No ratings yet

- Job Hazard Analysis ON Erection of High Mast Lighting SystemDocument5 pagesJob Hazard Analysis ON Erection of High Mast Lighting SystemKiran Bhatt100% (3)

- 0 JsaDocument54 pages0 JsaRavi AmarlapudiNo ratings yet

- Thyssenkrupp Industrial Solutions (India) Job Safety AnalysisDocument5 pagesThyssenkrupp Industrial Solutions (India) Job Safety AnalysisNitesh KumarNo ratings yet

- JSA For Lifting of RebarsDocument5 pagesJSA For Lifting of RebarsNiraNo ratings yet

- 39 Jha On Blok Masonary WorkDocument4 pages39 Jha On Blok Masonary WorkDheeraj KumarNo ratings yet

- Sarawak JSA for Concrete CuttingDocument4 pagesSarawak JSA for Concrete CuttingMohammad Irfan Kiki IsmailNo ratings yet

- Vehicular Movement Job Safety Analysis (JSA)Document2 pagesVehicular Movement Job Safety Analysis (JSA)sudam kumar raut100% (2)

- Job Safety Analysis Worksheet: Yes NoDocument8 pagesJob Safety Analysis Worksheet: Yes NoBorislav VulićNo ratings yet

- JSA Appendix Cutting, Grinding ConcreteDocument8 pagesJSA Appendix Cutting, Grinding ConcreteĐặng Quang Huy100% (1)

- Jsa PaintingDocument1 pageJsa Paintingclynne despiNo ratings yet

- Job Safety Analysis (Jsa) - Water Proofing WorkDocument6 pagesJob Safety Analysis (Jsa) - Water Proofing Worknitish tiwariNo ratings yet

- JSA for Scaffolding Erection, Dismantling and Other Construction WorksDocument9 pagesJSA for Scaffolding Erection, Dismantling and Other Construction Worksuttam mishra100% (1)

- JSA For Rebar Works Includes Working in ScaffoldingDocument4 pagesJSA For Rebar Works Includes Working in Scaffoldingyc safetyNo ratings yet

- JSA - Installation of U G PipingDocument11 pagesJSA - Installation of U G PipingOws Anish100% (1)

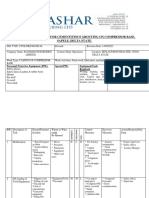

- JHA FOR CEMENTITIOUS GROUTING ON COMPRESSOR BASEDocument8 pagesJHA FOR CEMENTITIOUS GROUTING ON COMPRESSOR BASEaloysius akpanNo ratings yet

- Tower Crane Installation SOP SummaryDocument3 pagesTower Crane Installation SOP SummaryRashidi RahmanNo ratings yet

- JSA For Installation of Out Door UnitsDocument4 pagesJSA For Installation of Out Door UnitsMohammed MinhajNo ratings yet

- Back FillingDocument2 pagesBack FillingChandruNo ratings yet

- Jsa For Arc WeldingDocument3 pagesJsa For Arc Weldingtnssbhaskar100% (5)

- Jsa English HindiDocument12 pagesJsa English HindiPradip mallaNo ratings yet

- JSA FOR HT LT Panel - Transformer InstallationDocument2 pagesJSA FOR HT LT Panel - Transformer Installationwahyu nugroho83% (6)

- Safe Work in Confined SpacesDocument61 pagesSafe Work in Confined SpacesTree TaweeNo ratings yet

- Responding To A Known Contact HazardDocument3 pagesResponding To A Known Contact Hazardwahyu nugrohoNo ratings yet

- Operating A Drill PressDocument2 pagesOperating A Drill Presswahyu nugrohoNo ratings yet

- HM - Policy and Procedure For BookingDocument4 pagesHM - Policy and Procedure For Bookingwahyu nugrohoNo ratings yet

- Blue Jasmine Event Package 2021Document20 pagesBlue Jasmine Event Package 2021wahyu nugrohoNo ratings yet

- Response To A Release of An Inhalation HazardDocument3 pagesResponse To A Release of An Inhalation Hazardwahyu nugrohoNo ratings yet

- Responding To Release of Flammable MaterialDocument5 pagesResponding To Release of Flammable Materialwahyu nugrohoNo ratings yet

- Operating A Pedestal GrinderDocument2 pagesOperating A Pedestal Grinderwahyu nugrohoNo ratings yet

- Operating and Maintaining Mat CutterDocument1 pageOperating and Maintaining Mat Cutterwahyu nugrohoNo ratings yet

- Operating An Air BlowerDocument2 pagesOperating An Air Blowerwahyu nugrohoNo ratings yet

- Operating Motorized Vehicle (Petroleum Powered)Document1 pageOperating Motorized Vehicle (Petroleum Powered)wahyu nugrohoNo ratings yet

- Operating An Electric Spot WelderDocument2 pagesOperating An Electric Spot Welderwahyu nugrohoNo ratings yet

- Rigging WindsurferDocument1 pageRigging Windsurferwahyu nugrohoNo ratings yet

- Ehs 2 HM 10Document1 pageEhs 2 HM 10Ruslan ThompsonNo ratings yet

- Vehicle Driving Safety TipsDocument4 pagesVehicle Driving Safety Tipswahyu nugrohoNo ratings yet

- Operating The Floor Cleaning MachineDocument4 pagesOperating The Floor Cleaning Machinewahyu nugrohoNo ratings yet

- Operating A Wood ChipperDocument2 pagesOperating A Wood Chipperwahyu nugrohoNo ratings yet

- Risk Assessment for Wall & Floor Tiling CompetitionDocument2 pagesRisk Assessment for Wall & Floor Tiling Competitionwahyu nugrohoNo ratings yet

- Using Polar Guillotine CuttersDocument1 pageUsing Polar Guillotine Cutterswahyu nugroho100% (1)

- Operating the generator in the emergency response truck safely in 4 stepsDocument3 pagesOperating the generator in the emergency response truck safely in 4 stepssyafiq ishakNo ratings yet

- Sheet Metal Brake SafetyDocument2 pagesSheet Metal Brake Safetywahyu nugrohoNo ratings yet

- Using LaddersDocument2 pagesUsing Ladderswahyu nugrohoNo ratings yet

- Using Hand-Operated Power ToolsDocument2 pagesUsing Hand-Operated Power Toolswahyu nugrohoNo ratings yet

- Fsarcweld 02Document2 pagesFsarcweld 02Marcelo Gil SimõesNo ratings yet

- JSA. Grinder, AngleDocument2 pagesJSA. Grinder, AngleSajid Hussain0% (1)

- Using An Oxy-Acetylene WelderDocument2 pagesUsing An Oxy-Acetylene Welderwahyu nugrohoNo ratings yet

- Using LSC CocktailDocument1 pageUsing LSC Cocktailwahyu nugrohoNo ratings yet

- Archiving FilesDocument2 pagesArchiving Fileswahyu nugrohoNo ratings yet

- High Risk Job Safety Analysis: Contractor ArgonneDocument11 pagesHigh Risk Job Safety Analysis: Contractor Argonnehalfy safitriNo ratings yet

- Arc Welding 10.1.2014 - 3Document3 pagesArc Welding 10.1.2014 - 3soubhagyaNo ratings yet

- Bobcat S250Document6 pagesBobcat S250svcingNo ratings yet

- Saudi Arabian Oil Company: SECTION 15001 Industry Codes and StandardsDocument6 pagesSaudi Arabian Oil Company: SECTION 15001 Industry Codes and Standardsthahar ali syedNo ratings yet

- METHOD STATEMENT Gypsum Board Ceiling Gypsum Partitions Ceiling TilesDocument10 pagesMETHOD STATEMENT Gypsum Board Ceiling Gypsum Partitions Ceiling TilesHARISH ROHANNo ratings yet

- CS92 en LRDocument8 pagesCS92 en LRAnderson AntunesNo ratings yet

- Oles and Responsibilities For Leadership and Management of The Conference of African Ministers of Public/civil Service ProgrammeDocument8 pagesOles and Responsibilities For Leadership and Management of The Conference of African Ministers of Public/civil Service ProgrammeDepartment of Political Affairs, African Union CommissionNo ratings yet

- Hydraulic PressesDocument13 pagesHydraulic PressesAhmed Adel ShatlaNo ratings yet

- Iec 60034-14Document34 pagesIec 60034-14Juan Carlos Escobar Aros100% (1)

- Professional Practice I Tendering ProceduresDocument28 pagesProfessional Practice I Tendering ProceduresHannan Ruslim100% (1)

- Rebarsplicinghandbook PDFDocument72 pagesRebarsplicinghandbook PDFIrina_MeNo ratings yet

- En 13848-3 (2021) (E)Document8 pagesEn 13848-3 (2021) (E)Marcos marinhoNo ratings yet

- Lapp Usa CatalogDocument16 pagesLapp Usa CatalogNiten GuptaNo ratings yet

- Cash Flow Reporting With PSCDDocument17 pagesCash Flow Reporting With PSCDNadia NafeesNo ratings yet

- Special Features of The Twingo Fitted With The D7F EngineDocument314 pagesSpecial Features of The Twingo Fitted With The D7F EngineGyula75% (4)

- 6 - ORGANIZATION AND ITS ENVIRONMENT (The Learning Organization and Its Future-2) - Tin BautroDocument17 pages6 - ORGANIZATION AND ITS ENVIRONMENT (The Learning Organization and Its Future-2) - Tin BautroDARLENENo ratings yet

- Prestress Presentation SAB4323 OCW Topic 1Document50 pagesPrestress Presentation SAB4323 OCW Topic 1dasdhjhkjNo ratings yet

- Test 13Document20 pagesTest 13Диїяцԁн ЅндямдNo ratings yet

- Astm A53-18Document23 pagesAstm A53-18Cyd He82% (11)

- Ports Used by CitrixDocument28 pagesPorts Used by CitrixJuan IgnacioNo ratings yet

- Upgrading The Firmware: Creating A Serial ConnectionDocument8 pagesUpgrading The Firmware: Creating A Serial ConnectiontulioNo ratings yet

- Qcs 2010 Section 20 Part 4 Drainage Pipes in Trenches PDFDocument5 pagesQcs 2010 Section 20 Part 4 Drainage Pipes in Trenches PDFbryanpastor106No ratings yet

- Brochure FonsbdDocument41 pagesBrochure FonsbdM H Khan RonyNo ratings yet

- Harrington Ner Er Hoist Manual Parts ListDocument143 pagesHarrington Ner Er Hoist Manual Parts ListliftNo ratings yet

- 1 3Document34 pages1 3Gabriel BalcazarNo ratings yet

- Toward Developing Benchmark Dataset PDFDocument18 pagesToward Developing Benchmark Dataset PDFRahmatul HusnaNo ratings yet

- Evaluation of Various Traffic Loads in MANET With DSR Routing Protocol Through Use of OPNET SimulatorDocument9 pagesEvaluation of Various Traffic Loads in MANET With DSR Routing Protocol Through Use of OPNET SimulatorijdpsNo ratings yet

- Old Alk Manual 51000-18Document184 pagesOld Alk Manual 51000-18Yenser SantosNo ratings yet

- Sample Quality ManualDocument49 pagesSample Quality ManualNigel Lim100% (1)

- 3406e SpecificationsDocument126 pages3406e Specificationsnacho100% (6)

- 181012-180505-Multi Component Distillation (Department Elective-II)Document2 pages181012-180505-Multi Component Distillation (Department Elective-II)Nagwa MansyNo ratings yet

- Earthing CalculationDocument5 pagesEarthing CalculationprkshshrNo ratings yet